In Praise of Record QR Vises

I have a few different quick-release (QR) vises installed on workbenches here at the workshops. Eleven workbenches replete with 9" wide vises opening to between 11-15" in all. Through the years the old Record vises have all worked to a consistently high standard alongside my many Wodens and a really nice Paramo No51 on Hannah's bench. Other good copy makers to look for from that earlier era are Parkinson, Toga, Rededa, Paramo and Marples, they often go for less money, but they are scarcer. Lesser quality ones are out there, some overpriced and some reflecting the cheaper quality in the price, but be a wary buyer.

The three workbenches I work from in the day-to-day are Woden and Record quick-release versions. I probably would not buy a new copy if I could buy an old version but there is an Eclipse copy that I have used with reasonable functionality. It's hard to say how long these will last because there is a looseness to the parts that will most likely lead to an excess wear you don't want in a vise. Irwin Record stretches the truth by a marketing boast as follows: "IRWIN, 133 years of ingenuity and high quality." when in reality they simply bought the Record name a few years back. If you doubt that these vises are one and the same as the old Records, you'd be right. They are Record in name only. The quality is not the same and the price is up there if it is not the Record-of-old quality: they sell their 'import' larger woodworking vises Irwin 52 1/2 ed with QR at up around the £210 mark. Remember. Import vises such as Irwin, Anant, York are of lesser quality even though they look and weigh in as quite heavy replicas, I suggest that you buy with caution. As with most lifetime warranties, the companies rely on 99% of people never making a claim. A one- or three-year warranty is of no real value to someone using a vise an average of an hour or two a week. And what is a 'lifetime' anyway? Watch out for reviews too. One I read said, "Wonderful beast of a vice, really well made and solid engineering. Can't wait to try it!" Many if not most of the reviews brag on weight alone indicating this to be the main factor for buying the vise which tends to be the norm. Whereas weight is a factor (Newton's law of motion), there's more to a good vise than mere mass and the weight issue can be adverse if the metal composures are not equal to the task as wear is the key failure when the metals fail in the mechanisms.

A little history can be revealing. Evolution always tells us things improve with the better educated, the more athletic and of course, with the better engineering --survival of the fittest, if you will, and in some ways, things might. Science gives us so much. Additionally, science gave us things that could be hijacked and pirated -- and most things are. The originator of the plastic bags so freely given out almost per item bought in supermarkets for decades are likely at the bottom of the oceans and all places and spaces in between. Science gave us both the bag and the investigations into pollution. `All things considered, improved life for a single species should always be weighed up against its consumerism and world economics against the cost to the remaining life beings. In most cases, one improvement cancels out the sins of the other until they come back to bite us. Read the following for my experience of the latter evolution of the all-metal vise.

Roughly speaking the Record QR is about a hundred years old. I owned a Taiwanese-made quick release 25 years ago that did not copy any make that I knew of that was one of the best I ever owned and used over a longish period. I was happy but then, guess what? A Chinese maker came on the scene to undercut the price of the Taiwanese one by half. Visually, on the outside, they generally all look and feel the same utilitarian way. It's not until they are actually installed that you can really test the action properly and it is here that you might feel rattles, quivers and shakes you would never have found on those vintage versions once made here in the UK's Sheffield. Tool-making industry. That Sheffield is all but gone compared to its former years of glory as the steel empire of Europe when the town, permanently covered in the belching smog of the fuller industrial years of steel making, made the vises we relied on for decades and centuries. Everyone went for the second Asian maker in China and the vises sold through distributors in and throughout the USA where everyone was demanding ever lower prices, and so it goes -- another and another came and each undercut the former both in price and then, of course, in quality. The problem with this was that with each iteration the quality declined ever so slightly and the really good maker went into some other manufacturing business followed eventually by the others. So it is with progress sometimes. None of the purchasers knew that their version would become the ultimate bad copy until after a year or two of very minimal and part-time use, possibly an hour a week or so, the flaws began to show with the threads in the castings that received the threaded steel tightening bar began wallowing out. The QRs stopped functioning and slipped because the necessary catch on the threads failed to take place; this was the same with Indian copies too. Where most of them are made today we no longer have any idea. This includes the Eclipse and the Irwin Record. If these companies refuse transparency it makes them hard to deal with for their reliability. But mostly it seems to be about creating something that looks the same but isn't. By the time the part-time user in amateur realms reaches a few hundred hours of use the vises are well out of the warranty period and in most cases, no spare parts will be available because somewhere in the mix the companies sold out to a takeover company with no liability. I have a Record vise that I have been using for 50 years to date and it was old when I bought it.

I think that it is worth saying now that most vises will be imported from Asian factories and some will come with the seller's name in the casting but side by side you cannot tell the difference between three or four so-called brands because it is the same maker making them. I checked two new ones I bought in yesterday and cannot see any difference between the two. One will cost you £150 the other £100. Most makers in Asia will put your brand on the goods if sales are high enough in volume.

When I started my first teaching efforts in Texas back in the early- to mid-1990s Record was in transition of ownership having been partnered with the Swedish company Bahco. Bahco didn't stay the course for very long and Rubbermaid muscled in for a season before Irwin Record took over to divide and conquer and then came the giant of giants Stanley Black and Decker who owns Irwin (and a zillion other companies). The rest is history but I say all of that because there in Texas in 1995 a rep came into the workshop selling old stock Record tools and equipment. He offered me a slew of Record old stock 52 1/2 Es for a premium price of $45. I still didn't have enough for the school and that brought the Saga of import vises as working knowledge for me to write from. What's changed? The reality of course is that I use my vises for ten hours a day every day and at least six days a week. I don't imagine that there are many readers here doing the same. If there are, we are now the rare and dying breed. Still, buy a good vise and you won't regret the purchase price. I personally think a vintage Record 52 1/2E is worth a few hundred pounds yet we can still get the secondhand ones for well under that price.

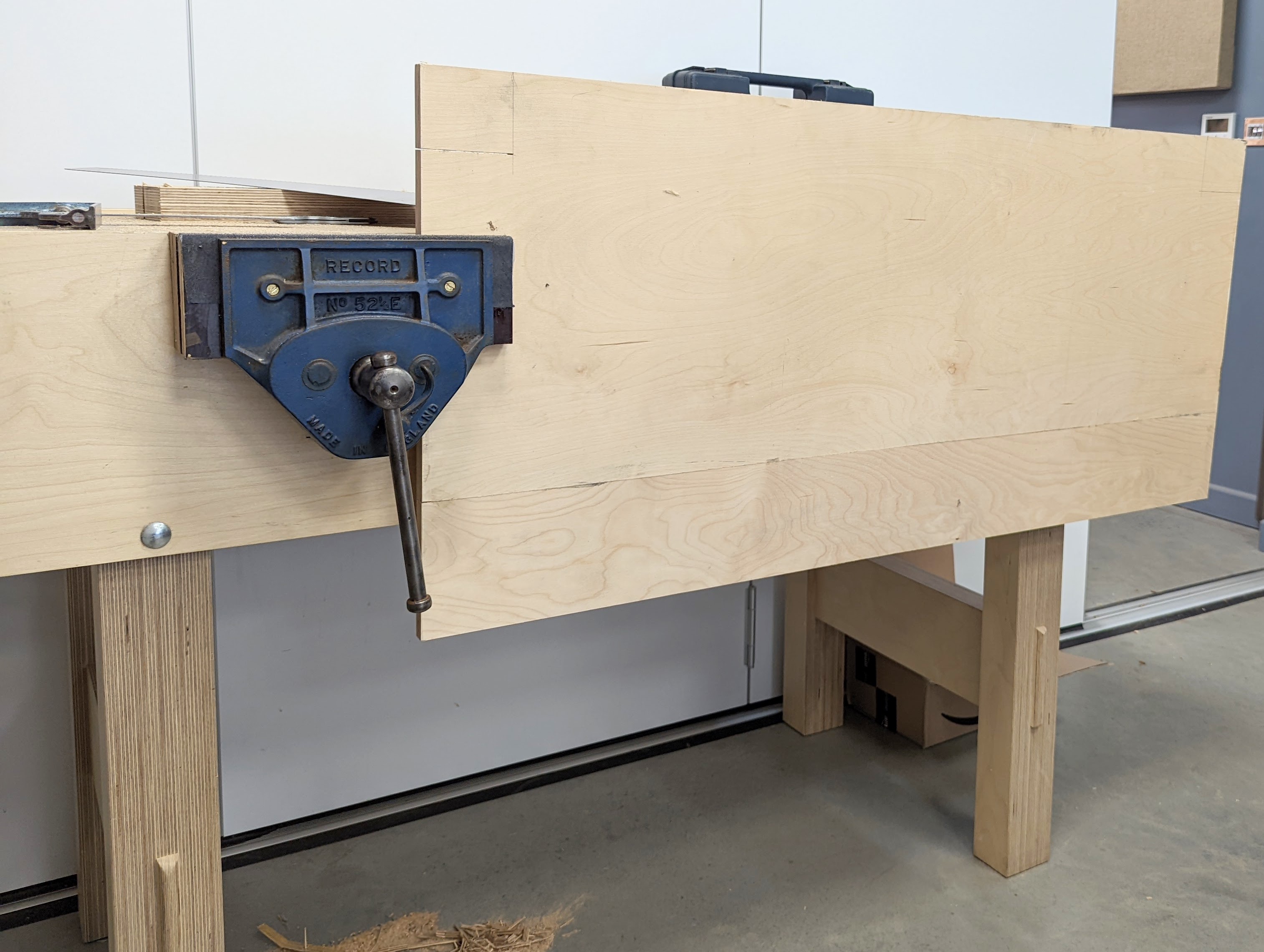

A good thing about living in the UK is eBay UK. Sellers on that platform are supplying vintage tools and equipment from an era of Sheffield making that is long gone and will never. Mostly this was the pre-import era when Sheffield goods lived up to a reputation earned through centuries of making and a domestic competitiveness that ensured reason in pricing. With those days now gone, eBay has become my best supplier for things like vises and of course suppliers of new tools and equipment also rely on selling via eBay as their so-called online shop. On one of my benches destined to return to my home garage, I had a Record vise but not my favourite QR. It's a great vise but I am used to my quick-release versions and would struggle without one because I use my vise six days a week. John knew of a vintage Record 52 1/2E (not to be confused with its littler cousin the 7" #52 QR -- too small for serious woodworking but a solid vise and really good for children's workbenches) for sale up the road here in town for just £50 so we went over and bought it. Now it's installed in one of my workbench for my home garage. Now I can get to my point.

John will soon be holding small classes and has been preparing the workbenches to that end. Along the way, he has been making sure all of the benches and vises are in top condition after being stowed for the last four years. Our conversations back and forth included staring into stripped-down vises to make sure the quick-release mechanisms fully engage, which means he has to come to know the vises from the inside out, more than just pressing a lever and sliding the front jaw in and out. This is really the best way to understand the mechanics of anything fully and his finessing these elements has given him a much fuller understanding of bench vises with quick release mechanisms. The more you do it the more you own the knowledge and our conversations are mostly surrounding what an amazing vise these larger Record woodworker's bench vises are. I also use a couple of Woden vises that are even bigger. Single-handedly, the vise jaw slides open from closed to over a foot, big enough for almost anything I care to handle in a vise for joinery and planing. I have chopped many many thousands of hand-chopped mortises in my vise through the decades and have never known a Record vise to fail me. If you are dogged about the front jaw vise having a vise dog you can make a channel in the wooden jaw liner and insert a piece of brass, steel or wood and that works as well as the metal ones if that is indeed what you want. Here's a link to a how-to post of ten years ago that might help.

Conclusion: If anyone disses a vintage vise by Record it's more likely that they are ignorant of what Record of old gave us. I suggest you can ignore them and buy a lifetime vise I doubt many others could parallel. In fact, any vintage vises made in Sheffield pre-Irwin days will be a good vise. Yes, things can go wrong, but these vises are really top-notch and with a little work restoration usually comprises minor surface rust removal from neglect. There will be many a thousand Record, Woden, Parkinson Perfect out there to be had that will give you a reliable version to install. Of all the vises I have bought secondhand I have yet to buy a bad one. The selling price will go up on eBay tomorrow for a little while but then it will steady down again. Never let anyone convince you that these vises aren't the very best and most practical of any and all vises. Great width, great depth and unsurpassable length with the single press of a thumb. This article comes from my 57 years of using quick-release vises and one of those vises for most of those years. It is doubtful that anyone out there relies on and uses a vise more than I do in any given day. I reiterate that even now at not quite 73 years old I still work 10-hour days six days a week. My boast is because I'm a hand tool woodworker and not a machinist so every single piece of wood goes into the vise for planing sawing and chopping. I still have yet to find any alternative that is equal to the comfort and swift functional holding power it offers: no wonder the quick release was originally called a quick-grip. Far more appropriate than quick-release as it is less likely to release quickly than give its sure and steadfast grip. Nothing has ever really come close to the Record quick release vise in my view.

This above wording describing the patent validation is taken from original text but, of course, this cover is more of a pain than protection and the guard was totally unnecessary. Open access to the threads ensured regular lubrication and almost all secondhand vises come without the guard because the owners and users took them off. Vises require regular oiling. For me, using them so much, it's about once a week. I think too that this is another example of an engineer designing and making something the user and the product never needed but came with the vise and became standard to it. Think thick plane irons, planes lying on their sides, Bed Rock planes and a zillion more.

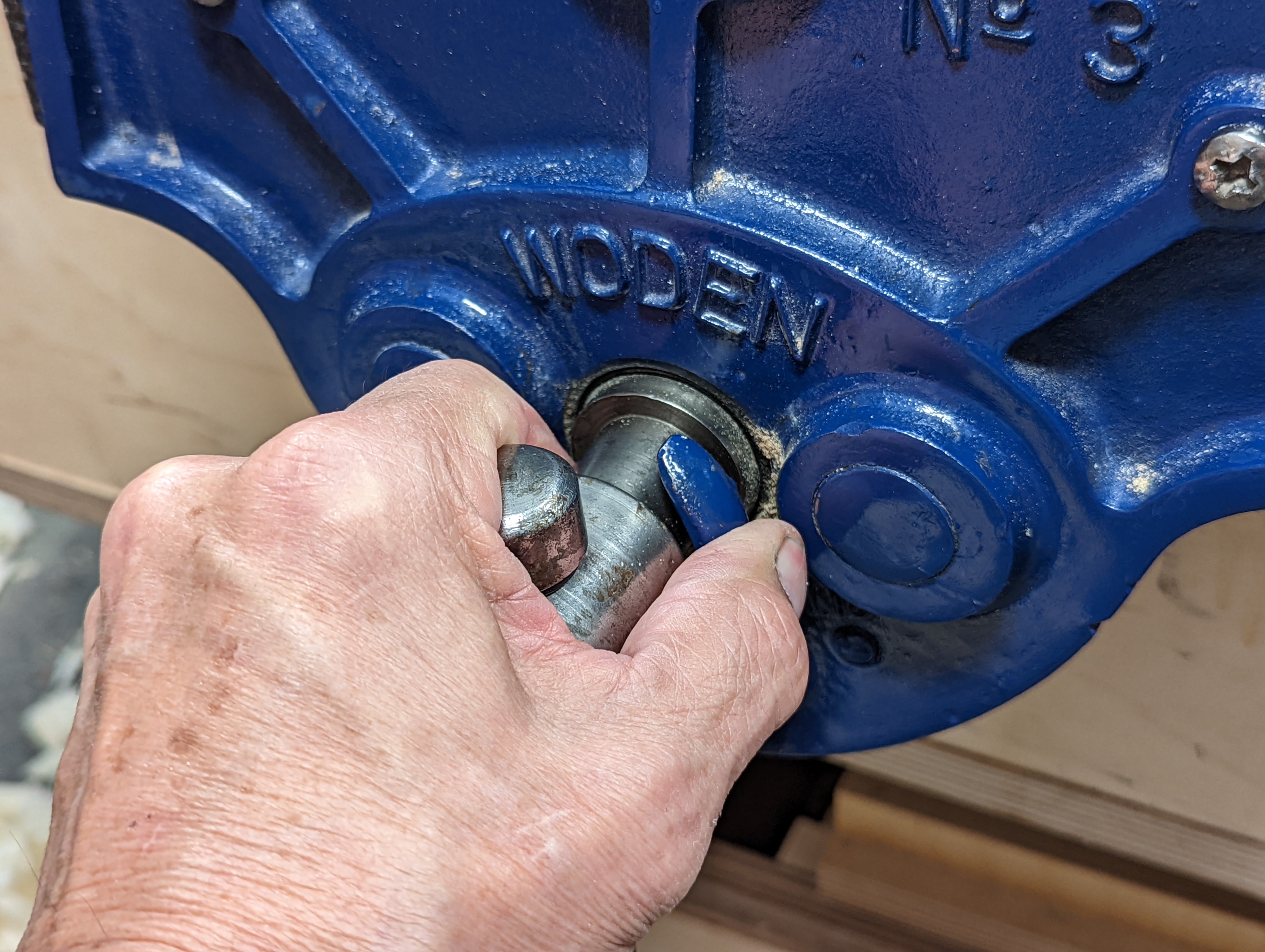

This is the screw thread on my Woden No. 3, uncovered for so many decades.

Comments ()