Persevere

Thank you for your support in buying my router plane. The income from the plane sales supports many aspects of my work and then my 'other' work beyond. I wish I had had it for my book back in 2015 and before but, hey! We are where we are. I remember arriving in the USA and shortly after my migrating there, travelling around the Woodcraft stores in different places to demonstrate the real value of mastering hand tools. The seats always filled and the aisles were packed to the hilt too. We'd usually start around 7 PM, plan on going till 9 PM but still be there after 10. I would bring my own bench on a trailer and my tools -- the store benches were always 3-4" too low. The audience was always amazed by my workbench height but after a good explanation, they suddenly confessed that they saw why they now had backache after backache. Though I never charged anything for demoing, even when it meant a hotel overnight, they often had a private whip-round and gave me a hundred bucks; such was the spirit of the woodworkers USA.

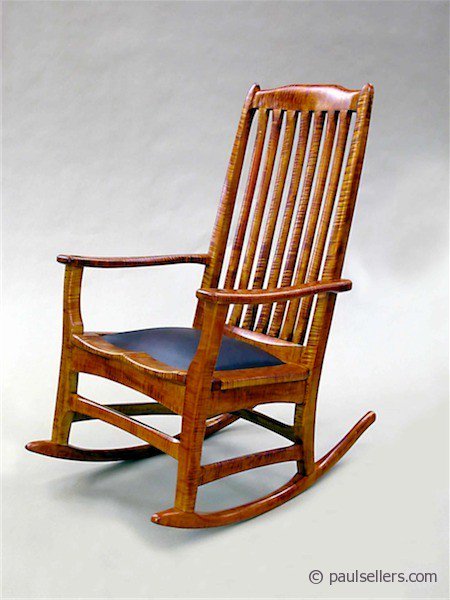

The main interests always surprised me. What I took for granted I would draw them into my hand tool world in just two minutes by cutting a two-minute double dovetail with a gent's saw, a knife, square, chisel and a chisel hammer and then hand it around, smooth and gap-free. I could make all four corners in under ten minutes and have the box planed in two more minutes. I met many of you at these events and also with The Woodworking Show US tour that travelled the USA.

In my show-off days, I would demo dovetailing using four different-sized saws including a panel saw. I was proving the versatility and the functionality of western saws in the face of the onslaught wrought by Japanese makers and importers of the day. Quality western makers were almost gone by then and the magazines became ever-more interested in Japanese woodworking as an alternative option in light of the demise of western woodworking. These guys always showed planes whipping off a shaving 3" wide and ten feet long or a myriad of highly complex joints as though this was day-to-day joinery used day to day by furniture makers instead of temple builders and repairers/restorers. I always wondered whether this happened in real life. many things are done to draw us in. Economy and consumerism are universally impacting and it's a special cluster group of the more wealthy who can afford truly handmade work. I still try to see the real value in three-metre-long shavings in Japanese Cypress when only a handful of makers build anything like temples or use Japanese cypress wood.

My quest at the time was to counter the erroneous conceptions both in the use of traditional hand tools from western makers and how they really apply to our real woodworking world making woodwork work. Having said that, I think some really fine woodworking and concepts of design comes from Japan -- both modern and traditional. I also think it is important to understand the spiritual implications of making by hand using hand methods too. Mostly it is in the concepts of design and the joinery used that interest me as a maker using hand tools. I love the idea that certain crafts still seem to hang on in there. Japanese basket weaving and miniatures always draw my eye.

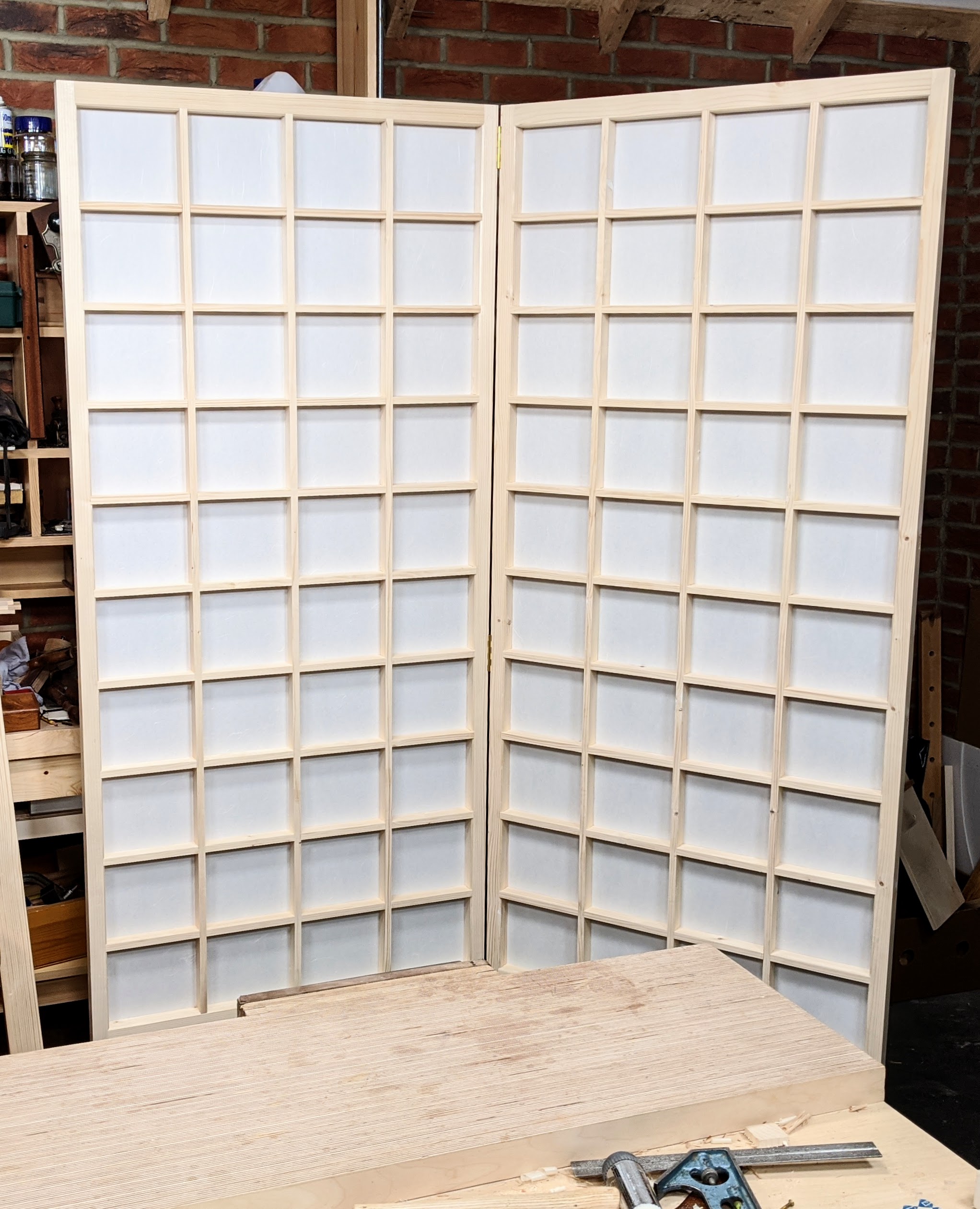

The lightweightness of room-dividing shoji screens fascinates me too. I use my shoji screen every day as a room divider and privacy screen. Make two or three and you have a private room to draw and paint in, filter, soften and distribute more even light for photography. I create a backdrop in seconds for displaying my pieces. Remember we made one for woodworkingmasterclasses a couple of years back?

We find the real at our own workbenches in the quiet places and spaces physically and mentally of the day negotiating the wood and the tools we use. We must make a decision at some point that takes us beyond the fascination of a shaving rising from the throat of the plane or the chisel's edge or the mouth of the spokeshave to the direct quest of planing surfaces by the dozen true and square, parallel too before the joinery takes place at our fingertips. It's to this end we must take ourselves, still equal in fascination, on to become not shaving makers but men and women who become masters of the craft of woodwork. We live and work when we can in a multidimensional world where craft is the art we immerse ourselves in. Establishing the cutting edges we rely on is the merest part of our day in the shop. The wood becomes the partner opposite to our hands where the constant reduction takes place. This then becomes our real woodworking.

Even now, at 73 and through a lifelong full-time woodworking passage, I still enjoy the union between one piece of well-cut wood that fits perfectly into an adjacent piece. When it's loose I fill a tad disappointed, but I consider it in relation to the other surrounding parts and nine times out of ten it's of little if any consequence. If the tenth one matters even slightly then I remake it. I am not a perfectionist. I don't believe that obsessiveness is perfectionism. There is rarely any sense of harmony in such a condition or a person though I do accept that it can be a condition to the point of becoming a disability and very discontenting. Woodworking is about the discovery of balance. It comes through a period of transition where skill has yet to arrive but you are on the journey. I worry that our instancy of clicks and artificial images gives us unreal expectations. My becoming skilled in my craft and others came through the years year on year. What I didn't know and couldn't do came split by split, saw stroke by saw stroke and plane stroke by plane stroke. Each one of the faltering strokes that halted me, jolted me with an awkward wrench taught me patience and led to greater care, greater interpretation and a seeking ahead of the tools to understand better my wood and my tactics to tame it.

Everyone can master hand tool methods of woodworking and become well able to work it if they understand the essentiality of patience. Hand-tool woodworking is not for the faint-hearted but neither does it have to be instant either so just take your time, think about what's happening at the cutting edge of your tools and be prepared to change direction with the tool on and in the wood. Anyone who perseveres will be rewarded by a deep satisfaction that they pitched themselves against the odds. I have seen too many successes to believe differently and it all begins with a sharp, sharp cutting-edge!

Comments ()