On Fastenings and Fixings

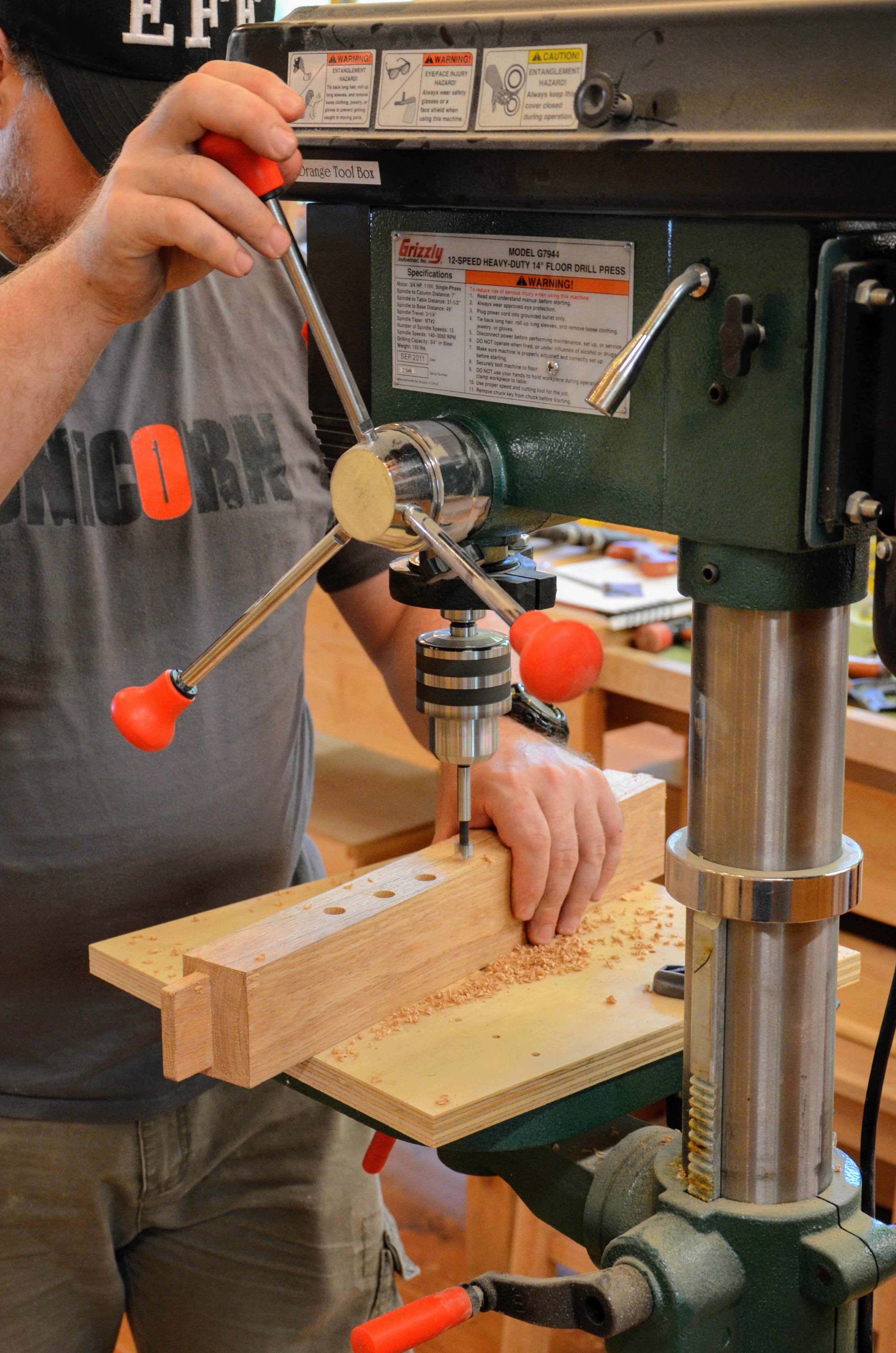

I think this is worth a visit. Some people suggest to others that Paul Sellers hates machines, never uses them and is a skilled craftsman who insists on using only traditional methods. It's not true, none of it. I am skilled though, and it is my skill that equips me to do things other woodworkers and especially machinists might shy away from. It's my work also that sets me apart simply because I never mass-make anything and never use mass-making equipment beyond my bandsaw and a drill-driver now and then. I have a drill press that stands idle for a month or so and I might drill a couple of holes with larger Forstner drills on occasions. Mostly it's not on my radar for use.

I use hand tools for my joinery, and in general, all of my work is indeed jointed with traditional joints, but then again not always are my joints traditional or perhaps not traditionally applied. I think that the braces I developed on the inside corners of my dining table leg are an excellent example. I have never seen this done by anyone nor seen its application used anywhere. On the other hand, I used fastenings throughout my new router plane and include threaded inserts in a couple of them to test them out. I liked the hold they gave me.

For my prototypes, I often use wood screws to pull parts together and to actually take off my angles from. See this blue bench stool! It has not a single joint throughout its construction yet back ten years or so ago I screwed and glued it together as a prototype. I then painted it to make it look nicer and I have been using it every single day since it first went together. It works just fine and in the scheme of prototyping, I had it together in under one hour just using ordinary woodscrews into the end grain of the rails. Is it safe? It is. Any of the joint lines [parted? No, not so far.

Whereas I most likely would not make a fine piece of furniture with just screws and no joinery, I have no problem using screws for elements such as turn buttons, drawer support rails and many other appropriate places in a piece. But I am occasionally asked for an alternative method when someone simply wants to not use screws or fastenings. I am not interested in this nor providing a time-consuming answer for someone working ore as a purist for pride's sake. Time and interest disallow this for me.

I think wood screws and even the recent developments are quite the remarkable invention. Spanning three centuries, these ubiquitous developments are forever evolving into ever greater products and perhaps this is where there might be a departure for me from the mainstream user. Whereas almost every woodworker I know uses woodscrews for speed and joining, I use screws solely for the pulling power they have to unite components either permanently or temporarily and also as a means of temporarily 'clamping' parts until the glue used between the parts has cured and secured the elements that will usually but not always rely on the glue alone for the union. Think laminations and such; where glue is used with screws, the screws can most often be removed and reused elsewhere in additional work.

There is also the appropriate use of screws depending on the work in hand. I most like would not use mortise and tenon joinery for a chicken coup or a dog kennel. Screwed components are more than appropriate and very adequate too. Shelves in my garden shed do well with screwed rails undergirding the shelves themselves as do brackets screwed together with an angled corner brace.

I am far from a purist in my work. I do not pursue the reputation of being so and you will never see me in any kind of reenactment or trying in an endeavour to take people back to before the Industrial Revolution. Pole lathes in the woods and in the workshop and for those who like to turn that way, I think that they have their place as do sandstone grinders treadled into action by two strong legs or an apprentice's arms. Most likely there are many ways to get rid of electric power on even machines like bandsaws to replace them with treadles or winding gears, but they are inefficient and impractical compared to the working properties of a simple electric motor with a pulled system for speed and power change. All in all, there is good reasoning behind woodscrews and fastenings and then joinery. I have always relied on and accepted both. I would never sell a piece of furniture held together with just screws though.

Comments ()