Why Amateur?

One of my most commonly asked questions. I'm not sure how long it took me to discover the fuller status and experience of amateurship, but when I did, it was both revelatory and life-changingly refreshing. Hopping the fence, I never once looked back. New coordinates enabled me to set sail, disengage from a world of commerce, to renew what drove me into woodworking in the first place. My teen years let me know what life was not and thereby what life was. Life was not school, and school was not life. Stepping out of school that day was the best thing that ever happened to me. I walked away from the wire fences, rigid rules, punishment by caning and strapping, and I was set free. So it was too when I first understood why amateurs had the better life, independence brought beyond peer pressure and authoritarianism. It was another of those, 'I didn't know I couldn't do it, so I did it' moments. They lived in the love of their woodworking, and it made no difference how good they were at doing it, or how very bad they were...they lived for the doing of it!

The single most important thing is not totally hinging what you do to moneymaking. That does not mean you cannot or should not make money doing it. That's what I did. For me, it meant that money was not the root reason for doing it and that even if you didn't make money or make enough, you still did it. So, just why is our amateur status so very important? Well, sad to say, and I know this to be generally true––almost every woodworking person I know and meet that is operating in so-called professional realms rarely if ever touches a bench plane, a brace and bit or a tenon or dovetail saw, let alone own one to actually use because they can't believe you can make money that way. I wouldn't ever class myself as a so-called professional woodworker, carpenter, joiner or whatever today, even though those are all the things of my occupation and I always strive to produce premium quality workmanship that would at one time have been called 'professional'.

Amateurs do not have to produce amateurish results, that has been well proven through the more recent decades, and so much so, so-called professionals have been stunned by the quality of workmanship produced by amateurs and that's because most amateurs train themselves through research, study, hands-on classes and experimentation to that end. In our present age, they are really the ones who have taken the baton from skilled artisans of old and decided, you know what, I am going to take my craftwork to its peak in my individual life and become expert at it. Furthermore, amateurs have organised themselves into associations, guilds and woodworking societies to bring structure to many areas of their craft. After doing so, over a number of productive decades, they have proven themselves in many viable ways and where professional bodies failed, they then allowed professionals to join their ranks. Whereas they did raise money to support their outreach and output, no individual made money as an enterprise or business. Do you see the difference? There was no $150,000 a year CEO as such, unlike many charities. Belonging to a union owned by professional workers of this or that trade or profession was mainly about giving a voice to working people so that they could get safer working conditions and better wages, not for the establishing and perfecting standards of craftsmanship.

The amateurs picked up the mantle professionals ultimately dropped, shunned and distanced themselves from to organise societies, shows, teaching workshops, and much more beyond. Amateurs need no qualifying bodies because they have internalised standards of workmanship that match or exceed those of the former authorities. They don't have to jump through the hoops of commercialism and can focus wholeheartedly on developing their mastery at their own cost, be that financial, time investment and so on. These are the ones who have the will and the dynamic to engage with conservation and preservation by becoming the new masters in just about every realm. These volunteers, and volunteers is indeed what they are, these entrepreneurs, these altruistics, pursue their quest for mastery no matter the obstacles they encounter. They willingly get together with other woodworkers, share their knowledge and skills, and band together to promote the art of what they believe in. Professionals tend to use the term amateur negatively, to draw a contrast between themselves and amateurs, even though, as said, amateurs might well be more knowledgeable, more dedicated and more skilful than any professional counterpart. Using the term derogatorily cannot really displace the essence and innocence of amateurism, so better to not distance themselves from the limitations of making only for money; many a professional will usually distance themselves from the term amateur as we have come to know it through the decades where most professionals fail to recognise the skills and abilities that carry the missing element in most professional realms and that is the significant ingredient we recognise simply as a love for the craft we do.

The term amateur takes its root from the Latin verb amāre, meaning to love, as in our word now, 'amour'. The English adopted it from the French, which originally described someone pursuing an activity purely for the love of it, and not for pay. The condescension by professionals and others suggests a lack of skill and competence, when in my experience amateurs have often grown in stature to a level that commonly surpasses those mechanically producing commercial output in one dumbed down, utilitarian form or another and thus meeting the demands for financial expediency and competitive pricing.

When the love of craft inspires us, self-discipline takes us into the deep

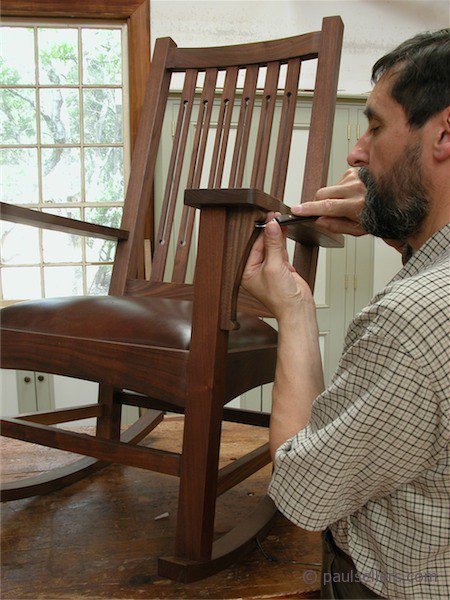

It's love of the craft that carries amateur woodworkers to research and invest in their chosen sphere. By this, they discover depths to their working that go beyond mere manufacturing and for most amateurs, the money-making factor and cost is removed from the equation. This is no small thing. They've removed competitiveness from all that they do and can enjoy the whole process of making altogether; how many is it who attack me from their professional realms in jealousy? So too, they've come to know the work so very differently, they look into the wood constantly, and the tools used at the same intimate levels men and makers of old knew in times past when the pace was slowed by the limits of the physical bodies of men-makers. I am often surprised by a comment, a note or a message where someone in amateur places comments on something known to the ancients that few would know of today. There is no assumption that they know it all, so their amateur interest drives them ever deeper and always to learn the more. This becomes therefore no less a vocational calling than mine was 60 years ago. I know, not all of the professionals have lost that thread, that link to vibrancy if you will, but a larger percentage than you might think, fail to recognise just how very good amateur woodworking has become and especially is this so with those now relying on traditional hand tools and methods. It's amateurs that keep the art of work alive, put the time in and go the extra mile. They've become masterful, they stand out in many spheres in exemplifying fine woodworking of all kinds. Gaining equality is to gain levels of mastery in workmanship; that is, then, equal to and dare I say exceeds those deemed so-called professionals by certification and diplomas. This is possible for everyone and all the more in today's realms of aspiring to become an amateur in the truer sense of the word, and our work is proving these more and more.

I think it was when two men stood at two diagonally opposite corners to their workbench in my class almost 25 years ago now that I became convinced of a certain positive distinction between amateur and professional statuses in woodworking realms. I'd associated with skilled professionals throughout my earlier years as a woodworker, joiner and furniture maker working full-time. The workers I knew started and finished bang on the dot of an hour's strike to start and end their workdays. In my new world exploring my teaching and training others, the ones professionals always referred to disparagingly as amateurs, showed me an enthusiasm I had hitherto found to be quite lacking and especially had I seen this in the newly emerging professionals. The professional carpenters, woodworkers or furniture makers, seemed to drag themselves around with no spring in their step; the amateurs were never embarrassed to show up an hour earlier and hang about as long as they could at the end of the day, and they were totally enthusiastic about any level of achievement. It was this that caused me to more disassociate myself from one realm and append myself to the other. All in all, I am an amateur woodworker and hope to be so for the rest of my life. Just like the amateurs waiting at the door an hour ahead of class, I am always there too. They are not staring at devices and rarely look at them over the next eight to ten hours. Then too, at the end of the day, after maybe ten hours of work at the bench, and they were not used to such physical work, they gathered at the same picnic tables under the Junipers to discuss how they felt they had done and didn't leave until 7pm or even later. Enthusiasm as a term expands exponentially when you add the word keen or eager in front of it.

Enthusiasm empowers amateur makers

Enthusiasm is an essential ingredient and in the realms of the amateur makers, it clears away the debris of commercialism, economics and the nine-to-five mentality of any and all working limits. I found the nervous anticipation totally refreshing, and it was always self-evident at the first day of every course and remained fastened on faces every day no matter the length of the course. I think this to be another ingredient of amateur woodworking; beaming smiles, the sharing of space, and then to the hanging on to every instructive word that so equipped their enjoyability. This alone equipped them through the dynamism willingness always brings to experiment, explore, ask and take risk. It was then that I also saw the cost it was to them to be there. Hotel, travel, the cost of a six-day course, the loss of a week's annual leave with their families, possibly a week's income if they were self-employed and such.

The two men I mentioned above had parted with $2,000 for the travel and course fee. Not a small amount and quite a commitment. And you cannot rule out the loss of earning for many who might be self-employed, as I said; often attendees were ordinary men and women working in other spheres and for themselves. These particular men were close friends and had both discovered the shared experience woodworking brings to so many amateurs across the USA. More than that, though, this was far from their first investment in a woodworking course. These two amateurs were quite intent on becoming masters. Their evenings and weekends were often filled with the adventure of woodworking, and their high-tech background at that time more than adequately funded their lifestyle. The thing was, though, they were not alone. Every class I offered was always full of the very same enthusiasts, and this meeting of the like-minded was multidimensionally new to me. I had never seen it in commercial realms of woodworking elsewhere. And that's not to say that they weren't there, but commerce can drive out what amateurs seem more able to keep––enthusiasm. Witnessing the influence by commerce in gatherings of commercial makers ultimately seemed always to result in them looking for their next piece of time-saving power equipment. In our world, we're looking to sharpen our chisels and saws, the plane edges and such. We want that kind of true independence, you see. We volunteer into it. It drives us.

For me, woodworking, and especially furniture making, had truly filled almost all of my life expectations. Even though, perhaps unfortunately and perhaps not, I had developed business plans that took me along that same commercial rabbit trails in pursuit of the faster buck. This might lead to greater security income wise, but commercial exploitation one way or another comes with it. The quest for getting off the commercial conveyor belt when it's linked to some kind of debt and monthly payments ain't always as easy as you first might have thought until it's too late. That, by its very commercial baggage and nature, soon detracts from the initial love that birthed your origin of your joy and fascination in starting out on the real woodworking path with hand tools woodworking; it's not always easy to see you took the wrong turn. In my case, I didn't find the journey back to be quite so easy because I was locked into the business the busyness of commerce demands. It was in the USA where I first encountered the perception people had that real men machined wood and those working with hand tools were somewhat lesser beings––that machining was the more grown up way, but then I saw clearly that handwork with hand tools would open many doors in my quest to take real woodworking to the amateurs I had grown to respect. Of course, machines have their place, they are viable and especially so when you are privileged to live in a wealthier culture, own property to spread yourself and your machines out, such like that. I'm not really interested in that sphere. It excludes too many, and for decades has put woodworking out of reach for far too many. The majority of children will never do woodworking even though their fathers like to woodwork, simply because 99% of it is using machine only methods. Why? Well, it's just flat dangerous for one thing, and then who wants to walk around with safety equipment on for hours on end? Privileged? Why privileged? For hand tool woodworkers intent on making their pieces, they need no more than a ten-foot by ten-foot space and a modest workbench. With £200 worth of secondhand hand tools they could be making their first coffee table.

I did have a machine aspect to my woodworking workshop; even so, I worked differently to any woodworker I ever met stateside. My work still relied heavily on my handwork, using primarily hand tools, and it was this passion that then and now kept and keeps woodworking fully alive, engaging and thriving in my life. Not only that, I found much greater affiliation and camaraderie with amateurs than I ever did in commercial sectors, though I did and do have friendship with professionals who are, like me, amateurs at heart.

In my world, machines were very much the equipment I reserved for the donkey work. Mostly resizing wood with long and deep rip cuts in different woods takes more than anyone would have the time and muscle for to be truly efficient and productive. My owning a single 16" bandsaw raises eyebrows at the mention of it, as would my using a random orbit sander or a belt sander if and when I do. In my commercial work, though, some hundred percent of my output was designed to come as much straight from the machine as possible. It was when I realised that I was starting to follow the patterns of my US peers, where only machine cuts were allowed, that I questioned its validity for every area of work. Woodworkers visiting my shop watched me pick up dovetail saws and chisels, all finely honed and sharp, were fascinated in the way these tools were cutting through the fibres so efficiently. They were glued to the spot and wouldn't leave. This was an entirely new consideration for me, for no visitors went into commercial settings to watch someone machining wood. My then open door policy meant an outreach to many a thousand woodworkers every year. Soon it became untenable, but for two decades I enjoyed all the visits we had.

Even though I always owned or had access to a machine shop in times past, I always reached for one hand tool after another for almost all of my woodworking tasks at the bench; there was no meandering or bopping between machines, pushing one button or another after another. Hard to imagine now, even though guides for dovetailing have been around since the 1950s, I have never cut a single dovetail using any kind of power equipment. I am so grateful for those early mentoring days where within a few hours I had mastered the art of dovetailing. But much, much more than that. I have to say that my early decision to work primarily with hand tools has given me greater levels of physical and mental health than I would have had I gone the machine route, well, that's my belief for sure. Hand tool woodworking by its very nature is, of course, physical and mental high-demand. You must keep up your strength and mental acuity by the doing of it.

Though I haven't used a power planer or tablesaw for over a decade now, I only dispatched the last couple of machines to the commercial scrap dealer about five years ago. I had stopped using them altogether and yet, that mental umbilical cord to electric power held me strongly to a 'just-in-case-I-need it mentality.' My commercial past of machine-making methodologies is quite a codependency, when in reality there was absolutely no need to keep them gathering dust and rust in the shadows. Better for them to be recycled and come back as bike parts or wheel hubs.

After not relying on thickness planers and jointers, tablesaws and chop saws that I realised exactly how efficient skill makes me in the day to day. If I had but one machine to hold to, it would be what it is now, the bandsaw. I can readily rip through 10" of oak or any type of wood come to that without wavering or drift. It was then that I realised just where the real problem lay for others. My way out was simple enough, even though the feelings of withdrawal were surprisingly strong, it was my developed skills that carried me through to what I saw as a way out for the majority of amateurs yet to find the doorway to the unplugged. I did have skill and ability working with my hands, but it DOES NOT take six decades to get where I am today. My hand skills and knowledge were accumulated over decades, yes, but with the mass of information we have put out through our work in the last three decades we have equipped hundreds of thousands of woodworkers to adopt what no one can ever take away from them: once you've got it, you can't lose it, except, of course, through some unavoidable disability that can happen, or you decide to simply give it up. One of the issues I see is that you will not know the benefits of better health until, as it is for me, you are on the other side of it. My decisions have given me good health. I'm just shy of a few days off, become 76. That has given me 61 years of six-day-a-week woodworking as a full-time maker and designer. Concluding the past six years of creating content for our Sellers' Home houseful of furniture, we have made over 40 substantial pieces. You can see them here, if you are interested in how we'e reached out to a wide world of woodworkers through our teaching and training.

The real problem for 98% of modern-day makers, even going back for five decades, is that they had rarely ever really developed substantive hand skills; in my experience, they seemed rarely to go much beyond a token nod to past methods, those you might get in a college class over single day's usually poor instruction from a teacher that couldn't actually make it as a maker. Being truly competent does take rote repetition to build speed, efficient ability and confidence. How would you become enthusiastic about hand work when you never actually developed that level of actual ability and working knowledge of just what could be done with them beyond reading about it? I had established an ability to pretty much guarantee that with any hand tool I chose to use at whatever time and on whatever I was doing, the outcome was both anticipated and predictable. You can get to a point where you no longer question yourself as to whether this or that will work or not: you just know that it will and you do it.

With an assurance of a predictable result, your positive feelings parallel the mind's intent of your thought processing. It's a level of high demand, I'll grant you that, and it's a level most woodworkers seldom get to without most of the work being one kind of machining process or another, every step machined for a predictable outcome but one that has all the hallmarks of a mechanised process rather than the organic of using hand tools and human power at its best.

To gain mastery, you have to climb over any negative start in learning your skills. As you ascend the ladder to new realms, there is a point when success and predictability happens. It's pure bliss. That being so, instead of you repairing damage by belt sanding out the flaws you created, the smoothest of planed surfaces results. My apprenticeship got me beyond that in short order. Our shop had many machines but no belt sanders, no random orbit sanders, jigsaws, skilsaws, power routers or drill-drivers. Every surface that came off any machine was then hand planed or scraped with a card scraper to a perfect level. Through this, no choice, I mastered hand tools and have used mostly the same ones over my six decades of continuous day-in-day-out making. So, for the amateur of today, with such ready access to any and all so-called power tool equipment, it takes a much greater determination to become a master maker. Therefore, if machines have displaced hand tools throughout the entirety of your life in woodworking, once you replace these hand methods with machines, it takes both ambition and determination to make change happen because, well, it's a bit like a bad diet, it's easier to do what you got used to and to continue feeding the addiction for the fast food processed stuff taken from a refrigerated display box. Unfortunately, I have to deal with the questioners, to whom it makes absolutely no sense for anyone to use hand tools for anything. These men from professional machine realms mainly cite Neanderthal, Luddite methods as being slow and inaccurate. Usually, not in every case, these are the ones that simply cannot comprehend, nor will they ever understand, my kind of reasoning no matter how or how many times I try to explain it.

To corroborate what I say, we now have fewer young people getting into any kind of woodworking than ever in our history. Most DIY in the past came during the younger years, when fathers encouraged boys to "Give them a hand." My four boys came into the workshop every single day from around three years old until they were in their mid to late twenties. I never intended for them to become furniture makers, I only intended for them to own true hand skills and in as many crafts as they could. Today, and because of their grounding, they tackle many mechanical processes to make tools and equipment in technical realms.

The main reason for me, and without even knowing it at the time, is that I understand all of my woods, parts of each tree types' growth structure and such, densities and variables within the species too in ways that a machine-only maker can never know. I know that that can seem a remarkably conceited statement, so I do make it cautiously. I have lived in the two worlds of machine making and hand tool making, and then the mix of the two. But it wasn't until I abandoned the ease of machine making altogether that I truly understood how machines became fully, dictatorially rigid and fixed and hand tools delivered the greater freedoms of versatility in the high demand of minute by minute critical thinking.

It's pleasing to me to gauge my wood's density through the actual tools I use because, well, hand tools are like registers designed to give musicians feedback. Every hand tool receives and transmits density, levels of friction, fibre interaction within the wood and so much more. Will the wood split well, or must it be sawn for a better result. Machinists know nothing of what I speak if all they've ever been exposed to is feeding their wood into the machine feeding the so-called power tool into the wood. They don't comprehend splitability, pareability, fibre-friction, etc.

Some might criticise my use of my alignment guide for mortising holes. This originated, as many of my ideas do, when walking across a Texas pastureland, concerned that my students could never chop a mortise hole that was parallel to the outside faces of their workpiece. You can see now how hand work and teaching others to do it triggered my desire to be a solution. People around the world now treat this as though it's always been there but, nope, it came about in the early 1990s at my workbench while sixteen students watched me use it for the first time. Using the router plane for facing off, tenons came next. Yes, I originated that too. And in that day you could pick up router planes ten-a-penny on Bay for between £5-10 apiece. Then when the prices went up to over £100 plus I came up with my wooden version and that has been the lowest cost router plane available for a little sweat-equity on your part. A nice afternoon in the garage using my £36 kit, and you've made a very good router plane that beats the very best of the rest.

Making my latest cabinet has innovation in it too. I care that plywood of the better grade is a remarkable material that suffers bad press because of the cheap veneered versions with skins the thickness of copier paper. I generally go for the time-proven birch plywood we get from Europe. The outer skin is the same consistent thickness as the core striations. For this work, the plough plane takes some beating. I made a drawer for this work and ploughed the four grooves in four minutes with no tear out or the associated burn smells you get from using a router. i cannot imagine someone justifying a dado blade lodged in a tablesaw just to cut these grooves. Their way makes much less sense than mine when you think about it yet all of my so-called professional maker-critics remain professional makers and that's because, well, simply, they don't believe and therefore cannot believe and the many diverse benefits of skill and health building on a daily hour by hour basis.

Comments ()