Educating Lazy Owners . . .

. . . or more likely those whose lives are simply super-busy ones.

Owning handmade furniture is not to just buy the piece we make but to educate owners as to the best way to treat it when it arrives so that they own it well. Our work is not mass-made for masses to own so much as customised work we make to specs owners cannot often get anywhere else. The woods used, the sizing and then the methods by which we make can not readily be bought in the day-to-day. We make not competitively but individually according to various dynamics. Someone once said to me, "You can't compete with Walmart!" I waited for a few seconds, looked them in the eye and said, "You've got that wrong. Walmart cannot compete with me because Walmart cannot make what I make." The discussion ended with the wisdom in my answer. There was nothing more to be said.

Wisdom comes to us in many ways if we do but recognise it. I decided 30 or so years ago not to work for money knowing that as long as I was willing and able to work my income would come automatically. That left me in greater freedom than ever before and I was much more able to focus on what I was good at, making.

Not all people are used to owning fine furniture and especially handmade work that's a lot more costly. Over the generations, manufacturers have presented no-need-for-care products as the easy way for customers. The finishes they use are extremely low maintenance and highly sophisticated. No maker in commerce would ever use shellac as a finish even though it is one of the most beautiful finishes there is. Their lacquers spray well and cure in seconds. Speed is of the essence. Longevity is guaranteed and five decades is nothing these days. if your customers own furniture polish it's mostly to make them feel good. They can always says it "nourishes the wood." Of, course it doesn't, we woodworkers know there is no such thing. It might clean off fingerprints and dust, nothing else.

Bridging the gap between a maker and an owner will be a new concept for both. How to move pieces, sit in them, clean them and maintain them for long-term ownership is a much-needed thing and no one else does it better than us. Did you ever tell your customers that leaning back in any chair other than a rocking chair is really bad for the chair and that you cannot guarantee that something is very likely to break and that if they do that you will not stand by a guarantee?

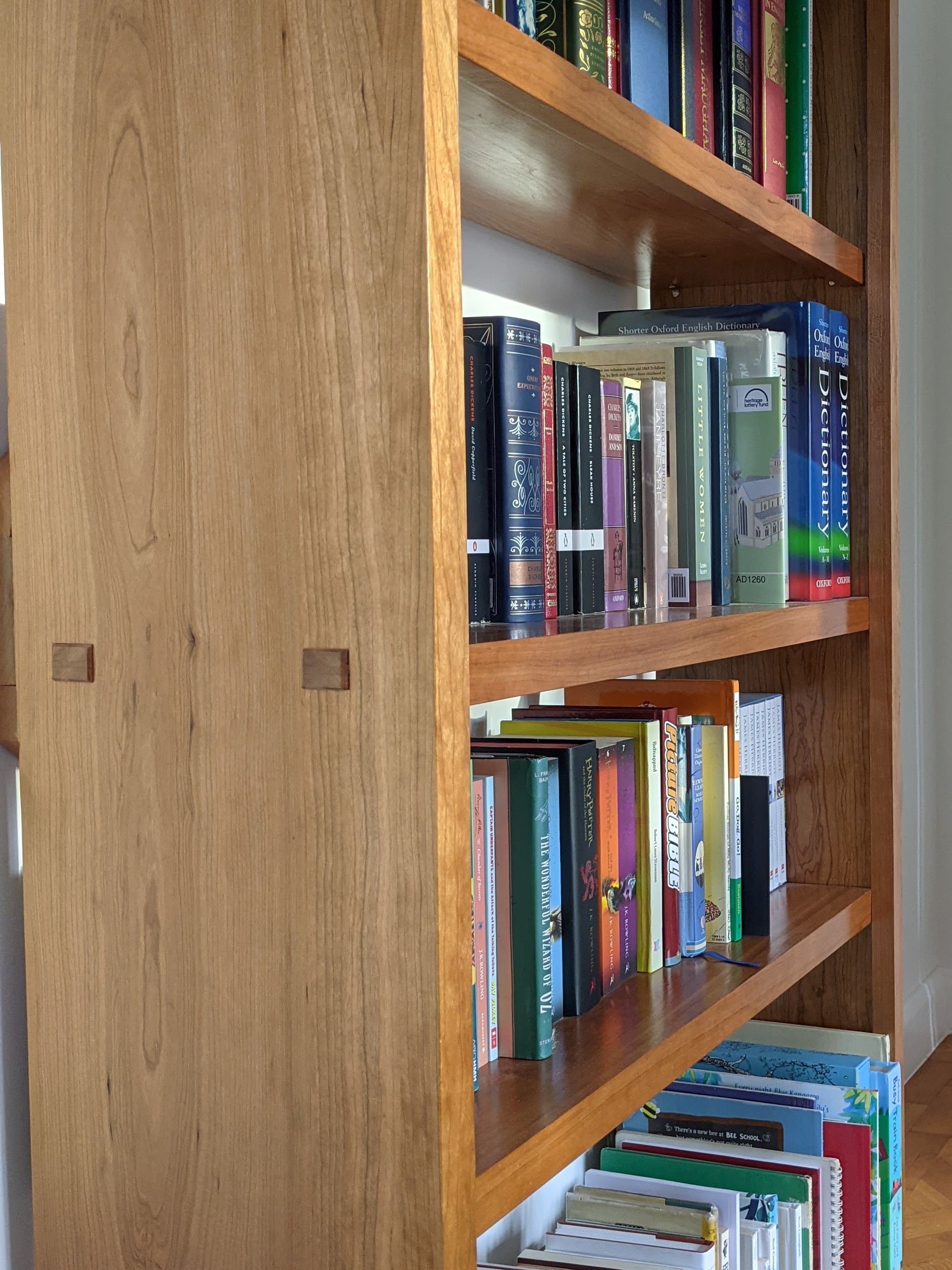

I know that 90% of bookcase owners will definitely not empty the bookcase of books if they feel it will shove along the carpeted floor. If this doesn't break the glue lines and rack every joint I don't know what will. And then there is the dragging of beds and long dining tables where leverage is massively increased against the mortise and tenons. Better for two people to lift and move rather than just one giving a good shove against a rucked-up and wrinkling carpet. What about stowage when out of use or travelling from one place to another or even one continent to another? A printed sheet will do this. On the point of handover, a nice After-delivery care note will never offend the new owner. Spilt spirit alcohol on a certain finish will destroy the appearance. tablemats are essential, inexpensive and easy to explain.

In the age when polyurethane was making its mark in wood finishing the TV sales pitch for the "housewife" was the ease of cleaning and the no need for placemats and such ever again. The idea was to sell their idea that finishes just lasted forever and kept their shine no matter how the furniture was treated or mistreated and, in reality, polyurethane is a hard-to-beat finish or durability. On some pieces, this can be overkill. Some furniture is only minimally touched by what usually causes the serious breakdown issues, the oils from human hands and forearms. On dining tables, the hands and arms are always in contact with the table and this is usually where the finish breaks down. The chairs that go with them are barely touched by hands unless the chairs have arms. So, my advice to new owners is to use placemats and drink coasters. They aren't for everyone but I doubt that any of my customers through the years were likely DIY refinishers.

Shellac is one of those few most remarkable finishes no one ever invented but more discovered centuries ago. French polish is not a substance but an act though brands sell it as a finish and that's because these companies invented nothing but were advantaged by nature. Shellac is the substance of a natural finish we call French polishing. It's so safe and natural, commercial candy makers actually coat many types with it to make them shiny. It's the primary coating on fingernail polish. Put shellac in Google and you will find more fingernail suppliers selling shellac than you can shake a stick at and a million times less supplying it for woodworking. But the art we now know as French polishing is a skill fewer and fewer will ever actually master or come across as progress undermines its value in our day because as amateurs we most likely will never have enough work to require our gaining competency and skill to any level of the master deserved of the title, 'French Polisher'. French polishing is one of those skills that needs total rote practice over a number of years to truly settle it an acquired and mastered skill. When we completed the two White House credenzas for the Cabinet Room of the White House we were applying two extra coats in a hotel to give them that final lustrous shine.

That said, shellac brushes on well but you must work fast and apply subsequent coats even faster. Why? Because the denatured alcohol we use to resolve the brittle shellac flakes into a liquid for application begins to dissolve and soften any previous coats within seconds. So, when we brush it on, these coats can drag into ripples as we pull the brush over the surface. The art with brushing on shellac is to load the brush, apply to the surface and do successive pulls along the grain with no fuss and no second strokes as you might with surface finishes like polyurethane which might give you ten minutes. With shellac, you have literally seconds, no more. Working quickly defies the softening period. Shellac repairs easily but what I like best about it is how well it sprays with an HVLP spray rig. Four or five thin coats followed by one fuller coat will give you a high gloss that buffs out beautifully. Because nothing touches sprayed shellac beyond the air it's transferred from cup to wood these coats can go on in fairly quick succession. Three to five minutes between coats if the atmosphere is dry and warm and then leave untouched for a couple of hours. No matter how many coats of shellac you apply you end up with just one. Unlike all other surface-coating finishes, subsequent coats of shellac dissolve into the previous coats whereas all the other finishes sit one on top of the other and in some cases these 'skins' separate and peel apart over time. And that is any of them including water-based versions. This is why when refinishing we sand between coats to give 'tooth' to the previous finish and indeed between coats of new finish too.

We don't always realise that many finishes now are little more than plastic coats going under the banner of water-based or water-bourne acrylic. It's too complicated to get into here but many of the liquid finishes we use are little more than plastic as is the case with our favoured glue, PVA. Washing out our brushes and surfaces with water down the drain is added to our plastics contamination of every waterway, lake and ocean we care to name

Further proof comes when we try sanding many of the waterborne finishes off a tabletop and the finish globs up en mass to defy the abrasive. On my recent tabletop task of stripping and refinishing, I used two ever faithful #80 cabinet scrapers and two card scrapers to get me from beginning to end without having to resharpen. All the material used could be swept into a bag and disposed of safely with no powder or dust. This removed both the finish and the thinnest surface of the wood itself. Minor sanding gave me the tooth for the first coat of finish and from there I applied new and thin coats to build up the surface finish. The finish I chose is easily repaired and recoated and my friends now know how to take care of and repair the finish in the future as they worked with me through the whole process. I am not looking for future work!

Comments ()