Signs of the Two planes

I bought two planes last week. One was brand new, the second was secondhand from eBay. The new one came boxed and wrapped in waxed paper while the secondhand one arrived well wrapped in a recycled and still recyclable second- or third-time used box with crumpled newspaper print as padding.

Unpacking the new Stanley came from me thinking I should not dwell on past Stanley failings but see if they are making the better #4s I have always enjoyed through six decades of working wood. I have several planes from the 1950s and 60s that I use daily in my work and daily for me is generally a six-day week.

Looking over the plane I saw several flaws. The frog itself was misaligned, the abrading of the sole and sides looked to be abraded with something like #80-grit.

Plastic handles, tote and know, almost always break in the winter of the temperature drops below freezing so I can never recommend any plane with plastic handles anyway.

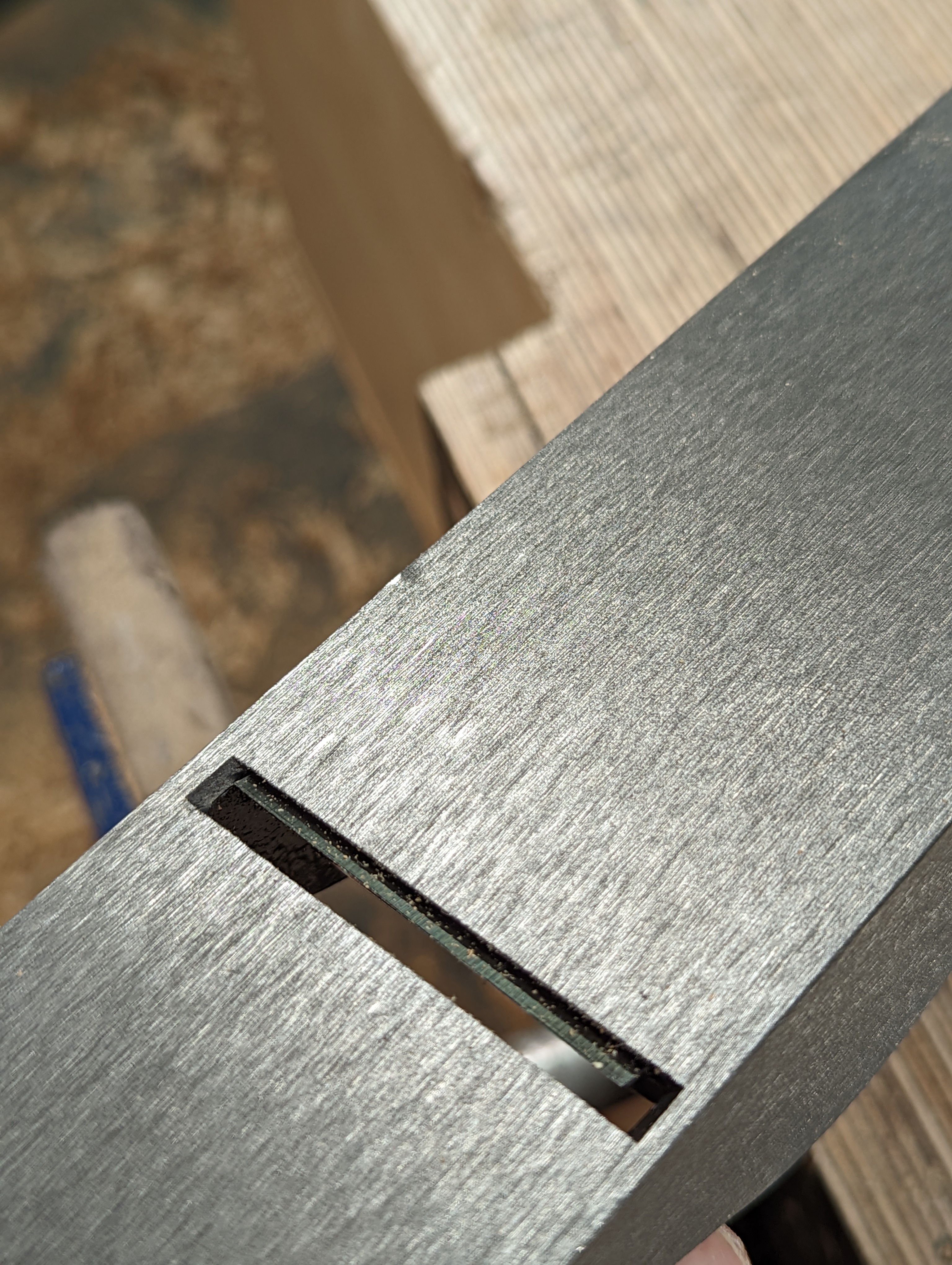

This plane came in at £56 and would need quite a bit of abrading to get it working and feel right. Would I recommend it? No! But more than that, the side of the plane had received some kind of impact that mushroomed the metal both on the side of the plane and then too the sole. I took some swipes with the plane and found half a dozen furrows in the surface of the wood caused by the indent. I'm sending it back. Additionally, these planes might give you the impression that they are still made in Sheffield, UK. They are not. One tiny rectangle affixed to the box as a sticker states UK Importer.

The joint lines along the plastic handles are much more distinct and stepped than they look. They will need filing level otherwise they will blister your hands.

This indent shown below doesn't look much at all but it badly affected the sole. It would only take a couple of file strokes to remove the swell on the steel but should I?

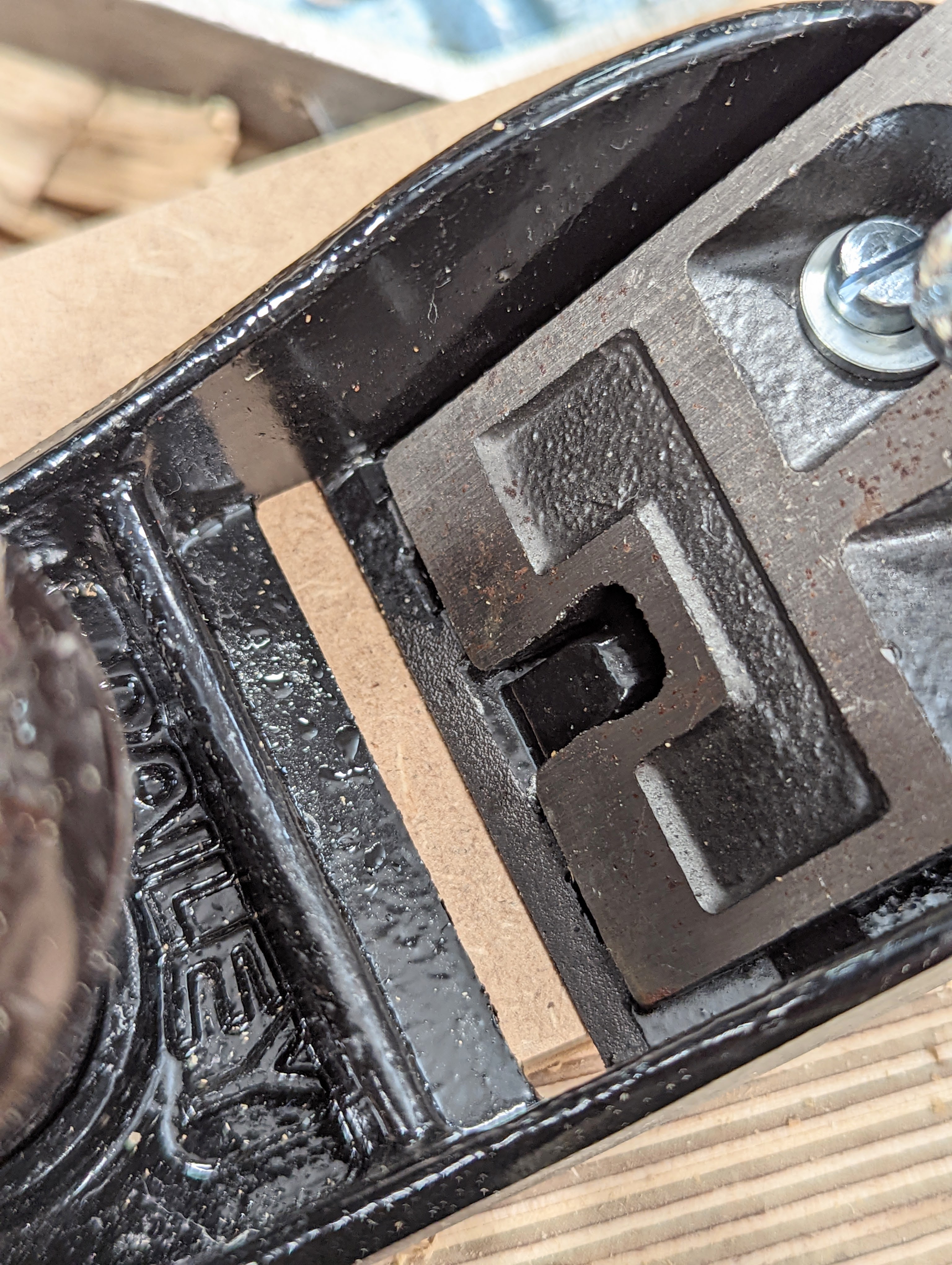

My second plane cost £16.85 and came in at £20 with delivery. All wooden handles, beech, not pretty, but a plane that would be in use in a few minutes.

All of the components are there and in need of no repairs. It has almost a full blade length so good for about 20 years if used six days a week full-time.

This plane was the better buy of the two planes. Metal clean-up, sharpening, a little sanding and some shellac on the handles and it will be a nice enough plane. That's less than an hour's work for a plane that will now last a lifetime for a 20-year-old. By the time such work is done the new owner, having gone this route, will be thoroughly versed in the Bailey-pattern bench plane. A good lesson starting out.

Conclusion:

Even though you can work on a new plane to 'break it in', and make it feel good, older planes carry the wear of previous users and the sweat-equity in used versions cannot be over-emphasized. It can take years to improve the feel of any new plane which can only be achieved through human hands working it. They just feel so different and so right in the hand. We are woodworkers and wooden handles can never be replaced with plastic or so-called composition handles. If they have some measure of discolouration or damage (other than cracks) they can almost always be readily revived with some minimal shaping, rasp work, filing and abrasive. Go to my blog and my YouTube for fuller restoration instructions.

Here is the rejuvenated plane after an hour's work. It works just as well as any high-end plane and will do all that it can and more. The sole was indeed flat and the cutting iron just needed sharpening and surface rust removal. For £20 including shipping, it was a good buy. If anyone ever tells you not to buy secondhand, ignore them; these are people who are scared to get out of bed in the morning. I have yet to come across a plane by Stanley of old that couldn't be restored enough to take perfect shavings within a few minutes. This one above took about an hour. And the very worst that can happen is you need to return it for a full refund including postage. Just check when you buy that they do accept returns.

Comments ()