Ten Years Ago

Looking back through my archives I found this piece I designed, made and videoed for Woodworking Masterclasses. I wanted a piece that could be made from store-bought one-bys but that would enable me to teach a variety of things surrounding housing dadoes by hand. It was a great project.

Ever since I began teaching other woodworkers the art and craft of hand-tool woodworking I have found myself more dismantling the erroneous perceptions that it's hard, complicated and even impossible without special training through an apprenticeship, things like that, but then too that it is slow, outdated, that you need years and years of practice or some special Moravian-style workbench with a range of vise components, holdfasts and much more besides. When I put myself in the shoes of someone who wanted to start out in woodworking were to face needing to spend a thousand pounds on three bench planes, over two hundred euros on a panel saw, another thousand dollars on three backsaws to cover the various needs of bench joinery and such, well, I probably wouldn't and couldn't have done it. Of course, it doesn't end there. What about a plough plane and router plane, both needed but five hundred pounds to own them???

I did eventually acquire such high-priced versions but not for the reasons some might do so. I wanted to know truthfully if any of them achieved more than say an older secondhand version by Stanley or Record, the ones I grew up with and saw used throughout the woodworking industry of my youth. I wanted more just to try out the feel of them and to give them an educated trial from a crafting artisan's point of view instead of a mere opinion. I wanted to see whether they really offered any more than convenience, yes, but I also wanted to get people seriously understanding that it's the sharpens and set that they must master early on if woodworking was really going to work for them. I also found it necessary for woodworkers to understand that most magazine editors were just that and most often not particularly good woodworkers if they were woodworkers at all. All of the UK woodworking magazine editors were not woodworkers in any way. That was a good enough reason for me to stop writing for them. thankfully, one by one they are going down. facing the reality of them, most of them if not all are associated with advertising and are advertising platforms and little more.

So, what happened to these premium tools? They are still back in their boxes. This year I plan to get rid of the excesses. I have accumulated hundreds of tools to do my research over the years. It's time to distil down.

One of our most successful video series has been the simplified English Joiner's Workbench. this workbench with my inexpensive source for bench tools got woodworkers around the world in the saddle straight off. Once I convinced new woodworkers to give it a go and sharpen that saw, make that bench and buy that old #4 Stanley we were off. The first project we filmed was building my workbench in the back garden of my rented house in North Wales where the seagulls screeched overhead and the children screamed in Welsh in the playground next door. It was magic. But in that early presentation of online Paul Sellers, I did wonder with the few hundred views how this was going to work. Fourteen years on, still no regrets. The days are full on teaching, training, making and sending it out to hundreds of thousands.

When we made the shelf unit we were able to create so much content packed into a few episodes people were stunned by it. We trialled four different planes covering 150 years of planemakers and found all of them coequal in ability and quality. The wooden Sandusky was the single most pleasant but of course, we couldn't recommend it because it wasn't available universally. What we did show then was that you could acquire a Record or Stanley version with three to a dozen cutters sometimes for only ten pounds but anyway, usually, under fifty.

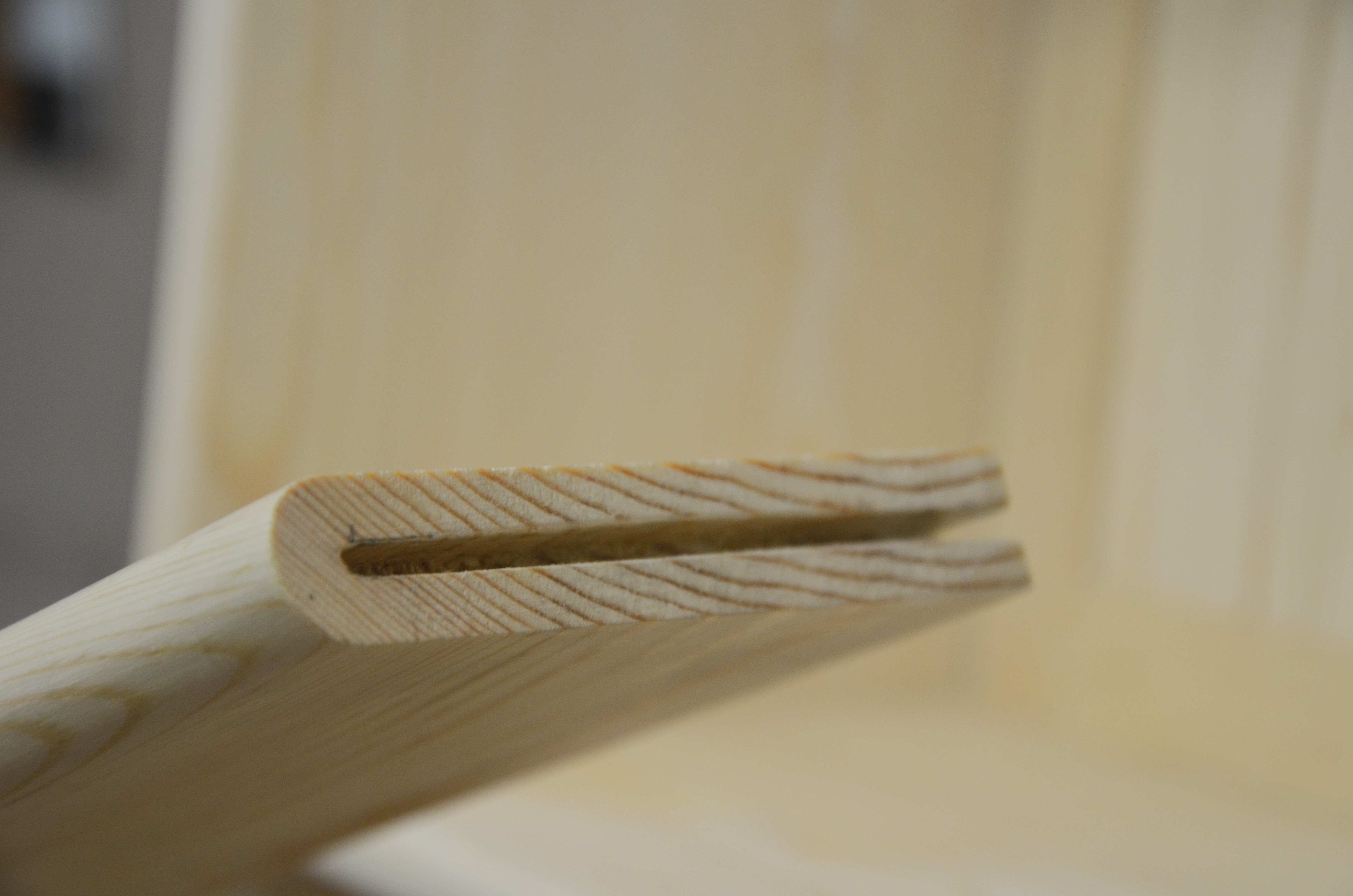

There are many elements in this project I included that will be missed in the overall and final appearance. How are the shelves adjusted and what holds them so well? Well, it's nothing more than a wire coat hanger with bends that form a spring in two holes. When someone shows you this thing with a slight spring you ask yourself now why didn't I think of that? And here is another thing. Over the decades I have shown a hundred thousand people how to make bull-nosed edges to shelves, stair treads and window sills using nothing more than a common #4 Stanley bench plane and any wood you care to name. You do not need a moulding plane or a power router. They will only mess you up and so too your workspace.

And just how do you cope a matching cove to correspond perfectly to a bull-nosed edge or an internal corner anyway? When someone shows you why to put the blade in so that it cuts on the thrust or push stroke and not the pull stroke it just makes good sense.

The cut is more powerful and you can see your line much more clearly. Did you know that this is the correct way to load the blade anyway, except when we are desperate because of things like COVID? In the last decade of producing online content every week, we have never missed a single five-o-clock Wednesday deadline. that's because we all have the same dedication to educate. we are not an advertising medium, we do not take payment for product placement, no manufacturer can afford us anyway and not one of them can match our reason for producing what we do.

So, with hundreds of episodes under our belt, you can access first-class help from the experts in every sphere of our work. you can access half of them for free simply by subscribing here. If you want to go deeper you should pay a modest fee for a membership where you can access every episode we have ever made. it's your choice.

Comments ()