It's All a Bit Twisted

When I cut the dovetail and sank the screw into the countersunk seating, I knew the joint settled tight that way would annoy some and not those that knew the reason behind the pull-power beyond the inventor-man's invention 2,500 years ago. This "father of mechanics" started something when he created a continuous thread, others followed on to perfect what we have today.

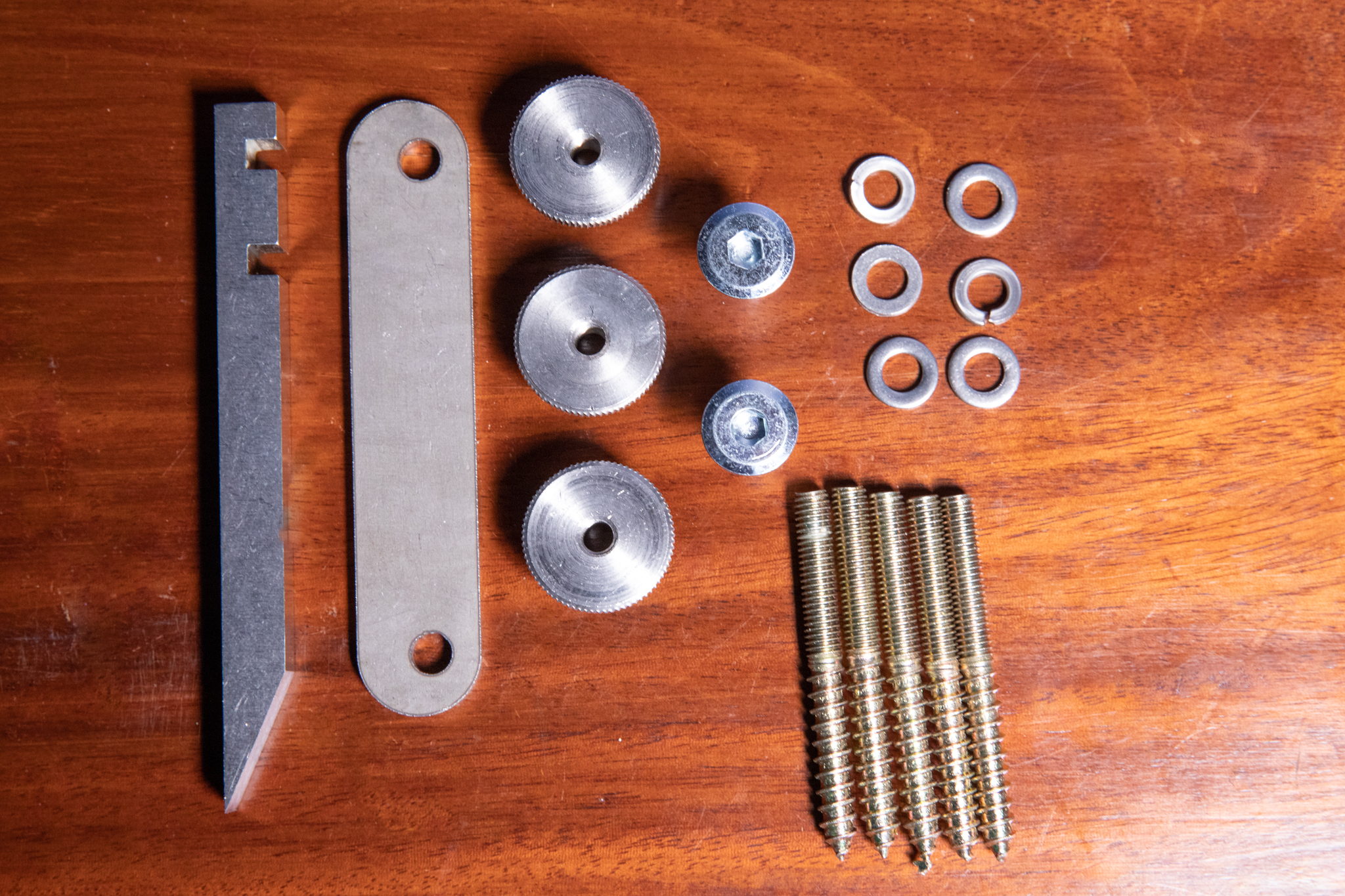

I find it a strange thing thinking about it that opposers to my work feel I keep others in the dark ages by working with hand tools, but when I use a screw for a single practical purpose, I just grew two heads. But I do what I do and hey ho. I like wood screws in practical places and use them wherever and whenever I can. I'm thankful for Archytas of Tarentum for developing the idea of a continuous helical ridge or rib around a central column that gave us the first idea of a fastener. Imagine, the thread started back in the 5th century BC and it keeps getting better. Two and a half thousand years in development, and it's still going. What a thread I've raised here!

Of course, the twist might be considerably different, but the theory of it remains with the same inventor of the day in the parallel or twin threaded flute of the twist drill bit I drilled the hole for the screw with. In this case, the ends of the flutes either side of the central column start with two cutting edges designed to slice-cut the fibres or material and then transfer the waste wood along both flutes as the drill deepens in the cut to create the hole. Archimedes took on the idea when he created the helical thread to lift fluids from one level to another, be that water from the hold of a ship or olive oil from the presses into barrels. I used an auger made by Ridgeway to bore the larger holes that took the screw heads so I could plug them with matching wood plugs. Of course, glue being stronger than the wood, so they say, and it is not always the case, I could just use glue rather than screws and plugs. Well, of course I could, that goes without saying, but the screws, the boring of holes, such like that, enable me to keep working, add extra resilience to my work and usually make the work of assembly during glue up so much easier. Thank you, Mr Archytas and Mr Archimedes the ancients, for your contribution to my daily work.

Many came along after these two inventors and developers to add their two-pennies-worth. William Sellers from Upper Darby, Philadelphia, USA was an American engineer and manufacturer became a developer and manufacturer who manufactured machinists’ tools and mill gearing. His formulas for matching screw threads and nuts (1864) became the U.S. standards. Today, of course, we have a dozen other inventors and developers to thank for their input into the finished options for fasteners., not the least of which would be individuals like William Allen who gave us the hex nut fasteners along with the Allen Wrench. Others have improved in minor detail too, like John Bondhus who created the ball end of the Allen wrench.

My recent project has given me a lot of pleasure. The design for me is an old design, though it's new to you in that I first had the thought for the design back in 2002. The idea then was to transfer downward pressure from the thinner mid-section through back through and to the corbeled extensions, where the stoutness and immovability of the leg helps to carry the superincumbent strain. I made that original work as a mesquite desk for a rich Texas oil magnate customer in Houston. The added height between the two side drawers gave additional legroom for crossed legs, and even though I only gained an inch or two, it was perfect for her. But it's these seemingly small details that can indeed make a big difference and though they might well look to be more an aesthetic, to break straight lines, they often if not mostly have practical considerations.

It's the hidden interplay between the various joints and the way they relate to one another I enjoyed as I developed this work. Yes, I had made the piece a few times back in the states, but I added other hidden details in this case. My first desk, similar to this one but proportionally much larger, sold for $6,500. I made that one from some highly figured cat-claw from mesquite, a stunning characteristic in some woods where undeveloped and dormant buds retain a distinctive pattern throughout a tree stem. My current version is designed as a dual-purpose piece. There isn't too much difference between a desk and a dressing table when it's intended for a bedroom. It could go in a small office, a hallway or another room.

The week of joinery passed quickly, with lots of repeat joinery. None of my wood is machined apart from minor resizing with a bandsaw. A mortise and tenon takes me about 15 minutes per joint to cut and fit. In the overall scheme of things, that's not very long at all. Stock preparation is, of course, the most time-consuming, but will I go back to machining this instead of working it mainly by hand? Well, I may bang on a bit about this, but there is no question that muscle building and maintenance knows no age. No matter how old you are, your muscles do not grow old with the rest of your body. It's important to maintain both strength and stamina, and then too to get your lungs pumping hard many times a day. While other parts may well wear out, you can keep your muscles in good stead simply by working them. That said, I am not a muscle-bound guy. Fact is, I don't seem to have the big guns of most men I see, but what I do have is matched perfectly to the work I do and the needs of my day. I never actually run out of energy, though by five in the evening I will often declare my tiredness out loud.

In the carcase of this new piece, I have sixteen mortise and tenon joints, two housing dadoes, two tongue and groove joints. I used ten commonly used hand tools to get this far and that includes the tapering the legs, bevelling the underside of the table-top, shaping the arched pieces and so on.

I'm about to start making the three drawers. I'll enjoy the work as I always do, even though there will be nothing new to it. Not only that, but I have already ripped, planed and trued up all the parts ready for filming. The last thing I did last night in readiness was to sharpen all of my planes and chisels. Today, I will sweep and put tools up to close for the weekend. It's important to keep order and to make time for it. The pressure of a given week is quite full on, but that's because there is a momentum of thought that I like to keep in the movement of my work.

At the end of my week, I am grateful to be a part of the great inventors who left the legacy of the screw thread to improve my life. I have no problem using fasteners, and that's because the legalism of purists often strangles invention. Combing the ancient with the current is an option we can choose or reject. By simply placing well-placed screws in a dovetail, a housing dado or the underside of a rail, I did three things: I ensured that the components were aligned immovably for my glue up, I ensured the components were pulled and anchored together, I minimised the need for clamping for an extended and impractical period, I added a second fixing that would never turn loose, and I enabled myself to continue working on the piece despite the fact that the glue had hours yet to come to a complete cure.

Again: Thank you, Mr Archytas and Mr Archimedes, gone but not altogether forgotten, for your contribution to my daily work.

Comments ()