Life Changes

It would be wrong for me to give the impression that all we (I) do is inspired with a dynamic that has a power to carry the idea as a concept through to actually making something happen in its three-dimensionality. Inspiration is mostly an idea you have about something you want to achieve that goes beyond just the bright idea, thought, or dream to a place of actually making it happen. That can be just about anything you might dream up because the release of chemistry in the brain didn't stop at the dream or thought part but somehow went on to develop and equip you to take the extra steps to make, write, draw, paint, bake or whatever. We tend to look at successful people as the developers of something that generated masses of money, influence, power and all types of wealth in large and small amounts. Seldom do we see or even recognise it as achieving simpler, more modest levels of pure, unalloyed self satisfaction. But the concept of an idea transitioning to a higher level is to see and recognise that that inspiration carries with that thought or idea the dynamism to make change happen in positive and inspirational ways -- that it's more than merely an idea alone but one that's more backed by the power that makes everything happen.

Starting our woodworking masterclasses videoing was a combination of thoughts by two or three people. In my world of making, I have often been nudged to take an extra step not because I wouldn't or didn't want to or that I faltered, no. It was because I might have missed the urgency of the need of it, or I didn't have something to make it happen. A business I started back in 1988 or so was a birdhouse and birdfeeder manufacturing business. It was a major step away from the comfort world I knew best of furniture making but the simplicity of making a log into a birdfeeder or birdhouse with half a dozen cuts on a bandsaw came within a single minute. A man asked me how I designed something. I picked up a short limb of firewood from the woodpile in front of him, took it to the bandsaw and a minute later held a wishing-well birdfeeder in my hand for him to see. A week later I made the first quantity production of them and sold them to a birdfeeder and birdhouse mail-order catalog company called Duncraft in New Hampshire. They sold many a hundred every few weeks and through that singular situation, I provided for my family finances for ther coming years.

Ideas in action like this crossover the limits and constraints we might have in our lives to reject anything that might be what we perceive to be risky. Risk almost always carries with it the connotation of fear, fear of losing something, fear of failing to succeed, wasting time, not carrying something through, fears of losing money, materials, support from others and so on and so on. Had I not trusted my heart and mind throughout the years of working as I have with my hands and mind, others would most likely have suffered along the way. Who actually knows the outcome of such a thing we will never know.

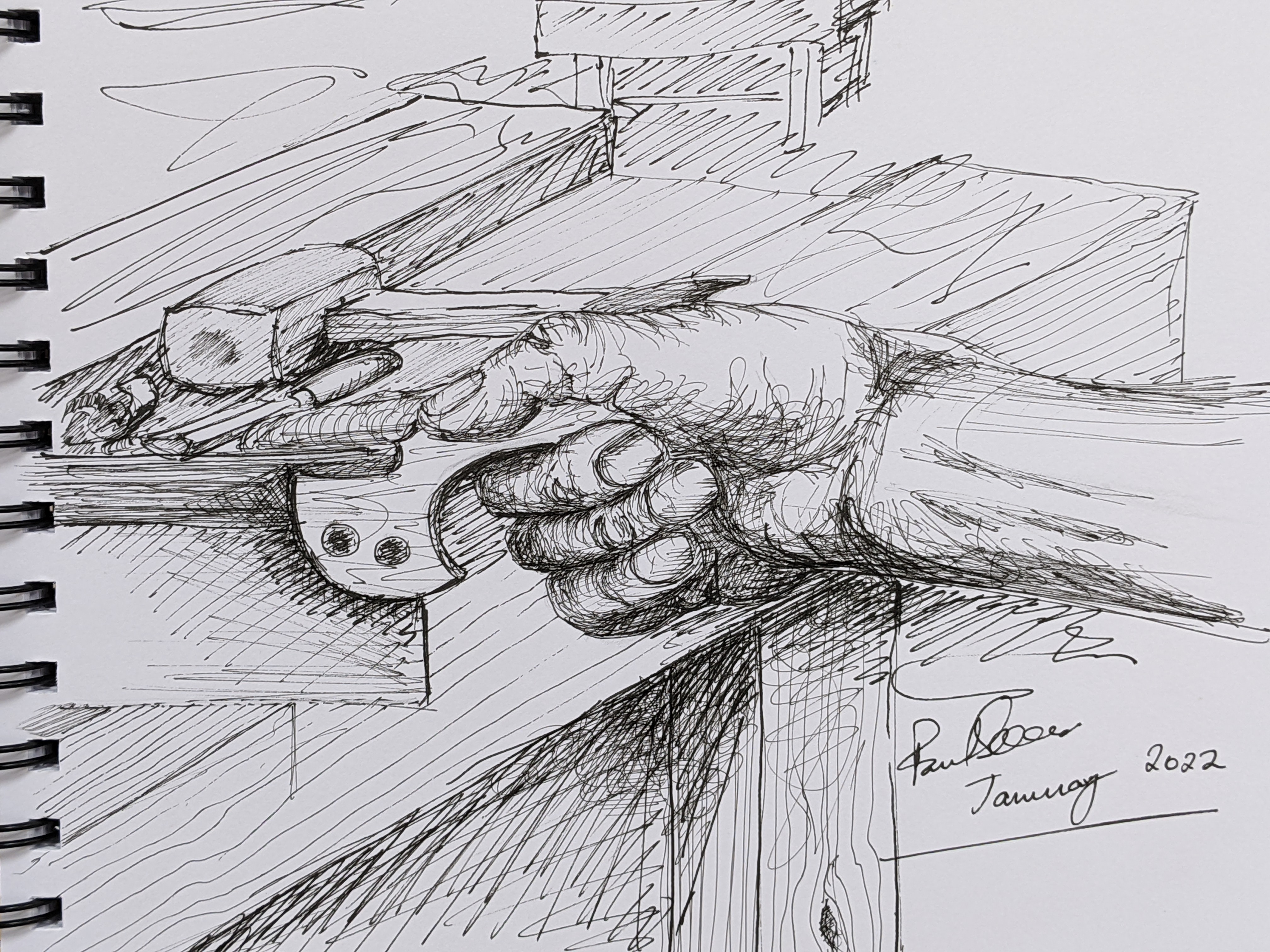

On many of my projects through the years I have had to reconsider my own perceptions of success. A success for anyone is often if not mostly measured in monetary return. How much you are paid as a wage, for a piece you made, what you have in the bank and I think we often boast in someone else's success by quoting something read about the worth of someone considered to be a self-made person. We admire billionaires flying into space as proof of their entrepreneurialism; their forward thinking becomes a status of their abilities to escape the gravity most of us must face in the day to day gring of just making a living. In my realm, it might be successfully completing a half decent pen and ink drawing or designing a good router plane. Can I be measuring my own success by others accepting the drawing as good or the router plane for its financial return when I sell parts for it to be made. Well, In my view, it was mostly about producing a drawing I can use as an illustration for a book and then to an illustration to illustrate what I am trying to say here in this blog. The router plane success was in giving my audience worldwide a means to making and owning their very own top quality, fully functioning router plane that they made with their own hands.

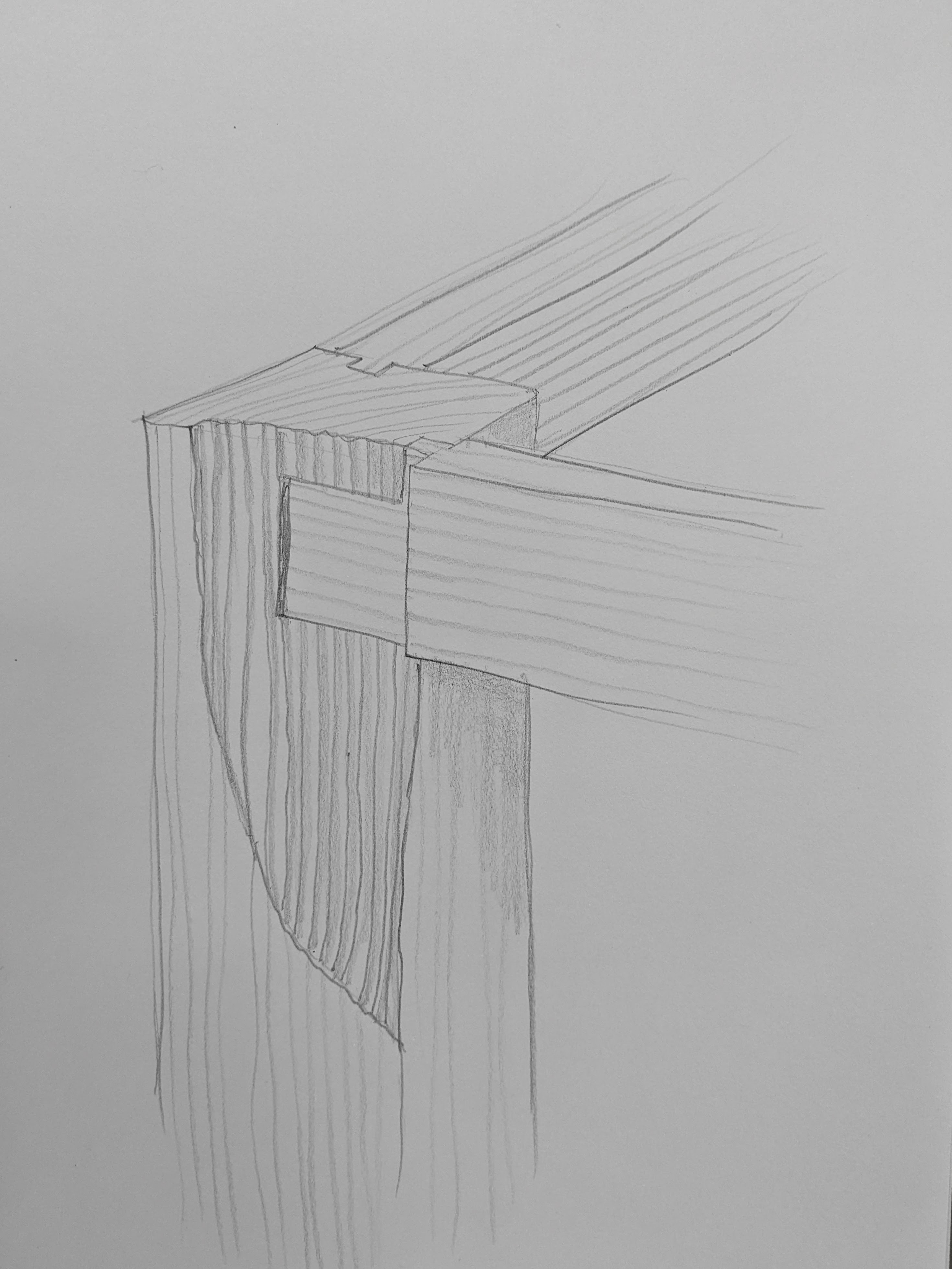

I have thought a great deal about dining tables that have mortise and tenons meet at the external corners. Why? Well, in 95% of cases this intersection is as successful as it gets. The joint holds up well, is strong and resilient and will indeed support great weight under the most demanding of uses that the table is put to. You might have noticed a fairly common thread throughout the Sellers' home furniture pieces I have been making at the house. Four of the major pieces have glued-up laminated components and all of these laminations have been done to add strength to the pieces to withstand the rigours of family living if a piece needed it. The remaining weakness of cornered mortise and tenons lies not so much in the joint chosen but the stresses that occur through life in use, house moving, missuse and more.

I have made repairs to tables where the outer face of the leg around the tenon area has split off altogether, leaving the tenon exposed. This can also be worsened by the use of pegs because the continuity of the grain is drastically lessened when you bore a half inch hole through the leg and shoulder. Add to that the reality that you are driving a peg into an offsetting of holes in the leg and apron tenon and you better understand what I am talking about. The issue with dining tables surrounds the reality that lower rails running parallel to the apron rails get in the way of legs and feet. Pulling and pushing dining tables of heavier quality and especially on carpeted floors can tend to apply excessive pressure on the joints and this is the reason breakage takes place the most. Transporting tables in removals also causes damage as they are sometimes stood on end for removal, storage and such.

Combining the laminations with fox wedging to the diagonal bracing, creating a triangular geometry, etc gave me an increased strength and resilience I felt would project my design into a long-term future of daily use with longevity planning -- an exact opposite to pieces made with built-in obsolescence whether intended by the manufacturers or not. One thing I like the most about my world of designing and making is that I can indeed think in such realms and find successes in the small things. It is more than likely that no one will notice what I have done let alone consider the reason behind the added work. I still will feel success whether they do or not.

Comments ()