This Wooden Plane . . .

. . . .cuts grooves fast and accurately. But it does a lot more if you want it to.

I think we might have undervalued the wooden plane but even more so the men that used them for centuries before we abandoned them almost altogether. It's the lightness of them that we really lost but then too we lost the reality of how well they worked in the hands of those who fully understood and knew them through using them for decades.

I worked with some men who used them and then with those working alongside them who smirked behind their hands because they did. What I did notice was that the old men never fell behind, could adjust their bench planes perfectly with a quick hammer tap or bench knock and achieved the highest standards in plane work.

My fascination for the long-term use of British hand planes and then other tools too grew gradually as I gained more and more experience. The working knowledge got less and less as the older woodworkers died off but then one or two books came out that filled in the gaps. Another sphere of knowledge came through well-known auction houses and catalogues listed by very knowledgeable auctioneers working with collectors and dealers. At those day-long auctions out in the sticks, you met up with third-generation tool makers with a family-famed past. What interested me most though was that Joinery workshops had lived through three centuries owning and using its vast range of wooden planes. to cover the equally vast range of tasks needed to work wood. Although I personally would most likely never use mouldings in any of my work anymore, I still find it amazing that millions upon millions of linear feet of moulding in all woods came from hand-made beechwood moulding planes every year. These mouldings used in, out and around any building you care to name are still there and the indoor versions will in many cases be 300 years old.

The privileged had woodworkers unknown from the masses to anonymously build what would become thousands of historic mansions as monuments to their superior dominance, wealth and privilege and then millions of more ordinary properties as homes, offices, schools, hospitals and workplaces the millions in Britain would occupy through the next millennia. For people like me, these buildings translate the lives of working people and work as a walking history tour in every door and window I look at, through and into as I pass through any town, city, village or farming hamlet. I look for simple side beads on back doors to old terraced houses and the classic moulds more extravagantly struck in hundreds of thousands of linear feet of stately homes. Of course, these days complex moulds are on everything everywhere from dado rails to skirting boards(base trim USA), architraves (door trim USA) and so on. But looking beyond the ubiquity and finding the ancients becomes the passage of discovery; like looking beyond the stain to find the real even if it is just pine.

The architects will usually be acknowledged somewhere; remembered and even revered, but never the man who once stood all day at the workbench for decades running moulding planes day in and day out making mouldings in oak with a beech moulding plane. I see that stopped chamfer to the chair rails and frames, roundovers and quirk beads that are a part of my tool history lesson, but then too a great lesson survives in the lives of the different classes we Brits are famed for in pretensions of the different eras and the people living in them. I thank the USA for helping me shrug off expectations of class. It's still here, after my 23 years living there in Texas, but it's different. Who can explain the massive and distinct change I don't know. I doubt anyone can.

Over the years I've watched as woodworkers I've known amassed their trophy router bit sets to their arsenal to mould everything they make. It's as if they can't resist adopting an orphaned profile for every corner edge of whatever wood they work and all the moreso today in some if not most Western cultures. Somehow makers seem wont to shun more simple looks to their pieces. Doesn't it make you wonder why? Well, not really if you think about it. Buy a £400 power router and you have to do something with it –– I mean, use it for something other than recessing dadoes and making grooves and rebates. The advantage of a power router is that it makes little difference going across the grain as with it. You can also whizz round internal corners to frames for doors and other cabinet parts, even if it does leave the telltale signs where the junction ends up router-round with the additional burn marks now and then. The elimination of copes speeds up the process and dispatches the need for skill once more too. Of course, moulding wood does have its place and we use it all the time. It's used as much to close off gaps at meeting points and then too to conceal shrinkage in several places. It also makes cleaning and wiping down easier in internal corners and such so mouldings do have their place to soften life for us. Oh, and you can also dovetail with it too.

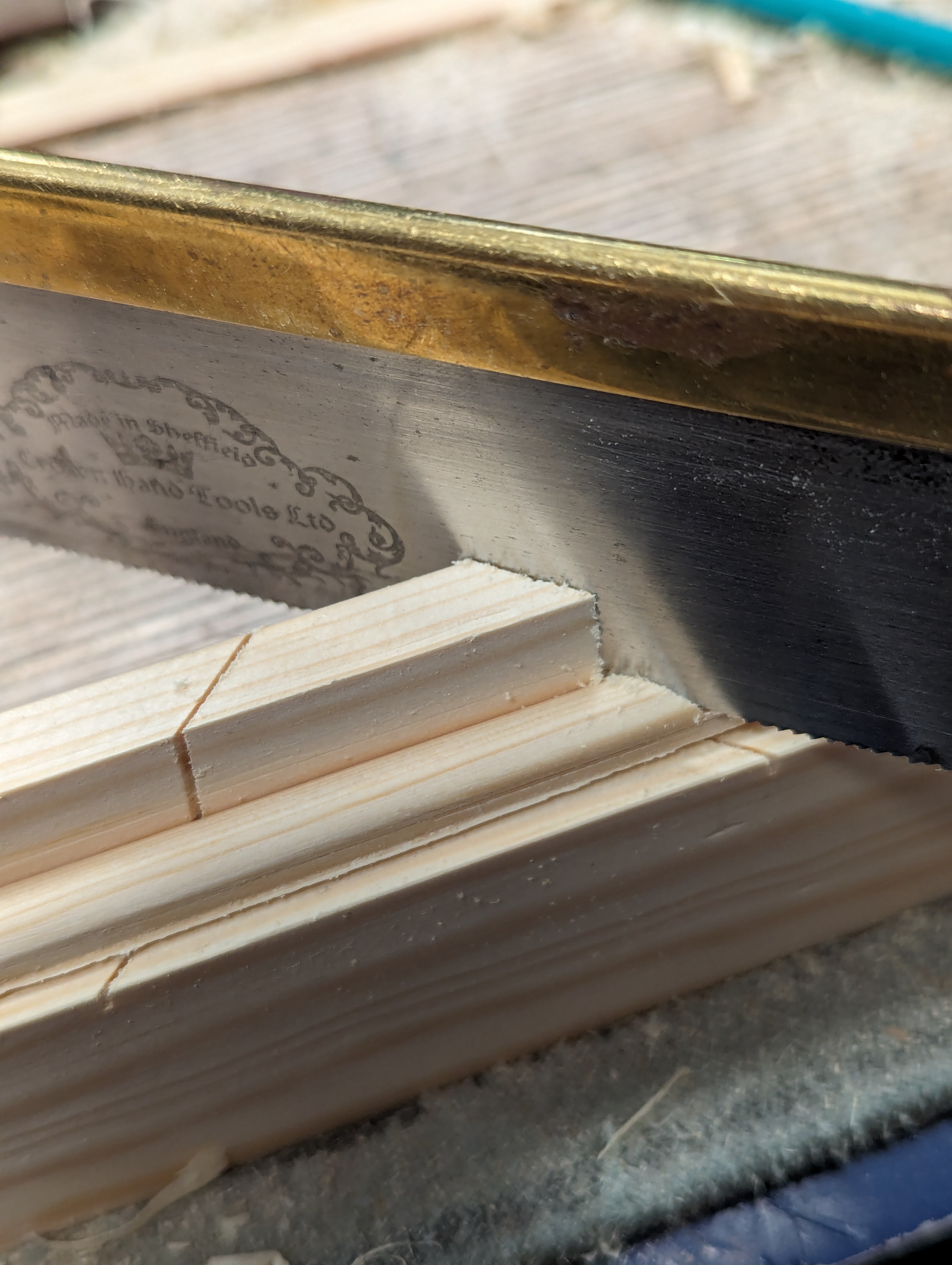

Whereas we can indeed reduce the overuse of mouldings, grooves and rebates are usually an essential to much of our work. Whereas plough planes offer wider options with the addition of stems to the body of the plane that then hold our fence guides further out, handles, etc, the more compact grooving plane will often do 90% of our work. The vintage wooden versions are still available for under £30. For grooving the inside, bottom rims of drawers to receive drawer bottoms and then too the inside edges of frames for panels, they work very well indeed. These planes are different from plough planes in that they often have no adjustable depth stop but rely on a stop point within the sole. This works well for repeat grooving as in drawers where we usually stop at 1/4" on everything. Crafting artisans often added temporary external stops to

butt up to either by screwing or nailing stops onto the plane body. Most of the craftsmen I ever worked with as a boy could gauge almost any depth they needed by eye as well.

The grooving plane feels a little more clunky than the cast metal plough versions at first but you soon get used to that. You can either find different cutting irons to fit the plane or pursue finding dedicated plane versions as in 1/4", 5/16`' and 3/8". Cutting irons from other planes can sometimes be used or adapted to a plane body you have and individual irons are sold without plane bodies all the time on eBay. This will depend on the wedge because the tapered irons may have a different taper to them. But you can tweak things and even easily make a separate wedge to make this work for you. Wood or metal, plough and grooving planes all cut deep and fast and the wooden versions absorb more vibration than metal ones do.

The features of a well-crafted, hammer-forged cutting iron in plough and grooving planes of this now more vintage kind lie in the trapezoidal shape making the back or underside of the cutting iron slightly narrower than the opposite, upper or flat face. If yours is not, then you can go in and abrade the shape not create the correct shape. I doubt that you will find one that isn't but perhaps you will. if that is the case then the blade will drag in the cut like a swim in molasses. This 'relief' to the sides radically improves performance and especially so with such thickly tapered irons.

It was interesting to see on this more recently made plane just how much things like the wedge came directly from a fine circular saw. Three faces clearly show circular saw kerf in both the wide facets, and one underside edge; some coarse and some fine.

Here you can see the vee in the back of the cutting iron registering on the fore-edge of the rear part of the skate that rides the wood and sets the depth of cut in relation to the skate which is the actual sole of the plane.

A 1/4" groove this deep on a one or two-foot length of pine, oak or any other temperate hard or softwood takes under a minute to develop; all woods will take about the same time except the ragged-grained versions like say yew and such, not many, and usually none is as easy as any other. using this plane is probably faster than setting up a power router to perform the same work but with no cleanup apart from two or three clustered strands self-clinging in balls on the workbench or shop floor.

The bottom inside faces of drawer parts groove quickly with a grooving plane like this one; twenty swipes in twenty seconds and you are done. Four times is a little over a minute's working and the exercise is really good for me. Do these in stints two dozen times throughout any given day and you will be surprised at the value and the volume of the workout.

The insides of frames are equally speedy ways to create grooves for your panelling too. You can offset the groove as I have done here or centre it according to need. Think on this too though: you can run grooves onto to adjacent faces to create rebates (rabbets) by leaving a tiny amount of wood in place and then slicing through what remains. Alternatively, you can run the plane from a non-adjacent corner.

This is just a question of adopting and adapting planes to take on other tasks. Oh, and what bout inlaying strips for decorative features or for something like inserted beading, separators and such? The list is endless when you have imagination.

Add to all of this the fact that you can feature other planes like bullnose planes and block planes to create side beads and such.

I have created small beads by ploughing out a groove and rounding the two corners with a bullnose and a number four and then slicing off the strip with a tenon saw. very neat!

You can even make a small mitre box from the rebate you created in a heartbeat.

Then you can take that little round-over and mitre the cockbead you just made from a scrap of wood.

All of this is to say explore your possibilities. Adopt new ideas and experiment with the planes. Want a tray holder within a box? plough out a groove either side so that the grooves are run in the dovetail piece and the groove butts up against a pin and you have a neat solution to the tray seating inside. The options are huge and all for the sake of a small purchase on a lifetime tool.

Comments ()