Using scraps

An offcut of quartersawn oak lay at the end of my bench for two weeks and I couldn't throw it away. The angled cut reminded me of the days when my geometry squares were all wood and stamped with the angles and the name Helix in blue. Then I was sent the most beautiful scale ruler in boxwood one day and I asked myself why breakable plastic? I still use my plastic scale rulers and my protractor and squares. They work well and have served me well for decades but I also like the wooden options; worthy of my name stamp at least.

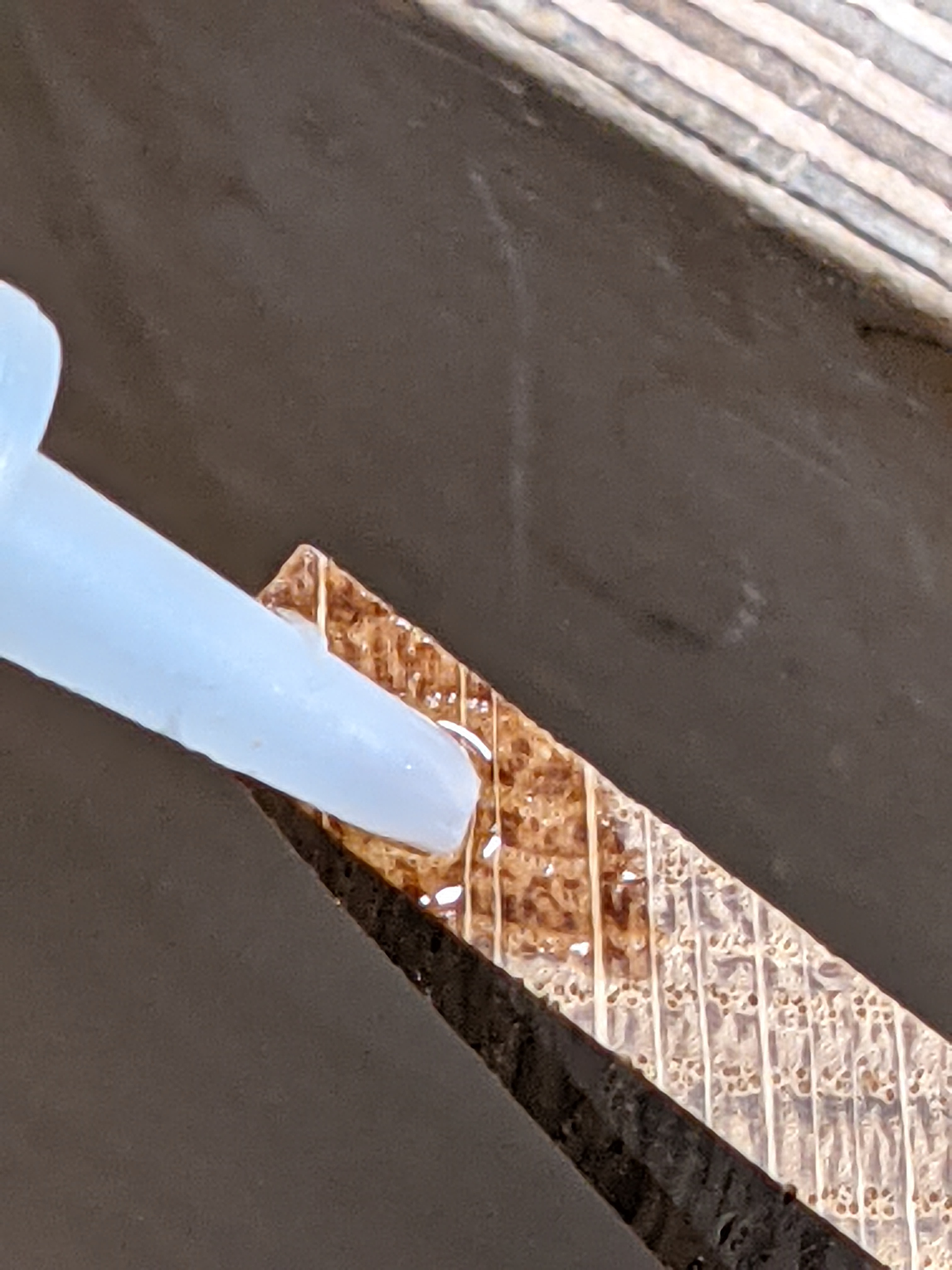

Once the edge planing and angles are done, I use a thin CA glue to fill the pores and grain fibres. Drizzling it on the end grain fibres allows it to wick in and solidify the edge. The capillaries suck up the superglue well into a good half inch and given a few minutes it sets very well. I usually take a single pass with the supersharp plane to clean up the edges and pick up any slight snags. Once this is done I bevel the edges with a low angle plane skewed to the long axis of the grain and that's all I need.

This week I finished the end tables for the Sellers' home series and put them in the living room collection where they seemed to nestle down perfectly. I used cherry, but of course, oak would also have gone perfectly well too. There is something special about these pieces but what I think is remarkable is what I have made from cherry I bought for £300. The first piece of the year was the cherry rocking chair. I made three of these at the same time, one in oak, one from two-by studs and then the final cherry version. Next came the cherry coffee table followed by the bookcase. Remember, I always make two of the pieces so that one becomes the first iteration of the prototypes. I made the TV stand from mixed woods but mainly oak and cherry tambour panelling from scraps. The total cherry piece of the wall shelf was another from the £300 lot and now I have four cherry tables, three for the Sellers' home collection. So seven pieces with still some cherry left for another piece yet!

Currently, I am prototyping the dining table for the Sellers' home dining area of the new kitchen. It will be an uncomplicated piece for the eating area by the big windows and doors. Remember though, I am prototyping in pine and this can be more than acceptable for a dining table. But, I also like painted wood finishes and this can be done in a variety of ways and not the least of which is to age the wood to make it vintage looking.

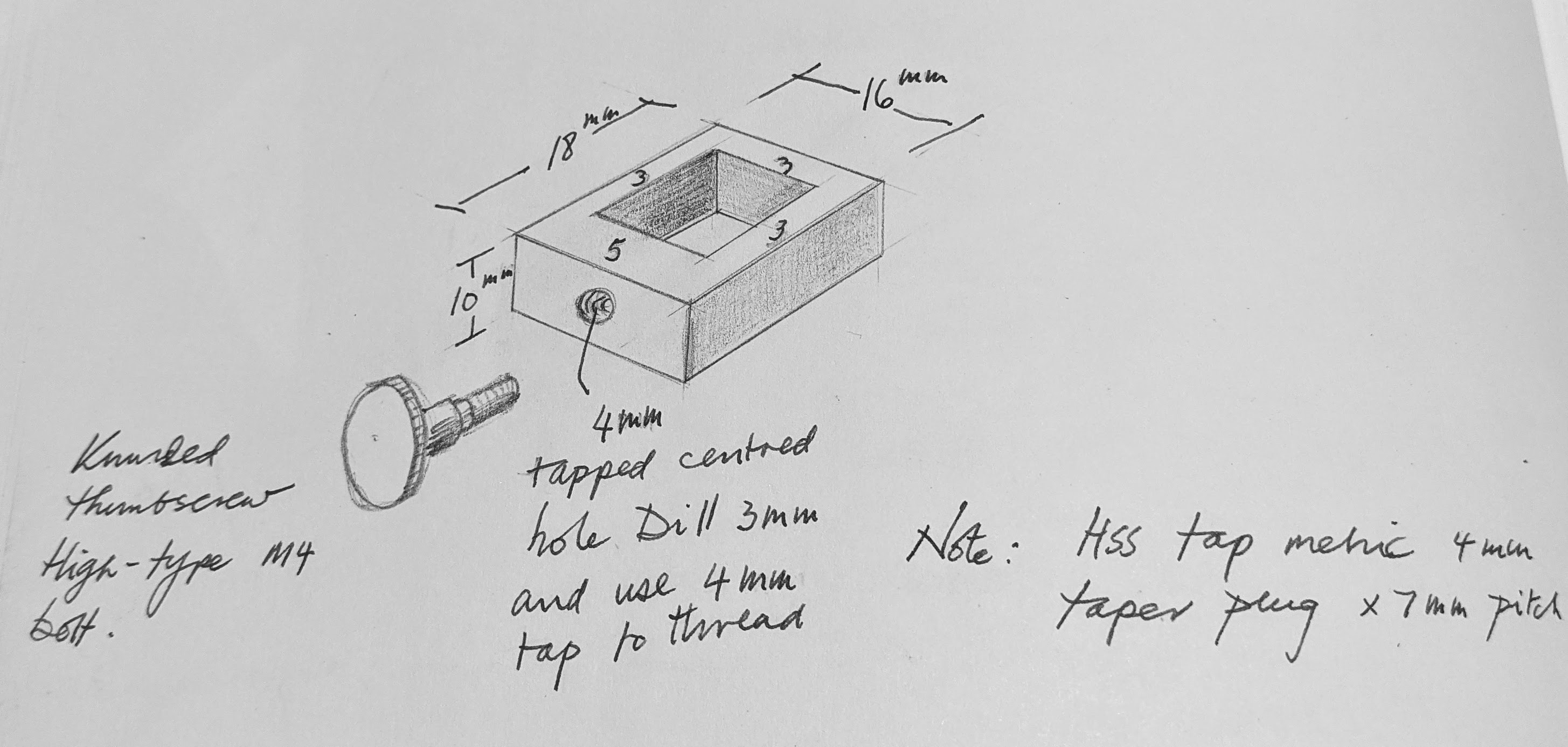

I have some upgrades on my router planes and will let you know about them when they are tested thoroughly enough for functionality and longevity. Here is a collar that won't wear out in a hurry. I made it as a depth stop from a section of O1 flatstock steel even though I don't see myself using it but once a year, maybe. A 10-12mm section of any steel or brass will do. It's nothing tricky, basic metalworking, drilling, filing, tapping and so on. I will show the whole process for this in a blog, most likely. I have another simple upgrade made from nylon I will show you when I am done, that will make the plane even better and more versatile.

Comments ()