Nine Years a Café Chair Equals . . .

. . . 50–200 years, a home version.

At least that's my consideration from what I found in the facts surrounding this mass made chair from the café I go to each day. At first, I said 50 years service, but then I thought, in careful use, an average family size of 1.7 children under the age of 18 per household, often raised by a single parent, these chairs will not be subject to say a family of 1800 with 5 children and 1900 of 3.63...at this rate, will we see .85 children per whatever family type?

Watching the abuse of any café chair in just an hour or two by attendees showed how careless customers are with their children and then they themselves. For some reason, customers expect to be able to abuse café chairs. They scoot them two feet and more with 200lbs of dead weight sitting squarely on the chair's four legs and think nothing of those skinny legs when they dig into the vinyl flooring or catch the edge of a floor tile or floorboard joint lines in quick succession. Leaning way back on the two back legs while pushing into the tilt by their own two legs at the front, it's definitely a man or a male-youth thing, is kinda like a really idle strut-expression of manhood. The low-angle, lean-back of men in a group also changes the dynamic exponentially, especially sports groups where the upper body muscle-weight overhangs the comb of the chair to exert high levels of pressure the chair was never designed for. The group dynamic of men in groups of this type significantly changes the stress on every component of the chair. The old adage of parents; "Don't slouch!", "Sit up!", "Back straight!" and many more is unlikely to be heard much any more but, if you think about that simple chair, the abuse by the average user is quite the new and highly impactful phenomenon. Those muscle-bound, broad-shouldered people might well be applying a hundred pounds of leverage through their upper backs to a spindle-backed chair, and the springing back and forth will inevitably break the glued union within the joint eventually.

I repaired a chair for more than the repair itself. It's a useful resource, a record, if you will, of all the existing components, so we can establish sizes, angles of splays, heights and expansions to take cross rails in the designs of chairs. The bulbous leg takes the end of a cross rail and so too the stretcher going into the dross rail. When these are missing in one chair type, it begs the question, "Why?" The answer might well be that Beech is stronger than pine or less likely to fracture than soft maple. Hard maple scores 1450 whereas soft maple, made from silver maple or red maple, has a Janka hardness of 700 to 950. Hard maple and beech are similarly rated as far as hardness goes. Hardness can reflect strength, of course, but it can also reflect brittleness.

This chair's facts

Taking any chair apart will reveal many things, good and bad. We can learn immensely from the work of others, whether that is in newish pieces from factorial mass-making or the archaic work of bodgers in the woodlands of England's past centuries. Of course, factory production goes back a long way, even when all the individual parts were made by hand on lathes lined up for production workers making parts by hand and eye in a factory production setting––the prelude to copy lathes and then automation that simply needed people to load and unload wood blanks.

The chair I took from the café had various parts that had separated from the chair seat, leaving the comb off completely and two spindle on the seat. It was obviously unsafe to use and had been withdrawn from use. Why did this happen? Well, we'll take a look to see if it was a bad design, structural breakdown or poor workmanship. I have seen these chairs in this café in use on a daily basis since 2016. They have never been replaced or repaired in nine years. Almost all of them carry the telltale signs of poor assembly work rather than poor design. Dismantling this particular chair, I was impressed with several things. Where to start.

Knocking the comb (the top back rail receiving the spindles) off the rails with my chisel hammer was straightforward enough, nothing really held much of anything, four turned loose with no effort and a single tap, the middle three were fairly secure, but I didn't need them to come out if they didn't wholly volunteer. The dowels into the top rail were stopped at equal depths of 3/4" even though the underside of the rail was curved upwards to each side. The dowels into the seat were through dowels. I could see saw kerfs underneath before I dislodged them, but no wedges or any other securement. I immediately surmised what had happened. Over the years of mass assembling the same chairs day in, day out and over many years, shortcuts were taken. Passing it on to next generation assemblers would confirm it as a technique rather than flawed workmanship. Eventually, the assemblers cut 95% or even more of any actual gluing anywhere to the joinery but knew where to apply sufficient at points to ensure it lasted long enough to go beyond the guarantee date. That meant minimal squeeze out for cleaning up after glue up but, also, dead sized holes with dead sized dowels in a row of seven would be difficult or slower to insert. The saw kerf meant the dowels would slip in easily and would be secured after passing the saw kerf ed area as they levelled out at the waist point where the saw kerf ended just below the sight line after insertion.

Abusive Behaviour

Of all the furniture pieces ever made, and that's throughout the world, the chair is the one subjected to more stresses, strains and abuse than any other you care to name or think of. Those stresses and strains are altogether unpredictable, but the most common of all is the weighted scoots in every sitting. Sideways, backwards, forwards, the half-hearted lift-and-scoot rarely relieves all the stress and inevitably, the scoots of decades will eventually take their toll. Can chairs live a life of unscootedness. That's not realistic. We first move the chair out from being parked under the table to sit, and then we sit before we lift ourselves partly up to scoot in to a comfortable distance to work or eat. That being so, most chairs are designed to factor in the stresses of scooting. Everyone but everyone scoots chairs in and out every time they sit, adjust for comfort and change and stand.

The lean of legs––chair splaying––is essential for stability in most small, lightweight, narrow-based chairs like dining chairs, working chairs and office chairs. It's doubtful these days that any office chair will not be made with five points of contact with the floor via casters and with a swivelling 360º seat so that no scooting is essential at all. Thus, we've seen the demise of the wooden office chairs through the innovative designs that resulted in obsolescence, and it is unlikely that we will ever see them return.

Modern office chairs of this type have infinitely adjustable components to customise every element for work or comfort, position changing, etc. Wheels wouldn't work too well in cafés and homes, and that's why you don't see them there as a rule.

Farmhouse captain's chairs like this one, where almost all the glued components failed because of shrinkage, still held, primarily because of the angles intersecting at the seat. The back support posts work in this chair only because the front arm posts leaning forward counter the upper weight passed onto the back frame by the sitter.

Looking on the underside, tells its story yet again. The mass making assembly workers did drive wedges this time, but once driven they broke them off with the last hammer blow rather than sawing them, as this was fast and efficient.

The front posts remained unwedged and never were they wedged to begin with. Notice also the two air-driven pins through the seat into the top of the leg. Security against coming out but not too much.

Analysing my repair chair

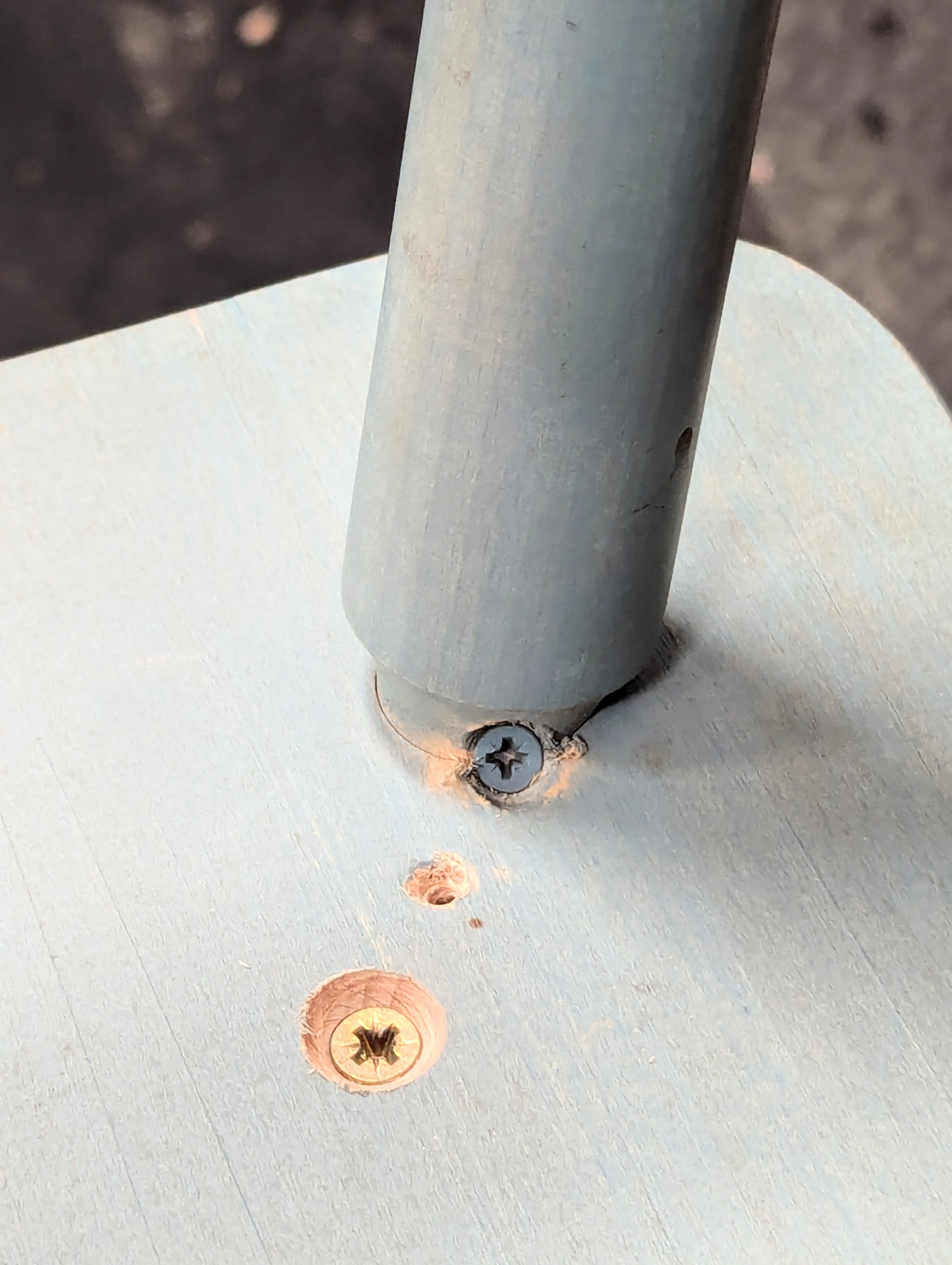

The legs felt quite secure. Were they? I used a hammer under the seat to see if they moved. They didn't. A screw by the joint told me there might be an issue somewhere, though. After removing the screws and giving a single tap to each adjacent spot by the seated legs, the legs came out of the holes despite the wedges from the topside of the seat beneath the padded panel.

Obviously, the issue with all of the joinery on this beech chair was shrinkage. In times past, this was taken care of with a tapered hole receiving a correspondingly tapered tenon. On my chair, removing the leg, cutting out the existing wedge, deepening the saw kerf, would allow new wedging as the shrunken leg tenons would readily expand via the wedges and the glue, having swollen the surface fibres in the hole and on the leg, would give good adhesion. Would I return the screws to the legs? There would be no reason not to.

I cut wedges and extended the saw kerfs to receive them and to lessen resistance to spread when assembling. . .

. . .but before I did, I did a little more testing of my own. Nothing like mechanical break-testing for your own knowledge. Here are my 75 kilograms (165 lbs) on the centre of a single beech spindle 5/8" in diameter for my at-the-bench test.

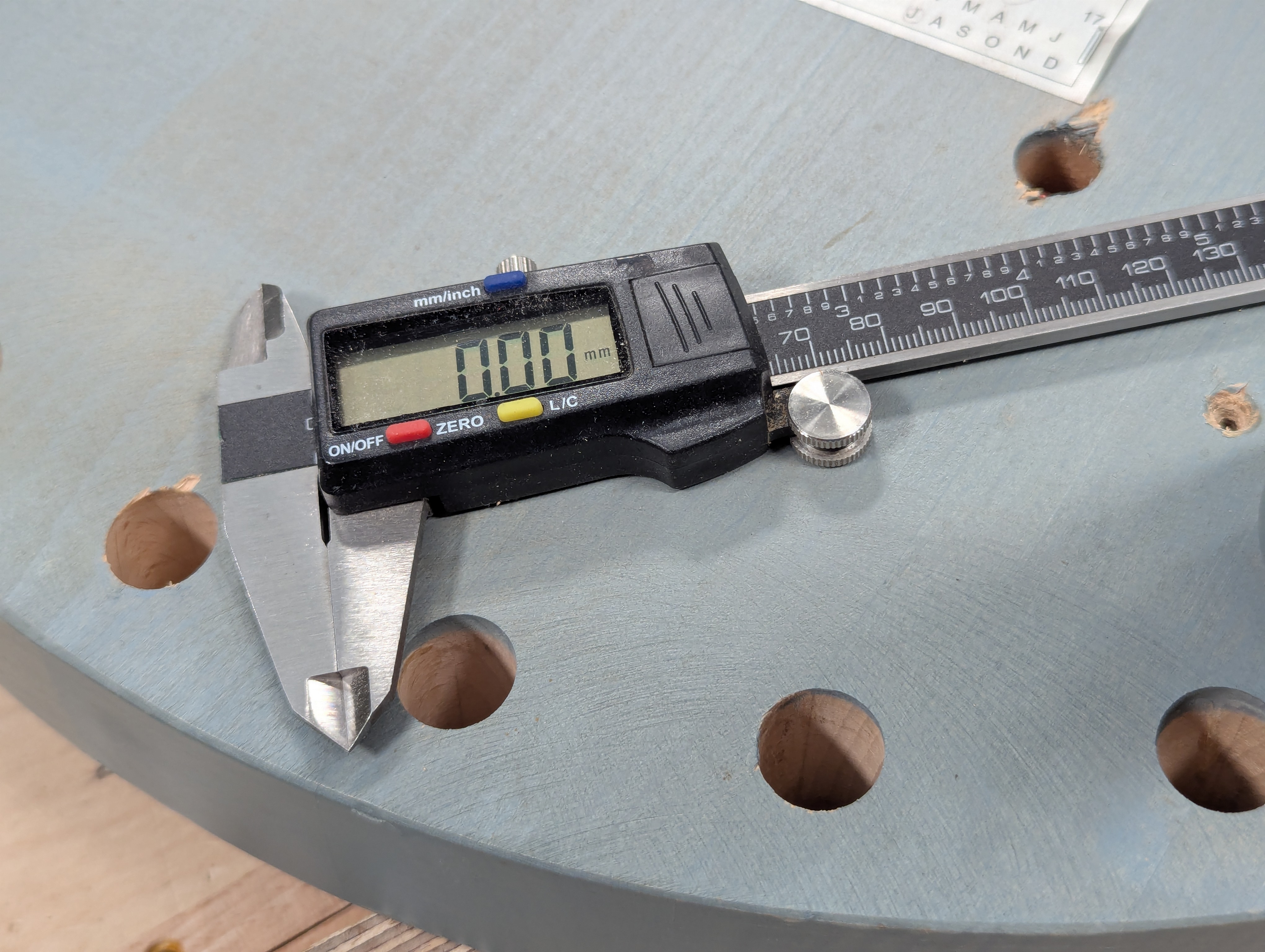

My cluster of tools enables me to check, identify and establish information on the chairs I come across, anything from the larger measurement spans on down to the minutiae, joinery and part sizes, angles and joinery strengths according leverage, calculations of beam strengths and expected pressures. The information is then there to assist me for keeping a record I might use somewhere in my future chair designs.

Getting past the general flawed endeavours of the assembly workers, I was able to garner a lot of information from what really is a solid chair design. I will not replicate the design as a whole, but having sat on it, scooted on it and used it for a while, the chair is a good dining chair and a good working chair too. If I was drawing, writing or weaving a basket or sewing, I would find this chair more than adequate. That being so, I can record all of the information and without copying to chair as a design, I can create new designs according to what comes in my own mind. In chair designs, there are often non-negotiables. Make a chair 19 1/2" from the floor to the seat, and not a single person in a hundred thousand will ever find it comfortable, no matter their height differences. The back of the slope is highly significant too. It must be in place when you lean back. Too steep, and you can feel like your knees are under your chin. Think Shaker chairs here. Too shallow, and you will forever be pulling yourself up to a working or eating position.

Putting Things Right

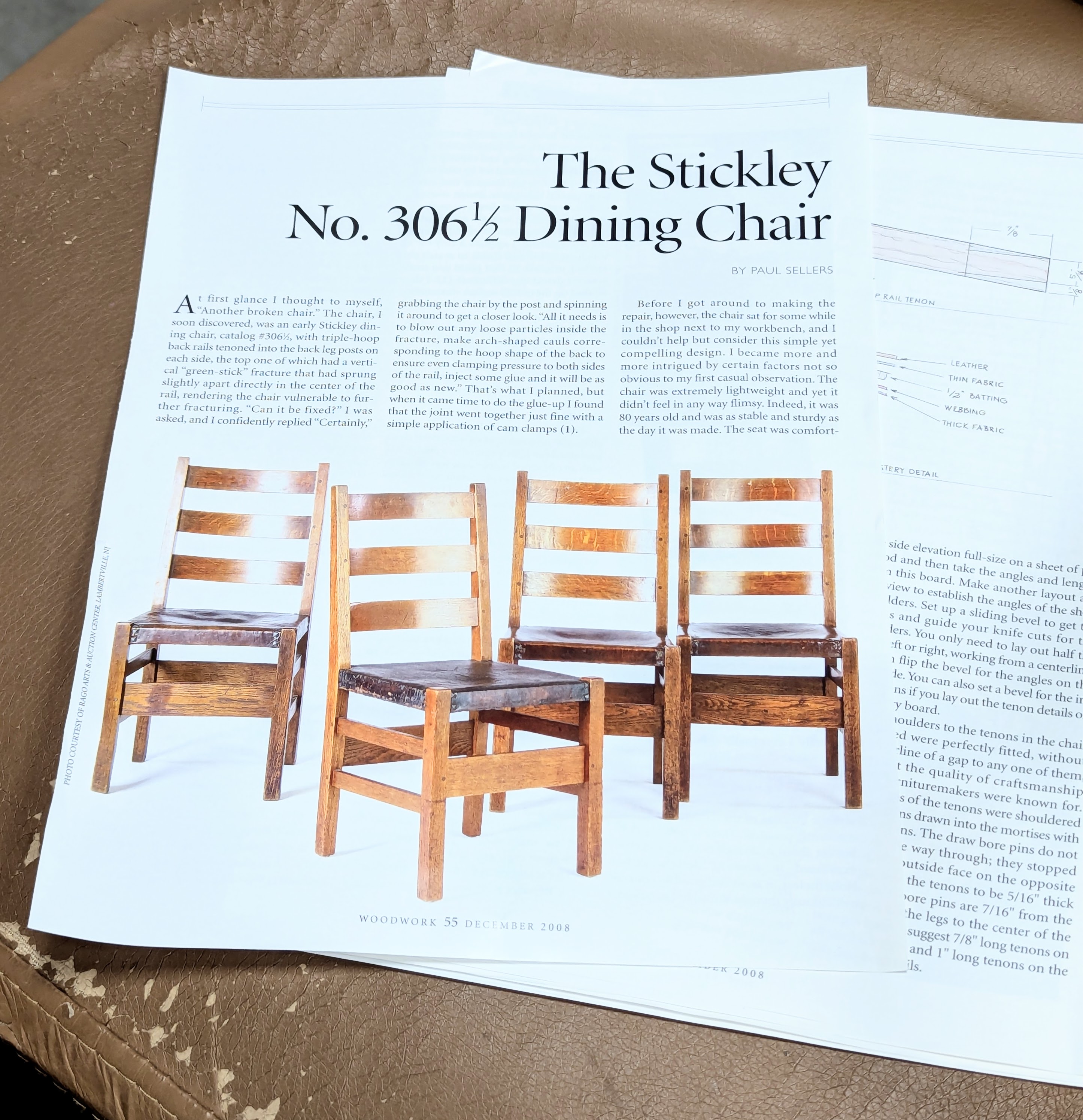

Chair repairs are highly informative. Some two decades ago I repaired a Stickley Dining Chair No 306 1/2. Taking my time, recording every detail for my journal, I ended up with some tremendous insights into the man's mind and his design and a few years after, ended up writing an article about the construction discoveries I made along the way.

Something similar happened with my consideration of the ultimate bistro café chair that lives an unparalleled testimony to the classic Michael Thonet chair. Here's a link to an article some years back.

My renewed work necessitated cutting wedges and using fox-wedging because of the non-through aspects of some of the joints. This was ideal for applying pressure until the glue dried the ends in their expanded condition, but also gave permanent pressure to the tenon long-term in the holes.

The saw kerfs on the bottom through-tenons were the wrong alignment with regards to the grain orientation of the seat, but beech being beech, I had no problem driving the wedges. Beech has tenacious grain and resists splitting as other woods might.

I pare cut the waste off and then planed the ends flush.

Before installing the spindles back in, I made sure I got accurate readings for the angle of the holes.

Scraping the paint on the underside of the comb showed the layers of a laminated comb, and I could take the sizes from that. I could also consider whether I would prefer laminating over steam bending. Steam bending has its strength in never delaminating and continuous grain strength, but then lamination is intensely strong and well proven, as can be seen here. Remember, this is not plywood per se, but continuous grain with each laminate oriented with or along the grain.

Conclusion:

Experience tells me that, all too often, but not always, assembly work in wood products and especially furniture, assembly workers who are not woodworkers as such can and will end up cutting corners along the line. The last thing they want is to slow down the other workers. Workers might be offered bonuses or targets for faster production, combined team bonuses for 'the team' can put peer pressure on those in the line and then the result is a product that looks the same as the intended design originating as the first models but one that has, as in this case, deteriorated quite quickly in a chair that could have lasted for a hundred years of daily use. Many of the café chairs had lost cohesion and integrity on the comb, but it was not the designer or the design that was wrong but the assembly work.

The reassembled and well-glued chair is how it should have been made. They saved a few minutes per chair, which is problematic in the long term, and all that happened was the work was postponed for nine years until I took it in for repair. In its manufacture, using machines for every component, this chair will take no more than a few minutes to make––ten at the most––including the padded, upholstered part!

Comments ()