Mesquite

In answer to Joe Leonetti's request for more information on working it with hand tools, I can say mesquite is more predictably unpredictable and then unpredictably predictable than most any wood. There is nothing in any way uniform or straight-grained about this remarkable wood and there is no doubt that it is a thousand times easier to work it with machines than it is by hand...that is until you find that occasional sweet spot when the plane slices off excess wood with downy featherlike whispers of light thinness you can see through and the pure scent of mesquite fills your head with a heady fragrance that compares to no other material in the world of woodworking. I know, generally, all woods are remarkably different, for no two woods smell the same.

Of course, the scent in my work comes mainly from the friction twixt a steel sole or saw plate and the wood itself. With each successive stroke, the air is filled with the unique fragrance only mesquite can give. Use the wood on machines for any substantive length of time, and it's highly likely that you will become allergic to it, and possibly to the point that it might well stop you one day from being able to breathe. So, I say that to say if you are a machinist relying solely on machines as most of you might be, get the best dust extraction you can straight off the bat for sure. Who knows? You might be allergic without long-term exposure. Machine woodworkers should have done anyway, machine dust from working wood is dangerous dust no matter the wood. You might not know that common oak of every type is particularly dangerous to your nasal passages and throat and bronchi when it comes to wood dust emanating from machine working. I don't altogether know how much more the mesquite wood dust? The UK health and safety Industrial Injuries Advisory Council produced a substantive paper for the Secretary of State for Work and Pensions because of claims made for benefits due to ill health resulting from wood dust:

'Sinonasal cancer is known to occur in many occupational groups, including

carpenters and joiners, wheelwrights and wainwrights, wood machinists, sawmill,

forestry, and timber workers, boat pattern makers, woodcarvers, and makers of

wooden shoes, vats and boards.'

Somewhat diverse and possibly archaic thinking about who it is today that makes wooden shoes, wooden wheels and repairs to horse- or oxen-drawn wagons and carts anyway, but the point is, if you are machining wood, don't do it thinking wood is some kind of pure and natural plant-based health product so it must be okay to work without top quality extraction and personal protection for all in the working environment.

My last substantive work in mesquite for me were the two White House pieces for the Cabinet Room. After many years not making hardly anything from mesquite, it seems I am no longer so particularly allergic to its dust nor its essence in the atmosphere surrounding its milling. My allergy started after a decade of working with it substantively by machine. Making thousands of mesquite birdhouses and feeders each year and using the bandsaw (a machine particularly difficult to isolate the dust from) for much of the cutting and processing left me nearing anaphylactic without much warning. The dust from the wood in that case was mixed green mesquite heartwood, sapwood, bark and very wet as it was absolutely green wood. Any residue in waste and dust was at a saturated level and naturally less powdery than you get from kiln- or air-dried mesquite. I suspect that there is a lot more going on in cutting through rough bark, sanding on a linisher as I did for that period and then other processing steps. Molds and parasitic plants, lichens and such factor in there too. While some molds are not harmful, other species produce mycotoxins, poisonous substances that can cause health problems including allergic reactions, respiratory issues, and possibly acute poisoning.

Part of my current work is focussed on my autobiography, which has sections of my mid-US life relying on businesses that harvested heavy mesquite use between 1985 and 1995. This was also when my work changed substantively to develop my idea of writing and teaching woodworking. I will say here and now that mesquite does not lend itself particularly to hand work using planes and spokeshaves, but it can be done if you have attitude and the right hand tools. Mesquite is not the wood for wimps and whereas it's not easy to work with hand planes, it works well with other tools like saws and chisels. Because of the high silica content in the wood fibres, you must be prepared to sharpen about 3–4 times more than with almost any other wood. Even so, when you have mastery through technique, working mesquite is especially rewarding.

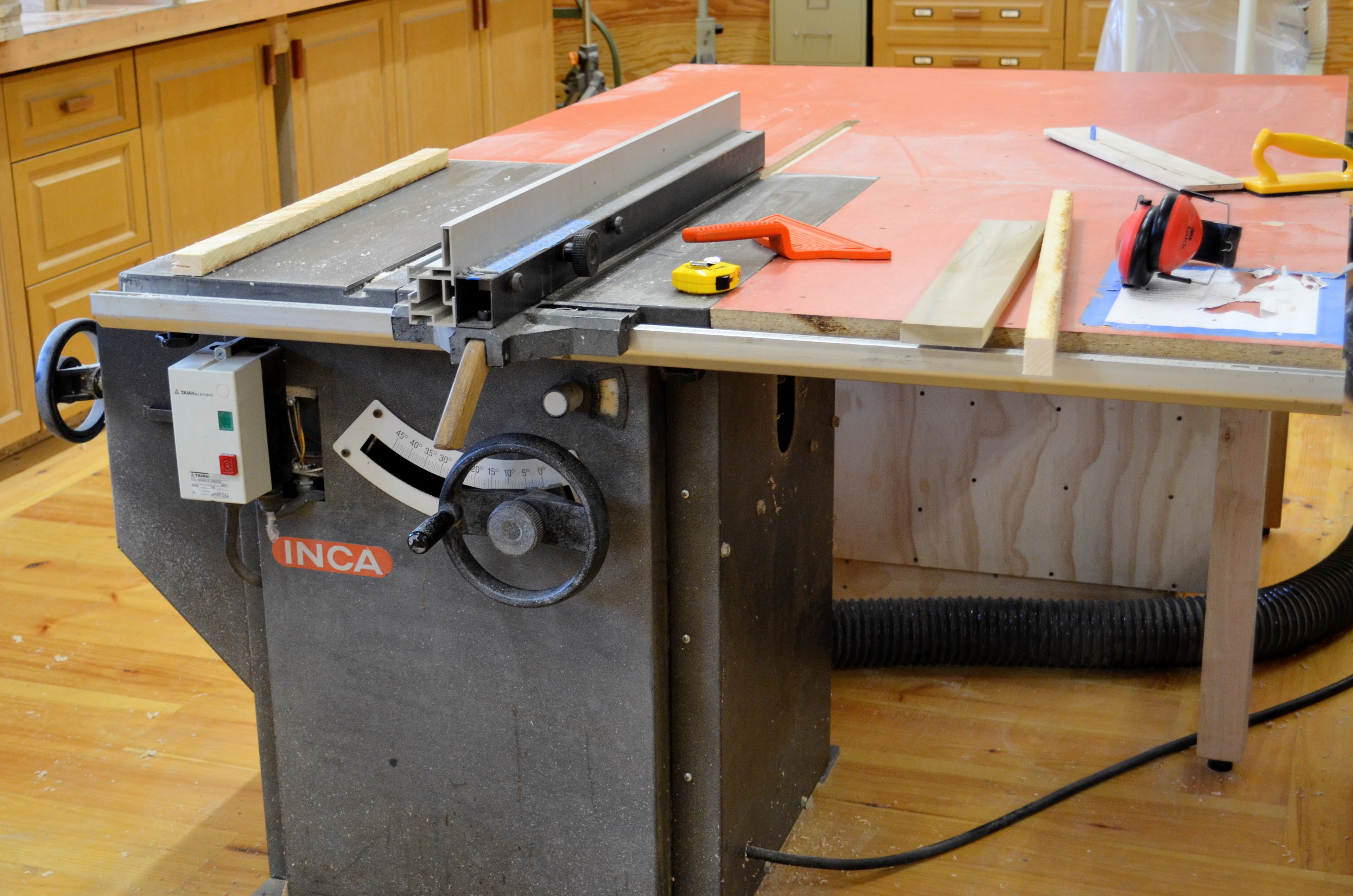

My world now involves the sole use of a single machine; the bandsaw alone takes care of all of my stock in terms of size reduction, as in resawing closely to the sizes I will conclude with bench planes. My system of bandsawing only and using extraction without fail makes my personal environment safe for all of the woods I use. I also use a sensor (expensive) to measure the atmosphere, and it has yet to acknowledge particulate in my personal working atmosphere. Why do I use a sensor? I have others working in the same space as I do when we are filming and such. I am often concerned where parents work with machines and forget others, especially children, who might be elsewhere but in the same space. There is no doubt that machinist woodworkers at any level over whatever period need to take extra precautions, but hand tool enthusiasts using belt sanders and random orbit sanders enter the same realms if indeed they use such equipment. The US OSHA advisory organisation, that's health and safety, advises this:

Exposure to wood dust has long been associated with a variety of adverse health effects, including dermatitis, allergic respiratory effects, mucosal and nonallergic respiratory effects, and cancer. Contact with the irritant compounds in wood sap can cause dermatitis and other allergic reactions. The respiratory effects of wood dust exposure include asthma, hypersensitivity pneumonitis, and chronic bronchitis. Certain species of hardwood—such as oak, mahogany, beech, walnut, birch, elm, and ash— have been reported to cause nasal cancer in woodworkers. This is particularly true when exposures are high.

Because it is so minimally made into anything much, mesquite escapes any mention, but that's because of its scarce use when compared to the list given. I am unable to speak of the real health issues without scientific proof, good or bad, so I limit this to my own experiences through three decades.

Sanders, and power routers, two of the most prolifically used machines used in home and commercial woodworking spheres, generally produce the most significant amount of actual airborne and therefore harmful dust. Conventional means for exhausting these machines are not very effective without some serious support equipment. New equipment is being developed for controlling dust exposure from machines intended more as a commercial practice but often used in domestic shops, these methods are not yet within a price range or availability for most commercial and domestic shops. One solution that's worked well for me, though, is to take hand-held equipment outdoors and work outside.

Now I am not an expert on health, so my advice comes from sixty years of working wood daily for ten hours per day and knowing what I know from my experience long term. I always took every precaution I could when working in my shop with my woods and with my chosen methods of production. I am so happy that the machines for me are now gone. Downsizing from the half a dozen most commonly used versions I once had is one of the best things I ever did. Mostly, these machines were for use when I had classes of up to twenty people, perhaps necessiating upwards of 500 pieces of wood needing sizing for students.

Working mesquite will have its challenges. Hence, you won't find it commercially stocked except in the most unusual supply stores and often as no more than a very highly priced novel alternative. I am frequently advised by rich woodworkers with high-end planes that using this or that plane with this or that iron in this bevel-up or bevel-down plane will plane the grain you are struggling with. Knowing what I know, it's mostly not true, not practical, and it's based on someone spending an hour or even more setting up a plane to high specs to prove their point. In the saddle at the bench, the advice is always erroneous. And in mesquite wood it is all the more plain bad advice. Mesquite somehow manages to twist, turn, rise and fall and spiral inch by inch like no other wood you will have ever come across. Yew can do the same, but woods like highly figured maple, oak, walnut, ash and two dozen more will be a joy to use compared with 95% of any mesquite you try to work.

Believe it or not, two hand tools will give adequate success for taming the mesquite. Assuming you have sized your wood to near sizing via a well set up bandsaw, the Stanley smoothing or and jack plane will get you to the final size with a level and trued condition. The work is mainly about sensitivity. My placing of the plane on wood tells me in a fraction of a split second whether I am about to face opposing grain by planing and without taking a single stroke, I can tell if I am about to plane the wrong way. The issue is that that can can change within a few inches, not many, as few as one or two. This then gives me expectation of change needed––tells me to make the split-second spin of my plane end for end on its axis to feel again which way I should go, and that might tell me to go at a tangent or even dead square across at 90º or so across the board. Mesquite grain bucks and twists like a rodeo bronco, and you don't usually know exactly what it will do either. That being so, the critical preface to planing mesquite will always be to sharpen the cutting iron before you take that opening stroke, take shallow depths of cut and be ready to sharpen again in just a few minutes. As I said, mesquite contains masses of silica, and this dulls the plane iron as fast as teak and a couple of other woods. I have a dedicated sharpening station that remains as a constant because of my self-discipline when it comes to sharpening. People say to me, "Do you sharpen every day?" My answer? "How about every few minutes, depending on the wood." Thankfully, I have sharpening freehand down to under a minute a plane iron, and that includes reloading and back to task. Yes, I am fast.

But the sharpening station comprises a platform of heavy abrasive paper that's like the stuff you might abrade flooring with. I keep it on the roll to drag through for fresh abrasive as needed. This rough-cut cuts steel faster than anything and returns me to my fresh macro-camber in five to ten strokes. I quickly switch to my three diamond plates where five strokes on each polishes the whole bevel to 1,500 grit ready for stropping on leather charged with buffing compound to around 10,000. Sharpening three or four plane irons takes three to four minutes max. Without this kind of speed, I would procrastinate and not sharpen enough.

What am I saying about advisors advising me to use this or that plane, this or that low angle, bevel up version, that cryogenic cutting iron and that York pitch frog for a steeper bed to the cutting iron? And who in their right mind pays over £50 for a single plane iron that might, might, give a 10% increase in plane use cutting time but takes 20% longer to gain a new cutting edge anyway? Nah! Think about it. Here is what I am saying. In a world of mass choices we are given the impression that the world has become a better place and then all the more for everyone when that simply is not the case. In our richer nations it's just a question of working hard, not being lazy, working "smart", a ridiculous term and that we can all own swimming pools, luxury cars and every type of hand tool premium makers want to throw at us. These makers invent the better mousetrap and have to sell ever more of what they make, we, the customer, can easily feel that the road to better woodworking skills comes with that cryogenic cutting iron and that $500 dollar plane type we need five or six versions of. A £500 set of five USA-made chisels will do no more and no less than a set of eleven German-made chisels, except you get twice as many in a much better range of sizes for about a third of the price. What not one of these makers can sell or give you is skill, competence and the determination it takes to become master in your own right. Thankfully, they leave that up to us. There is no greater speed to gaining mastery than at the bench, working through difficult woods and situations.

I say all that because in a world of artificiality you can be led to believe you have the time to trade out a frog for a steeper pitch or to change out your regular cutting iron for a harder steel version or one made by a particular maker who is doing not much more than printing his own money in persuading you to buy this or that cutting iron as a thicker, heavier retrofit to compensate for what is more likely to be an actual lack of skill or knowledge. Remember that thin plane irons that come with regular Stanley and Record planes DO NOT chatter. Skill will never come by changing the blade in a plane or paying five times the price for a chisel. All of the furniture made in 98% of my videos have come almost entirely from the cutting edges and points of my non-retrofitted hand tools; tools I have mostly owned and used through 60 years of daily use. Even now, shopping secondhand or even new, they would likely cost no more than around £350. You will never catch me promoting a £400 plane no matter what, but you will catch me giving an ultra-honest guide on what tools you can get the job done with best.

After the hand planes I use on mesquite, I reach then for the tool that takes all awkward grain, and that is the #80 cabinet scraper. It does not matter which one you choose to buy, except I would not buy a Kuntz version. Secondhand or new, Stanley and Record #80s will work well once you learn to sharpen the hooked edge. Here's a link to that end, and then I have blogs too. This tool can be used against the grain and on a grain that twists and turns on its own axis. Having a sole, it levels the highs but reaches into expansive low areas too. Combining this tool with the card scraper, you can get the most remarkable results in mesquite.

Comments ()