My Accuracy

The things we woodworkers do to jig up for a tablesaw process or all the more to expedite cuts with a power router is phenomenal. If we'd mastered using just a few hand tools, setting them, training our bodies and minds to use them, life would be so much simpler. Oh, well, that bus passed three or four decades ago. Or did it? My work to get people off conveyor belt woodworking started about the same time. Students I met didn't even own a decent set of chisels or if they did, they spent far too much on owning something they saw more as iconic and placed them as a centrepiece on a shelf above the chopsaw––something they used more as shop decoration, along with vintage planes and saws. With this as a backdrop, they gave a token nod to the past and no longer expected to be achieved in daily woodworking, despite very sophisticated machinery guided by equally sophisticated computer software, since. The thing is, all of the jigs they make are again from the cutting edges of machines, which is, in and of itself, usually a sledgehammer approach.

I recently cut several components using and adapting different hand tools to expedite the cuts. There are 33 components, all hand cut with the same or better precision others might get using their machines. It's not so much a competition or a fair comparison, but more offered as a simple reality; what I achieve by hand turns out roughly ten to twenty times faster and easier by my not going back and forth for a machine process. I do generally rely on my 16" basic bandsaw for deep rip cuts and some heavier resizing to a rough-cut level, ready for a few swipes with my #4 Stanley. I say it's not a competition, but in some ways it is. I'm not concerned about hand work, trying to prove something, what I am precious about is my time. I can't afford to waste this precious commodity, it's expensive, and so too is allocating permanent space to house machining. For me, handwork is all gain and no loss.

Now to add balance to what I am saying, I'm not saying planing and thicknessing isn't faster; rip-cutting on a tablesaw and such has benefits, but for 95% of my work it tends slow things down, there is dullness to the work itself, and, dare I say it, I find it quite uninspiredly boring with absolute zero exercise? These are not small things in my book. All of these issues are important to my wellbeing, my intelligence and my health. There is nothing wrong at all with simply loving handwork. I've always it! But even more than that, 98% of my audience (for want of a better word) don't have nor could they have that much-sought-after ideal machine shop for other woodworkers to admire them for. Over the years of striving, I have made a major impact on persuading woodworkers to simply rethink what they are looking for in their woodworking, what triggered them to get started and why they usually went the machine route first. It was simple. It's what everyone else was doing in their woodworking. They listened to machine sales staff who knew zero about woodworking and everything about how to hook new want-to-be-woodworkers to buy a machine. But we've converted many a thousand machine-only people to engage with a more relational way of working their wood and who now have become enthusiastic and accepting towards hand tools.

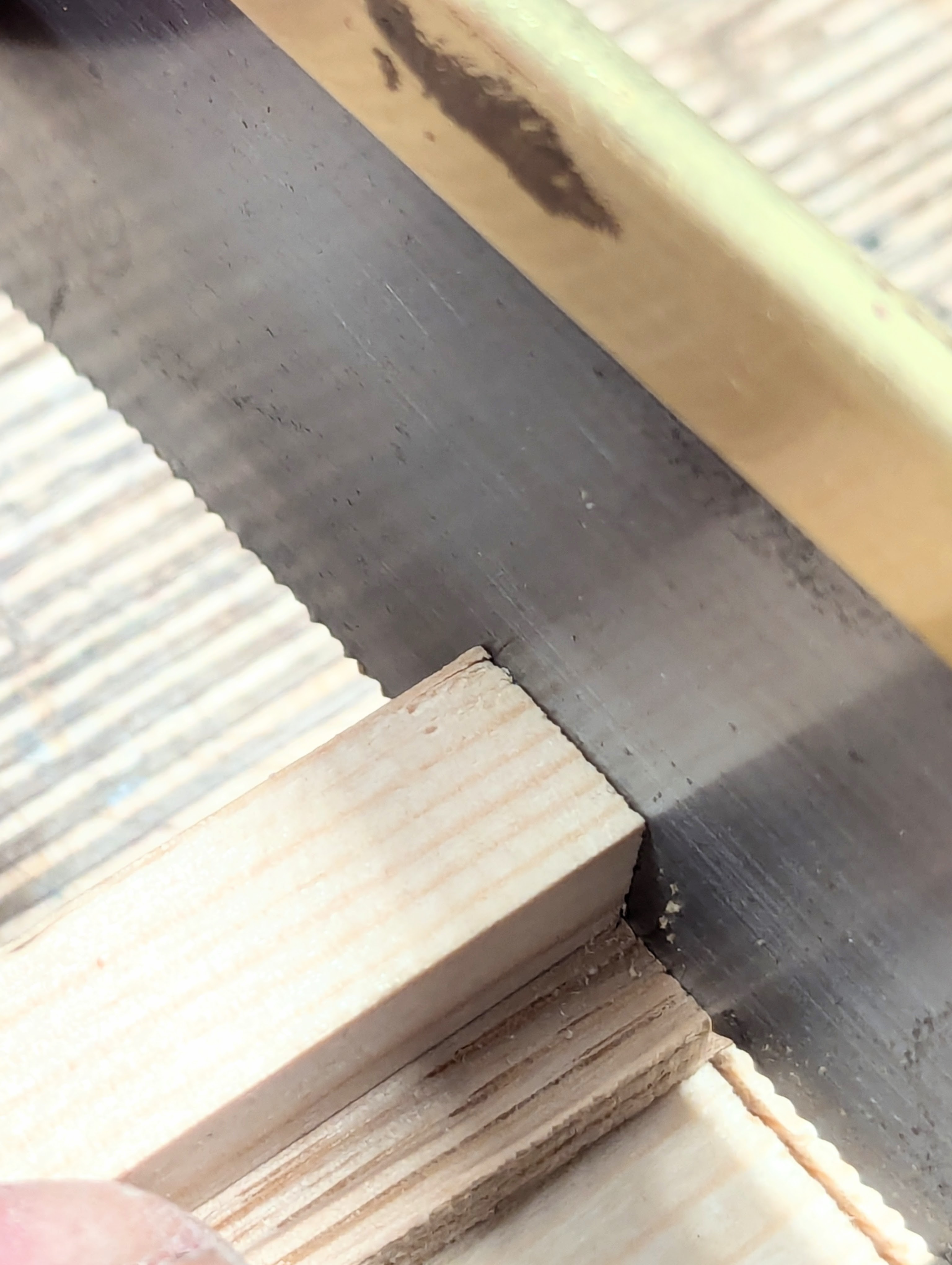

For crosscutting small sections like beading, mouldings, trim, shoulder lines to smaller tenons and such, wherever there are repeat cuts, I simply pick out two scraps of wood, mark a single parallel pencil line to align a second piece to and clamp both in the vise.

This alliance of two pieces is sized to the wood I will be cutting with a little added extra. Then I take a square and a knife to make two knife walls and cut to the lines using the same saw I will use to cut the subsequent stock with. Though these are at 90º both ways to the long axis, any other angle is possible too. So there is a simple and basic precision guide. Add length to the guide if making with a longer project in mind, and then add stops as needed, if you think it's worth it, and if wanted. Stops can be glued with CA superglue and popped off later as needed, or they can be clamped or simply pinned in place when repeated cuts are required.

For my dovetails to a single joint with only one dovetail directly from the outer corner where it is hard to start the saw dead on and dead true to the line, an inclined plane will guide the chisel to the exact angle. But it is not just used in this situation. Sometimes we might cut a dovetail askew and need to correct the dovetail. Clamp a piece to the dovetail piece at the correct angle, and you can correct your out of squareness or the angle or both using the same approach with the chisel.

I have made dovetail guides for my hand work through the years. This is especially useful if you have a box you repeat making time and time again, as well as when you have many dovetailed drawers to make.

Thickness planing is not reserved for the machine thickness planer. Instead of our feeding wood into a machine though, we can get pristine results by passing our plane over the wood held on our own platforms and, stroke by stroke, we can achieve the specific thickness we need. Using this method, we can take stock down to a millimetre thick, with smoothed-out surfaces to both sides that never need sanding. These are quick to make, readily changeable and get the thicknesses within thousandths of an inch when done right.

End grain planing seems always problematic to most, and yet I freehand my end grain planing most of the time and I would say with equal alacrity to long-grain planing. As an apprentice, we were expected to do this and so learned and knew only this way. And no, we never relied on shooting boards for planing square ends. We could do it accurately quite soon after being introduced to it, and it took only a fraction of the time. How is that possible? We didn't have a choice. We were taught how, and we had to master it. It was simply how we learned everything about mastery.

Freehand is easy on larger stock or long ends, as in tabletops and so on. It becomes considerably harder when the stock is small or thin because you have nothing of substance to balance your plane on or to reference to. I know I had a little pushback from the more traditionalist advocates, saying just use a shooting board. Well, I kind of maybe, sorta, agree. Why fix what ain't broke? But there is good reason for making my ultra-simple vertical guide and I can guarantee that once you try it and understand the simplicity of my advocacy you will go with both types but rely more on the vertical guide in the vise for speed, accuracy and low space occupancy; you never have to clear things off the bench, the work is clamped in the vise at the same time as the guide, and you have absolute security of the workpiece and the guide together in one. Mostly, I developed this for square ended stock that needed accurate squaring. I am not in any way boasting about my aid, it just works equally as well as a shooting board for square, unmoulded sections if not a lot better than any other method. Being as 95% of my work has no moulding to it (strongly dislike moulded material), it is a perfect solution in terms of speed, accuracy, secure holding and so on.

Comments ()