I read Woodworking Differently

I read a recent comment from a former student friend I came to know named Scott. Scott wrote to thank me for my input in his life by changing the direction his path was taking to go more for creative working with hand tools and away from power machines. Well, of course, it's humbling! Our paths into woodworking start differently for all of us and little did I know back in 1965 when I started my woodworking apprenticeship as a fifteen-year-old that woodworking could take me on so exciting a journey. What an adventure it's been that I would get to design and make hand tools and then teach my craft to others. Who was I but a nobody, unknown in woodworking circles, unpublished? Suddenly I decided to write woodworking articles for magazines and then my first woodworking book and manuscripts for many more. What about building furniture for my own woodworking channels and becoming a blogger reaching woodworkers around the globe? I never thought when I studied hand tools and hand tool woodworking that I would become a specialist in hand tool woodworking and be filmed three days a week to teach an audience of hundreds of thousands and even millions without any of that being my hope, aspiration or intention. I had no idea that I would design and make pieces for the White House Permanent Collection and a cello with my son, Joseph, the two most amazing works in my life. And today, that I would be sitting up in a leather chair excited that in these next three coming days I would close the chapter on designing a dining chair for sellershome.com, a house that will ultimately be filled with every stick and stem of furniture and woodworking that I have and will have designed and built from scratch using my own two hands using hand tools for 98% of the work.

Here is what Scott said:

Like many woodworkers, I started my woodworking journey thinking that I need all of the various power tools available to make anything. I busily and happily embraced this style of woodworking and made many nice furniture projects.

I remember going to a woodworking show where you had a booth and were demonstrating hand tool techniques. Being intrigued, I enrolled in a dovetail class and was hooked. This started my journey of using hand tools and has reached the point that just last weekend I sold the last of my major power tools. The only thing left is my bandsaw which will be for resawing slabs.

Paul, know that your philosophy and talent has been greatly appreciated by many, least of all me. Thanks for your words of wisdom and instruction.

It made me think, of course it did. Here is my reply:

Hello Scott. Thank you for your encouraging words. My life has had so many twists and turns not the least of which was a wonderful privilege of living and working in the USA. Living back here in the UK since 2009 has indeed left a hole in my heart not being there and especially in Texas, but then the whole of the USA. Every so often I will hear some Brit say something disparaging that starts out with something like, “Well, you know what these Americans are like . . .” And before they can get another word out I answer, “. . .Well, no I don’t and yes I do!” I then go on to say that, “. . . in my experience they are a nation of amazing people that can never be defined by anyone who has not lived amongst them. It’s a nation of nations and I love all nations because all nations are made up of the most amazing people !“

Another comment made me think too. I answered him with this that came from the bottom of my heart:

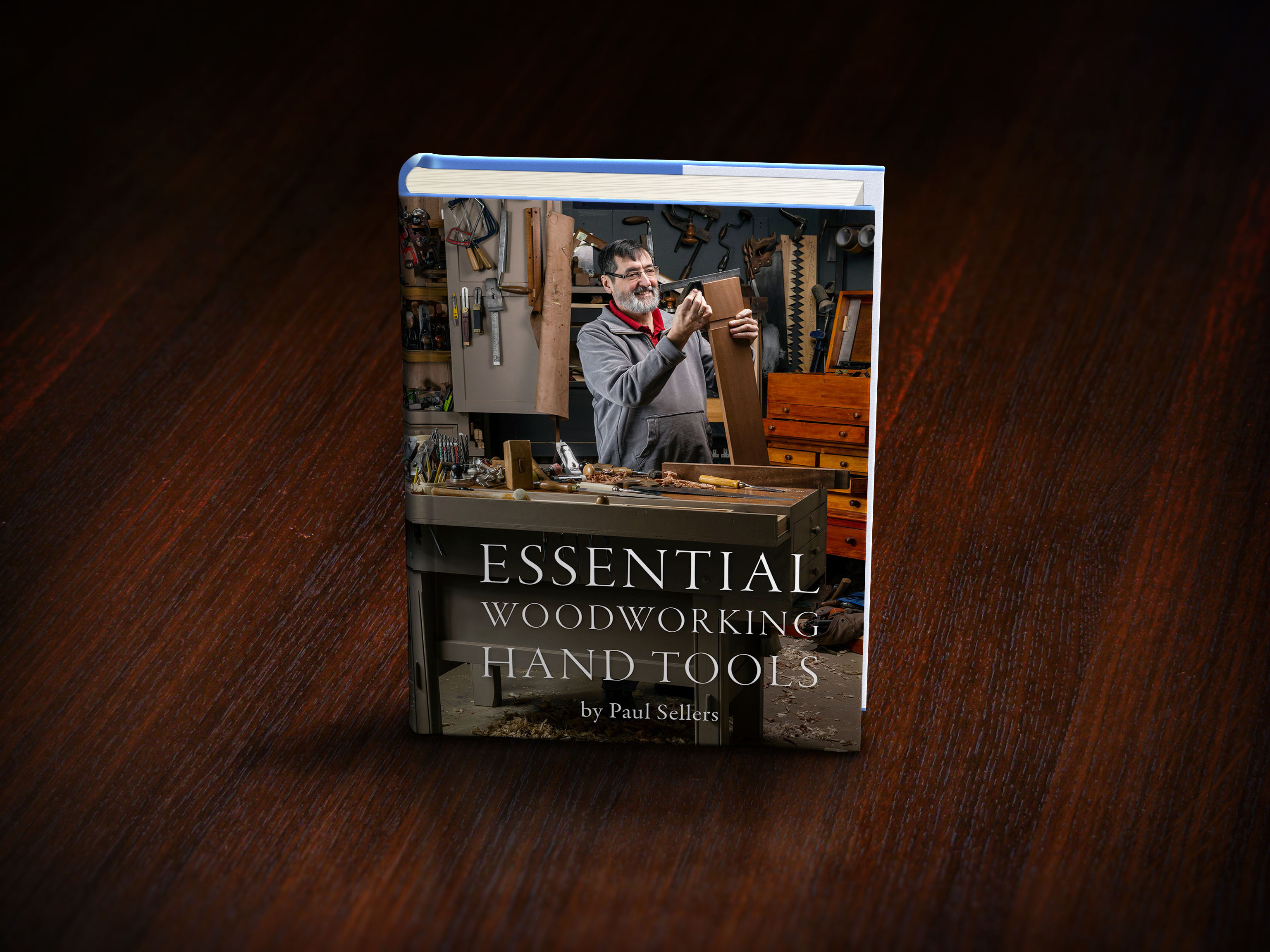

Oh, this is such an exciting point in the whole! Today, I will be closing in on the conclusion of my dining chair as I did on my router plane which so thrilled me a few months ago. These three-dimensional puzzles have come together throughout my life. Twelve years ago it was the completion of the two White House credenzas I designed for President Obama’s Inauguration that now stand in the Cabinet Room of the White House and I was standing inside the Cabinet Room as we set them in place on the eve of President Bush's departing speech. These recent additions mean as much to me as they did at that time. When I wrote my last book Essential Woodworking Hand Tools I was equally thrilled to hold that book in my hands for the first time as I was watching the first 10,000 copies being printed at the UK-based printers.

Of course, when I was just 15 years old I didn't know that I would take a lifetime of using those tools over 50 years later to write a treatise on each of the tools to teach and train others to use them from my background as what might well be one of the longest-term users living today, a user of them and not just a writer about them. This week has been a most amazing week of recollection for me. That re-collection of gathered considerations that woke me this morning at 1 am with such an excitement that I had to just write this blog only to say THANK YOU!

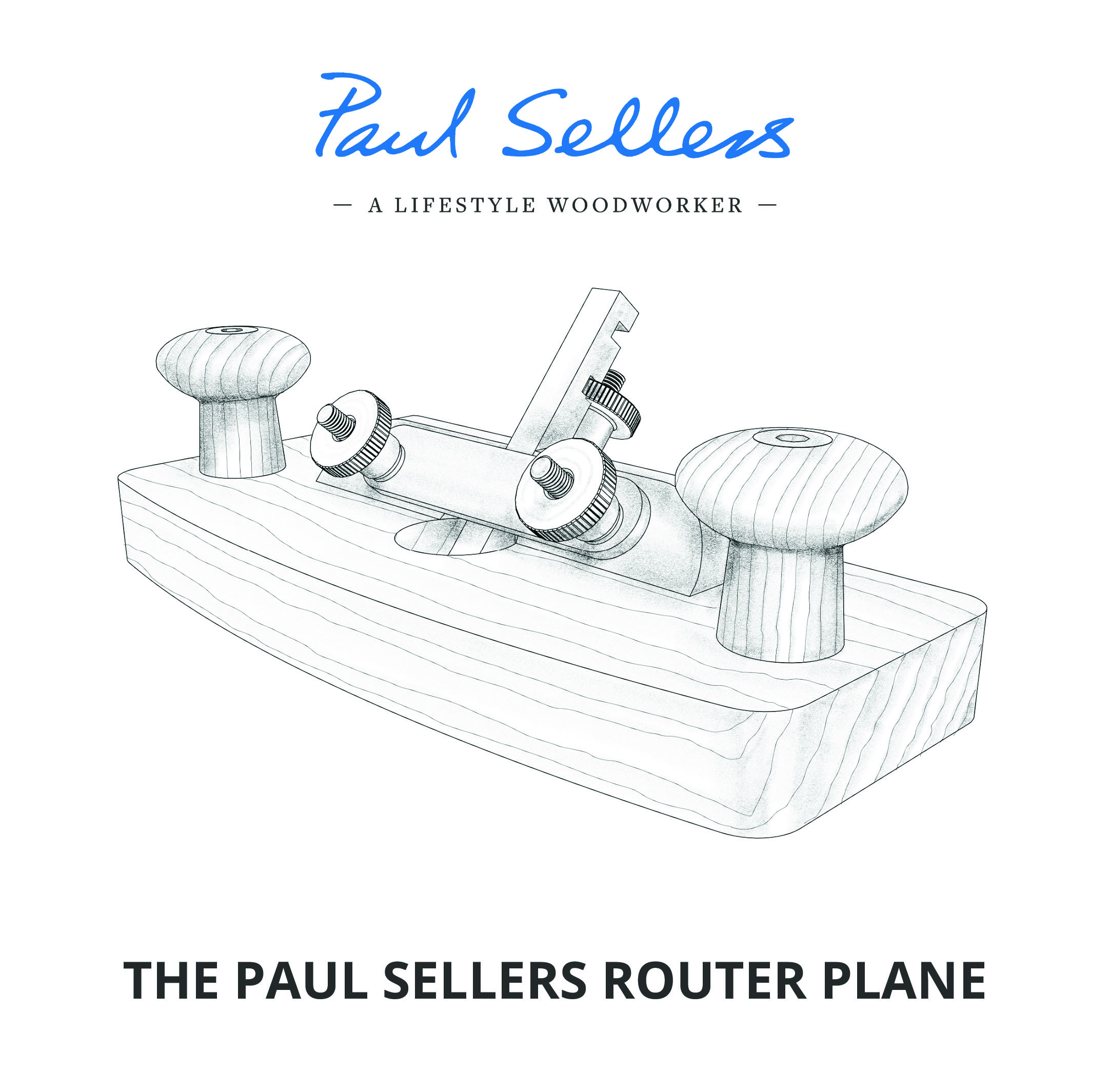

This week, the last and remaining part of my router plane pieces finally came together with the router plane blades being made in Sheffield by a Sheffield toolmaker to my specifications as I type here. This also is the close on a new chapter in that I wanted the cost of owning a router plane to come down to affordable levels. This began with a burden that I had indeed caused a problem by showing as never before how a router plane should really be used in more than just housings and dadoes by using it to surface plane tenons and so on. If you want to hear when the router becomes available fill in the form on this page.

I reiterate, this alone was never done before and ten years ago you could buy a Stanley and a Record router plane for £10 in its original box with all parts still there. Today they sell for upwards of £140. I had to do something because I had caused the demand to go up and the shortage led to a price increase that was prohibitive for most so I did. I have used mine now since mid-2021 every single day and this tool means anyone can own one for a quarter of the cost and it is indeed a better plane altogether even if what makes it better is that you can custom make it using your own hands!

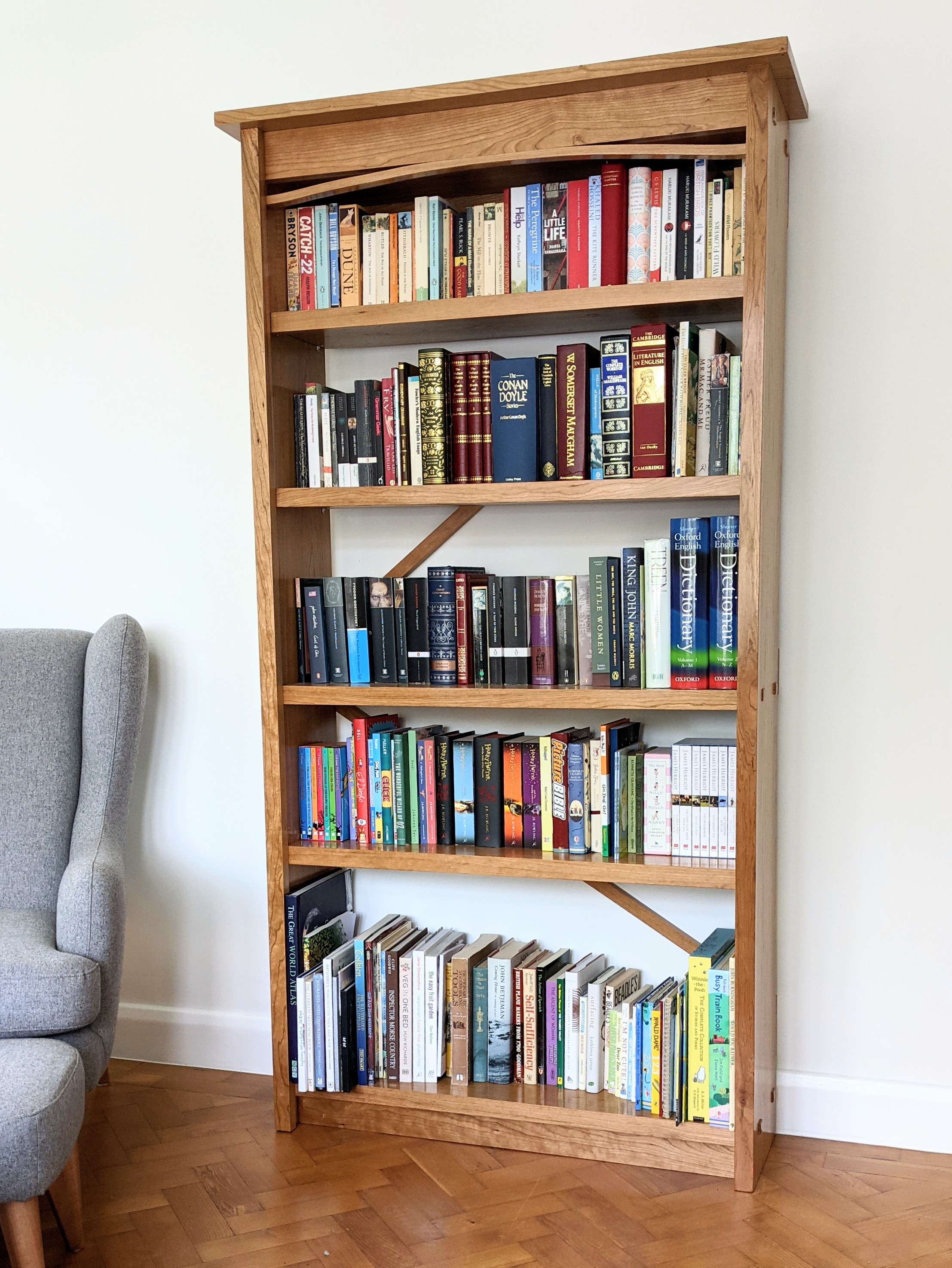

Sellers Home is my longest-term project yet because what I am carefully crafting by way of all the furniture and woodworking generally accepted as needed for a physical house built as an ordinary home in my native England is providing me with the vehicle to train and teach woodworkers from every background and every culture throughout the world. You can watch these videos being released each week on Woodworking Masterclasses.

Reaching millions of woodworkers was yet again a completely unexpected and unintentional outcome of my simply being a simple carpenter who thirty years ago started to see that his craft would be taken over by machine-only exponents who were indeed going unchallenged. Every woodworking show I went to showed only the work of woodworking machinists and woodworking machine manufacturers.

I decided that something had to change and I started out on a journey to teach woodworkers that left out skilled work and the development of skill could indeed add much more to their journey and it didn't need to be an either-or. From the beginning, I was well received by most woodworkers (with a few naysayers and scoffers mixed in) and that was because I offered what they were really looking for all along but could never find in the confusing world of woodworking. How do you sharpen a saw, a chisel, set up a spokeshave to work well, and then too turn the edge of a card scraper? What techniques does it take to use them effectively and efficiently and how do you restore an old Disston saw anyway?

So here I am seeing success after success as a mere joiner from Stockport, England piecing this amazing puzzle together in the crafting not only of a houseful of furniture for sellershome.com or pieces for the White House but crafting the reality of what I once coined the phrase of as the new-genre woodworker or the lifestyle woodworker. Riding over the crest of a hill in Texas 25 years ago, I think it was around 11 pm at night, I asked myself, "Is this really working?" and as I reached that crest peak I saw a huge billboard ahead caught in the headlights with massive black letters on a white background that said quite simply in block capital letters, "IT'S WORKING!" Of course, I had no idea just what was working but I felt spurred on by the answer I took it to be.

Not only is it working, but it has also worked, it is working, and it will continue to work? Why? Because this IS the continuation of an unfolding strategy I call real woodworking at its best and it is the biggest apprenticeship strategy I ever launched in woodworking bar none!

Comments ()