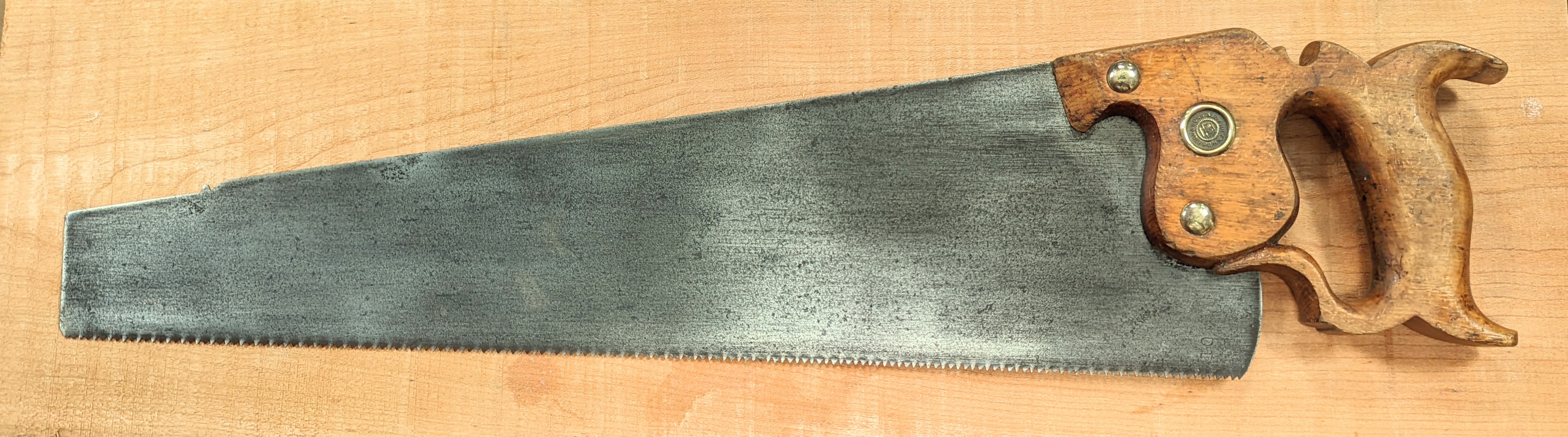

Disston 18" saws

Look for any handsaw anywhere you like, new or secondhand, and the most common length is around 22" with others going up to 26" and very few less than the 22" I mention. In my daily use, I still rely on the Spear & Jackson I have recommended over recent years. It takes and holds a good cutting edge, costs peanuts to buy new, and requires only five minutes to get it to work like the best of premium saws. V+Conver the handle as I have and you have a winner destined to work for a lifetime of comfort and functionality.

I am never sure why so few short handsaws exist in the world but this reality makes them more collectible and I have gathered together several 16" rarities and own some less and some a little longer. I don't follow them on eBay but occasionally I will glimpse one that draws my eye. You become conditioned to spy them out. In my case, it is mostly the Disston shorts I have always loved the most, the ones they made with oak handles. I recently saw a cluster of three saws, all Disstons, offered with a low-grade picture on eBay. My eye caught first the colour of the handle and then the shape. But what drew my eye the most was the length compared to the other two. With no close-ups and minimal description, I went into the purchase blind and followed my gut feeling. I was buying something less than 20" long, or was I? I posted a sniper bid of £27 for the three saws and home to me they came a few days later. I was very happy that the saw was a scarcer 18" Disston with the oak handle and there was no pitting in the plate.

The saw seemed to have been dropped on the horn and there was some minor cracking in the handle. I have learned to really value superglue for repair work on many things. It's an amazing glue that can also be used as a filler and it is very permanent. the saw handle with the damaged horn is very uncomfortable on any saw and will readily cause a sore spot on your hand if not corrected. The horn was almost complete but fractured. Adding thin superglue first permeates the loose fibres and wicks all the way in because of its thin viscosity. I drizzled in a few drops and left it to do its job.

Next, I added sawdust to the wet surface and the reaction between the glue and the sawdust sets up rapidly. Repeating the process builds up the surface level in several applications until it came above the surrounding level, allowing me to rasp the shape I need for a continuous surface. My handle was ready for filing, scraping and sanding. I can colour the finished shape so that the repair disappears but I for now I will leave it.

The saw teeth, 10-point, are well shaped but well worn and past their use-by date. I topped them with a flat file and then filed them to a semi-crosscut pattern so that it will work well as a rip- and a cross-cut saw. I cleaned off the grime of a few decades of unused and then oiled the plate.

I cleaned off the handle and waxed it with furniture polish. Now it feels like a well-loved saw.

You will see me using this saw into the future and I am looking forward to this.

Comments ()