Hold On, It's a Bench!

I receive questions from woodworkers who start out with, "What's your opinion of . . . ?" It might be a tool, a vise, a workbench type I have never used or used or never even heard of. Opinions are funny things in the same way assumptions very often are. When you find something that works for you then most likely there is no need to change anything without good reason. Higher degrees of engineering quality with less slop somewhere seems all the better to go for but often, well, no it's not. I owned a vise that was highly engineered but too tight to move. My now 'vintage' planes bought new always had some slack in the take-up of threads and the sliding left or right of a lever. I have bought different versions of so-called high-end (and higher priced) tools like planes, chisels, saws and such to trial and use and ended up shelving all of them for different reasons. Most other such buyers started swearing by them and of course gurus slip their hands into or around the handles as much as a statement as they do advocacy for others to buy into them too. When you spend a few thousand on such tools to start woodworking then you better use them or you'll have some explaining to do to others around you watching your range of investments.

The only bought benches from my youth were the commercially made school woodworking benches. I grew up with joiner's workbenches which were made by the joiners using them or their forefathers in the trade. Back then the only Bailey-pattern planes were made by Stanely or Record. For some reason, I still cannot fathom, joiners kept some Scottish-made infil planes near to hand but never used them. I am guilty of owning some and not using them and the reason is simple. One, they're too heavy and cumbersome and, two, they don't work any better if as well as the Stanley alternatives. That said, the ones I own were indeed extremely well-used. I suspect this to be because they predate the emergence of the Bailey-pattern versions in the 1860s, the shunning of them at the start and then these users liked the idea of steel soles because of longevity. But weight and bearing down over a plane to maximise pressure seems to be a common teaching from some modern gurus. Working 'overhead' supposedly works better but that is far from true and I might suggest my suspicion that a lazy attitude to sharpening their planes on time or well enough might be nearer the truth. A well-adjusted and sharp plane pulls itself to the surface unquestioningly. Using force in downward pressure reflects the neglect of the user in one way or another mostly. We really should not forget that the more you press down on a plane the more you will increase friction to cause drag on the plane. It's one thing applying wax or oil to the sole to ease the friction but for 95% of the work, this should be unnecessary and especially with the lightweight planes given us by Leonard Bailey.

Workbenches have indeed needed change through the more recent decades. I went to a woodworking school in a college a few years ago where I was invited to inspect the commercial workbenches. The massive behemoths occupied a footprint three times the size they needed to and all because of the perceived maxim that bigger is best when It comes to workbenches. The head of woodworking proudly stood with his prizes, perhaps expecting a little more from me than he got. It was sad really because he obviously knew very little about what was needed which was twice as much free space for working and a bench design a third or even less than the size extolled. He really needed benches that could be moved around according to the needs of the classes; something two people can push from here to there is a good size and even though joinery benches should be larger they do not need to be heavier than is reasonable. In a training facility it makes much greater sense to move benches together rather than hog space with a surface that is 50% and often more unused. But with some people, mass and weight are all they understand: Matching a bench to the space and weight to the work would be more critical. I was generous with my comments because after-sales is always hard to correct when you've just spent a ton of unnecessary money. Anyway, what would have been far, far more impressive would have been to see woodworking benches made in-house by the second-year students. Now that would have been something to see and to endorse. I have yet to visit an institution with homemade workbenches. I think that that reflects the lack of vision by colleges more than anything.

Your workbench needs to fit your space be that a garage, shed, attic or basement workshop and yet it still need not be massive even if you have an aircraft hangar. My workbenches for everything I do are resolved at between 5' to 5'6" long and two feet deep. Any bigger and it just fills with junk, believe me. In my garage workshop, I cannot have a centrally placed workbench to work either side from because of space. It must go against a facing wall. But I can manoeuvre it to turn around or place one end against a wall to have it 90º to the long axis of the garage as needed. Anyone watching my videos will have seen me reposition for projects that need different space.

There are those who suggest mini benches atop regular benches. I think that this is likely a good idea to cater to inability and disability. I have never in my 58 years needed a range of bench heights to expedite my work nor any bench-on-bench mini versions. And more than one bench is a luxury I can ill afford, but even if I could I would probably not do it. That said, any disability can indeed change a situation and some will need an alternative to help them in different aspects of their work. I do not want any secondary options that often come from little more than something like an opinion rather than a practical working option or solution. Personally, I've had 6,500 woodworkers work using the same bench scenario I use and never had one complaint or suggestion for changing anything. It's also worth noting here something I have never mentioned before: I gave out an extensive three-page questionnaire at the end of each class between 1995 and 2009, 14 years, asking three dozen questions about the class, the facilities, the hand tools and equipment and, yes indeed, the workbenches. How many that was I cannot say now but thousands would in no way be an exaggeration. Such was my intent to discover how my students felt about the teaching and all that went with it. In the end, we pulled that endeavour because we never had any need to make any changes to what we offered.

Tail vises are of little real value to me in any of my work. It's an additional expense that offers very little or more likely nothing in return. I know, someone will comment that they use theirs all the time and cannot live without theirs. No matter. I think there is a certain pride that promotes advocacy for maximising options for a workbench thinking it to become more functional but I think that's more that we might be looking for something to do rather than true need. I am sorry if this might seem a bit hard to some but it's equally hard for me to just sit by and see an article come out saying this or that is a must-have. Workbenches do evolve but I have noticed with mine that it is more the keeping of tools close to hand rather than work-holding stuff. The two tail vises I have installed on two workbenches in my lifetime just increased the complexities of housing them and then the expense of buying them. And I found zero use for either of them in the end. The one I have left holds my electric cord neatly on the bar of the winding handle, nothing more.

Inevitably, installing the tail vise introduces another addition to the workbench I don't care for, dog holes. These holes scattered along or around the benchtop house bench dogs that work as stops opposing the vise closure to hold the work on the benchtop or take holdfasts to hold stuff to the benchtop. My solution is far more versatile and less invasive when I want to hold things to the benchtop for some types of work.

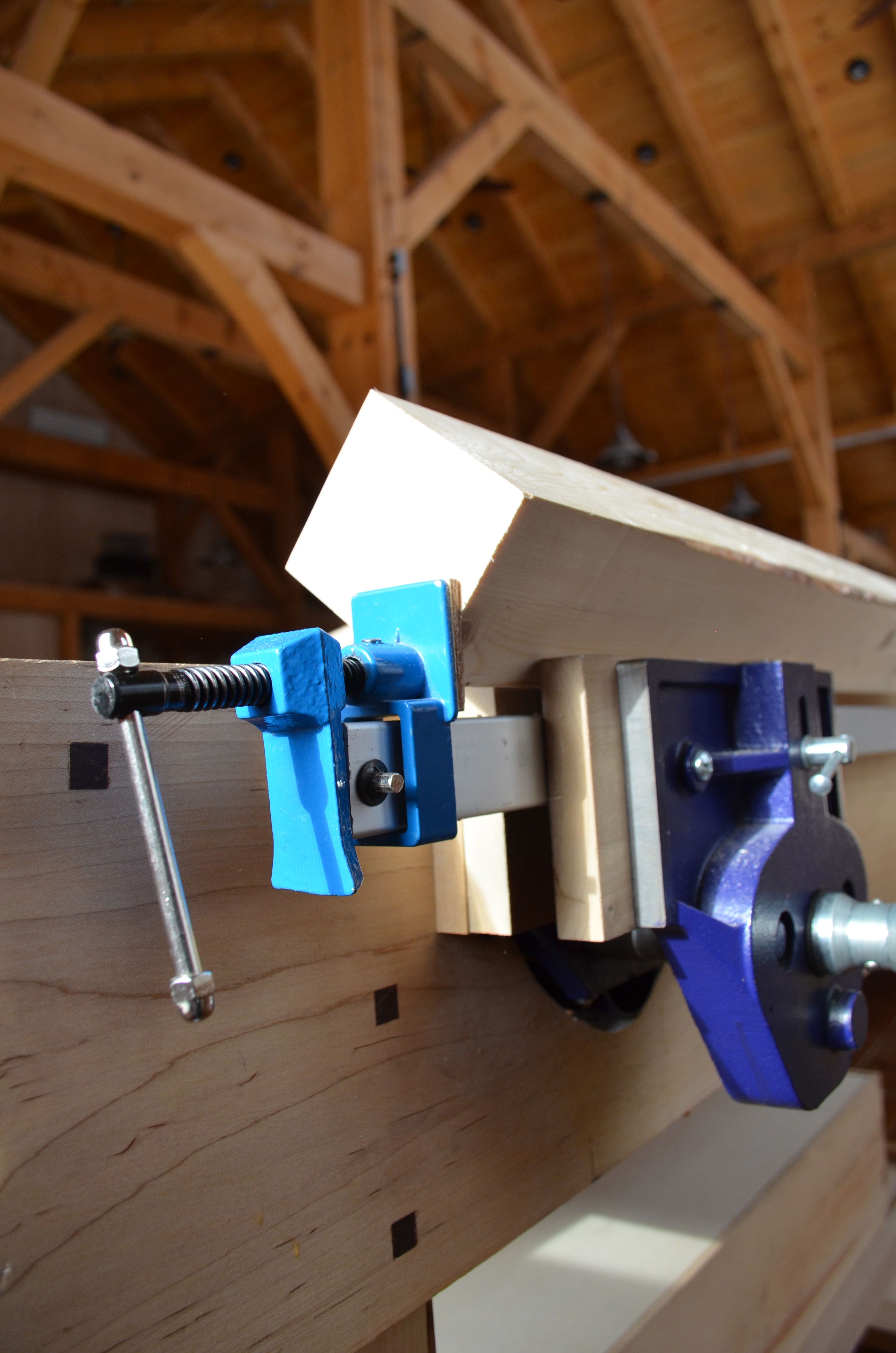

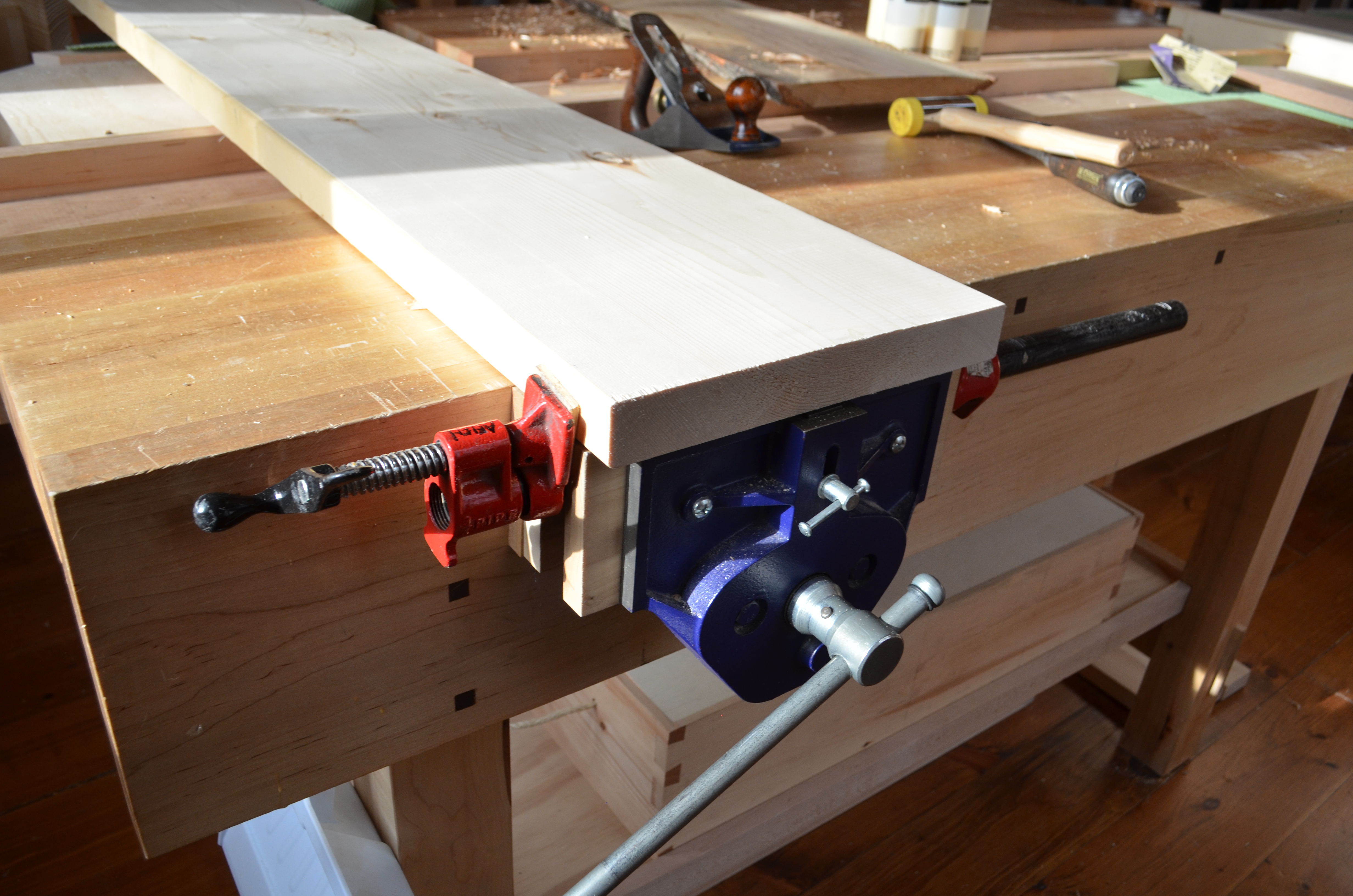

I generally use a shorter sash clamp held in the vise for anchoring things like tabletops and frames when they need to be planed and scraped or, dare I say it, belt sanded. This has to be the most comprehensive anchor point for holding anything and everything you can think of. Also. remember sash clamps will hold almost anything to the benchtop too so if you want to anchor a table leg for mortising it's straightforward to apply a clamp or two. For sheet goods needing ripping or planks that need crosscutting, it's the same.

Comments ()