My Workbenches

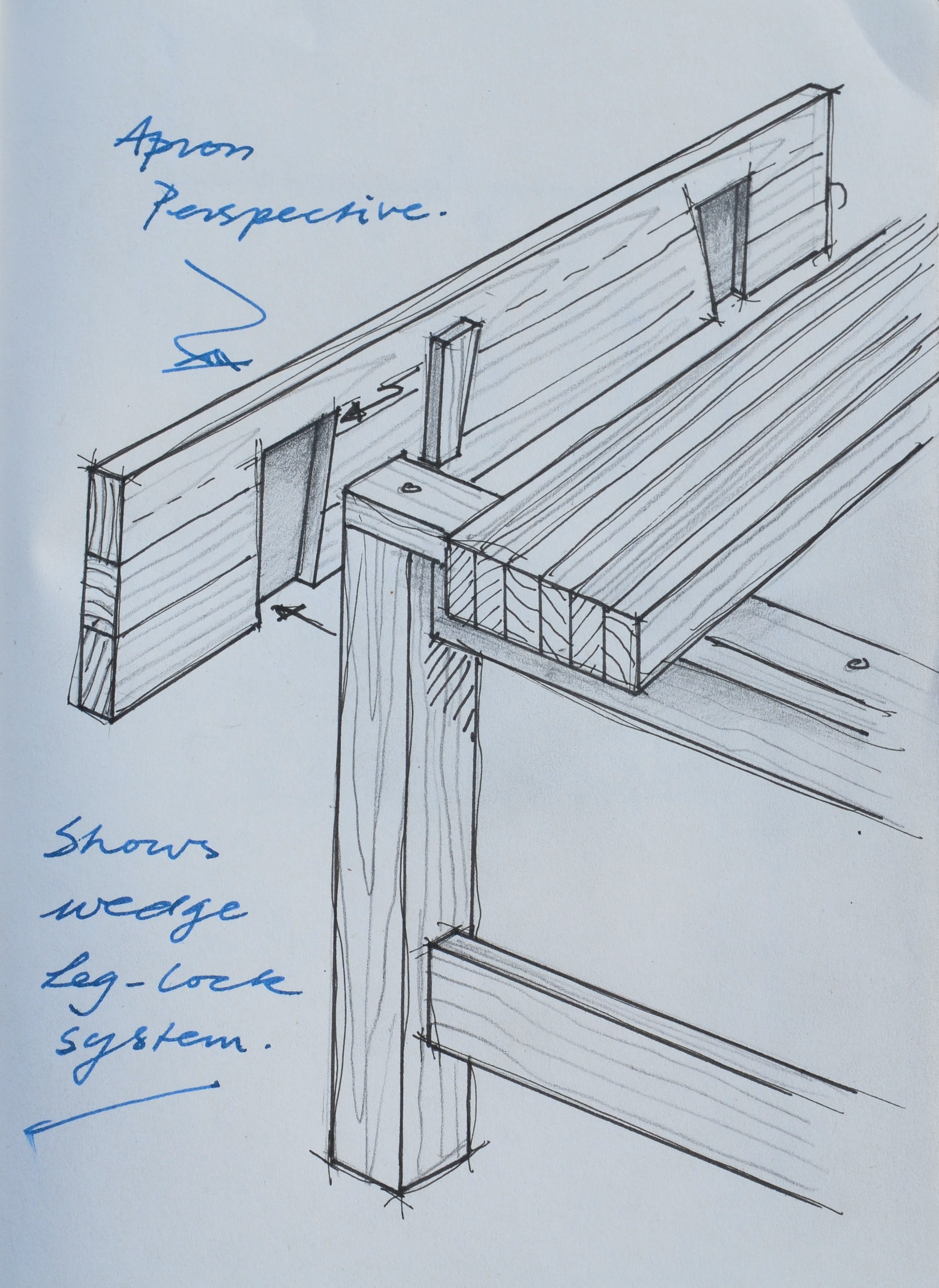

The first workbench I ever made was back in 1967. Aproned benches were the commonest of workbenches for a variety of reasons, not the least of which were simplicity, stability, strength and functionality. In a good day's work, two or three for some, you have a quick-release (QR) vise installed in your just-finished workbench and you're in business. By the time 2012 came along I had made many a dozen workbenches using my own upgraded version refined by using the same bench style for almost six decades. I may be biased but having worked at many different types of workbenches through the decades, this one is the best and for many good reasons. I have made them from everything from construction-grade pine, secondhand reclaimed wood, and every kind of common pine to hard maple, oak and others. They've ranged in size from 5-foot-long versions to two-man ten-footers with a vise at opposite ends and opposite sides. I refuse to fix what just ain't broke'. Anyone can make it!

It was in 2012, following a dispute with the publishers of my first book that Joseph made a suggestion. "Why don't you do what you've always done and show people the real you and the way you sometimes found yourself doing real woodworking in less than ideal working environments and often on your hands and knees or on a collapsable workstation? When someone needs a workbench it's often because they don't own one or have access to one–neither do they have a workshop to make one in. Why don't you build a workbench in the back garden (yard USA) and we will film the whole event right there to teach and train others that they too can do the same?" Here is the link to episode one if you didn't catch it.

In June 2012 we did it. Back then I had a really fine workshop, twelve workbenches, full sets of hand tools to each bench. All setup and ready for the usual students in my newly set-up school in Penrhyn Castle on the coast of north Wales, but that would not have been real enough. We could have made it there on the benches but we wanted the realities others might face. We made an eleven-part series with the first episode taking in a million viewers and subsequent episodes around half a million each. It was the best thing we ever did. Who knows how many felt the inspiration to build their own first workbench from a few sticks of construction stud material?

Was the bench in any way inferior to the solid beech behemoths many now advocate as the only way to go? In no way. Fact is 95% of the wood we work in furniture making is under a metre long with most of that being around two feet or so long ready for making frames. My present workbench is around 5'6" long and two feet deep. When it's bigger it just gets crowded out with stuff. My bench is action-packed with everything I need close to hand. I can make anything from it.

Back then I had written my first book and filmed the series with a professional team. It wasn't fun at all. Events like that can be a takeover and that is what almost happened, sad to say. Since then I have recovered every element of my decades of work and own all of my intellectual property. Today, I work with an amazing team who strive always to make my dreams come true. Since 2012, when we went it alone and put the new team together, it has been inspiring for me to enjoy all the young people I still work with and have worked with through the last eleven years. We have filmed additional bench-build videos to offer variations and some improvements. My innovative plywood workbench made from better-grade 15-ply birch plywood is in full-time use these days. I like it. Do I like it more than my spruce construction stud version? No, not really. In fact, because I added a large catchall drawer underneath the aprons, I made it too heavy to move without lots of help yet I like the bench to be rearrangeable for bigger pieces in my compact garage workspace.

Hard even now for me to imagine renting part of this castle for my first UK-based workshop and teaching school. 60 acres of beautiful grounds and woodlands surrounded the space. It was a good starting point for my restructuring my life and work in the UK.

This is Hannah's workspace and she works at a bench that's 7 years old I made it from secondhand and recycled, upcycled wood. It follows my usual pattern of homemade workbenches but I left the wood rough to give it the old appearance when I applied the antiquing look.

John made this workbench from the roof timbers removed from the roof of my house when we restructured the roof for a third-floor bedroom. He added a couple of features like the twin tenons but otherwise, it's intrinsically the same.

Comments ()