I remember

I remember Mr Cheapy arriving in his blue minivan, and I mean the true Mini minivan--two seats in the front, touching both door windows with your shoulders, and the meter behind being a flat-floored, tin-sided van with no frills, padding or anything else. It was always loaded with tools, many seconds quality with minor defects and I'd ordered my first Stanley #4 the week before for this Tuesday delivery, the day he always came each week. I watched as he checked down his list and lifted the orange box from several others stacked and ready for delivery. He slipped the box into my hands along with a Spear & Jackson tenon saw, a Stanley marking gauge and a Stanley combination gauge, all Sheffield made. Mr Cheapy had a pickup Mondays where he visited different Sheffield makers and suppliers and bought tools for him to sell to different trades, mainly woodworking. Tools were generally a third cheaper than shop prices and you could get what you wanted even if you had to wait a week or two to get them. I couldn't wait to try them. These were my first ever tool purchases. George had directed me. He stood smiling as I approached the bench. "Go on then, try them!" He rolled a two-by-four towards me and I tightened it in the vise.

Eye-balling the set for depth of cut was new to me. I'd done it some but was far from an expert at it. George watched me but left me to it. The plane jagged and jarred into the wood and left a perfect washboard finish on the wood. The wood staggered, the plane staggered and I staggered and George just laughed. It was then that the best lesson of my life ever began. In under an hour, my plane worked like his but minus skill. In his hands, the handles were dwarfed. He owned a #4 1/2 Woden, less common than Stanleys and Records, maybe a touch heavier in the casting. Until this time I had been borrowing his Stanley #4 and I'd got used to that as it was well broken in and had the smooth action of a well-used tool. It's not at all unusual for us to cling to our first tools . . . and our seconds and thirds too.

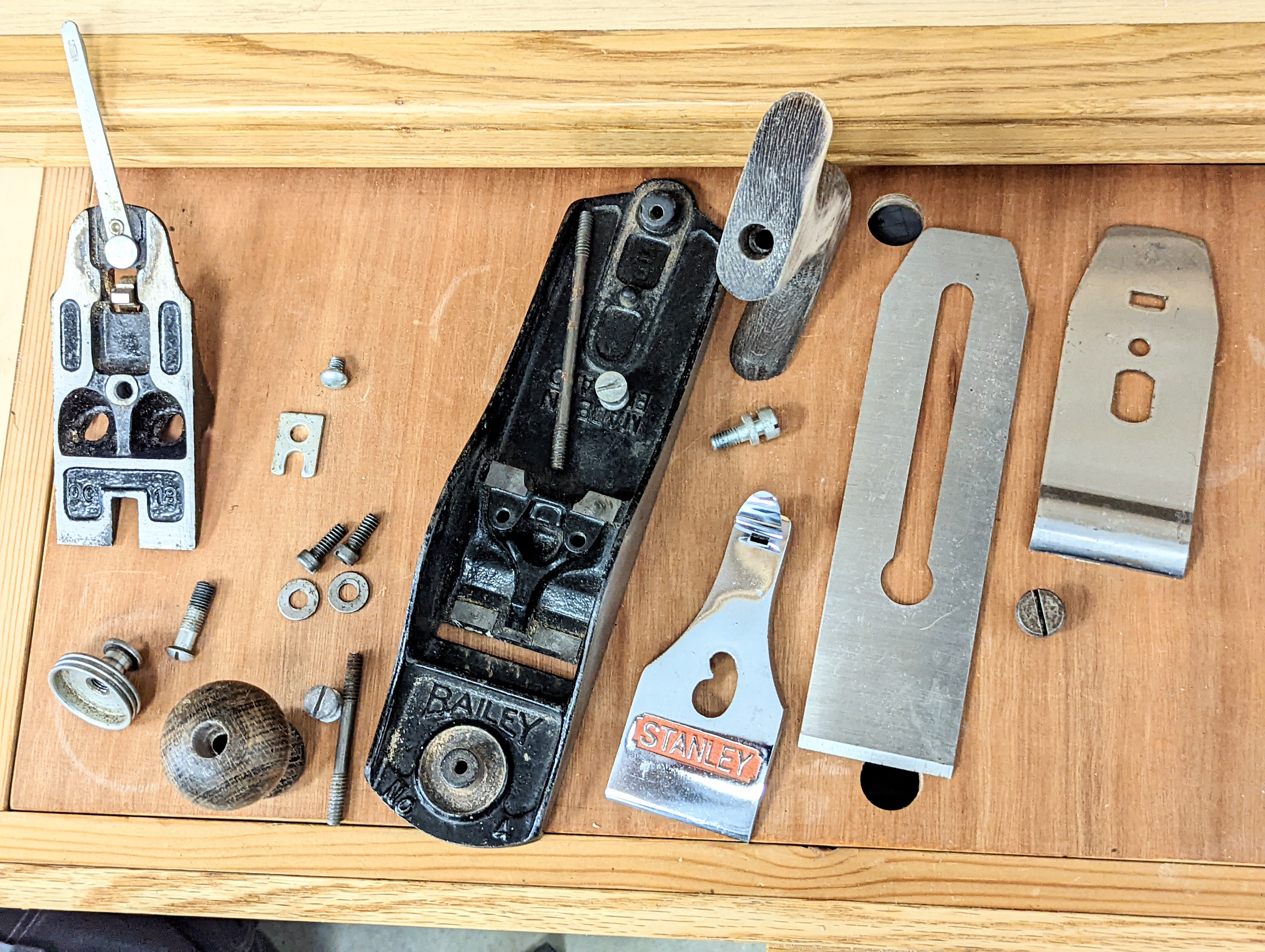

George told me to take the whole plane apart and then put it back together. "Every screw, nut and bolt off first!" he said.

The parts were all somewhat greased and the whole plane had been wrapped in a greaseproof wrapper with the name Stanley printed all over it in the brand logo. I used steel wool and oil to cut the grease and wiped all of the surfaces with a rag. It's hard to find the words for how I felt that morning as I lay the bits onto the rough benchtop. Sawdust soaked off the newly oiled surfaces and stuck to the plane iron and the cap iron, the plane sole, frog and screws. This reductive approach consumed my whole being and my confidence waned markedly. It's an approach I have used throughout my life, dismantling and reducing, its how we best learn about how things function, how to set things and such. Machines too. Living in near wilderness places (exaggeration) in pre-online days, dismantling a bandsaw or a planer was most essential. Realigning mechanisms, replacing parts, bearings and such, was essential-- it all started with a #4 Stanley bench plane.

To dismantle a plane is not particularly complicated but it does take something to believe in yourself. No cell phones to take pictures with, no Googling, just a pamphlet with a schematic and a low-grade print job. In my case, I had a George. All I needed.

When I began to teach others some 30 years later, I used the same system. I told 15 students to take their (my) planes completely apart and then reassemble them or sometimes they arrived to dismantled planes, I gave a demonstration on dismantling, assembling and setting up the plane and they followed suit. These planes were already fully settled and functional. It wasn't a restoration class but a familiarisation class. When I learned about various firearms it was the same. The best way to understand guns is to take them apart., clean them, oil them and put them back together There is more to owning guns than shooting them.

It was surprising how much the students knew and got things right in these hands-on workshops but then how many just got things wrong too. The most common mistake for planes was fitting the cutting iron to the cap iron the wrong way around. Some also tried installing the whole cutting iron assembly upside down. With spokeshave blades, it was the same. But I understand it. If you've never seen it, how would you know and why wouldn't it work?. Same with planes.

The obvious things are easy to remember. When George showed me the distance the cutting edge needed to be in relation to the cap iron (chip breaker USA, for some unknown reason), he wasn't showing me one thing but two. First, the distance, but then without words, the way the cutting iron faced the cap iron. Holding two parts in your hands switches on all of the synapses for most people. Tripping the switches that link everything together is mostly a one-shot lesson requiring no more reinforcement. "Anywhere between 1/32" and 1/16" George said. "On a wooden plane it's more." he went on.

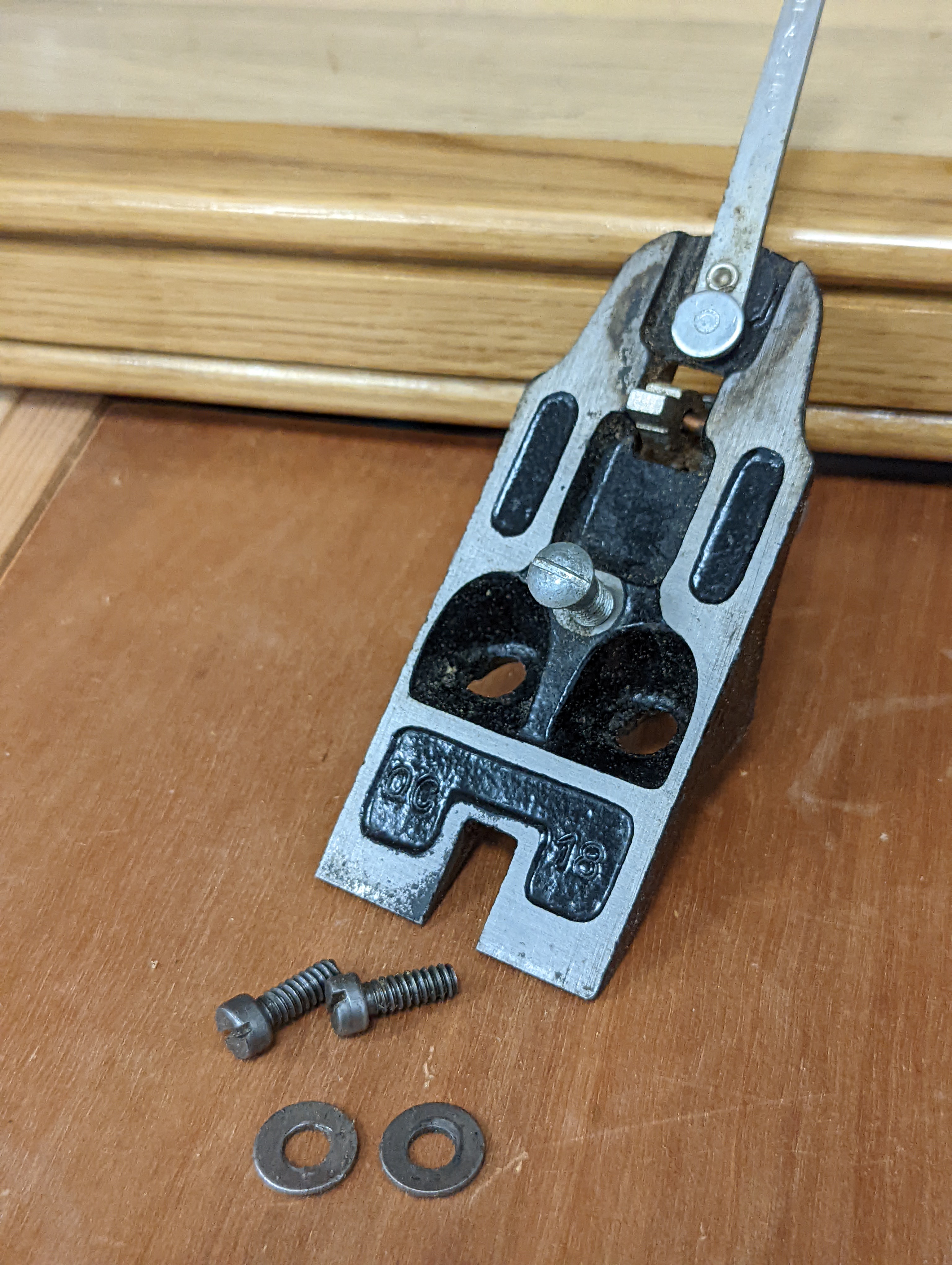

Reassembling the components was pretty obvious in that there was but one frog (the cast angled block that hosts the cutting iron assembly and lever cap and central hub from which all of the adjustments for the blade alignment and set take place) that could only fit one way into and onto the sole and the only component that has two identical setscrews with two washers for securing to the inside of the plane sole. Then there is the 'U' shaped slot for adjusting and setting the frog distance controlling the throat opening which had its single setscrew through into the frog and one into the sole for adjustment back and forth, so, once again, an obvious placement. Once these parts are bolted on the only other attachments are the plane handles fore and aft. George had me remove both of these too. Any other components revolved around the cutting iron assembly, which were all bolt-on components allowing for immediate quick-release for sharpening.

I should point out the absolute flawed thinking people have about BedRock bench plane soles and the main reason for users rejecting the BedRocks both when the design was released to the market and throughout the ensuing decades to follow. You see, the BedRock plane was less successful and for good reason. Whereas some say it was primarily the cost that put craftsmen off buying it, that was not the case at all. Four main reasons defeated Stanley in selling this plane over its Bailey-pattern cousin. One, the weight of the plane was heavier and especially was this so over wooden ones. We tend to believe that all metal plane versions were superior in several ways to the wooden ones commonly used for centuries but they were not at all. The fact is, woodworkers at the highest levels of craftsmanship produced some of the finest work ever produced using wooden planes. Two, and the main reason, was that when you adjust the frog on the BedRock plane you automatically changed the depth of the cut one way or the other. This is because the frog is set on an inclined plane. Two opposing inclines allowed the frog to slide up or down to open or close the throat opening for an ultrafine distance setting no one needs. The main advantage supposedly is that you can set the throat opening without loosening the frog from within the body of the plane but that alters the depth of cut and so markedly diminishes any and all advantage this feature might offer because we change the throat opening so rarely, and I'm talking possibly once every five years if that, there is no advantage at all. In actuality, you can set the frog of the Bailey-pattern planes without removing or loosening the frog of the plane anyway and it will not alter the depth of cut, you just need to know how. The third reason was of course the added cost over and above the Bailey-pattern plane. The very best of basic planes from the Stanley stable of the day remained the basic #4 plane by Stanley or Record which outsold the BedRock many times to one. It is still the best all-metal plane out there bar none really. so no one should ever feel that buying the less expensive lightweight model without the fancier frog produces any lesser quality of workmanship. It does not.

There was and still is much snobbery surrounding metal cast planes. I knew men in my youth enjoying a post-war period of more plenty in peace who from newfound wealth spent on planes more for status than functionality. They just enjoyed owning a Norris or a Spiers, a Mathieson or such that they rarely if ever used just for the joy of owning the greater scarcity rather than this or that being a better tool. Today's snobbery might be more from ignorance and false belief and it can be from simply owning something that is just well-engineered. My tackling these issues more vocally and from a platform that influences is to counter the false information that this or that £300 plane performs better than their less expensive counterparts. We should never confuse less expensive with cheap and neither should we confuse a lower level of engineering with poorly engineered leading to lesser functionality. I like the minor take-up of a couple of turns on my depth adjustment wheel and I have owned planes with lateral adjustment levers that flopped from side to side like a happy dog's tail. neither affected the plane's performance and I used them for years. So in our present age, we generally find marketers dissing one tool purely to sell another. Every maker of fine planes tells its buyers that this nor that doesn't happen to their planes because of something they did to prevent it when in fact the this or that never happened in the first place. This is a basic tenet of sales and marketing. I've met them at every show I ever went to and seen the blurbs in every catalogue. Please remember that ALL online sales outlets are good at selling and most selling is about being confident about knowledge. It does not mean they have anything more than head knowledge. Experiential knowledge is radically different and it doesn't happen by just using a tool for an hour or two.

I see nothing wrong with wanting a nice-to-look-at, well-made woodworking plane. As I have illustrated, the men I worked with kept their better planes under wraps and mostly out of sight year in and year out. The one plane-type hundreds of thousands of full-time makers relied on for a full century and more was the Bailey-pattern bench plane with the internal mechanics to each plane line being identically interchangeable so that one or two central control units could fit into planes of different lengths. `very innovative for its time and good for manufacturing costs, mass-making, etc. But people owning a better-looking anything is often to be more status conscious and not much deeper than that, that will never end, and if anything it is getting worse today than it was in times past. People involved in manufacturing and selling planes are excellent marketers and of course feeds the supply and demand needs of any consumerist society. With the minimalisation fo and in some cases the elimination of true craftsmanship in furniture making and woodworking generally, there is only historic works of reference to draw any comparison to. We've lost the middle generations of almost a century that stood testimony to true artisanry and we have been left with untruths standing in truths stead that lead to greater confusion rather than clarity. Owning a fancier plane with tighter tolerances does not automatically produce higher levels of artisan quality but it can be inferred that and dare I suggested by manufacturers that their heavyweight plane can give the results you wasn't for superb artisanry. It is mainly an artificial impression when you compare the work of two furniture makers making the same project with a Stanley and a Norris, Spiers, Mathiseon, Lie Nielsen, Juumma or whatever. The outcomes will likely be identical.

The way to test out our preference for a particular tool is try them out side by side for a period of a few days or even longer. Making sure that they are well adjusted, sharpened and set well, simply use them as much as possible and see which one or ones you lean towards as you work.. The one you reach for the most will likely be the one your body and mind are telling you you feel the best about. This is a good test for any tool. Anyone purchasing a half-decent Stanley or Record plane secondhand can fettle it in an hour and own a plane for under £30 that will outlive them if they use it every day throughout the day for a hundred years. So much was the humble Stanley plane disregarded 12 years ago that you could pick one up on eBay (as I did) for around £1 with a shipping cost of £2. We have reversed that directly through our output simply by telling the world, "Hey, hang on there just a minute!" and then showing people why we got what we did with the cheapest plane on the block. Subsequently, the price has levelled out at somewhere between £20-30 today on e`Bay and elsewhere. I just bought a very nice Record #4 for a lowly £28.50 with free shipping. The plane looks as though it was sharpened just the once in its lifetime once and used until it dulled, I expect. It's a seventy-year-old model with no issues apart from some very mild smattering of surface rust.

Comments ()