It's Silly to Say . . .

. . . some things.

A commenter once watched me tweak the knurled setscrew to my plane fence using pliers. His comment said, "It's bad practice to use pliers on a knurled nut because they will damage the knurling." Of course, even when being used carefully, as I was, they can, and long term they most likely will. I think from my part I liken it to getting revenge on the engineer who put it there in the first place (not really) because on many tools you cannot apply enough force by finger tightening alone and the fence or depth shoes often move as they loosen through the vibration and rigours of working the wood. Unfortunately, often before you realise what's happened, the moving part has misaligned to create a wider groove or rebate and a staggered step, or the depth has deepened more than you want and you have to then find some way of repairing the damage.

I suppose if you only design an item and never use it you might not realise just how much energy goes into using tools like plough planes and rebate planes like the #78 Stanley. Imagine all the upper body weight behind a short and narrow-soled tool coming up against wiry grain and some knotted areas with say a quarter-inch wide blade. The top pressure on the incline of the blade is phenomenal. The blade is car-crashed into a brick wall and the shock waves emanate throughout the body of the plane with all of the same domino effects you would get in a car crash when every bolt is shocked from the engine and car body by the impact. It's most doubtful that the engineer in his office, 3D printer and computers at the ready, can actually road-test his product in any real and tangible way or in the same environment they would get here at the bench with someone like me in the saddle. The truth is that you must get through the knots in the wood in the same uniform and regulated way you do the rest of the wood. You can't just bin a piece of wood you're working on because of obstacles like wood grain. We have some tricks up our sleeves to help, saw kerfs and chiselling, but we don't always see before the blade hits the recalcitrant area of wood. I have had wiry grain that looked just fine dislodge all adjustable parts in a single swipe before now and without warning.

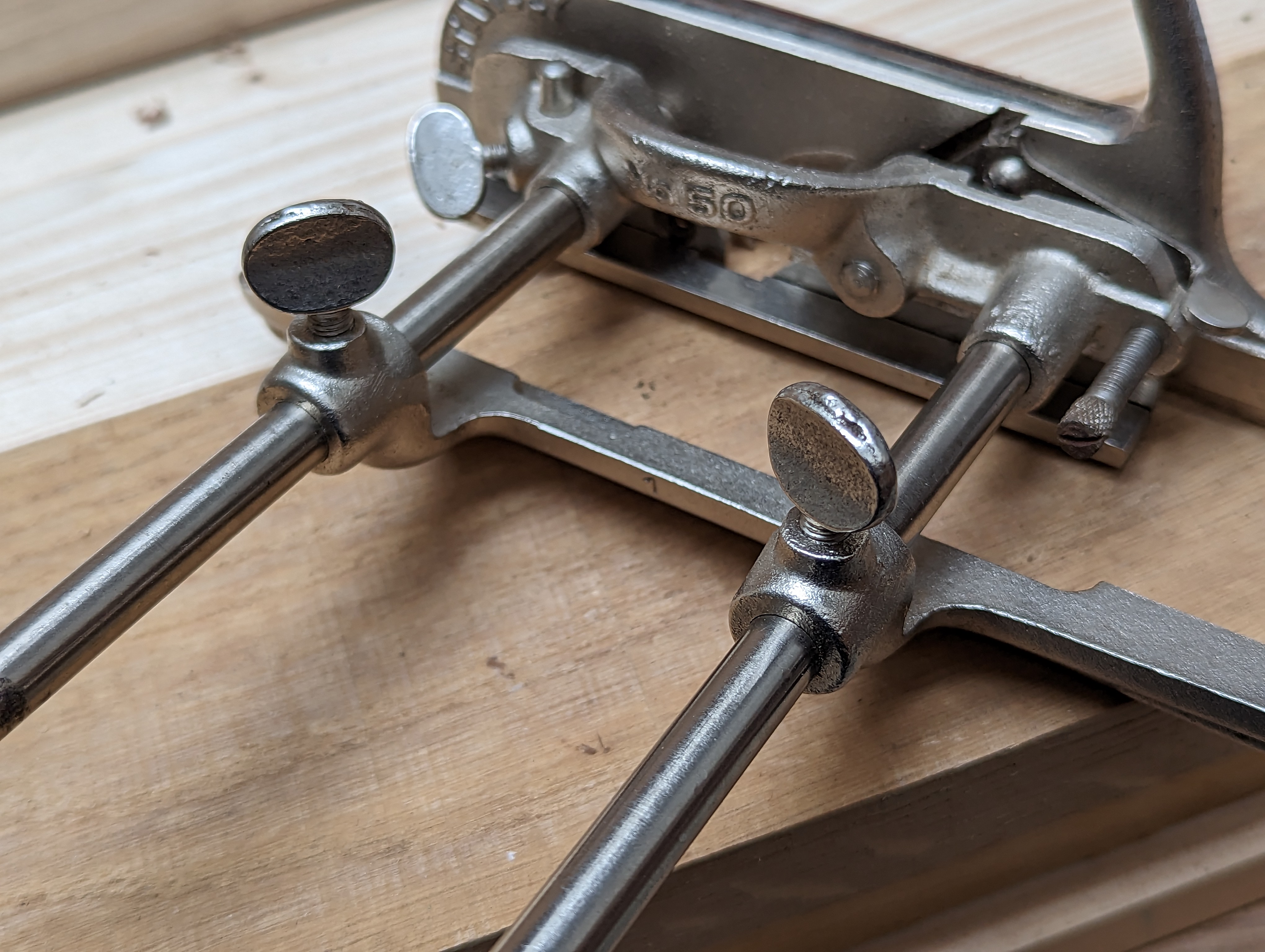

My tests over many years and now even decades reveal some interesting facts and some that woke me up to the design flaws too. The above two planes. One is no longer made while the other is currently made. Stanley plough planes all work well but of course, they are no longer made. That means eBay and secondhand finds are the only way to get your hands on one. I often see them without blades because by selling the blades individually for £5-10 apiece a plane that might only sell for £30 will make £30 for the body and £50 to a £100 overall. But making your own is dead simple, they take only a matter of minutes to make and aside from the fulfilment you get for having a set you made you can also match them perfectly to the chisels you might use alongside them too.

In my case, tweaking hand tools with pliers has never resulted in serious damage though on brass it definitely marks the softer metal. On steel, it is less so and though I have done it on most of my tools through many decades it is not so bad I can't stand the neglect of it. I want the confidence of tightened down fence and depth stop but seldom get it from knurled screws on plough planes and similar. The convenience of a pair of pliers goes unsurpassed unless there is a slot for a flathead screwdriver. The pliers are there in my drawer by my right hand and I pull them out, grip the setscrew (not too tight) and put them back in a matter of seconds. The tool designer-maker should have used common sense and used either thumbscrews (not always slip-free) or a slot head to take a flat-headed screwdriver. I suppose doing that would be to admit doubt about the holding ability. Thumbscrews and pliers go well together too though. In the case of the Record versions, with no slot heads to the screws, no one complained about this oversight to the overall design in the early days of the plane's release; that being so the makers made them for over half a century and saw no need to change. Had the designers stood at the bench using the tools in daily making the faults would be obviated by use and they would have made the changes pretty soon after manufacture.

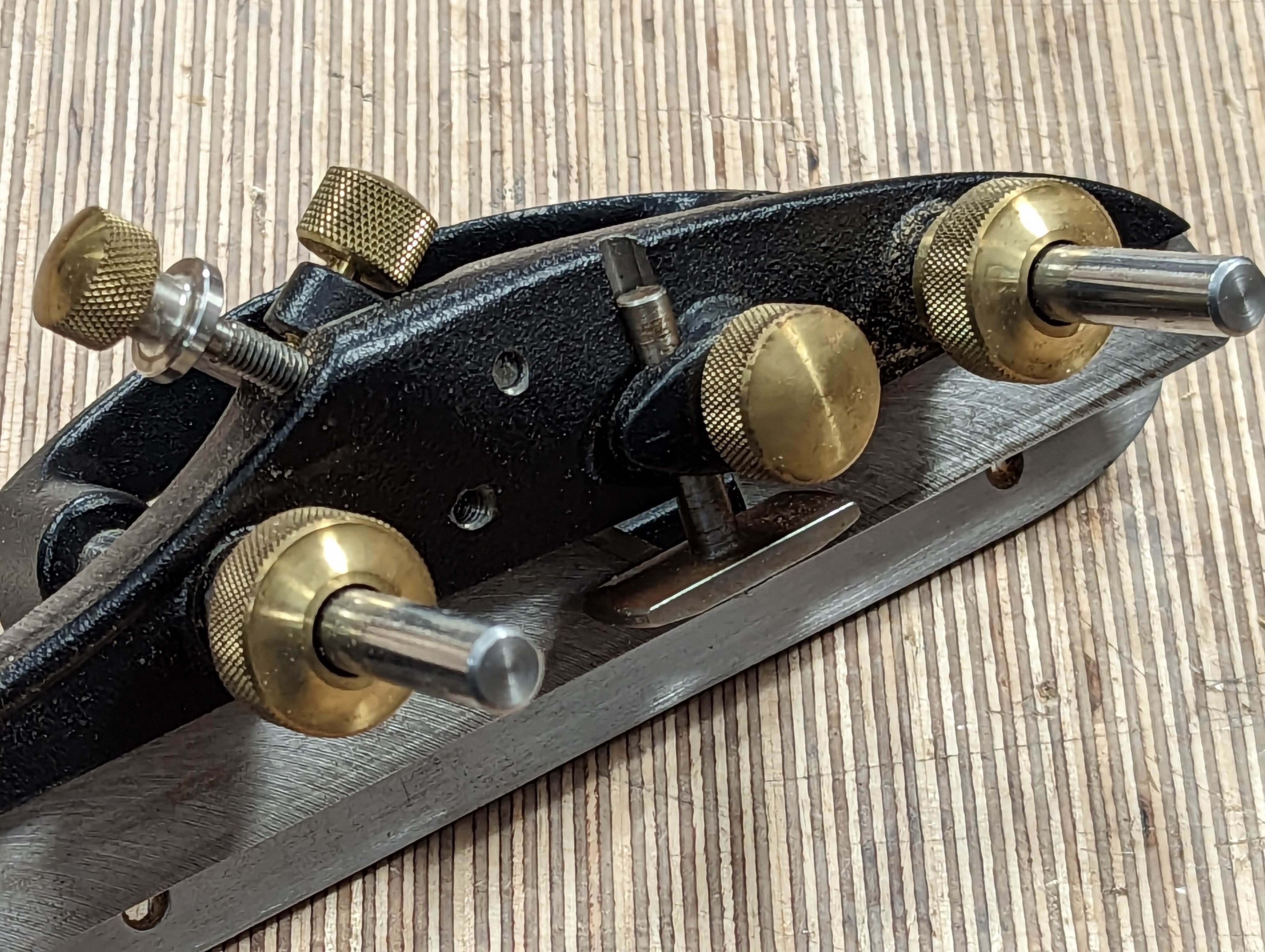

This week I tested two plough planes side by side with regards to the guide fences holding their power positions as non-negotiables on the bars for guaranteed parallel cutting of grooves and then to on the depth stops. The Stanley (2nd above) is now vintage I suppose but it is probably the best plough plane made because it's so rock solid in performance, the fence is gripped solidly to the twin bars even with just finger tightening and rarely if ever slips, even when just finger-tight and when you tighten with a screwdriver the bolts will never move no matter what you encounter. The second plus is that the depth stop stops you dead on too.

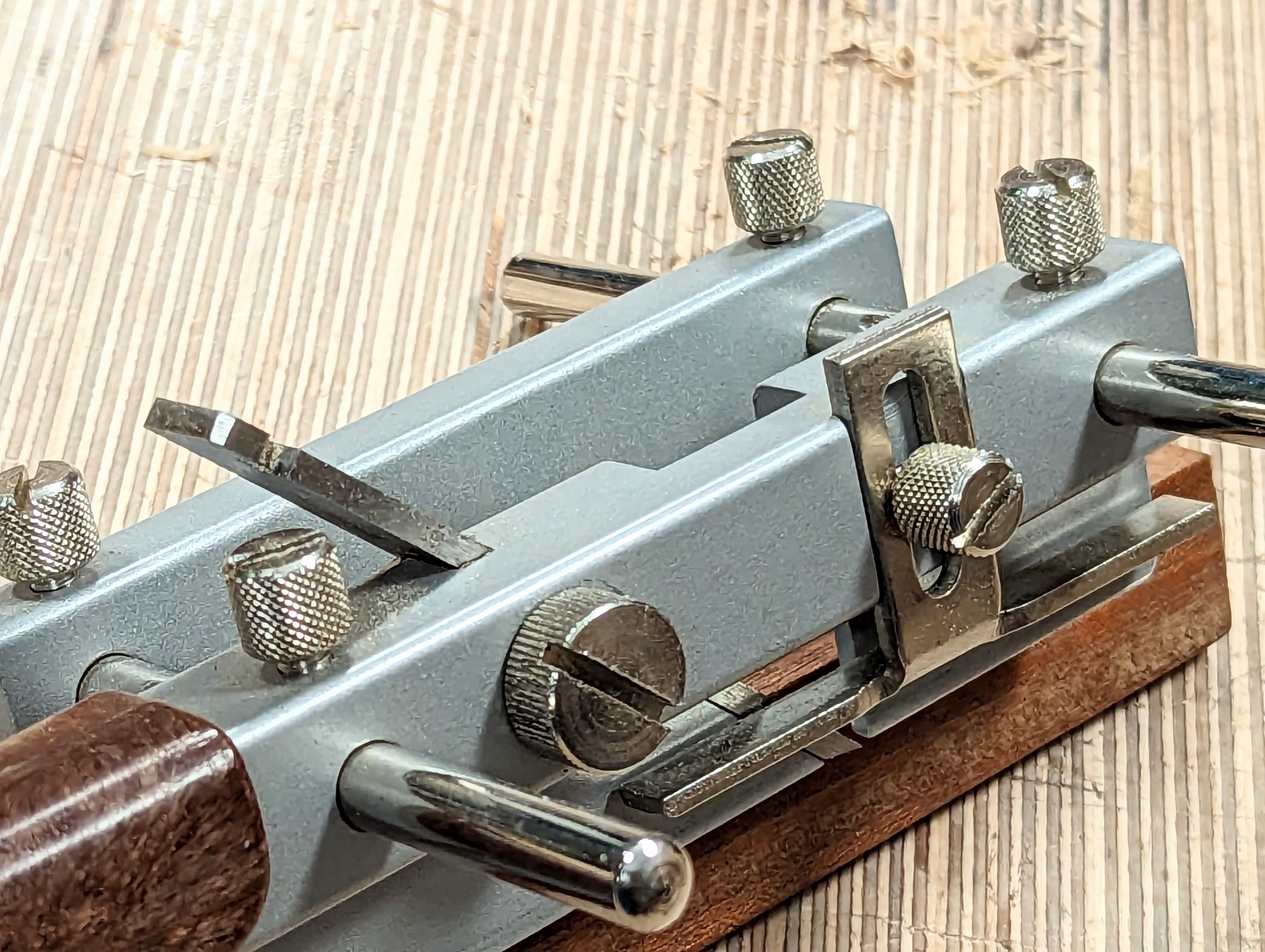

The second plane is the Veritas small plough plane in the picture above. What I did was set both the plough plane fences and depth stop/shoe absolutely as tight as I could with my fingers. On the Veritas one, this is the only option. I then tested both plane types by tightening the setscrews on the plane body and setting the ends of the two parallel rods onto the benchtop and pressing via the bodies of the planes. The Veritas offered very little resistance and slid easily along the rods all the way. I did raise this issue with Veritas a couple of times BTW. I understand that they have fixed the issue with a revised collet and it's now rock-solid and immovable so no longer a problem. The Stanley on the other hand would not budge applying the same pressure and method of testing and yet I was using only the finger-tight tightening I used on the Veritas plough plane. The Stanley plane gave the additional option of a slot in the cheesehead machine screws they used.

So what made the difference between the two planes?

The Stanley applied pressure via the machine screw directly centred on the two parallel rods and so too onto the rod of the depth stop. With strong fingers, this is usually enough. I would probably still use the screwdriver for added security. It's necessary to apply good lateral pressure pushing the fence to align against the wood when ploughing down grooves and then in wiry grain and hitting knots you must deliver certainty as the resistance comes from the wood.

This is the innovative Veritas version of locking the bar to the fence and the plane body that didn't work too well on my early model at all. The collet mechanism locking the fence to the rods via brass screws through an internal cone shape applies pressure to the split tube collet fastened securely to the plane body. It's a clever device even though it didn't work well at all in my plane. Think hose pipe tap attachment where the hose is fixed by the outer threaded ring, maybe. They changed the collet (I just heard) and that fixed the issue and I am glad because I do like the plane and the overall design.

Some good tools are ill-thought-through in certain aspects of the design because of the small things mentioned. The knurling on a nut can be enough for initial and convenient setting but I often feel there is insufficient force and that a spade head thumbscrew or the slot head will secure higher confidence.

It takes almost nothing for manufacturers to remake or add different components to offer as alternatives (it could be charged for to cover all costs, so no loss to manufacturers) and they could all offer brass or steel thumbscrews to reflect their thoughtfulness and customer care. Of course, it's too late for some makers who passed along their output to those who bought them out and discontinued some of the original product lines

I have different fastenings to one or two planes that are questionable as to authenticity; they look as though an owner/user switched the knurled cheeseheads out for thumbscrews that tighten more easily and securely while one has slot heads with the knurling.

So we see that many things are silliley said and equally so in the making of things work. Pliers resolved the main problem by introducing a secondary one of lesser consequence. Many people toss comments over their shoulder (and I am guilty too) and walk away from the issue, taking no responsibility for expressed thoughts but poorly considered in that self-righteous way we have. Yes, I could wrap the locking mechanisms with leather or shelf liner inside the pliers' jaws, but that's not going to happen. I just use pliers where necessary but my good report on the Veritas plough plane of many years back, made in good faith, is now of course, negated by a fuller performance in practice. At the bench, after many slippages, I had to abandon the plane because it was not dependable. The pliers on the Record or Stanley work well and though I have done it for decades now, the knurling is still intact. I refuse to worry about the nickel-plating.

Comments ()