Card Scraper Question

Thanks Paul.

I have recently picked up a cabinet scraper. However, I seem to get a better finish with my card scrapers. Is that normal? When do you use a card scraper over a cabinet scraper? I need to revisit your cabinet scraper video as well.

These scrapers are amazing. I don’t know why more people don’t embrace them. They are much more enjoyable than sanding and much faster.

Richard

Hello Richard,

This is one of those truly great, unassumingly innocent questions I love: As it is with all such questions, no one with true knowledge can ever withhold themselves from giving a whole and complete answer. We cannot help ourselves.

Card scrapers like chisels and some, not all, edge tools are readily adjustable for sentient optimisation. Second by second, unconsciously, even, we can skew-slice, alter the angle we present the tool to the work and much more. With a card scraper, we make many incremental shifts to negotiate the grain we encounter according to what we feel as the steel cuts the fibres. This is the reality of our type of woodworking. We're not grinding off wood with abrasives, rotary cuts and machines; our work is always through our own power and the extra input we want to engage with. Using a card scraper might be compared mostly to moving around with the flexibility and agility of an Arabian gelding. Without romanticising or exaggerating too much, we are making shifts around the surface of our wood as we work, which often means a complete reversal of direction, a quick sideways move, a pull and push in quick synchrony and in all of this there is nothing we can put into words because the moves we are making are too quick for any verbal input. We are constantly engaged with the work, and we feel for the edge in our encounter with resistance––the steel between our fingers sends the most direct information we can get as an impact statement from the moves we're making into each of our individual cuts. Even a skew, mid-cut, delivers amazing quality, though we may be going contrary to the direction of the grain. These surprise encounters bolster our confidence as we gain by continuing our ever-growing experience. The cabinet scraper, on the other hand, is still capable of fine work too, but then it is different in this. These two-handled tools are more like powerful draft horses, a Percheron, maybe, by comparison, much less agile and more like a lumbering bulldozer. That said, by skewing the cabinet scraper, we lower the angle of presentation along the actual cutting edge, so there is some flexibility, just not anywhere near as much as with the card scraper. With both tool types, the more we skew, the lower the angle, but the #80 cabinet scraper will never give you the same versatility as the card scraper. The main advantage of the cabinet scraper is that it is great for bulk removal of highs to bring them down and the lows up.

In this explanation, I want to show that, unlike planes, spokeshaves and tools that hold the blades and cutting irons at fixed angles, the card scraper allows us to change the angle by a quite wide range. Lift up for a thinner shaving and lower the angle for a deeper cut. This will depend on the amount of hook you gave to the scraper, and then too the amount of pressure you apply in the strokes you take. It's also worth noting that we can turn the hook, that's the corner we burnished, to take a deep cut or a very fine one. The finest might take two or three strokes with the burnisher, whereas the deep cuts will take more. I often vary mine according to the work, so I might have two or three settings depending on the work I anticipate as well as the wood I will be working. Thin veneers as a surface will not need deep cuts, so a shallow and refined edge will work best. A solid oak dining table, on the other hand, will allow deeper more penetrating cuts.

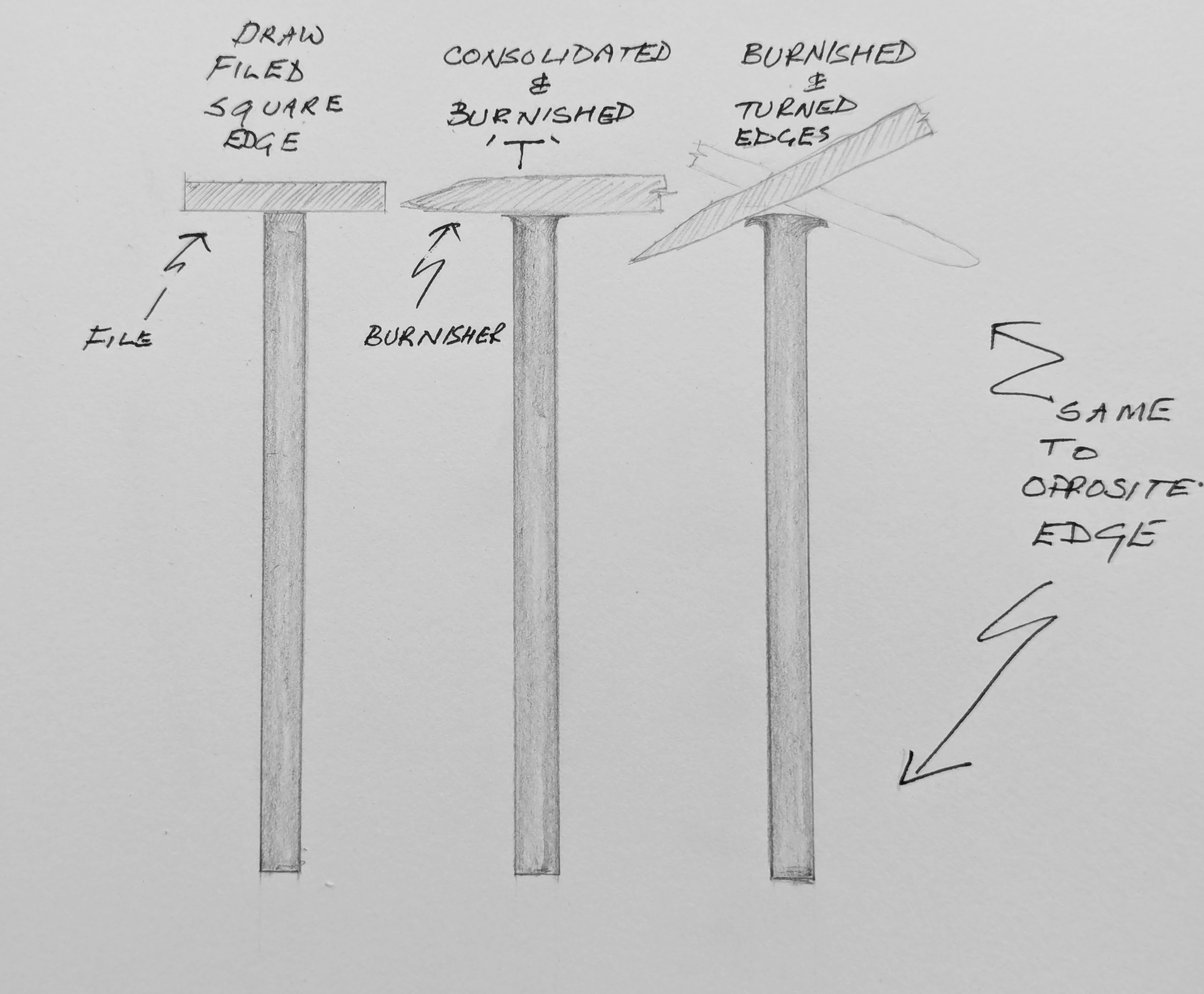

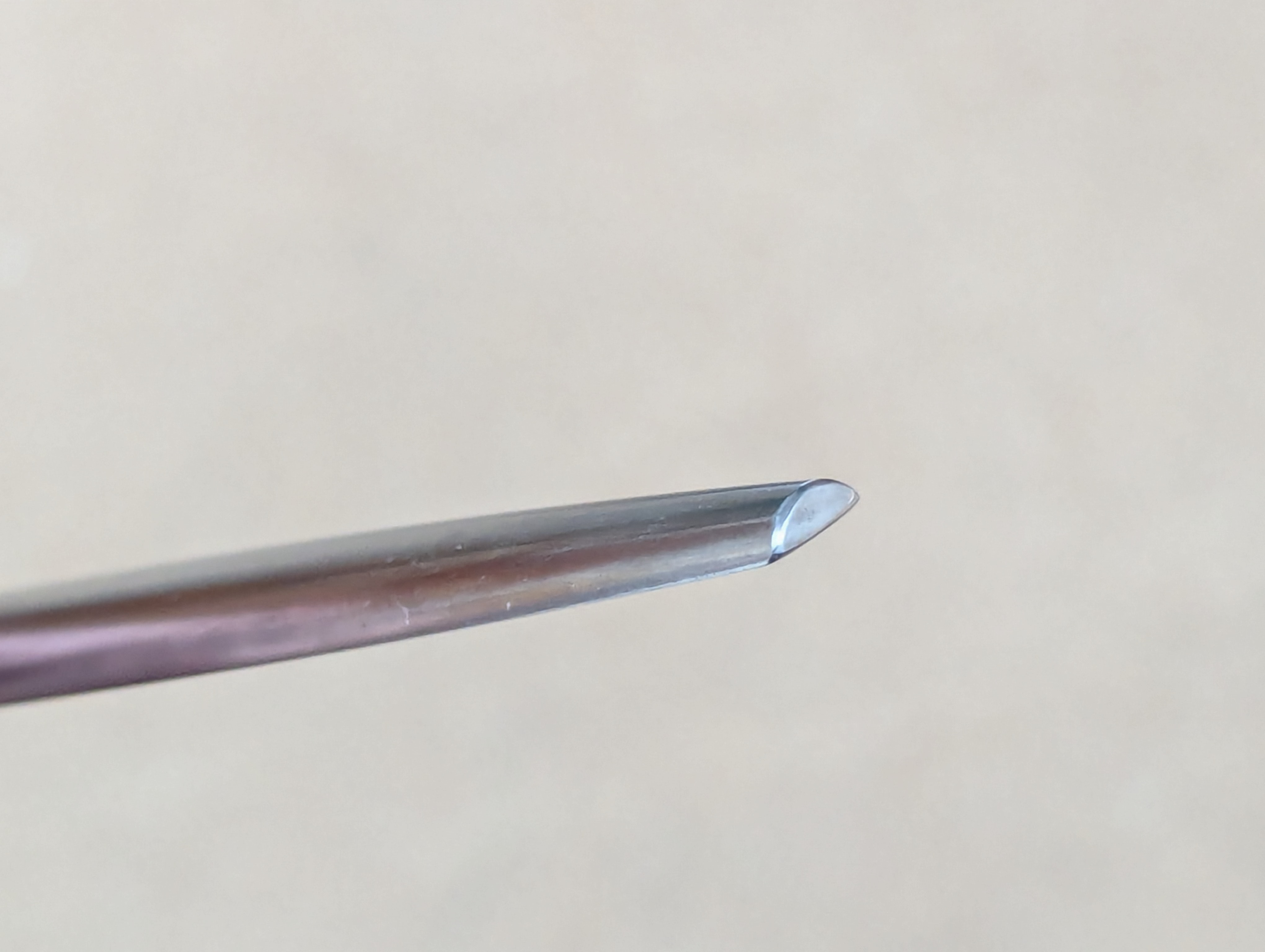

Card and cabinet scrapers are truly misunderstood tools, mostly because they don't in any way scrape, and they don't look like any kind of scraper either, but I do understand that looking at them in use, someone might think of them as some kind of blunt instrument rather than a highly pristine and sophisticated cutting tool. Because you can't see the fineness of the cutting edges on a card scraper, you might, on the one hand, think the card scraper is just a piece of steel with square edges. Even after you've sharpened them (both corners of a single edge become cutting corners), and even in the sharpening process, you can't altogether see what you are doing to the edge. Hopefully, my drawings will show what changes take place when you transform a dead square, square-filed, draw-filed edge into a turned edge. This creates the thinnest cutting profiled bevel humanly possible by hand. `The eye would need magnification many times to see the actual cutting dynamic.

I'm asked why the bowed plate steel in use doesn't create a series of hollows in the surface of a board or tabletop because of the bow in the plate extending to the cutting edge. An image will show the curve as being quite pronounced, so it's a great question and a logical one. The answer is simple, but don't kick yourself. Whether freehanded or held in the holder, pressing the plate to the wood surface and pushing with the mass of your upper body down to your hands and thumbs forces the bulk of the long edge down to the surface, which consequently flattens or straightens the edge to the wood as you take your strokes. I suggest that this flatness will vary according to weight and pressure, but between 50-75% would be my guess. The extreme outer edges, those that rise up from the now central straightness, create a feathering edge to the outside of the swathe you took. Subsequent strokes, as we move over to the adjacent sections, level out the surface so any discrepancies across the board will be thousandths of an inch. In other words, not discernible by sight or even touch.

Finally, I think, we tend to think and can be led to believe by misinformants that a card scraper will deal with any and all awkward grain in any wood type. I can hear myself saying such a thing and that is because when you work with an intention to resolve some grain-torn issues you learn various tactics that will eventually get the good result you're striving for, but that takes perseverance. These difficult woods are but 2% of wood types and wood conditions, and 98% of woods will readily be refined with a standard card or cabinet scraper edge. The woods that offer the greatest resistance to scraping (which is not scraping) are the soft-grained woods. In temperate climates, these will mostly come from the softwoods like spruce, pine and fir, but there are others that can be problematic, like poplar. These are the ones that seem to readily indent with your finger nail, or even when you simply stare menacingly at the surface. The density of wood will vary greatly and unpredictably even within the same species and wood from the same tree in an adjacent cut. Rapid growth in trees intended for fast turnaround and with no canopy to slow down growth, plantation grown crops, will have wide growth rings. The major spring and summer growth in warmer, but still, temperate regions can have that growth spurt measure as wide as a 6-8mm and even as much as a centimetre between the slow and harder growth aspects of the growth rings. This is the hardest wood you will encounter because the scraper will dip and dive into the soft material either side of the narrower band of harder, denser-grained wood. The softer the wood, the harder it is to get any kind of shavings, and so this means repeated sharpening to optimise the cutting edges. There are hardwoods that are soft, less dense woods that are problematic. The list is too great to cover

When it comes to burnishers, I have used every type. Someone selling a so-called teardrop or triangular or elliptical burnisher will extol its ability to deliver the premium edge you want and so will those who bought this or that or any other type.

Take away the lack of ability of any salesperson, and you have the truth that they are indeed selling what they want YOU to buy, and most likely never used or relied on any one of them to make their living from using them. I would say the same for many or 95% of any other so-called influencers. All you need is a bar of hardened steel without hard corners, being sure that the steel is considerably harder than the steel you are intent on sharpening.

Less comfortable but one that works well because of its hardness is a basic nail punch

A screwdriver is likely not to be hard enough, and so too the back of a gouge, though they can be. The reason is that the shaft is not usually hardened as much as the business end of the tool.

The important parts to the burnisher after the hardness of the steel is the handle. I like a handle that I can grip whole handedly and firmly, one that gives protection to my forefinger and thumb, the two digits nearest to the cutting edge, when I am carrying out the successive pulls. There are a lot of them, pulls, to an average edge; consolidation can take 20 or more pulls with quite intense pressure being exerted to that narrow edge. The consolidation is important as this gives you the sharpest and strongest edge. We apply very direct and hard pressure to the steel edge and sides of the scraper along its full length, and that's before we form the turned edge or 'hook'. The length of the burnisher steel need not be too long. More than 3" is a bit of a waste, but it is also leverage against you, as is an overly long handle. Of course, we all have preferences and biases. My favourite is one I designed and made from O1 round bar stack hammer forged from round to oval and with a bend in it. I turned the handle, and it has served me for decades now.

And then there is the back of a gouge and the nose of a pair of pliers. These will vary in hardness levels but still worth trying. As long as the back of the gouge is near to the hardened end, it will turn the edge fine. Watch out for the cutting edge near your hand, though.

Of scraper thicknesses there will be no end, so I will tell you now that I generally rely on three alone. For general, everyday work, my favourites are .80 mm.

For any work requiring conformity to rounding, I use a 0.35 t0 0.40 . . .

. . . and for intimately tight curved work, think violin bouts and some other stringed instruments, etc, I would seriously consider a modeller's saw plate at0.20mm as these seem to take and hold a good edge.

Finally, put into the hands of an engineer, you can end up with a plate that is too hard and this can damage whatever burnisher you own. Extra hard cutting edges on blades where we use only hand work to sharpen them is rarely ever much of a bonus and can result in more work, brittle edges and edges that fracture under the rigorous aspects of our using them. All are worth considering.

Comments ()