Repeatable, Scaleable Dovetails From a Single Layout

I developed this strategy to give me repeat cuts from a single guide and I can slide up or down the guide to give me different sizes of dovetails within fractions of a millimetre if I want an alternative size from as little as half a millimetre on half pins with 1 mm on full pins to 12mm for half pins and 24mm for the full pins. The neat trick in this guide is you can have any size you want by a simple split-second realignment yet you never have to layout for any change of sizing you make again. It's my own invention but it's free for you to use whenever you want to. I can make the guide in five minutes and you can watch the video here and then follow the guide below to make yours if you prefer.

https://www.youtube.com/watch?v=KHSjOtLpUts

Explanation first: The guide you make can have as many dovetails as is practicable for you and you can make the guide as wide and for as many dovetails as you want according to that size of width. I will assume you will practice with me as you follow so I start with three pieces of wood. One piece is the piece I will present as say a drawer or box side. The second piece will be the final guide and the third piece is the sacrificial piece we will discard after the guide is made as we will not need this again. The square-across guide is 6" long x 2" wide x 3/4" thick. Any near size will work. The Dovetail guide is 8" long x 4" wide x 3/4" thick. The width size is arbitrary but usually, it will correspond to the size of drawer or box you will make. The third piece is your pretend drawer side or box side; this is whatever length you want or your drawer side length so in this case I'll say 10" by 4" wide by 1/2' thick.

In the image, I have marked the pieces of wood to show what each piece is for.

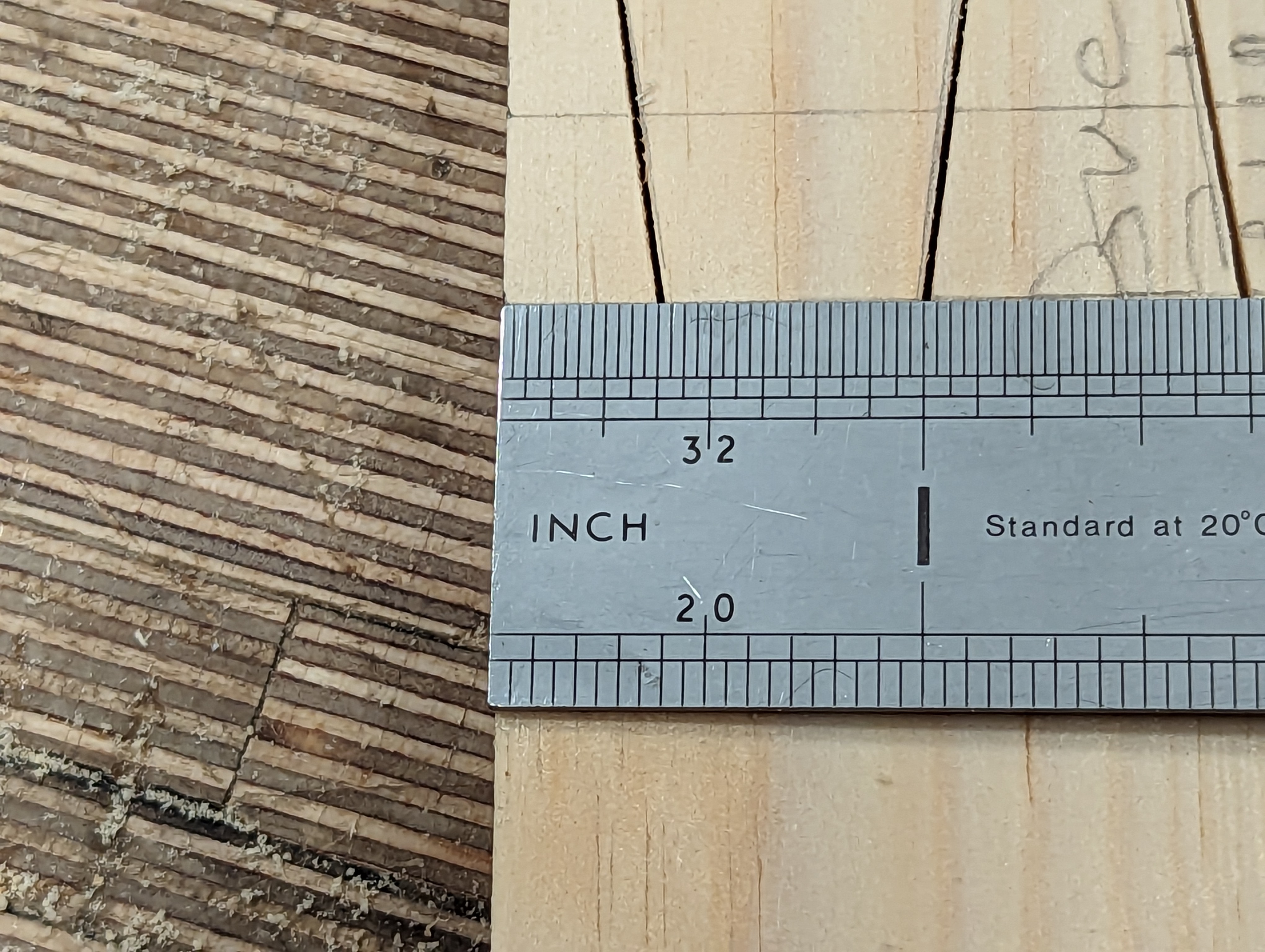

In my case, I used 4" wide wood or 102mm. If you want five dovetails divide the width by five. In my case, I want three so I divide 102mm by three and get my 34mm division for three dovetails totalling 102mm.

I clamped my two pieces into the vise level with one another. The sacrificial square-across piece is at the back.

I divided my wood equally into three for three dovetails. Had I wanted two I would divide by two or if I wanted five, divide by five.

The knifewall gets you dead square with no discrepancy. Follow this and you will have a good guide emerging.

With the knifewall as your guide, saw across dead onto each knifewall.

Use the dovetail guide or a sliding bevel set to a 1:7 ratio for laying out the guidelines on the guide piece.

This is to show centralising the saw kerfs on the position lines as near as possible. These kerfs will guide the square-across cuts. From this point your saw will be square and you can focus on the angled cuts alone.

With the square-across saw kerfs in place, angle the saw to follow the pencilled guidelines.

Extend the depth of the cuts in the guide further as needed.

Marking for the 1/4" pins. This mark is squared across and will be used to align the end of the dovetail side piece to the guide.

Marking for the across-line for half-inch pins.

Marking the position for the 3/4" depth mark for aligning the workpiece to.

Showing 3/4" positioning with 3/8" outer half pins.

Quarter-inch pin position.

Half-inch pin position.

This is for the 5/8" pins . . .

. . . and sliding further down the guide gives you a wider dovetail size. in this case, it is 3/4" for the pins between and 3/8" for the outer half pins.

The squared across line comes from the width of the adjacent pin piece you will use be that the same width or thicker or thinner.

Align the end of the workpiece with the distance line according to the width of the dovetails you want. In this case, I went for the 1/4" pins with half pins of 1/8" on the outer edges.

The guide streamlines the saw in the cut and all you have to do is follow the path of least resistance. So nice!

Here are the cuts straight off the saw. They are crisp and clean and as near perfect as they get.

It works really well with Western saws because there is zero of the flex associated with pull-stroke saws. This also preserves the cuts in the guide for future use so I think I could get about a hundred dovetails off the one guide. Also, worth doing, why not make three or four guides from this one when it is so brand new?

The face cuts are clean and good to look at and show none of the waverings you might often get from normal saw cutting.

The outcut is as good as the incut because the inside face is supported wholly by the guide itself acting as a backer board too. So, there you go!

Comments ()