More than a Scrape

I scrape a lot, and I mean a lot and most days scraping is part of mu=y daily ritual in dealing with hardwoods like oak, sycamore, cherry, maple, walnut, ash, teak and so many more. Scraper is of course a misnomer for what a card or cabinet scraper is and I have never understood how the name became so fully adopted in the first place as this tool does not in any way scrape at all, it slice-cuts like no other edge tool and has the most sophisticated cutting edge of all the woodworking tools there are. I cover this extensively in my Essential Woodworking Hand Tools book too, how to create the edge you need to take care of every kind of wild and contrary grain. This cutting edge deals with everything you encounter and can be used quite locally with a simple flex of the steel beneath your thumbs or the heel of your hand. The question came to me as to whether the tool could be improved on and the answer is yes it can.

You can usually pick up a scraper like this for around £5-7. I just bought a Bahco 6" (150mm) by 2 1/2" (63mm) by 21g (0.80mm) thick for £6.42 with free delivery through Amazon. Often they are overpriced so shop about a bit. Amazon had the best prices for now. Better than eBay. I also found some Irwin Marples 5" there for £4.25 so the cheapest and bestest yet. But please, no one write in and tell me you can make one from a worn-out throwaway saw plate. Buy a proper scraper and amortize the cost over 80 years of daily woodworking. That works out at.02916 of a UK penny a day or 7/240ths of a penny a day. if you spend around £7 a pop.

The scraper I converted in about ten minutes max is a pretty standard 5" by 2 1/2" and .032" or roughly 0.8 mm thick. No need for thicker or thinner. It flexes just fine. These scrapers are mostly made from sharpenable high carbon plate steel which is quality steel with great spring so it can be flexed to task and retains its flatness no matter how much pressure you apply to it. The Irwin Marples is also cold-rolled, hardened and tempered to Vickers 470 so 47.5 Rockwell. I like both sizes of 6" and 5".

The radii are different for different applications and you can sharpen all for corner edges according to preference. use them interchangeably and you have a cutting strategy at your fingertips for just about any grain you might encounter. Radiussing your scraper edge is amazingly beneficial. To localise an area within a greater surface means you can flex for depth and feather out to the outer reaches so as not to indent the surface noticeably.

Scribe the radius onto your steel plate with a steel point marker. An awl will do it. Use an upturned bucket or can to a similar radius to strike the lines but don't go with too small a radius. I think for general surface work the 19" radius is the best.

Grind or file the shape to the lines. Takes two minutes.

Draw file the edge square or near to. Another two minutes for both edges.

Hone on a fine stone as per usual for scraper sharpening. I just sue the fine diamond plates. No need to hone to too fine a detail as consolidating with the burnished takes care of any deep score marks.

Hone the outside faces to lessen the burr. . . the burnisher removes most file burr.

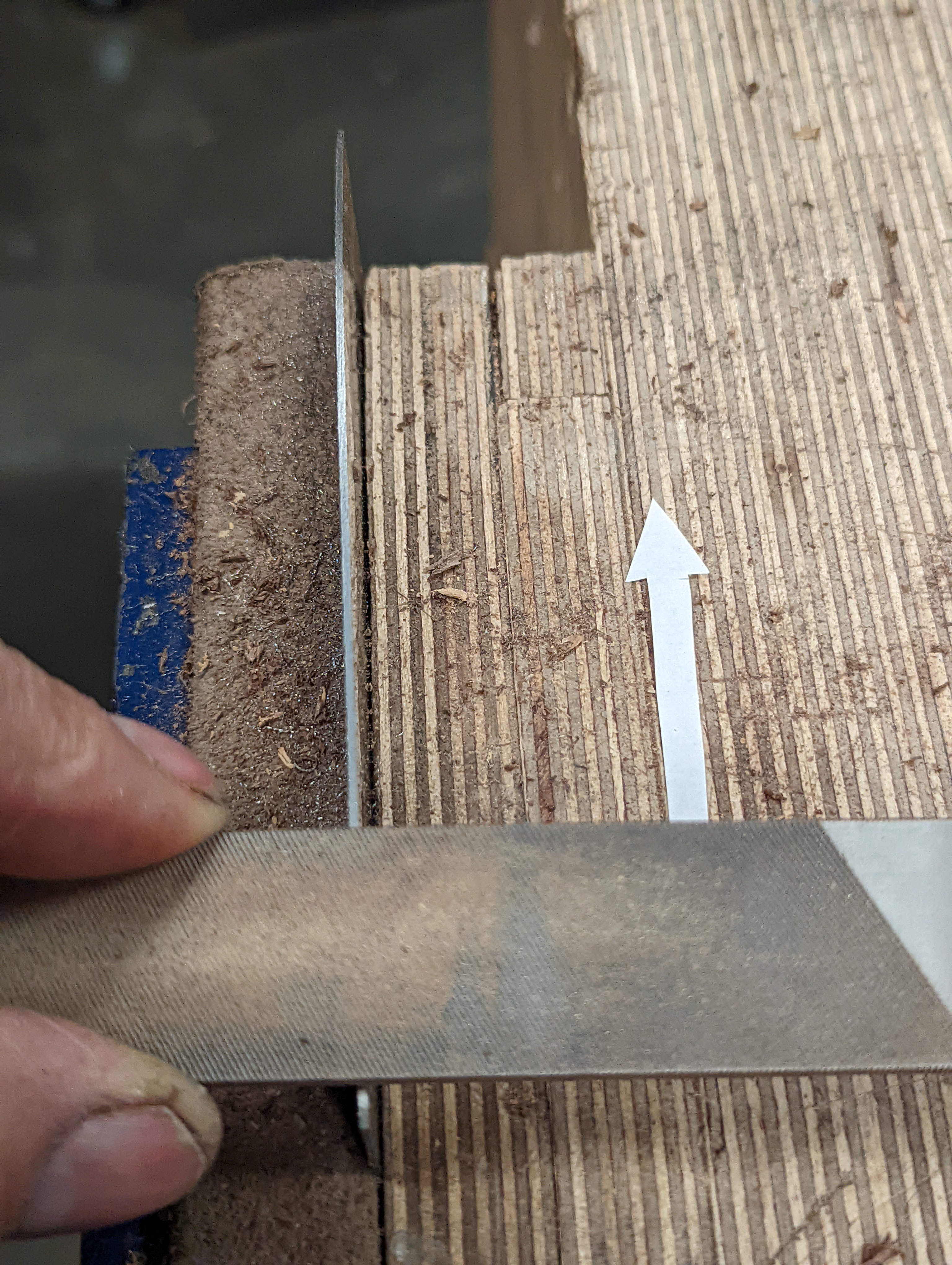

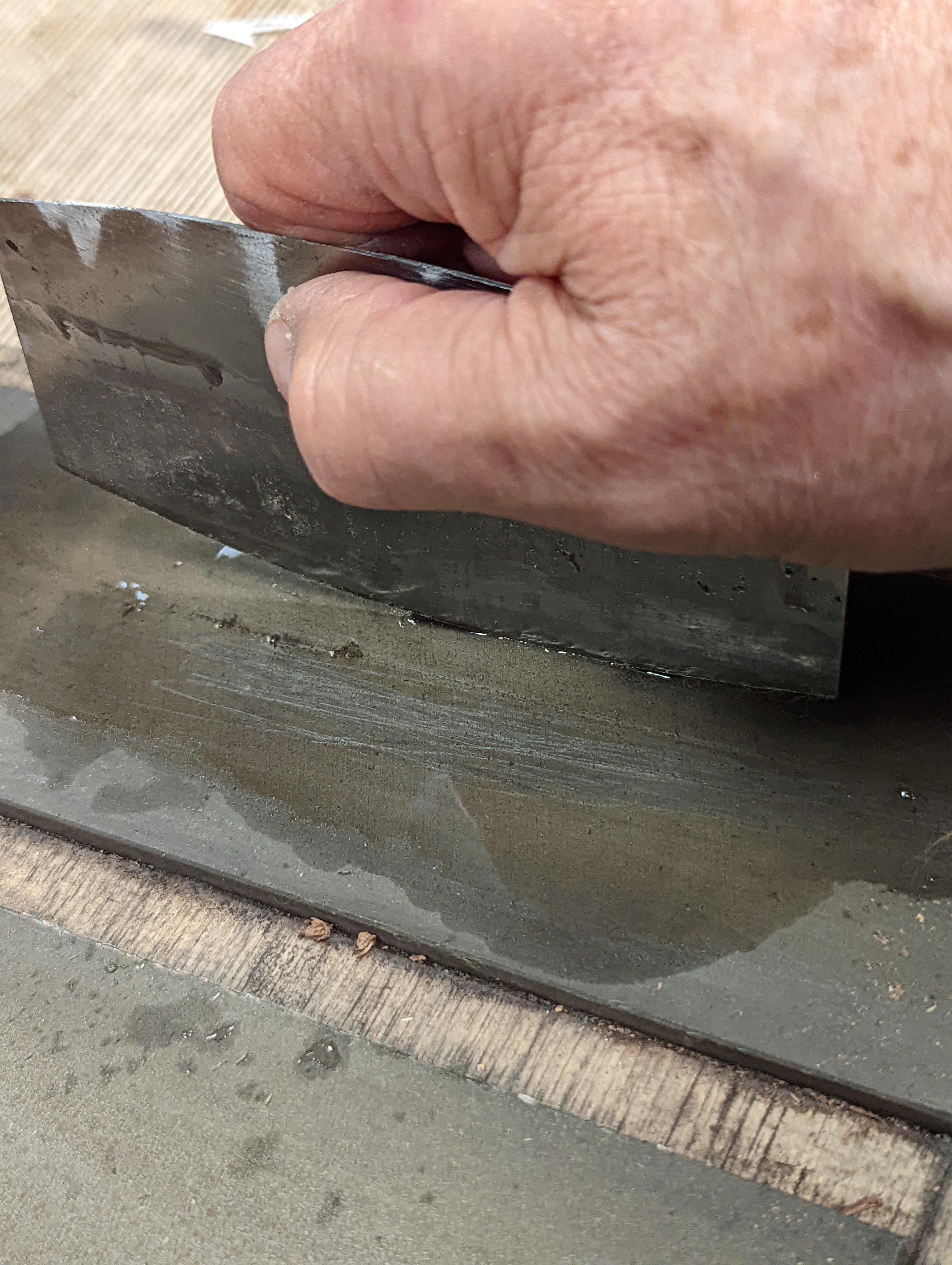

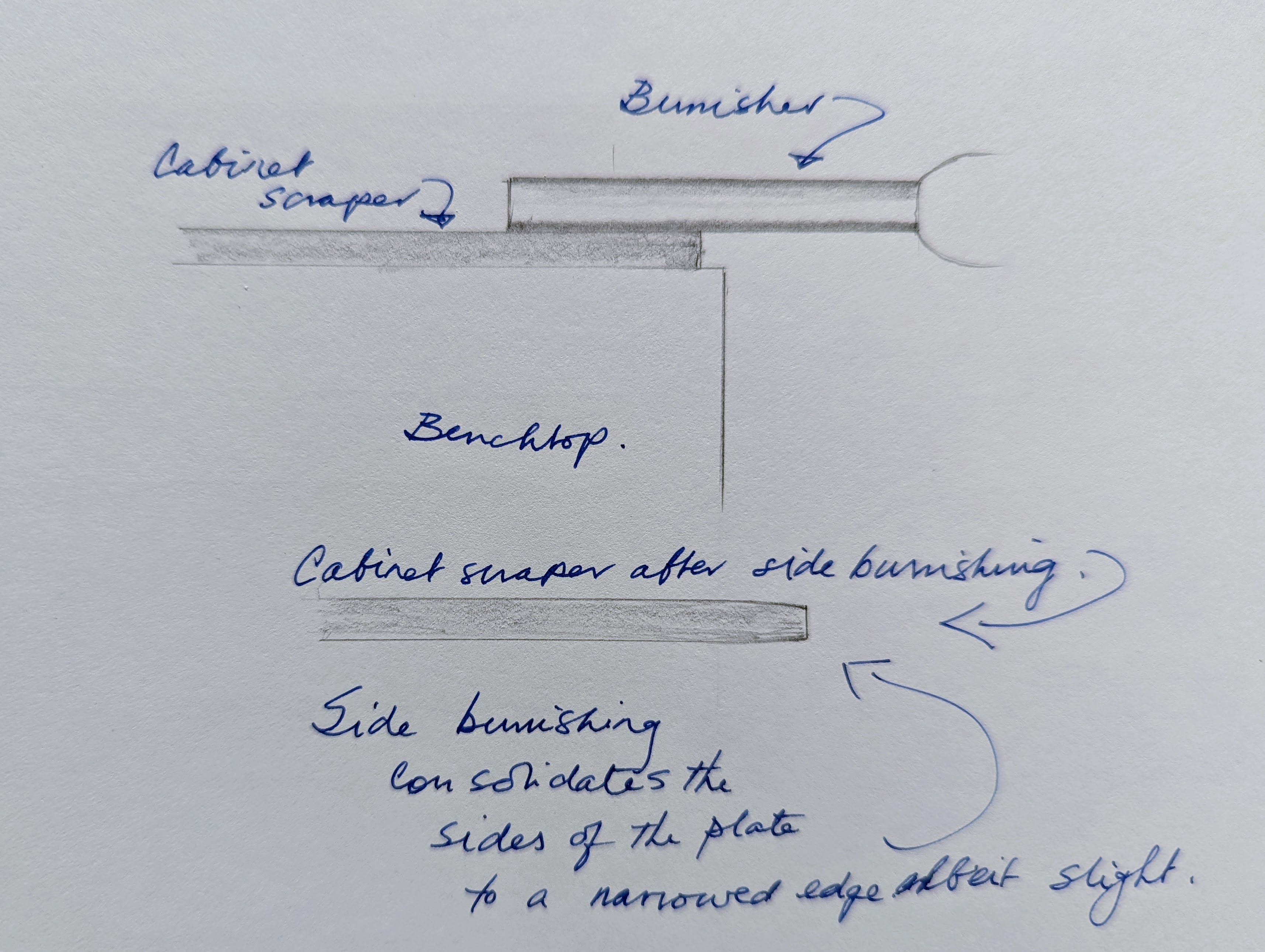

Consolidate both sides of the scraper plate on the benchtop 30 or so times. This sends the steel down into itself and also gives a super-polished edge ready for turning.

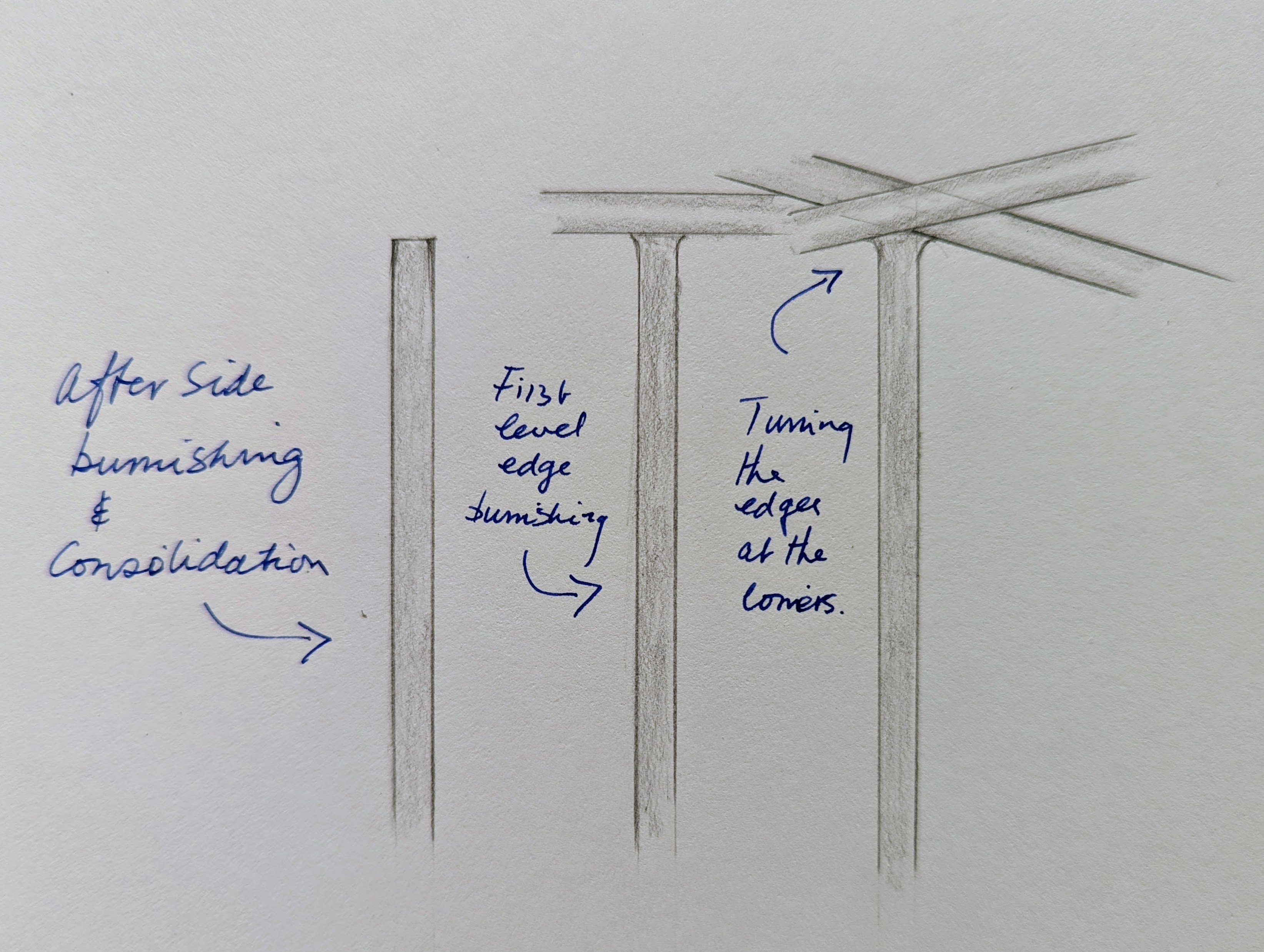

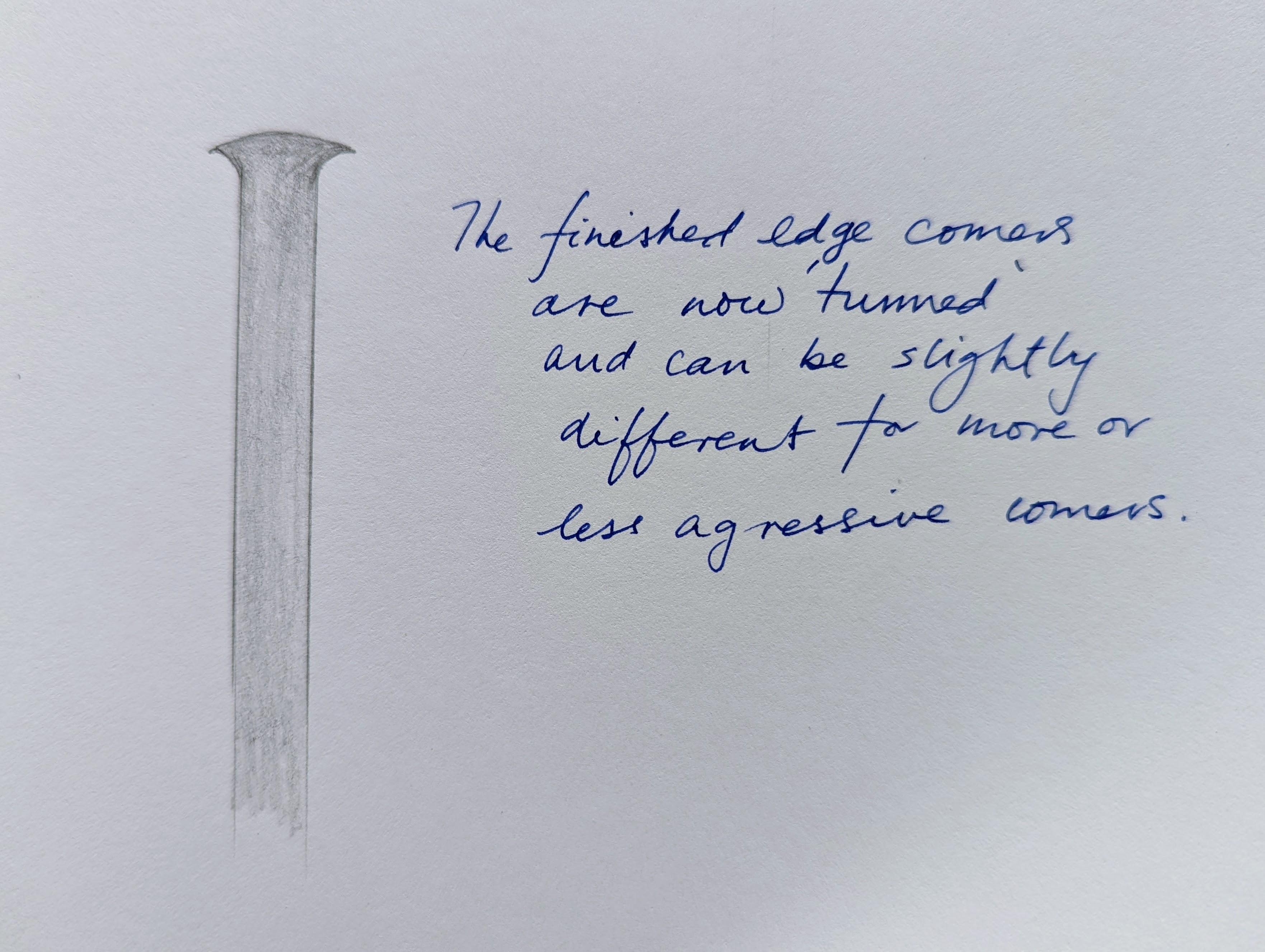

Consolidate the edge square across at first and then . . .

. . . angle the burnished over gradually so as to 'turn' the edge into the hook you want.

I prefer a light hook to one edge corner and heavier to the opposite in the same radius edge. That way I can go heavy and soft with the flip of the scraper.

The end result is a marked improvement on a flat scraper giving you the power you need all the way through scraping a tabletop and a narrow surface adjacent to other sections too. You might consider this closer to the equivalent of a scrub plane in relation to a jack or a smoothing plane. The 19" radius is quite aggressive but not too much so. The advantage in use is that it minimises the need for constant bending of the scraper as with a straight-edged version. so, it is much more user-friendly. If you want localised aggression for deep and significant removal of stock then make the radius greater by pressing hard to make the scraper more cambered. This will give you twice or three times more than a straight-edged version.

Comments ()