A couple of Things

Welcome to a new week, everyone.

I am not sure if I have hand planed quite so many pieces in a single week for a project series as I did this week. I admit that this to some seems a waste of my time when I could use power equipment (if I had it and I am glad I don't) and some do indeed criticise my projecting that hand tools work so well, but time restrictions curtail those working in the so-called "professional realms" in "the real world" and so on. I accept that machining wood is better for those earning their living from selling carpentry and some joinery, but then there are those of us who hate gyms, running on concrete sidewalks and then simply the boredom of exercise seems all the worse for wasting the time we can spend doing woodworking and at the same time getting our exercise by good, physical work. I am grateful that I can do both in my own specially devised 'gymnasium' where bench presses have a completely different meaning and comprise clamps and vises, squats and much more using the weight of a balk of wood or straining at sawing and planing in consistent measure and such throughout any given day. Upper body exercise here builds only usable muscle and without excess, keeps the joints supple and working and, of course, the heart and lungs are pumping incessantly, often at speeds I cannot muster the same levels of enthusiasm for that I get from making something that will be both functional, useful and beautiful beyond a few bulging glutes and big guns.

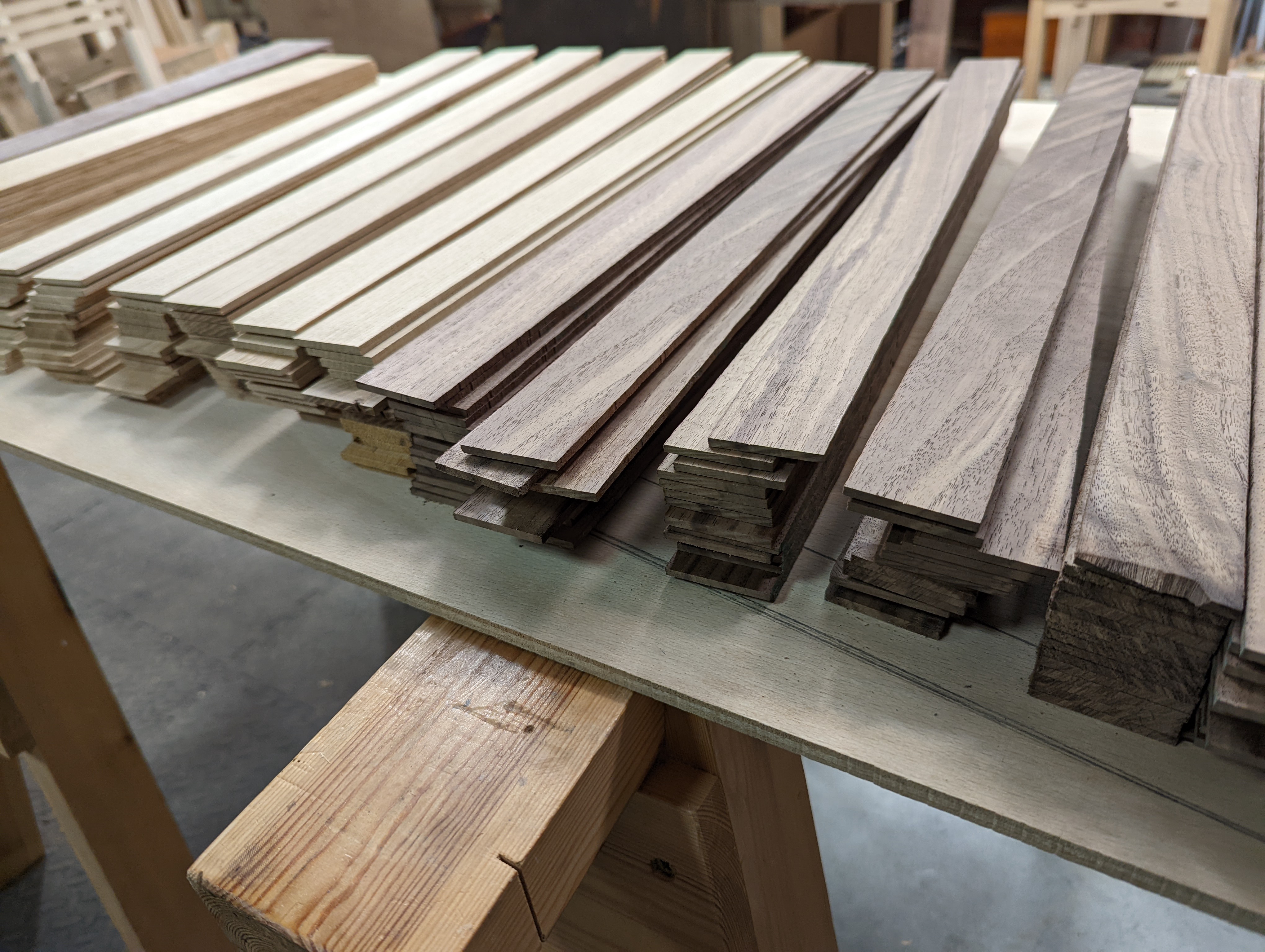

128 pieces and various section sizes of wood go into each of the eight chairs I am currently working on. I was amazed that my plane edges hold up so well planing both oak and walnut. 95% of my planing follows my strategy going from scrub #78 to scrub#4 to #5 1/2 and occasionally my low-angle Veritas Jack plane where I have added a steeper-than-usual bevel to the front of the bevel at the leading edge of the bevel-up plane iron. This is to deal with some of the ultra awkward grain in the walnut figuring I didn't expect from outside appearance so came as a bonus. I mention this Veritas plane because of its superb blade alignment features that keep the blade aligned along its long axis of the sole and the registration of the depth adjustment which is amazing even after removing and sharpening. When I reload the blade there is barely any discrepancy between what I had previously registered for depth and alignment and reloading.

I have filled six 100 litre bags with hand-planed shavings this far in the chair project. This workout alone leaves me feeling fit and happily healthy at the end of the day. This morning I planed up the last few sticks of wood for the batch of chairs. Now I am not pretending this was easy work but I would not swap it for using a power planer or a gym for anything. Why? Well, at 72 years of age I feel about the same health-wise as I did at 45 although I did always have a machine shop too. Had I not chosen this path I believe my health would be like many of my age and much much younger who are not in good shape at all. Most woodworkers these days will not realise that although we had machines of every type and size as an apprentice, we always hand planed and scraper-finished every surface of every stick and stem before, during and after joinery. I don't think that I have ever seen that written down. Handwork in high-demand craftwork like mine thus far has proven to be the very finest exercise I can imagine. It is evenly distributed throughout my life and throughout my days of woodworking now and it makes me feel unreasonably happy still.

So there you have the first two things I find of great value -- the quality of healthy exercise in the way of my working and the use of the additional plane by Veritas, a plane I have owned and used for 15 years. Yes, to some these are both luxury items and perhaps I could do without both. Hmm! I wouldn't though.

What next? Well, I do enjoy owning my lone machine which is my bandsaw. I use it for every kind of resawing and shaping and currently, with eight or so chairs underway all at once, and replete with arching, shaped back legs with tapers, etc and many a dozen linear feet to be ripped per chair, there is a lot of ripping to be done and all with heavy cuts to boot. Anyway, I have two, one for me alone to use in my garage workshop and another in the general shop where I mentor the three emerging woodworkers that work alongside me, Hannah, John and Jack. I couldn't really spend so much time resizing my wood by hand and do all that I have to do in a day. I mean we're talking over 700 cuts 1 1/2" to 3" thick with a handsaw for this series of chairs. Not too practical. But, additionally, these three need their wood sizing and so on too. Hannah is currently working on a commission for a dining table, jack is honing his skills making a couple of wall-hung spice racks and John has several pieces on the go all at once. He has been using some teak he redeployed from a vintage desk so he has made a couple of nice boxes for small tools, etc.

My bandsaw kerf removes just under 1/16" of saw kerf and leaves a finish that needs only minimal swipes with my bench plane to get a pristine, glass-like finish needing no further improvement especially by sanding it machine marks. That's half of the waste of a tablesaw and a considerable waste at the current price of hardwoods. My bandsaws are both 16" versions by the same maker in Taiwan (95% of all modern bandsaws are made in Taiwan even if you think they are not) though sold under an old British maker's name. They do all that I need. I took time and tightened up on all of the tolerances to keep everything fine-tuned in the cuts. This is well worth doing and for the pristine cuts I needed I installed a new blade from the start. With a single blade, I use one I love from Tuffsaws UK, which I can thoroughly recommend, I did cut all of the slats so for under £15 I think that that is excellent economy and quality and the blade seems to still be cutting fine and easily without any deviation from the path.

The bandsaw blade I recommend is their Super Tuff Premium Band Saw Blade 1/2" x 3/4 Vari-tooth pattern. It gives an excellent cutting speed with quality. I have cut wood 7-8" deep in every wood with no problem.

Comments ()