Drawing and Seeing

Hands at work have always intrigued me. In a New York café, the walls were lined with rough sketches of baker's hands kneading dough, forming bread to shape and sliding bread into a brick oven. The sketches caught the essence of the baker who drew them. I was fascinated by just how much the sketches conveyed about the movements and pressures.

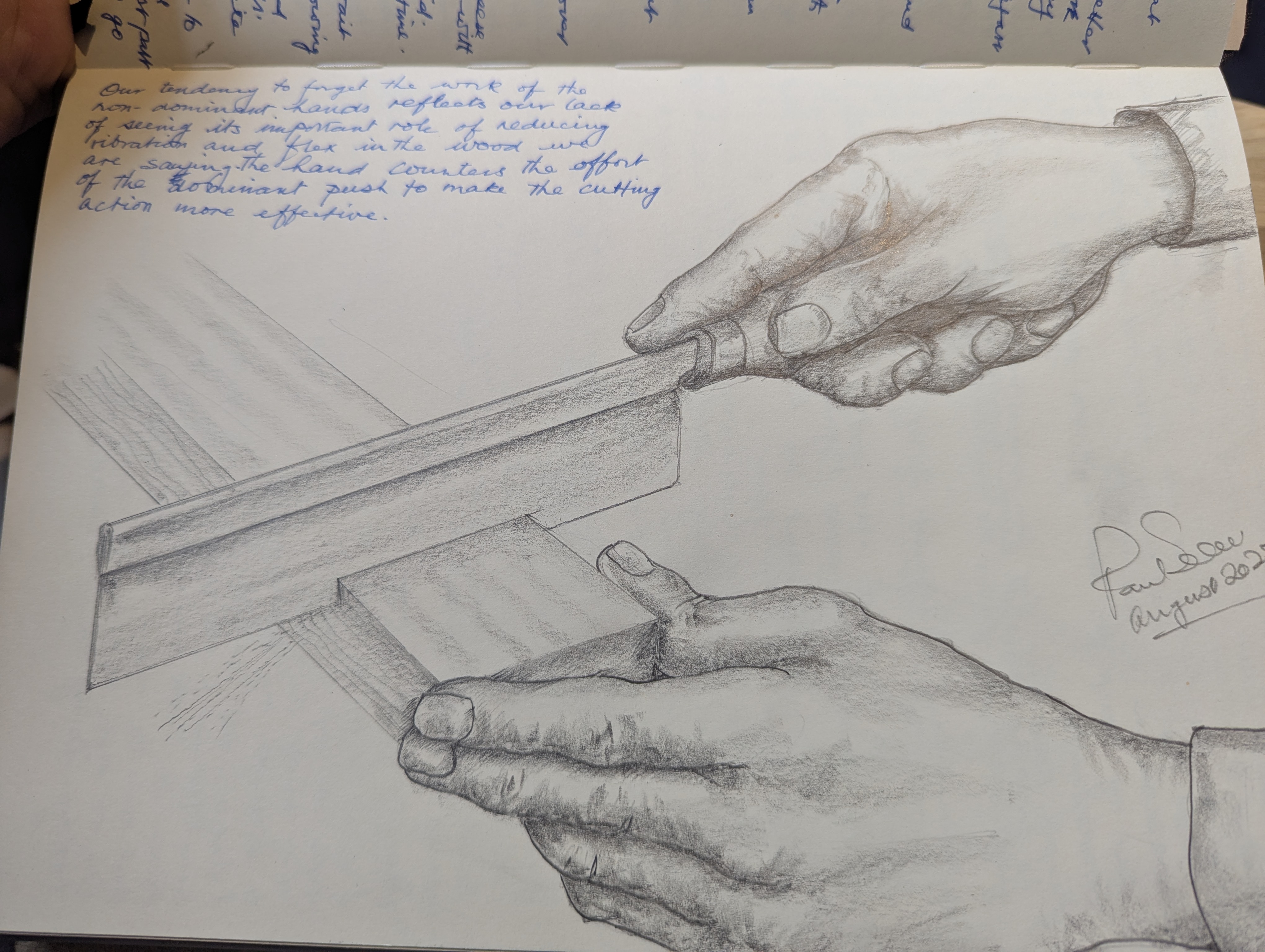

Thinking about the lesser hand in a different way I realised four decades ago that to call it the non-dominant hand was to see it as the lesser of the two when without it the other the dominant would be almost useless, only partially accurate and everything this dominant had tried to accomplish would be less than half competent. The non-dominant hand brings as much to our work as the right if we are what is usually disrespectfully referred to as manual workers. I watch the street sweeper sweep into the corners of concrete buttresses, stair ways and kerbs every morning and see how incredibly skilled he is. We talk, and he imparts wisdom to me in a handful of words by the crossing lights at the kerbside and I know his name because I stopped to talk to him five years ago, and we shared our names with one another. What a remarkable man he is.

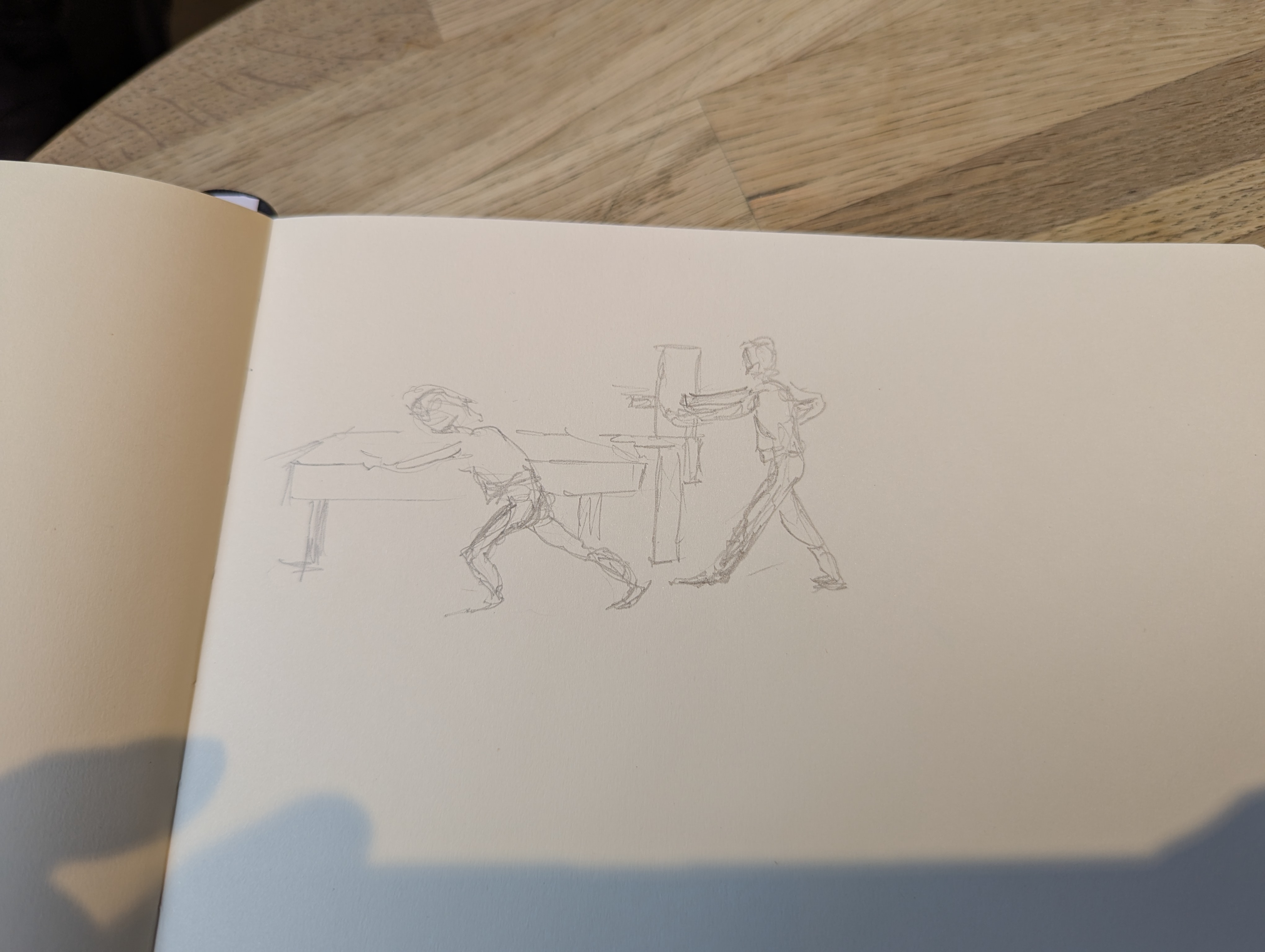

Drawing to See

These are my sketches in my journal from this past three months. They convey the essence of action in the moment. I have considered this 'seeing' issue. When it was `I can't quite recall, but I came to the conclusion that even a bad drawing, if there is such a thing, retains in the mind what was seen as a distinct memory that enables recall in a split second. These flashbacks impact us. The retentive ability from a drawing is remarkable. I'm saying that even the simplest of stick-figure drawings will facilitate memory recall. Drawing is the vehicle of memory...more so than a photograph. Why? Because if you haven't drawn it, you haven't seen it. Let me qualify that, though. Drawing it takes you into deeper observation, to a point where you see things a thousand times more fully.

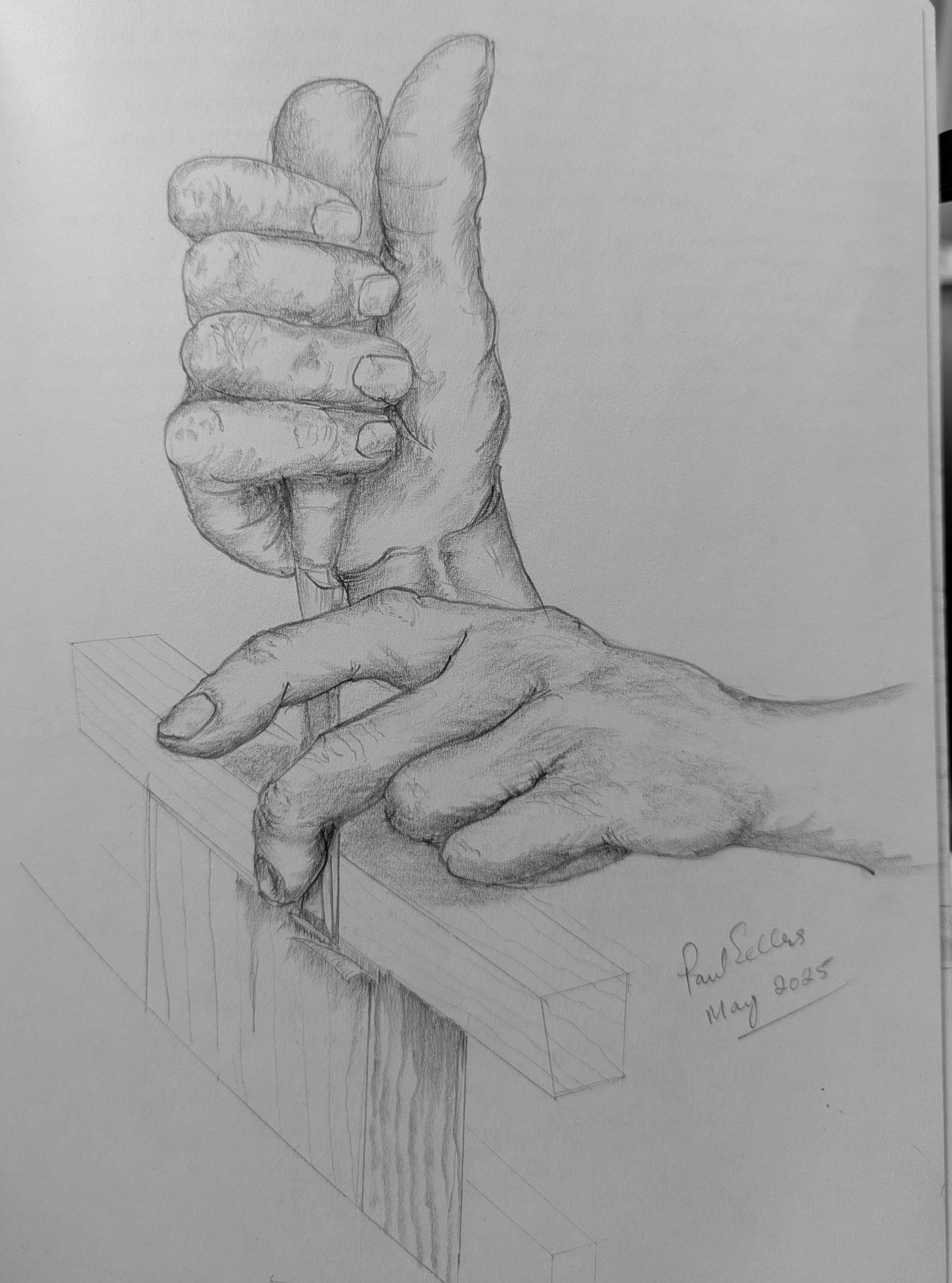

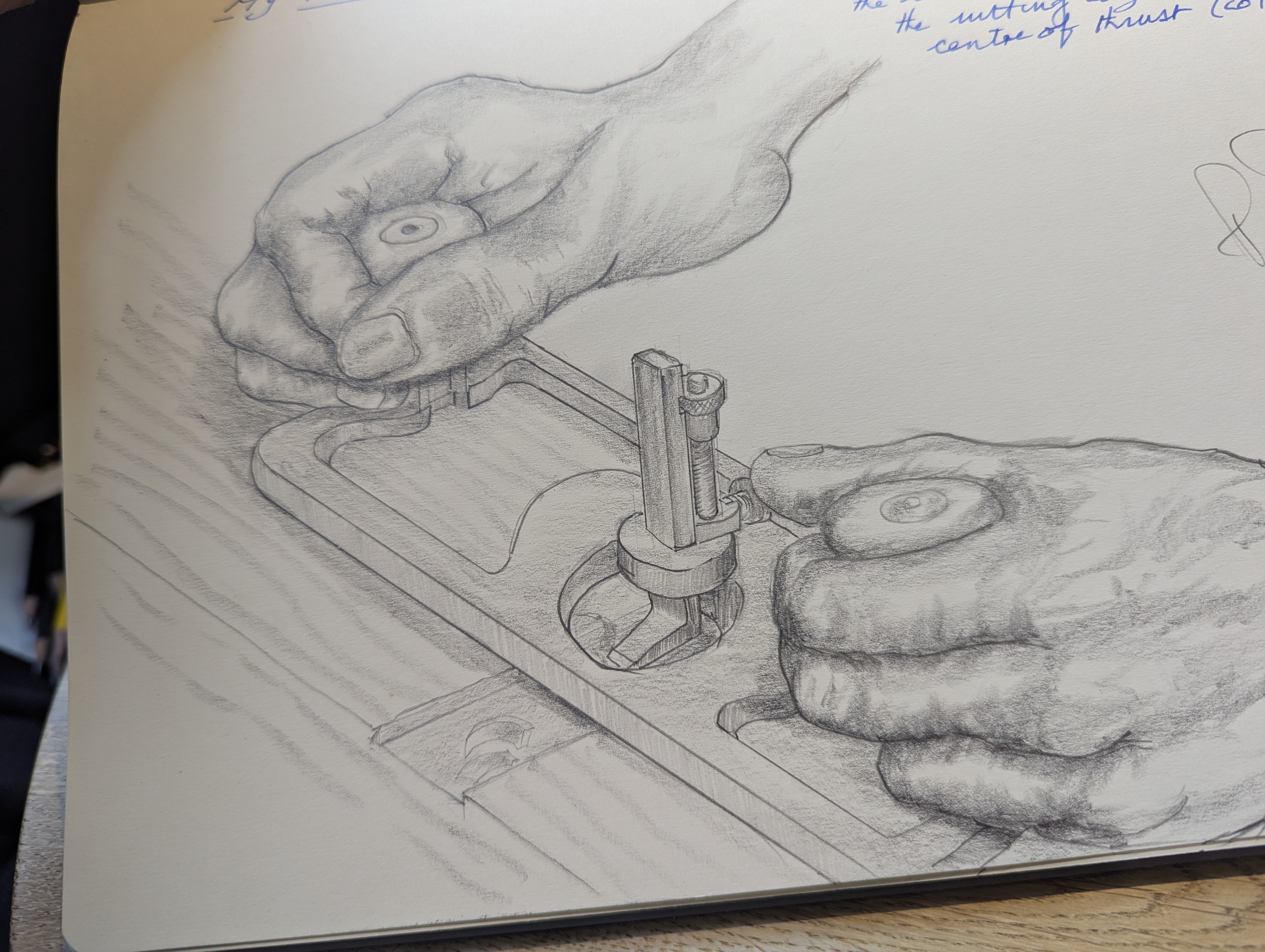

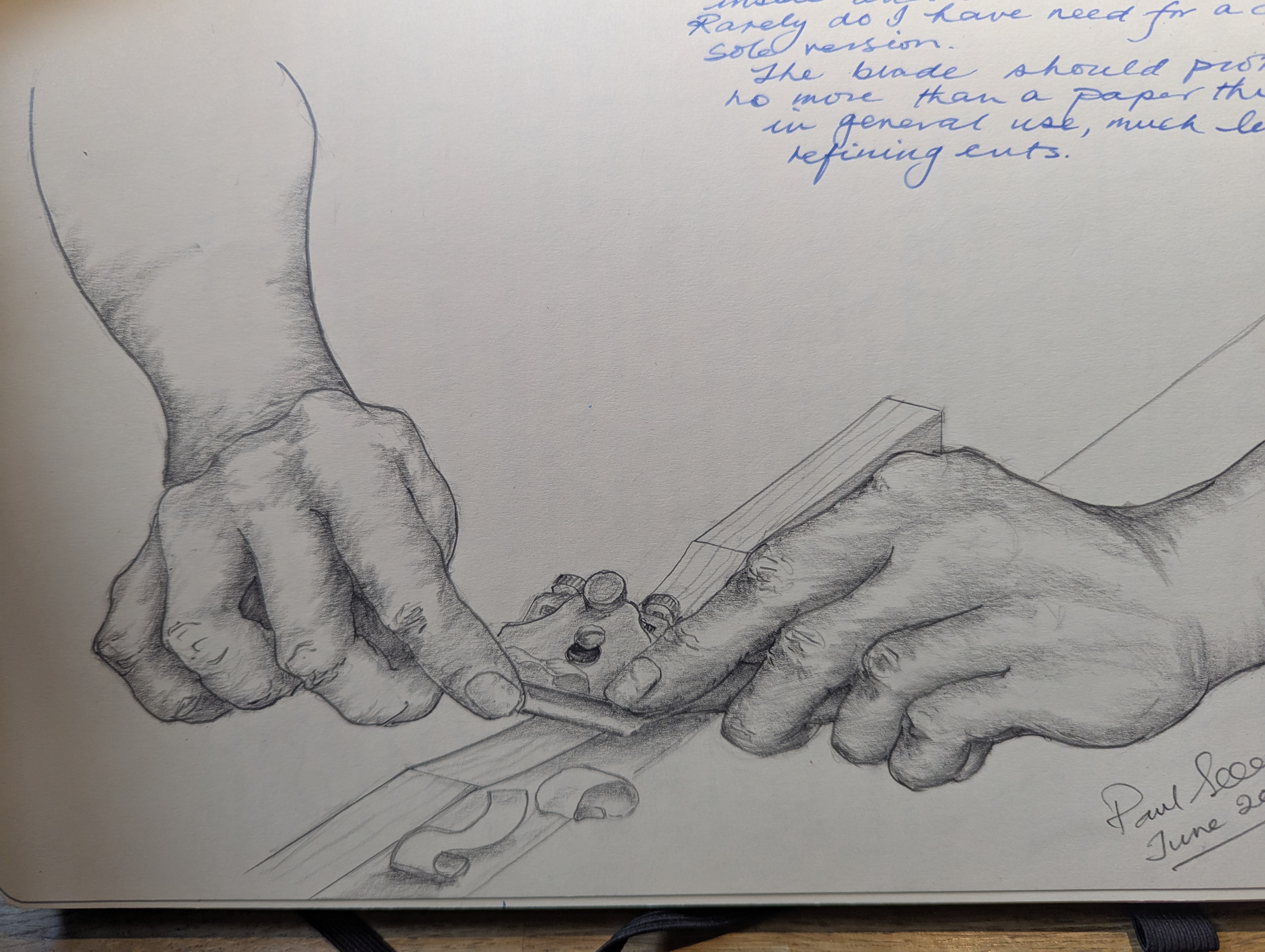

A guide helps me to establish consistent angles in two directions for my sliding dovetails. How do I hold the block guide in place?

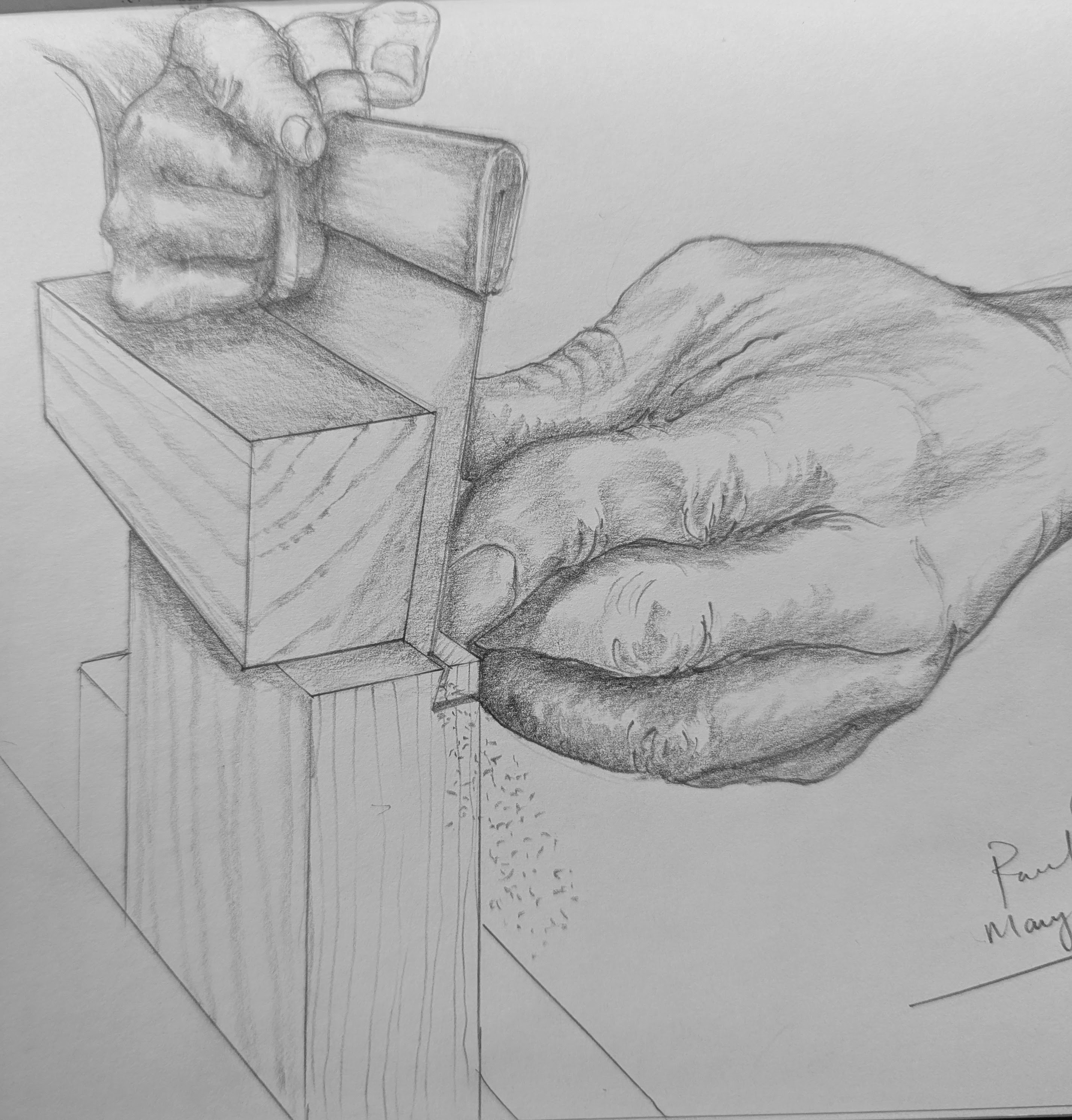

Dovetails demand consistent squareness that's more important than the angles, but we spend more effort on following the angles than the square-across lines without thinking.

I am so glad that I spent a few weeks on developing this. It's changed the lives of thousands of woodworkers around the world simply by giving them plans, video instruction and access to making their own fully adjustable, lifetime hand router plane for the lowest possible price (£35 currently). You can order your kit for the metal parts directly from us here too. Please remember you are also supporting our impact on the hand tool woodworking world into the future long term.

This is one of three Preston or Preston type router planes that I own and will soon be selling; one of them is the red Tyzack version. I have allocated sets of tools from my existing gathering of tools accumulated through the decades to my children and grandchildren, but as I will unlikely teach in one-on-one classes in the future I will be selling on the excess and the class tools as sets too.

Seeing the Unseen

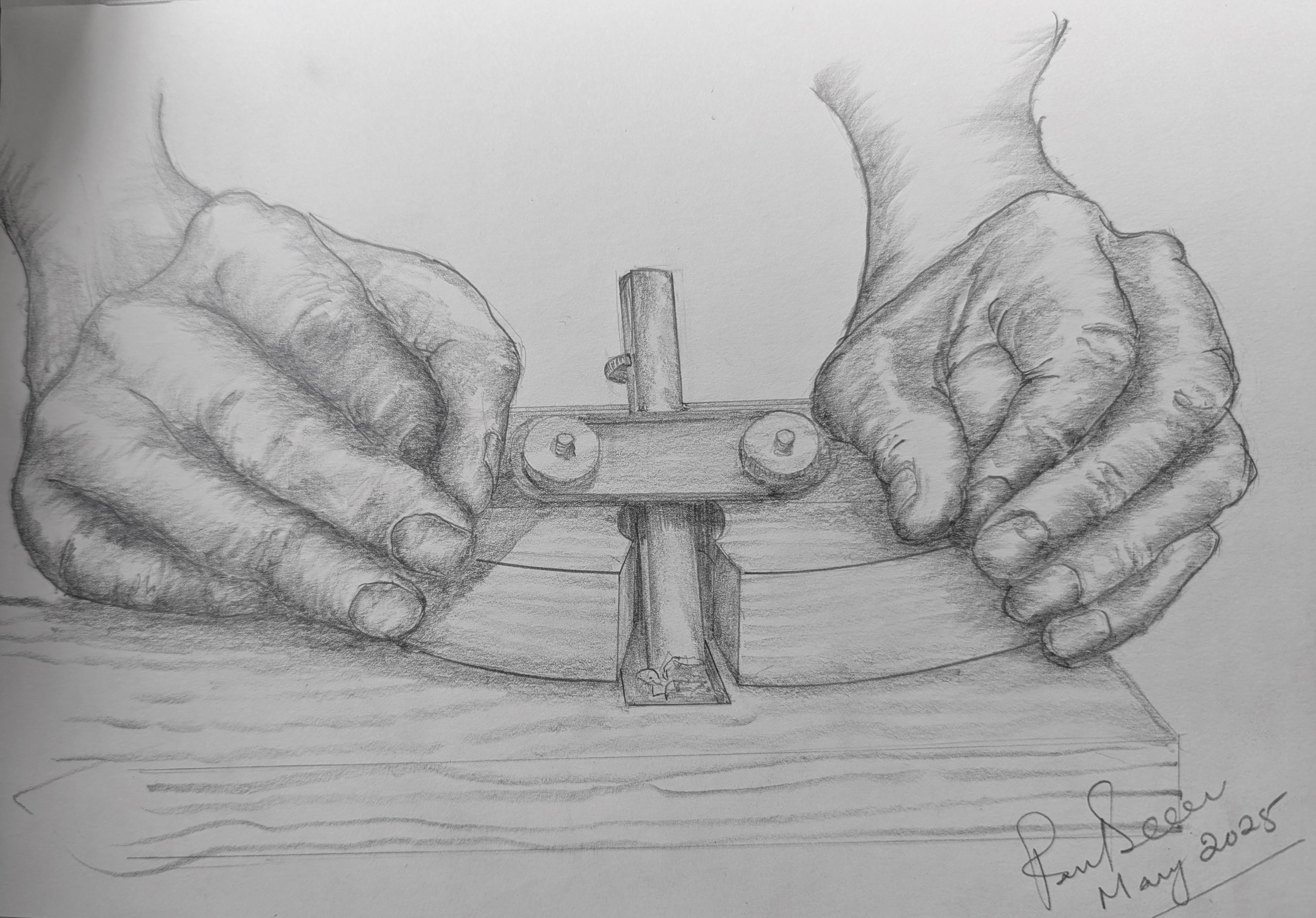

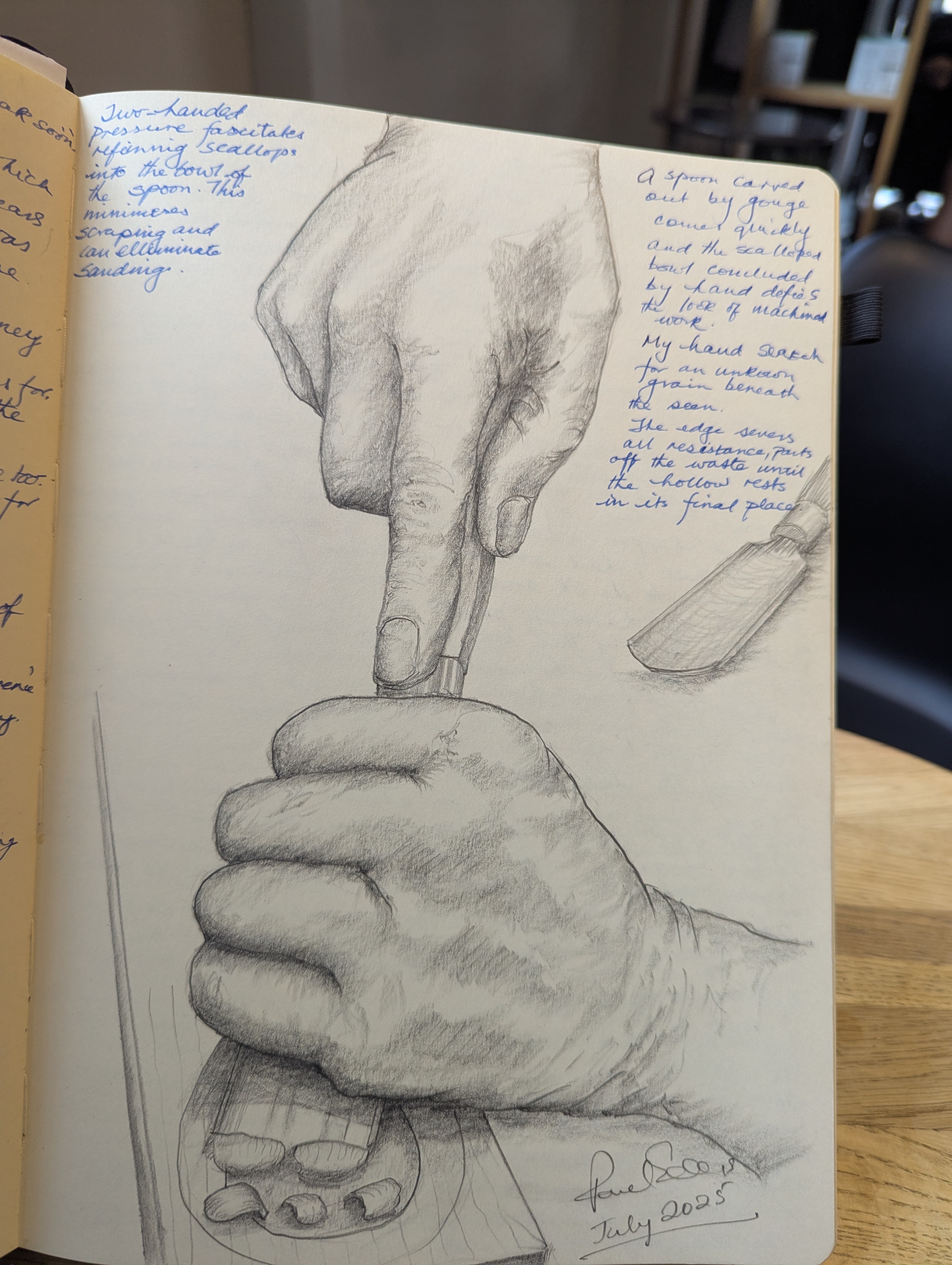

We made planes for specific tasks in our online work, and then too in classes through the decades. Round-both-ways planes were popular and useful tools for truing the gouge marks from seat scallops, and then we made compass planes too. See how the fingers bend to apply pressure through different points.

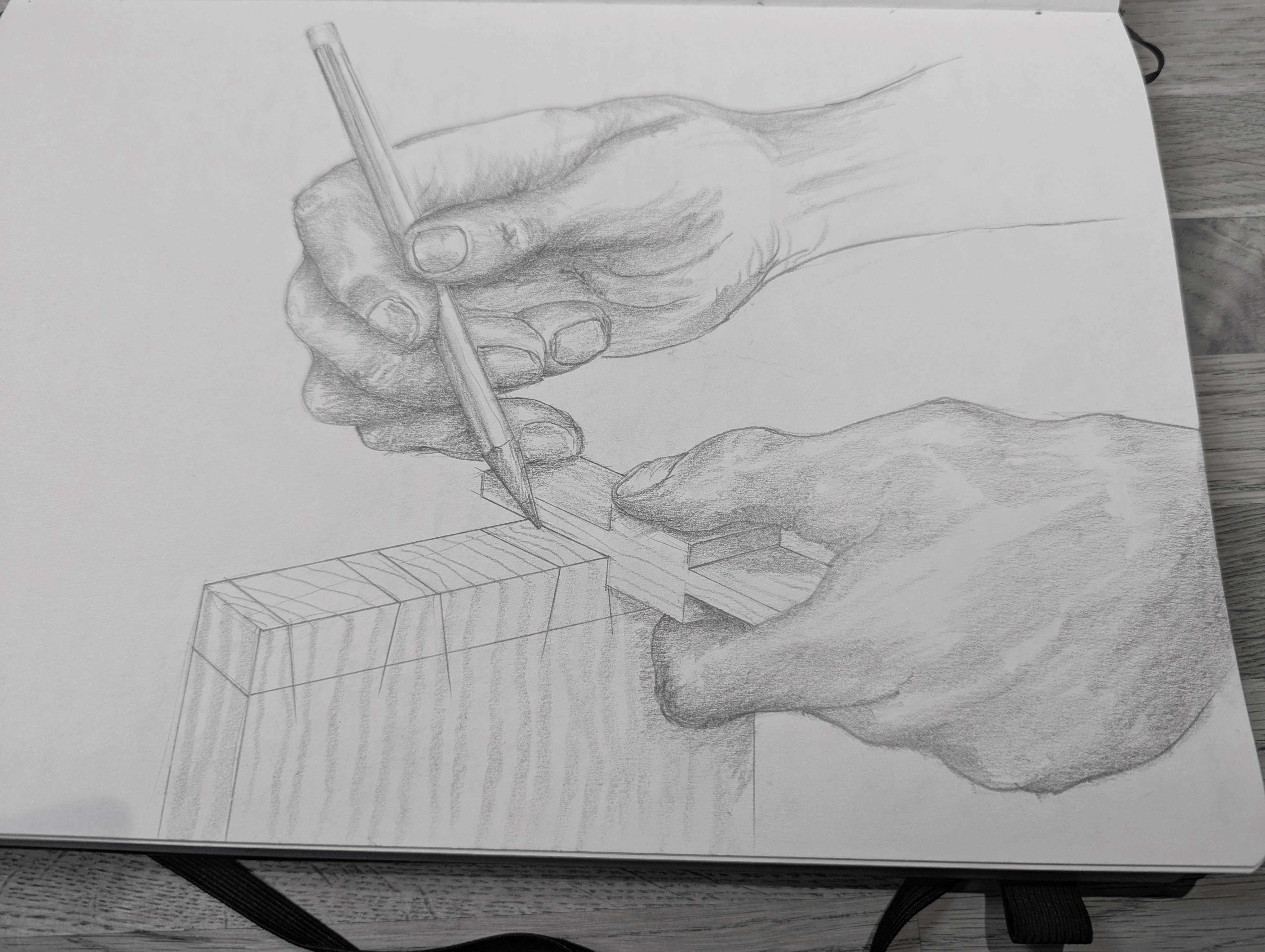

Knifewall

Who decided to call the cuts made across the grain for shoulder lines knifewalls, anyway? Paul Sellers did, and he did it for good reason. Hitherto, it was called a knife mark, scratch line or similar, but it didn't really match we were mostly creating in furniture making and joinery. It was a small tweak but a significant one nonetheless. I always thought it quite a rubbish term because in our world of fibre severing it was more than a mere knife mark.

Sometimes it's a singlehanded operation, and sometimes two works better for steadying. Notice the corner to corner pin for visibility and trailing the pin in the marking. I have come up with a completely new design for this tool and when time permits I will post on making them.

Holding the gauge comes in many ways, we optimise according to positioning in the workpiece.

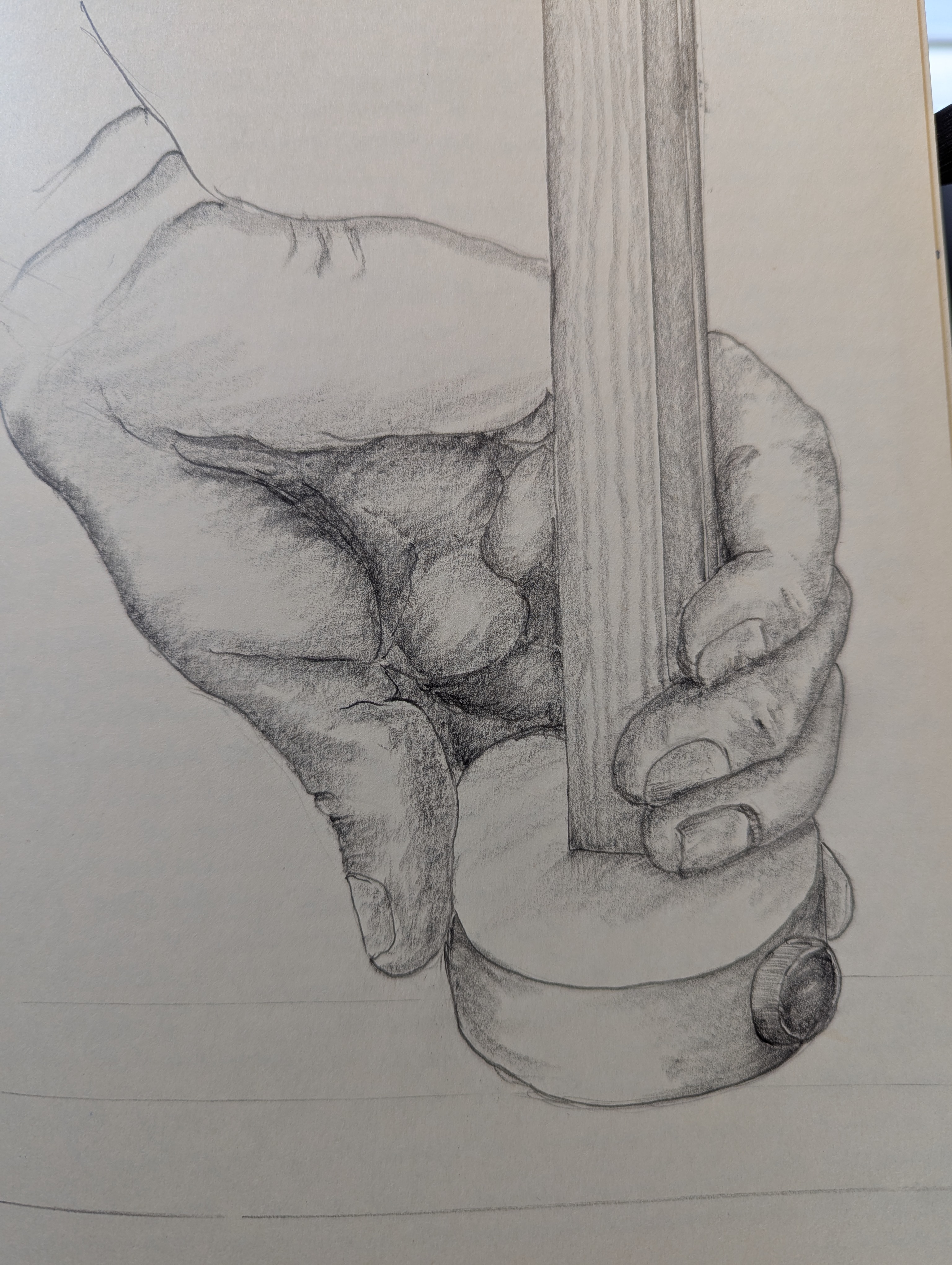

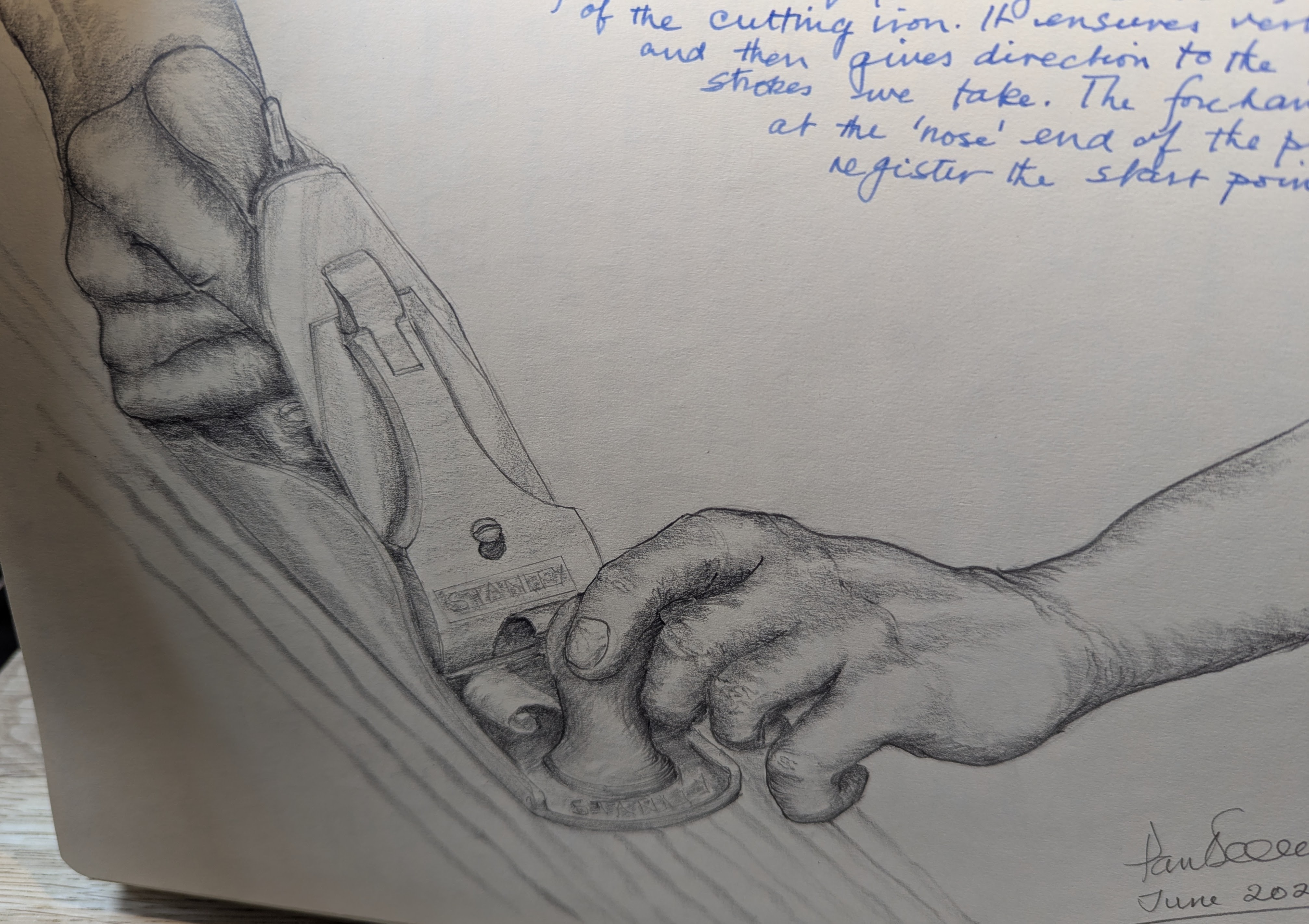

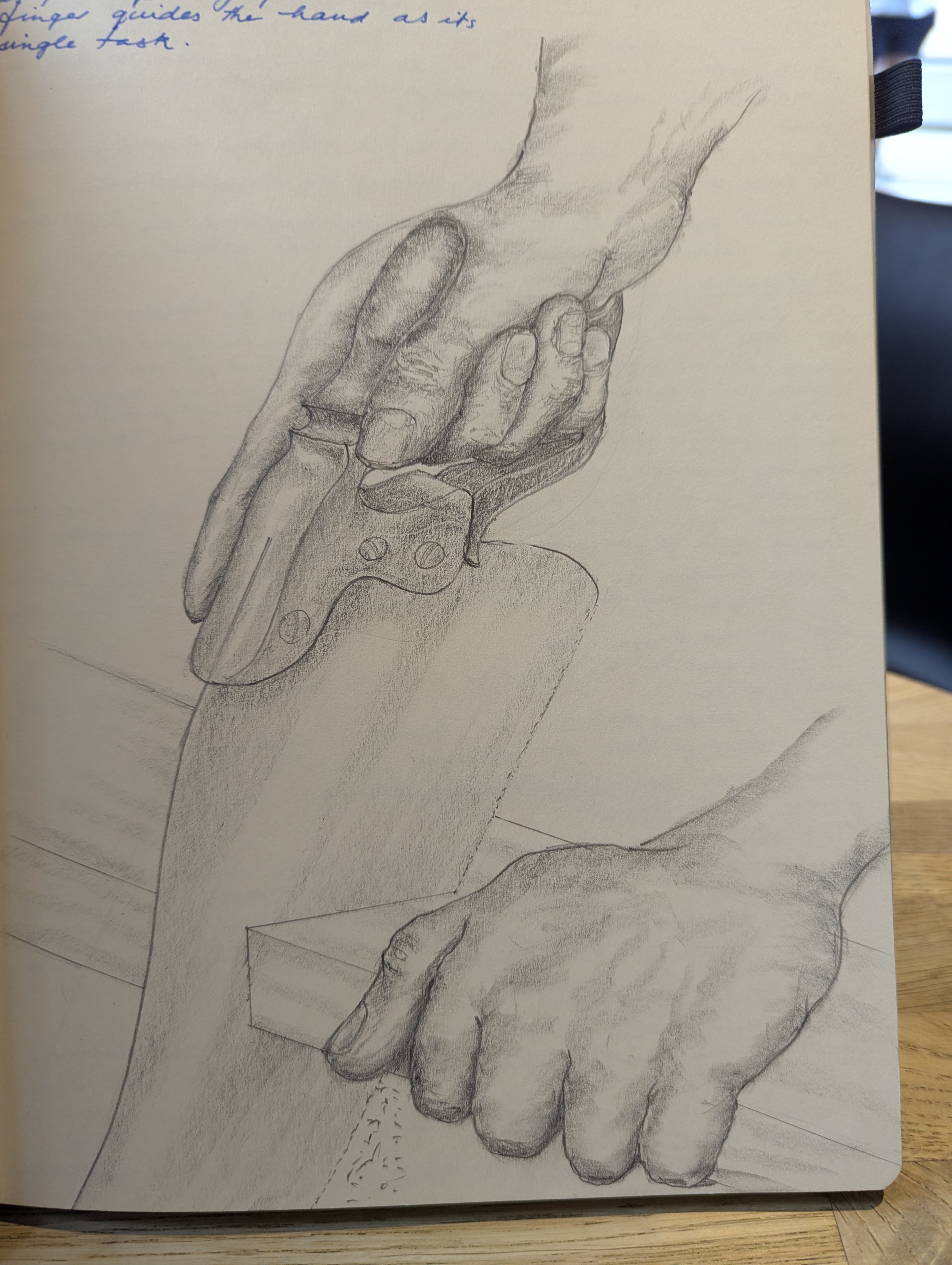

It's a partial fist grip, but the forefinger always slides alongside the cutting iron assembly as shown because this guides the hand and establishes control of the whole plane. And then there is the non-dom hand we tend to forget. This hand presses the fore-end of the plane to fully register, a split second before the push begins.

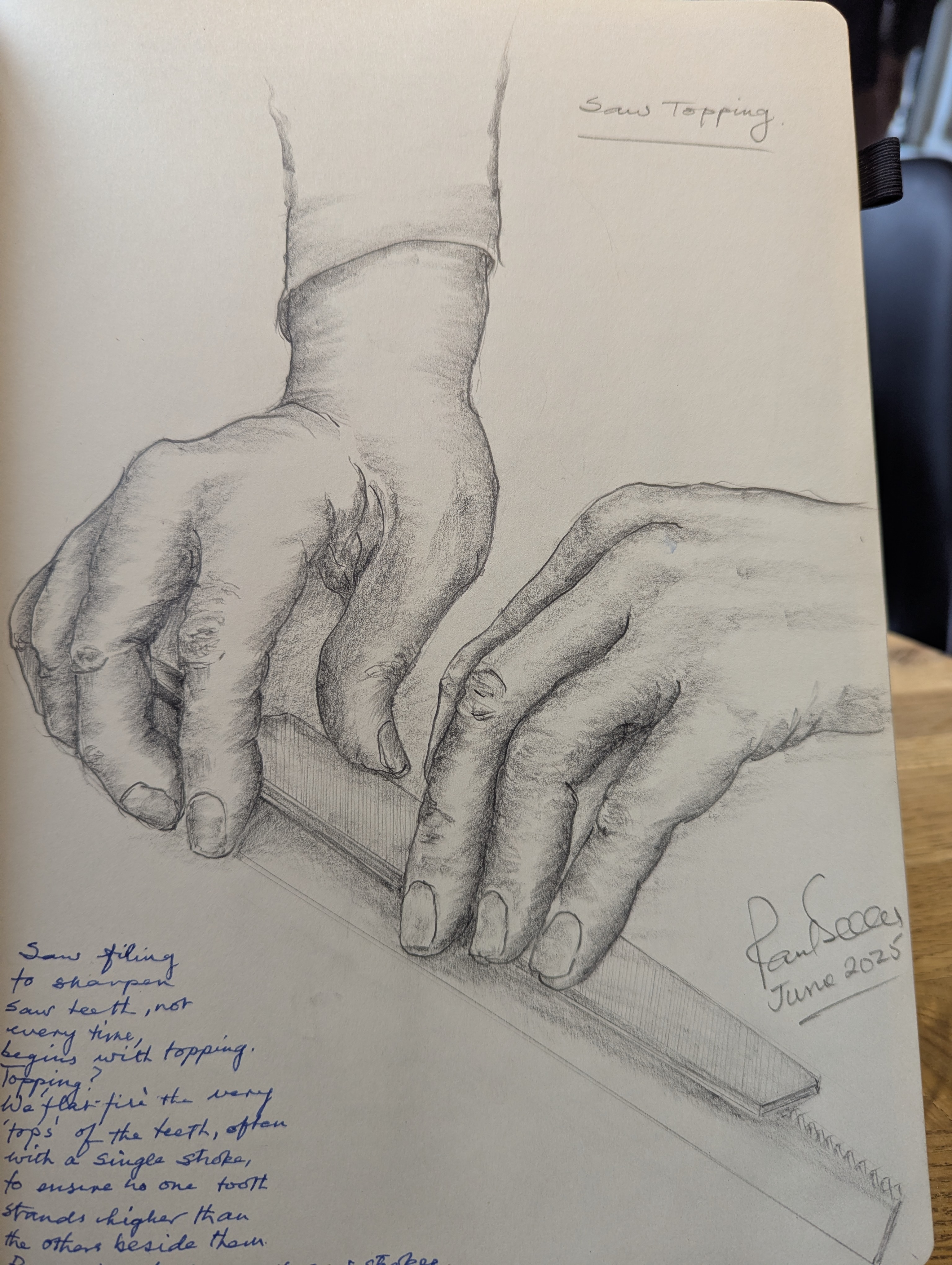

Saw topping in the UK and jointing in the USA are terms that mean the same thing except jointing means to straighten whereas in some saws we do not want straight but slightly cambered, so topping is more definitive, I think.

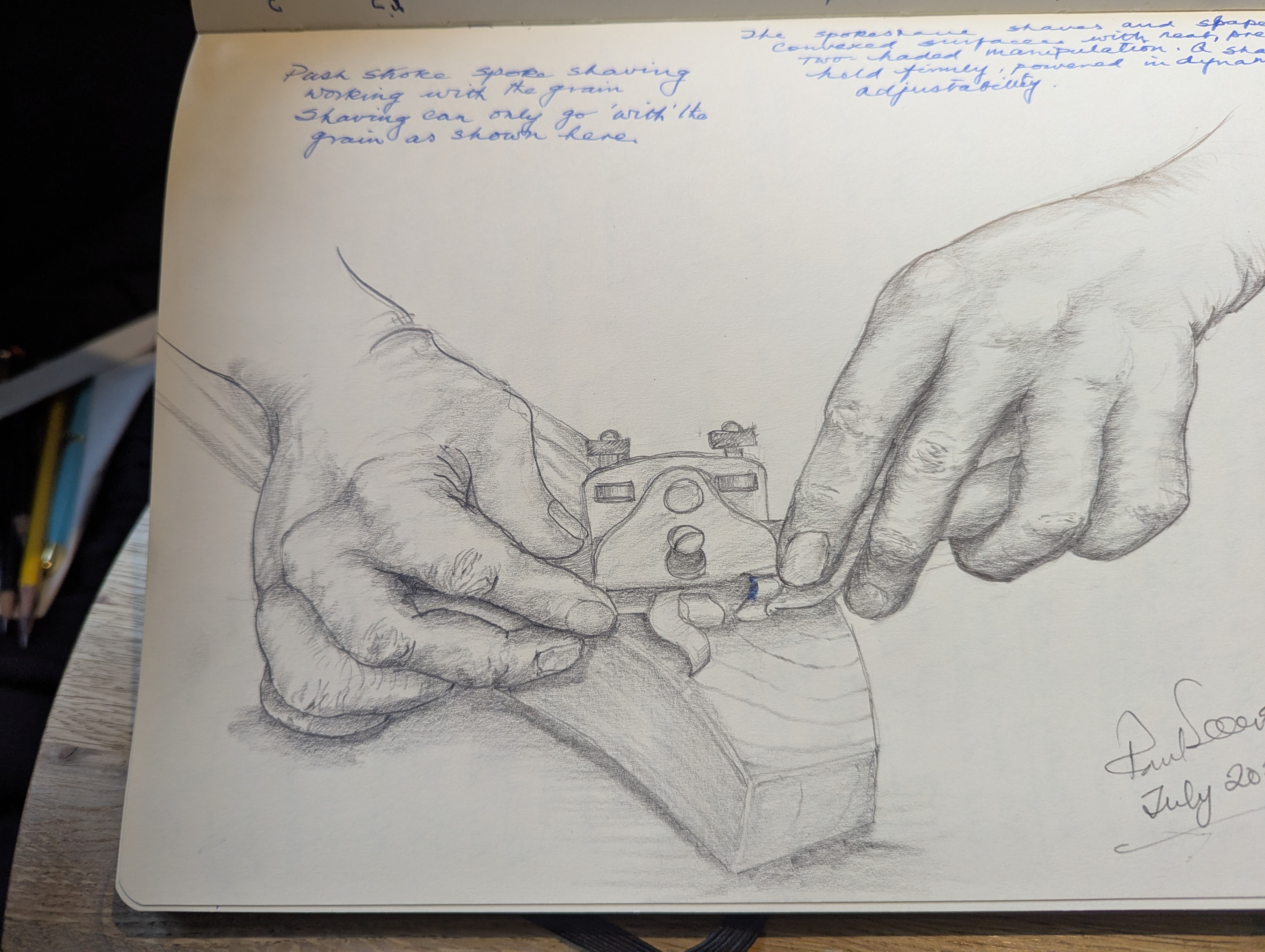

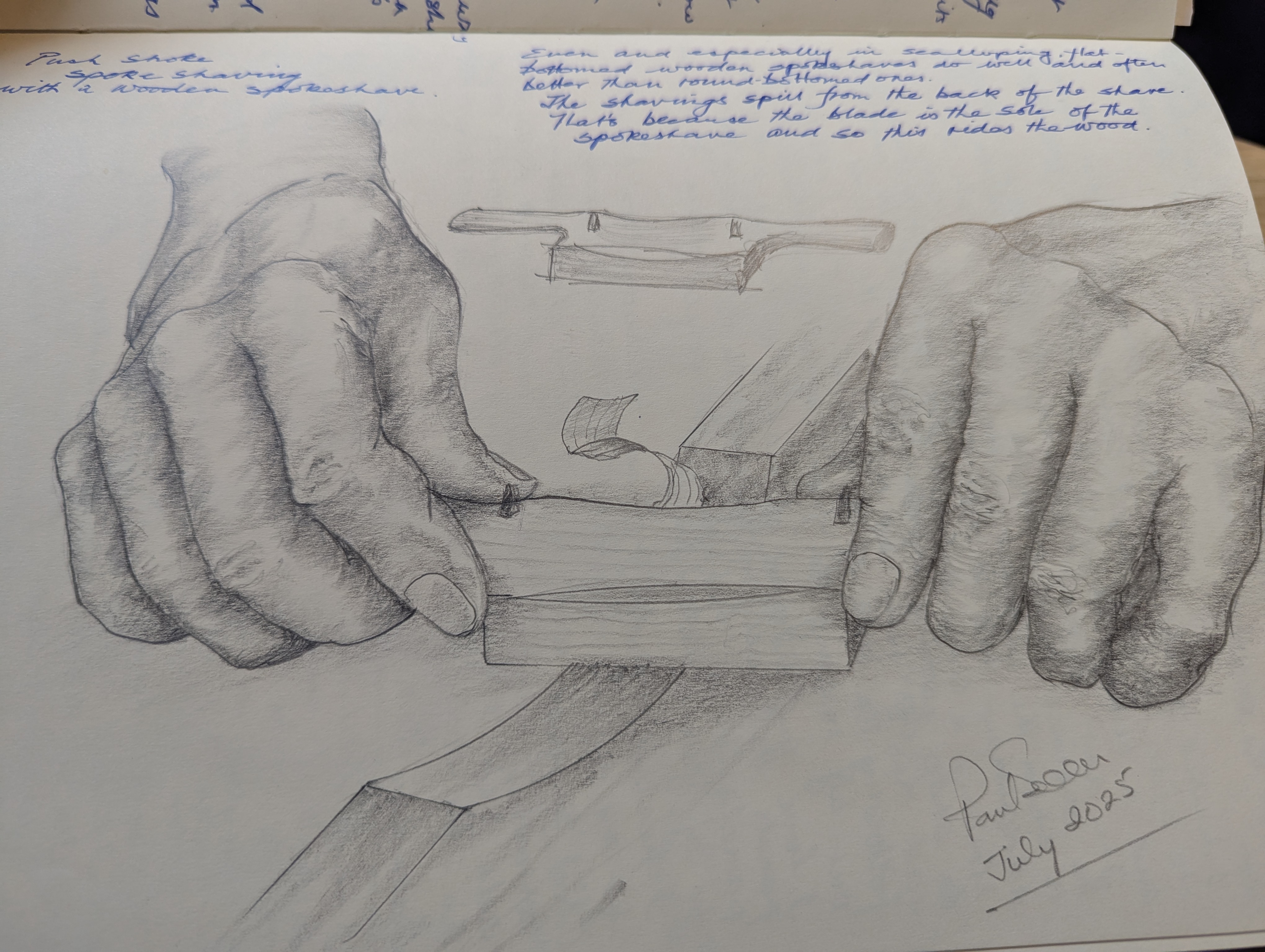

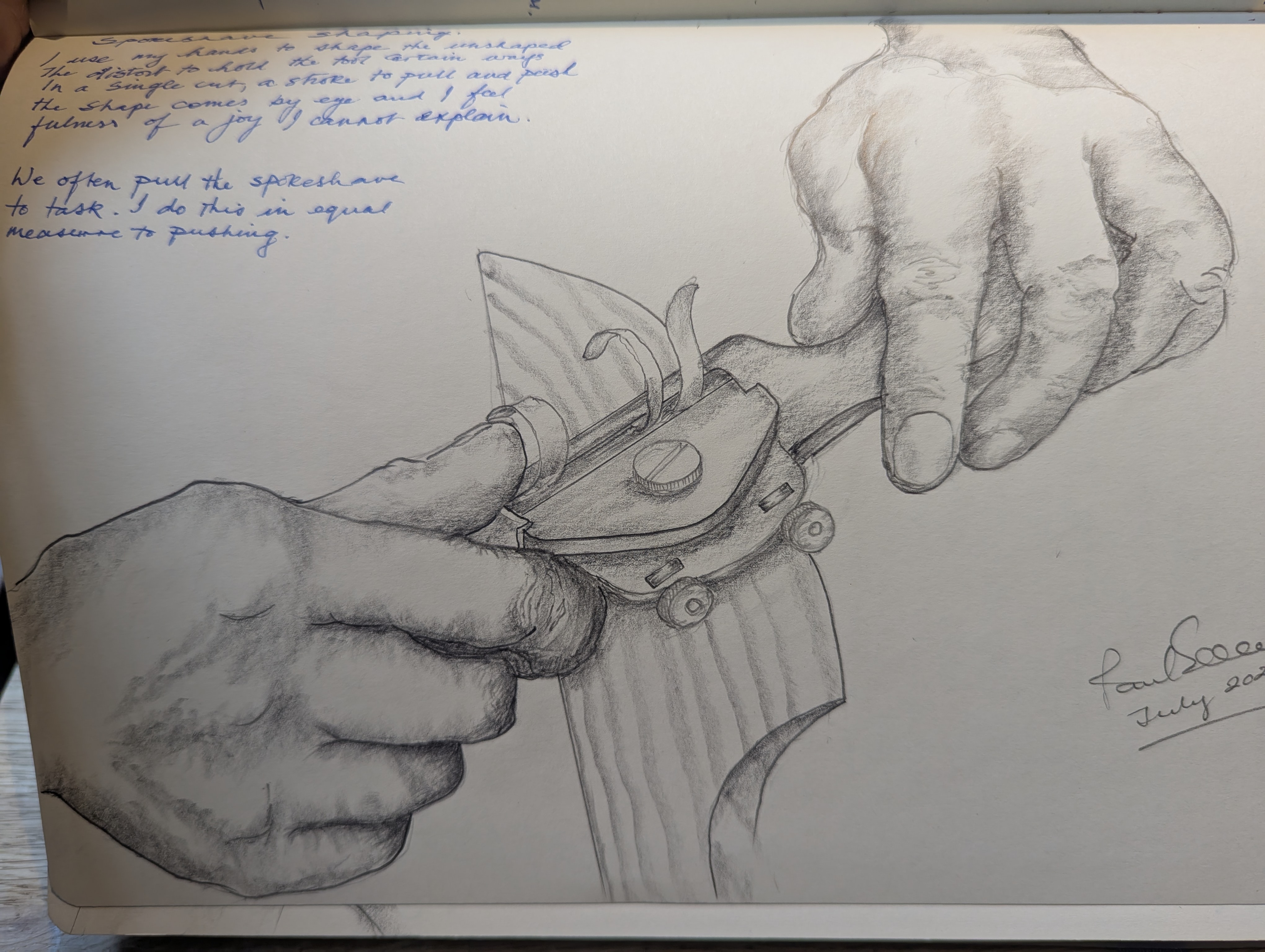

Woodworkers strongly believe that hollow cuts need a round-bottomed spokeshave to optimise the cuts, but that is far from true. 95% or more cuts are more effective with a flat-bottomed 151 spokeshave––take my word for it.

The shaping world is readily transformed with a #151 spokeshave. I even use it for chamfering and planing up end grain too.

I use my #7 sweep 1 1/2" out-cannel gouge for bowl carving large and small and then roughing out chair seats too. Mostly they work well for an even hollow on a spoon. I carve the bowl before shaping the handle and the coved back with a spokeshave.

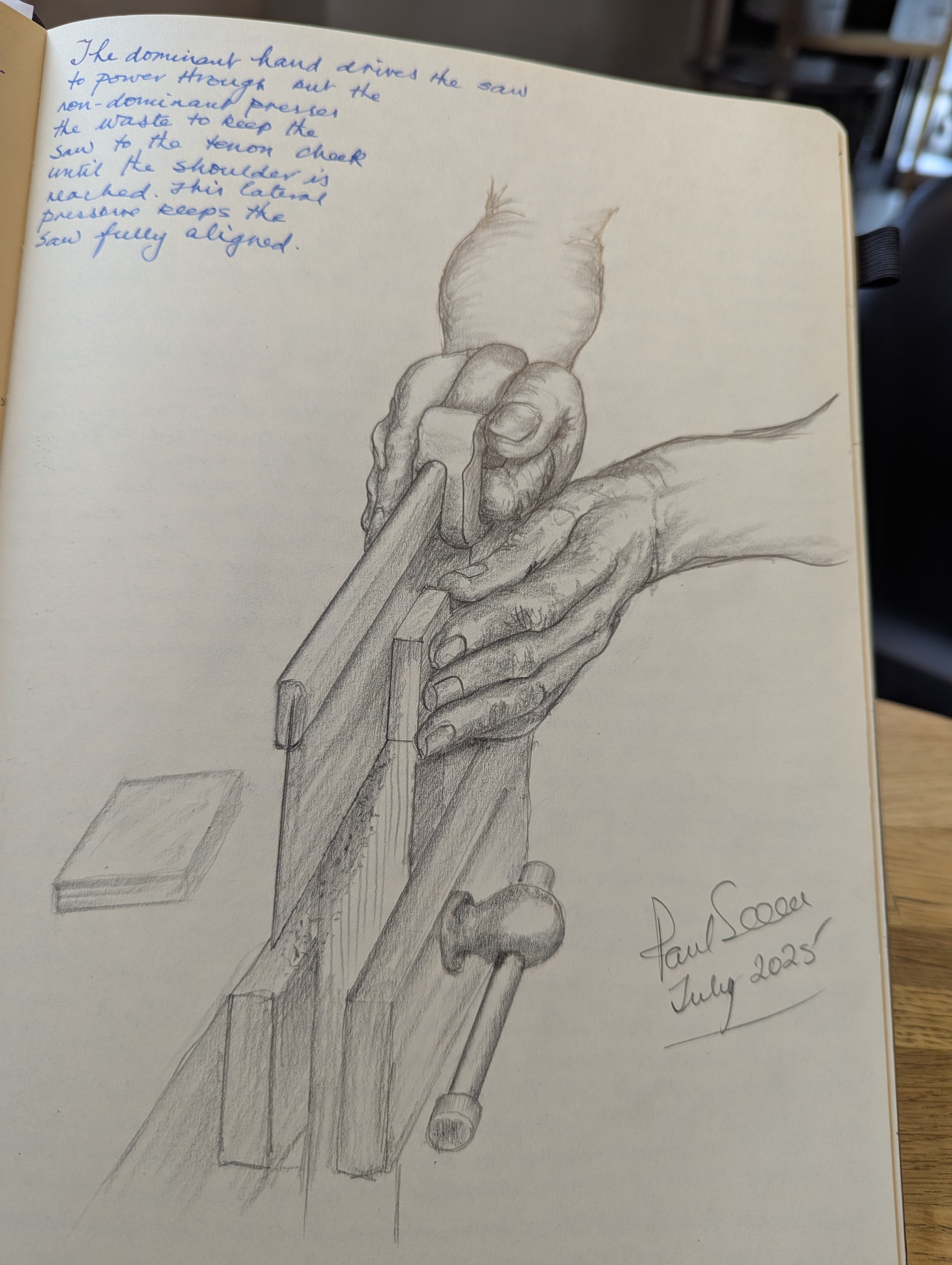

See how pressing the waste wood against the plate before the full depth of cut is completed sandwiches the plate and keeps it fully aligned to the gauge line. The small things make hand tool woodworking work.

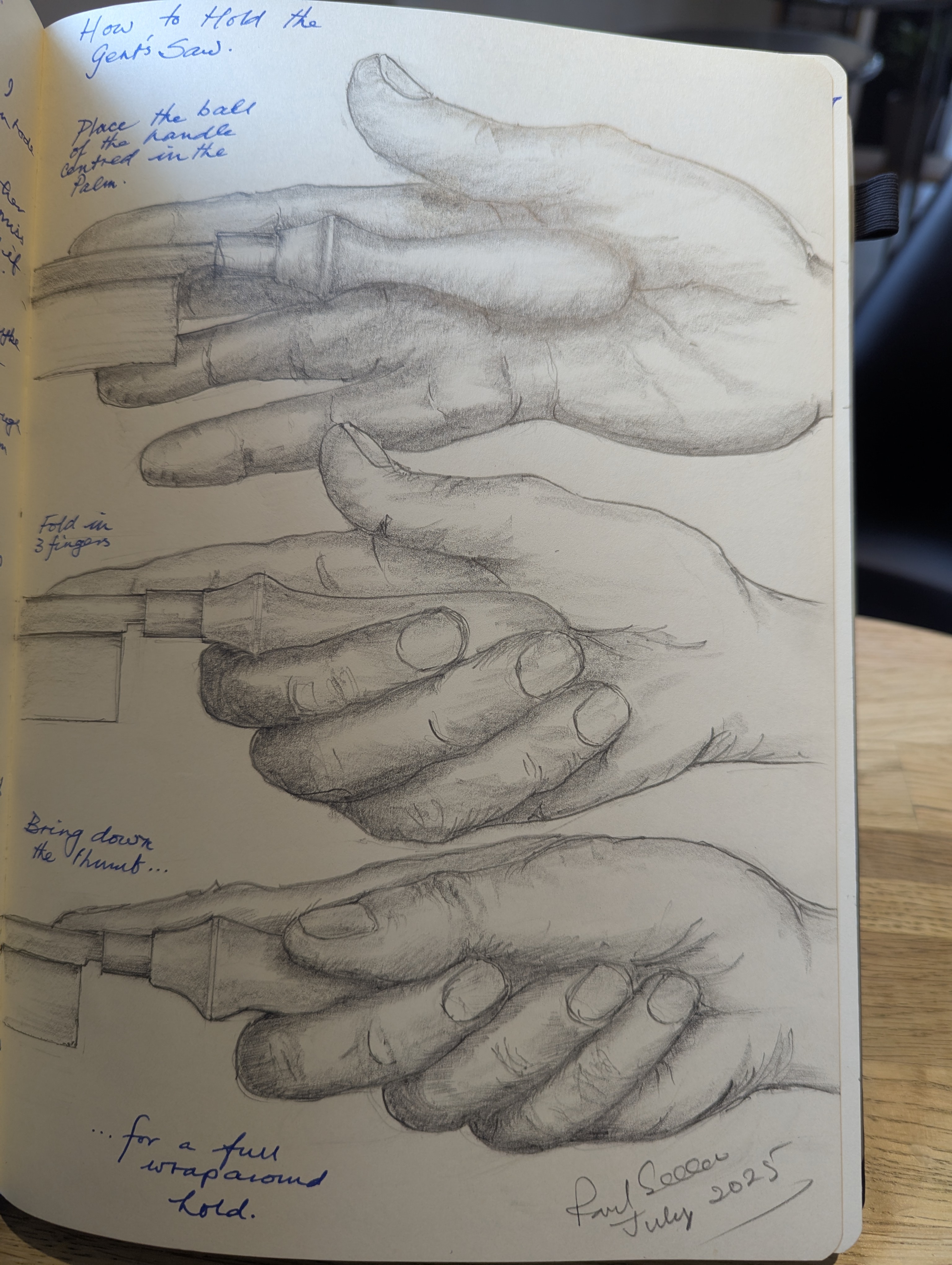

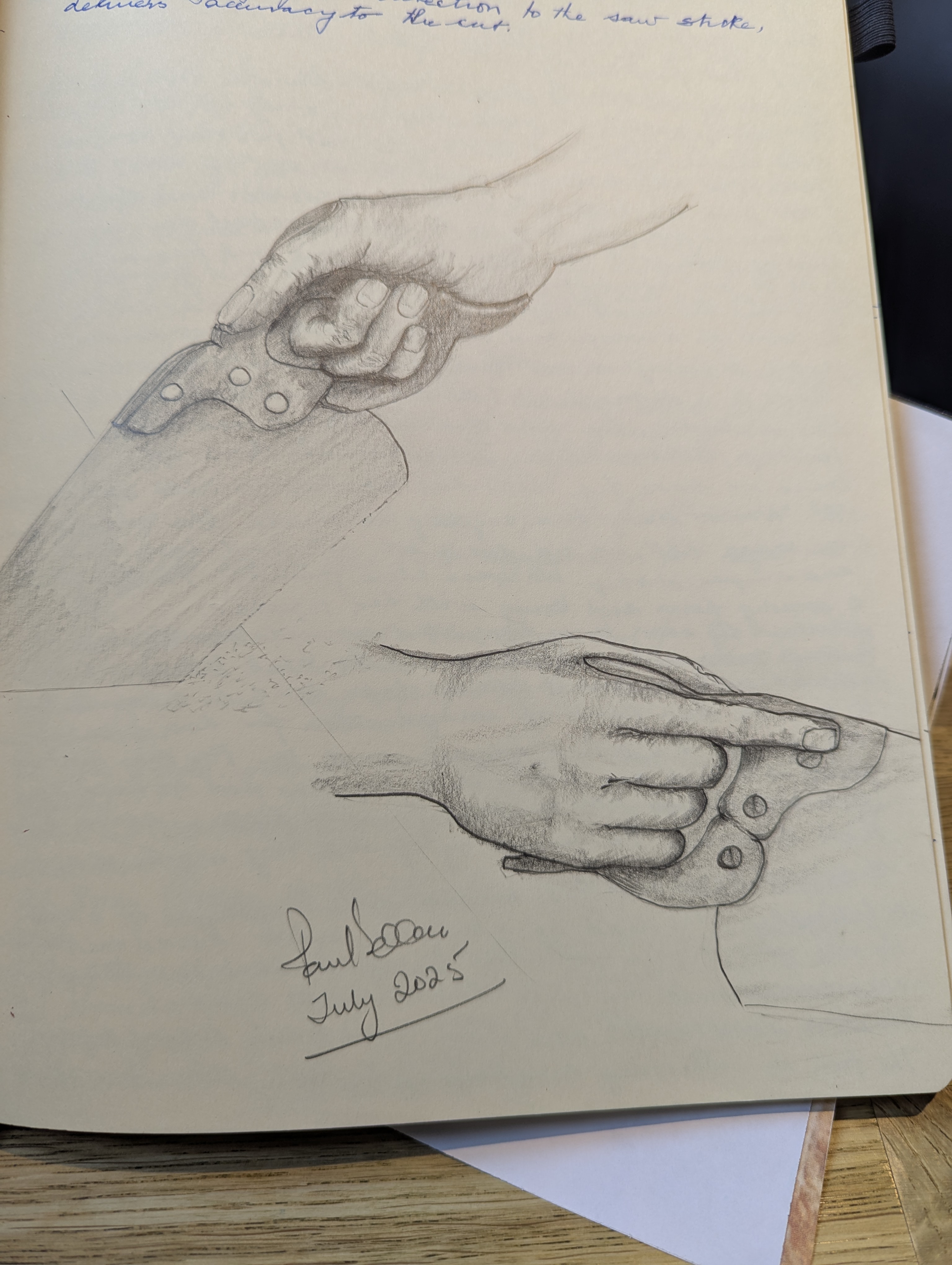

It's not always obvious, the hand hold of the Gent's saw, so there you go! It's surprising how many use an overhand grip to fold all four fingers around the handle. That makes sawing awkward and less powerful.

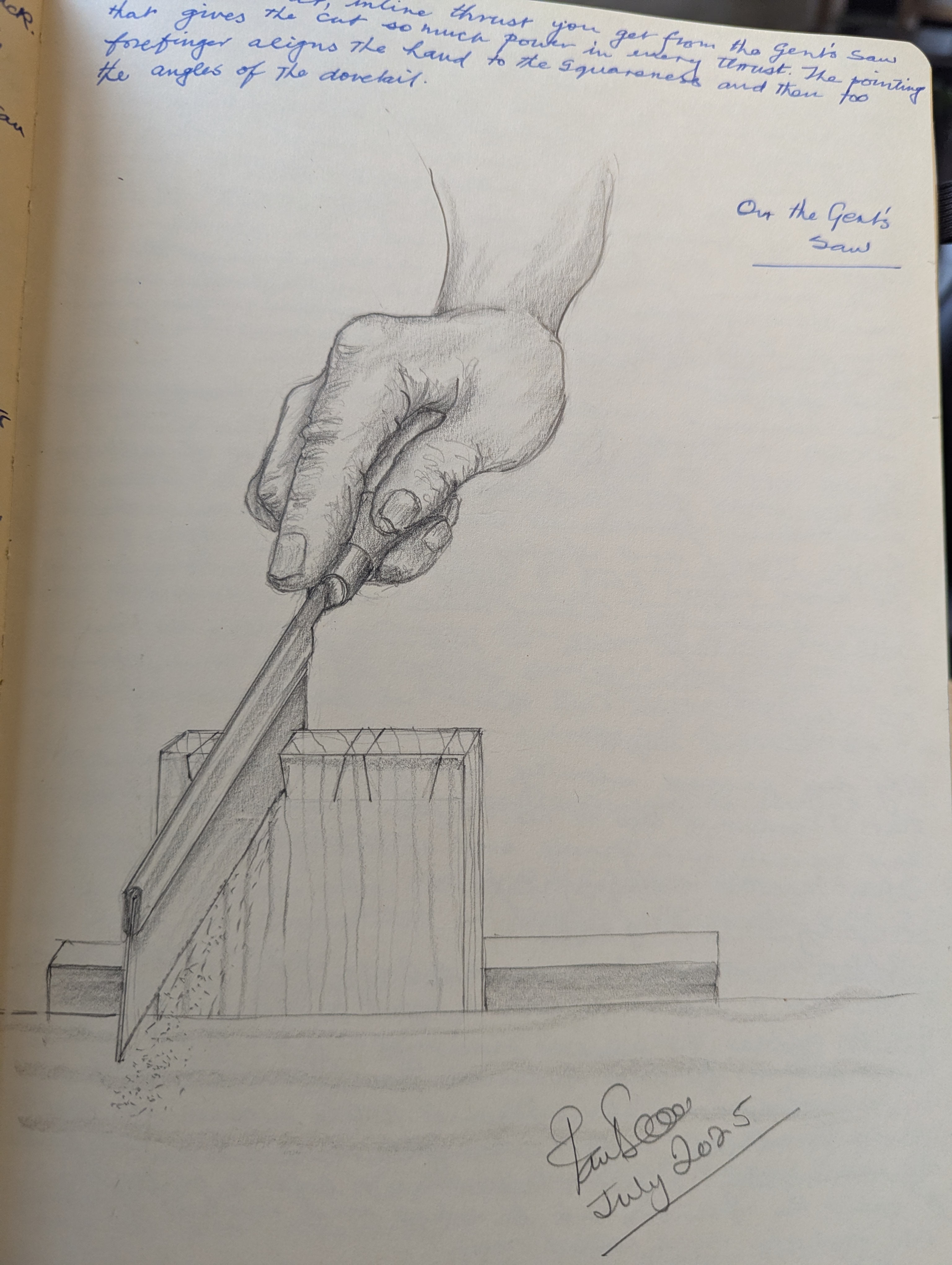

And in use, we see once more how the forefinger changes the hand grip to a more direct, inline linkage to the wrist and forearm with thrust power. . .

. . . while the other hand, the non-dominant hand, counters the pressure to remove flex and minimise vibration from the power hand.

Oh, such wonderful tools, but steadily disappearing year-on-year as there are more buyers than spokeshaves made and available these days. In these planes, for planes is what they truly are, the blade itself is the sole of the spokeshave and has direct contact with the wood through the underside of the blade riding the wood.

The #151 lives on after so many decades since they were first introduced at the beginning of the 1900s. These cast metal versions are equally remarkable to the wooden ones but take almost no skill to make by comparison. Fact is, they take a matter of minutes to prep for assembly. It's still a remarkable hand tool and the first one I introduced to my boys when they were still under five years old and now too my granddaughters.

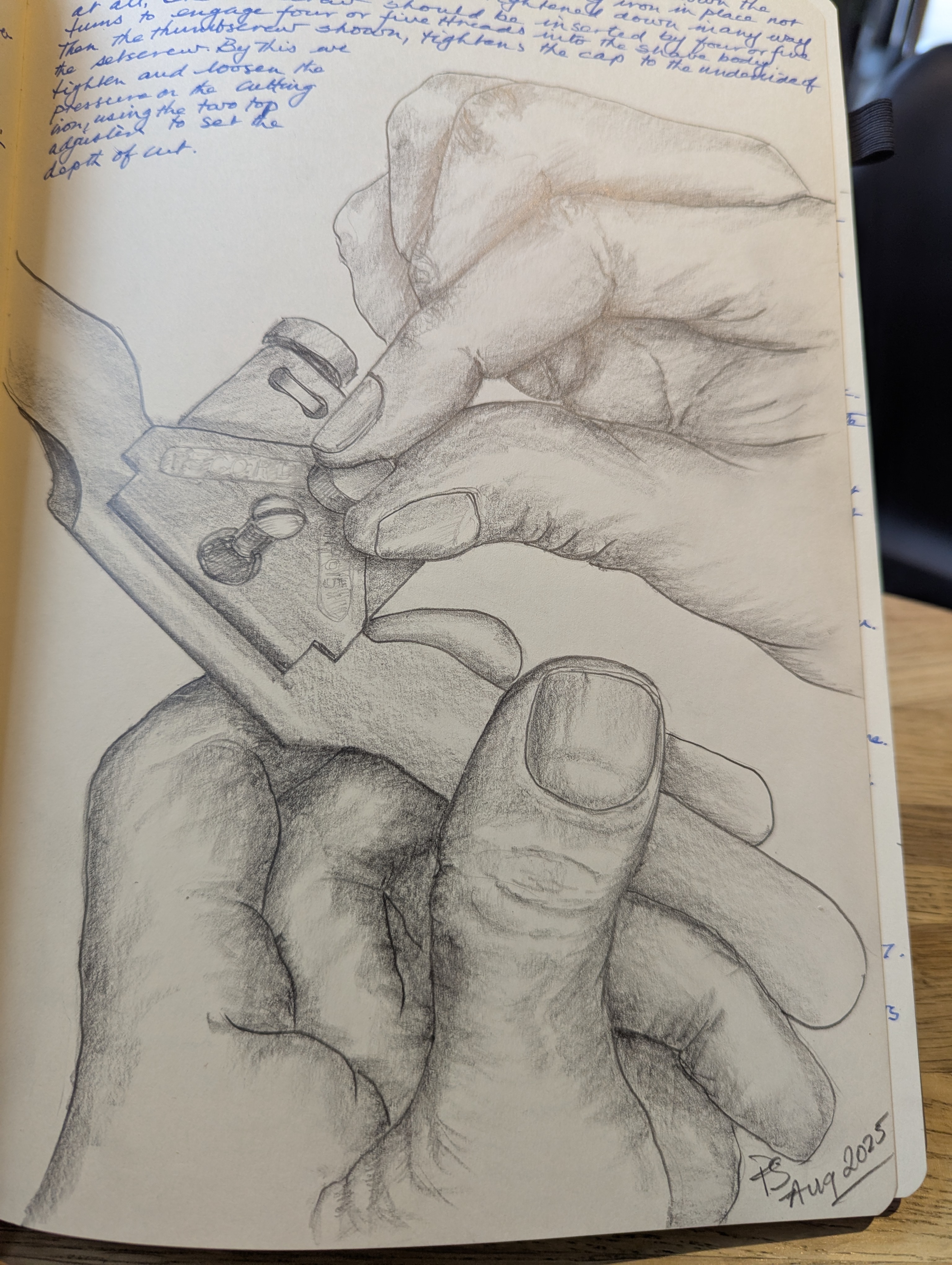

We tend to see the slotted screw as a means for cinching down the cutting iron, but that's not the case at all. The knurled screw reverse cantilevers the pressure down to the fore-edge of the cap iron to apply pressure directly behind the cutting edge. . . that means the set setscrew is set a distance from full seating. I cover this adjusting area between the two screws in my book, Essential Woodworking Hand Tools. Very important to see the flexibility for minute adjustment in this tool.

How much misunderstood the handsaw grip. A full fist only bulldogs the saw to task, but the pointing finger gives total control and direction.

Just needed to show how to hold the handsaw, which is the same for small saws like tenon saws too.

The minor sketches are good for recording thought in action for larger work...

Comments ()