Handling Your Work Part I

I designed the doorknob below in early January 2009 for a special job I was engaged in, but a friend turner actually turned the six I needed. This one is the original prototype. The woods are ebony and oak and whereas it's the ebony that's more dominant and distinctive, it's the oak that sets it off in contrast because the oak in this case is the special and rare detail. It came from a tree planted by USA President, President Harrison and though not a species, it got the name Harrison Oak when it arrived in the workshop.

President Harrison had planted the Scarlet oak tree in the grounds of the White House in 1889. Then, prior to my need of it in 2009, the oak he planted dropped a large limb, which was kept and preserved by the groundsmen and eventually, it ended up with me. My cabinet doorknobs are made from three pieces rather than two. The parallel ring of the Harrison oak, sandwiched between an ebony eye and surround, compliment the panels in the doors we made.

This doorknob put the full stop (period USA) on the doors and finalised the cabinets.

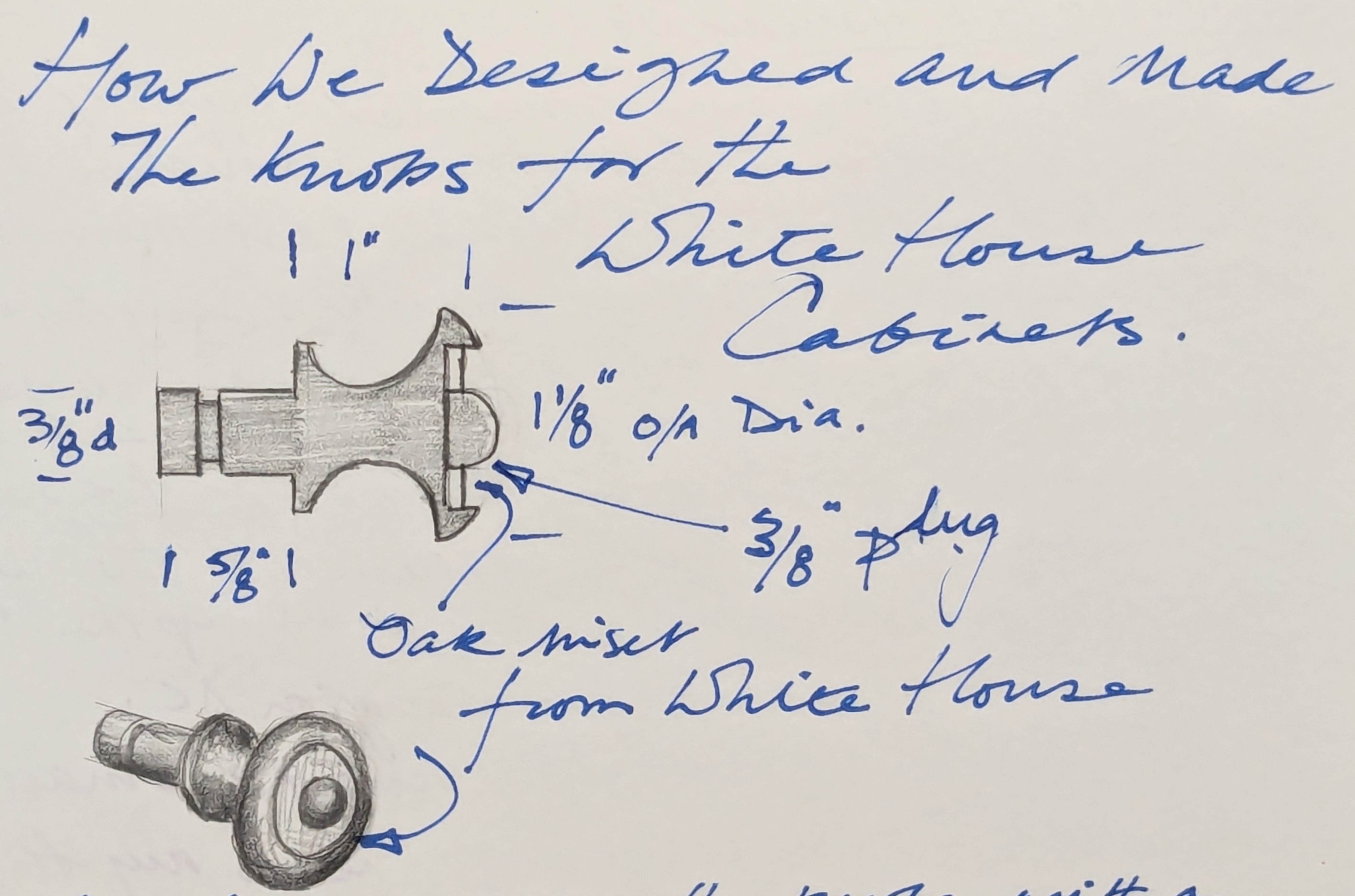

The method of making was straightforward and simple. First, the knob was shaped with its cove, foot and stem and the bulk of the waste on the dome. Following that, we removed a 5/8" diameter recess with a parting tool to receive a 5/8" diameter oak plug, which we created with a 5/8" diameter plug cutter housed in a drill press. The plug was parted off and then recessed with the parting tool again. Then we created the ebony plug with a plug cutter, drilled out the 3/8" hole in the centre of the recessed oak and installed the black plug. The last step was to dome the ebony plug with a small fingernail gouge. The final finish was three coats of clear shellac.

Creating your own handles to suit your work creates all manner of options you will never get from manufacturers. The shapes on the lathe inevitably give you round knobs with a million shapes you can wholly develop yourself. These will be the fastest to make and take only a few minutes. With a thousand options in grain colour, configuration and so on, your custom designed cabinet will find magical peace with a handle from your hands.

In the Sellers' Home pieces I have been making, most of the handles have come as new designs, but I have kept them simple. Below is my latest handle and the last part of the work on my dressing table cum work desk. Your choice or dual purpose. The next blog tells you how to make the handle step by step.

These handles came from small sections and scraps of oak, and the wardrobe below is where they ended up. They only take a few minutes to make, even using only hand tools. That's what I totally love about hand making. Your energy, your direction, and your exercising all of your rights as a freelancer.

In the dining area of the kitchen, I made a drink's cabinet and two sideboards in various woods. Below are the wall-hung drinks cabinet handles made from end-grain oak and long-grain walnut.

The theme for this cabinet was solid oak with walnut trim to the door panels. I used the same handle on the drawer too.

The two sideboards (below) were a joy to make from a mix of hardwoods; sycamore for the cases and door panels, mesquite for the drawer fronts and door frames with walnut trim and then, I kept the theme from the wall cabinet, I used sycamore with mesquite for the handles.

Making door handles is a matter of personal choice. You can keep things square and blocky, shape them with curves or round them as much as you like for a softer look.

The large wardrobe took these long handles well, and I liked them very much. Again, easy to make and distinctive without flamboyance. I used a slightly different but complementary style on the chest of drawers and that went well.

For the busy-wood bedside tables, I laminated oak as a sandwich between mesquite strips and then created the quarter ellipse shape with a spokeshave and a rasp.

If you don't know that we teach hundreds of thousands of woodworkers around the world how to make everything above and a thousand times more, you might want to join us on Woodworking Masterclasses and if you are totally brand new to woodworking or indeed you've been a machine only enthusiast you might want to dip your toe in there and our sister site Common Woodworking.

Comments ()