Challenges

It's a strange phenomenon that I cannot always place. Jealousy and envy can be two close bed partners, of course they can, but then there is expert knowledge, insider knowledge and a range of levels between just disliking someone and all the way up to hatefulness. Challenging the status quo of any majority and suddenly democracy is thrown out the window. People believe in the democratic vote, which simply means that the majority rule always and in all ways over the minority to indeed force that will on those who simply cannot agree. I take the saying with consideration when Benjamin Franklin said, "Democracy is two wolves and a lamb voting on what to have for lunch." . . . and we all know where that went. On the continent that used this analogous statement against a governing colonial empire, it was the minor entity of that day endeavouring to establish its new quest to rule itself under its own sovereignty. That, you would think, would make it more sensitive to the power of majority rule not to just discount every minority that comes along to counter the existing big country to see if a minority might still have excellent input as a small rudder to steer the great hulking mass of a sea-going Titanic.

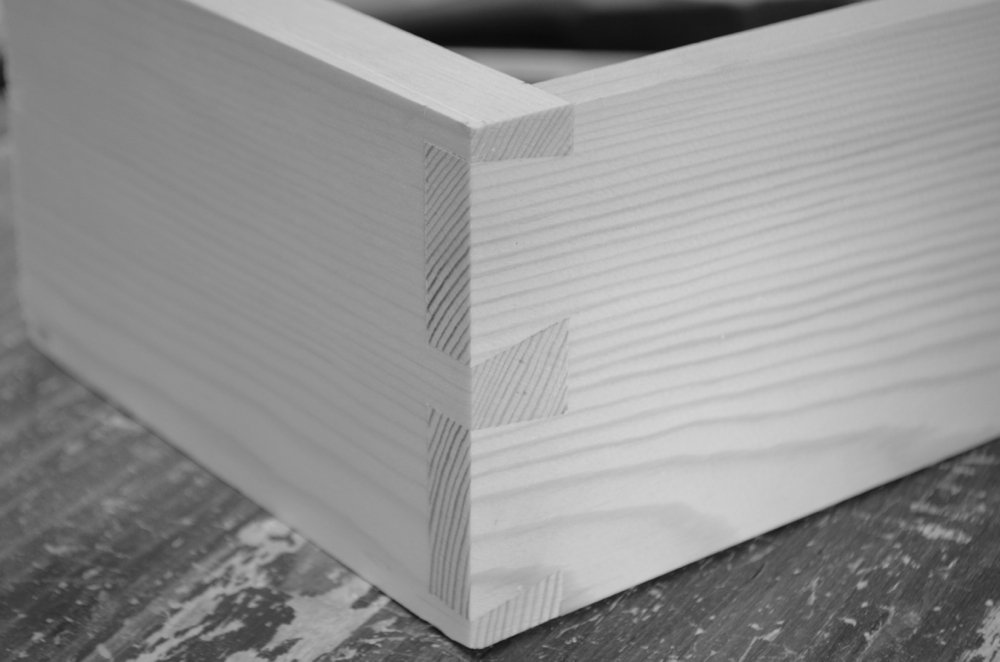

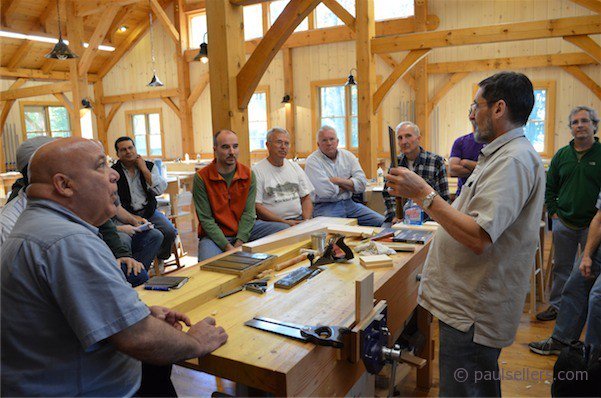

My advocacy for skilling-up people wanting to use more and more handwork for many better reasons than those countering me with snipe and snide has come at my own expense over many decades and at a considerable cost to me in both time and money. In the late 1980s, doing my first shows in the USA, woodworkers saw my basic wooden workbench and ten hand tools and chuckled to one another in the aisles of progressive woodworking. With their arms laden with the latest and greatest gizmos, the big boy booths were offering the newest so-called "big-boy's toys" from the surrounding booths and selling machine-only woodworking. They waited for me to make a fool of myself, but then they heard the gentler sound of a Gent's saw against the screaming backdrop of power routers as I sliced into four opposing dovetail angles, and they stopped without moving from the spot they were on. In unbelief, my saw slipped easily into and through each kerf to make a dovetail in under two minutes. My demonstration went on to cover many topics, from making a mortise and tenon to an inlaid picture frame. They didn't move an inch for forty-five minutes and complained if anyone got in their way. Many of them came back on the hour every hour several times throughout the day to see what to them before that time was quite unbelievable. I moulded the wood for the picture frame with a two-hundred-year-old moulding plane and then made the mitres purely by eye and joined them at as near a dead-on forty-five as was humanly possible, replete with 1mmsplines. They were stunned. Part way through I would sharpen my plane and chisels, four or five of them, and have all of them surgically sharp before they could say 'Boo'. To say my demonstrations were a showstopper would be to undervalue what they were seeing with their own eyes. That is how I started out in the pre-internet days. I was very much the minority, and I still am. And here is what happened too! After a few shows, at that time, the circuit starting in January and ending in April, the machine sellers selling all the machines and gadgetry that went with them asked the show organisers to stop me from coming to their shows. What they did not know was that the show organisers paid for my flights to and from the UK and also internal travel with hire cars and hotels because, in the end, we were bringing a new audience to their shows.

So, where am I going with this. My last blog post was to encourage new woodworkers to discover the reality that skill does not take sixty years to become competent, and these skills could indeed be had by all. It wasn't to condemn any other world of woodworking, but to actually expand it and include machinists if that is what they wanted. I like that people challenge what I say, but the truth of what I said was from the reality of a lived life...mine! It was the one comment that said the most after advocating the method of machining edges to cut with that he used. I'd already said in the blog post that if anyone preferred to use machines to achieve their results, I was fine with that. But his closing line said it. "We've moved on." He was advocating that new woodworkers spend upwards of £1,500 on a particular grinding machine and special grinding wheels. What he said in his three words would be the equivalent of saying, "Luddite." in all caps! And of course, now we look back to see the tip of the iceberg industrialism and the great revolution has wrought at the expense of all areas of life. My method of sharpening relies on industrial processes to give me the ability to sharpen my cutting edges, but the plates I use and the compound of abrasive to polish out the edges are extremely serviceable and long-lasting. But the best thing for me now is that for about £30 I can sharpen all of my edge tools surgically sharp. And I can do it in under a minute apiece and be comfortable in the process that seamlessly gets me back to the task of woodworking. And even more than that, this £30 investment will go for the next ten years of daily woodworking, so that's .0082 of a penny a day. Unbeatable!

Another area of concern came when I made my panels for my project using some different thicknesses of birch plywood. It wasn't a big thing, but some thought that this was the beginning of the downward spiral. Of course, it wasn't. It was a brilliant move that I will indeed use again and will be using in the future too. For one, I really did like the look of it. The simple, clean lines. The inherent strength and solidity of plywood, it's well-deserved and proven longevity and much more. What I strove to establish here was that it is okay, with careful thought and consideration, to use plywood to save time and material that might otherwise make a project prohibitive because of time and cost. Three-quarter inch birch plywood comes in at around £3-4 per square foot, which generally is much cheaper than solid hardwood but with near zero waste. The savings in time is exponential, too. I simply devised a way to use it using hand tools to go along with a framework of solid oak or any other wood. That's yet another great success for me.

I'm not much of a challenge to the commercial realms of woodworking. That was never my intention anyway, and you can tell that by my never having ever advocating that people stop using them. And even though many people say "Paul hates machines!" which, of course, is not true at all. It's funny, though, if you simply don't use this or that that the rest of the world does use, you suddenly become some kind of enemy. I have reached the audience I wanted to reach and teach, though. That's because I have simply proven that machines are not as essential as the advocates selling and using them say they are. Those that abandoned their machines for hand tools had already bought into the machining systems, so those sales are now done-deals. This all said, there is absolutely no doubt that those using only machines and only ever having used hand tools do not own hand tool skills. In the evolutionary process, perhaps their processing of wood will simply become a thought process.

Comments ()