Many Mortises in five tables . . .

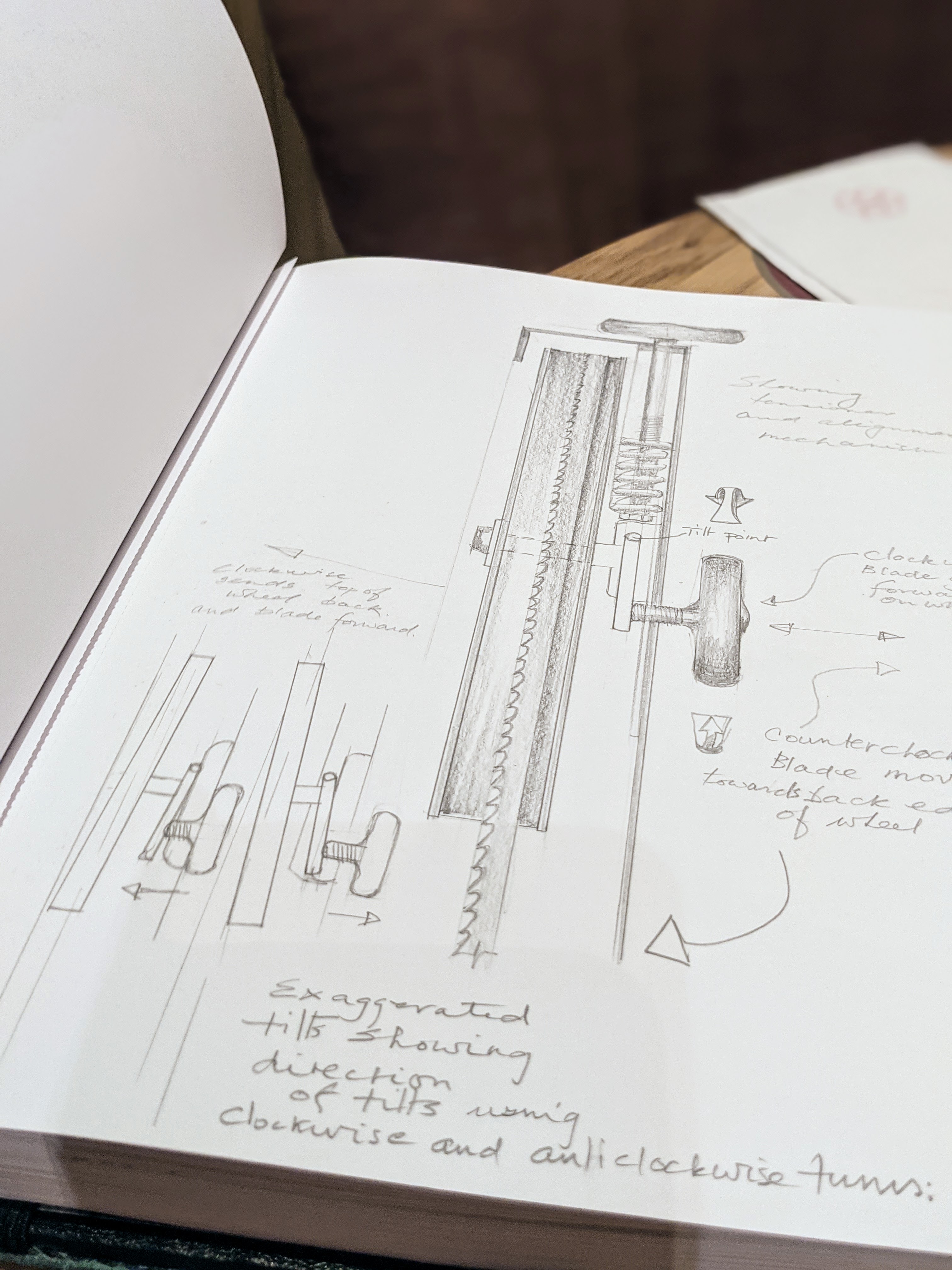

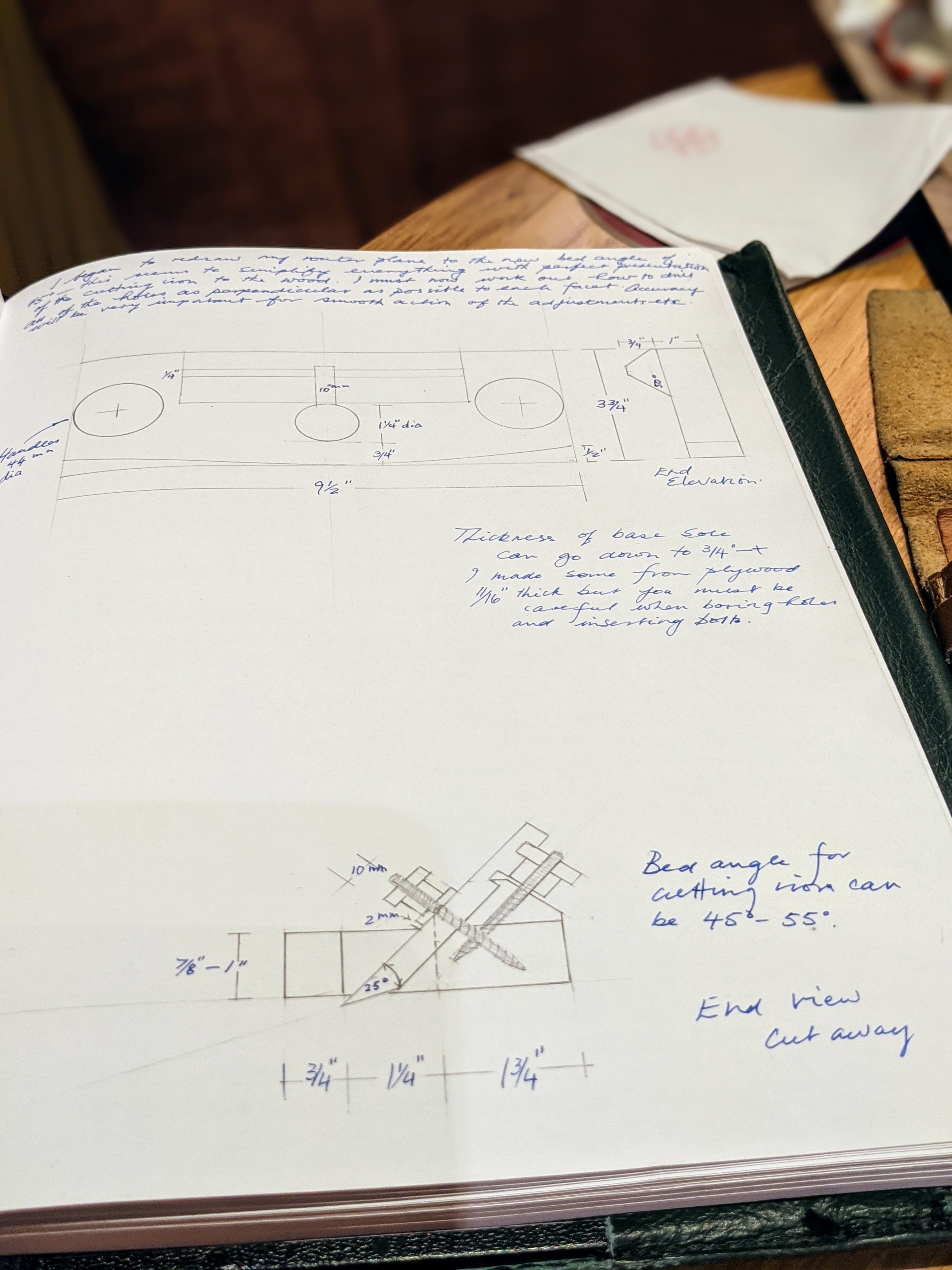

. . . but only half the number needed by crisscrossing the cross rails using a simple halving joint to level the top field ready for the tabletop. The crossing of the unifying top rails allows for added potential we don't always see or realise. Seller's home allows me to explore and share things that might not at first be obvious and this is what I love about the opportunity we have created. Take the new router plane, for instance. Creating a dozen and more tenons eventually will translate into followers making maybe a hundred or two if indeed they make all of the pieces. In the living room alone, over the past ten months, we have made 100 mortise and tenon joints, 20 sets of dovetails, and about the same in housing dadoes. I can't imagine making the 120 joints that needed the router-plane refining capacity. I kept telling myself, "But not everyone has the luxury of owning a good router plane!" I had to do something and now it's done.

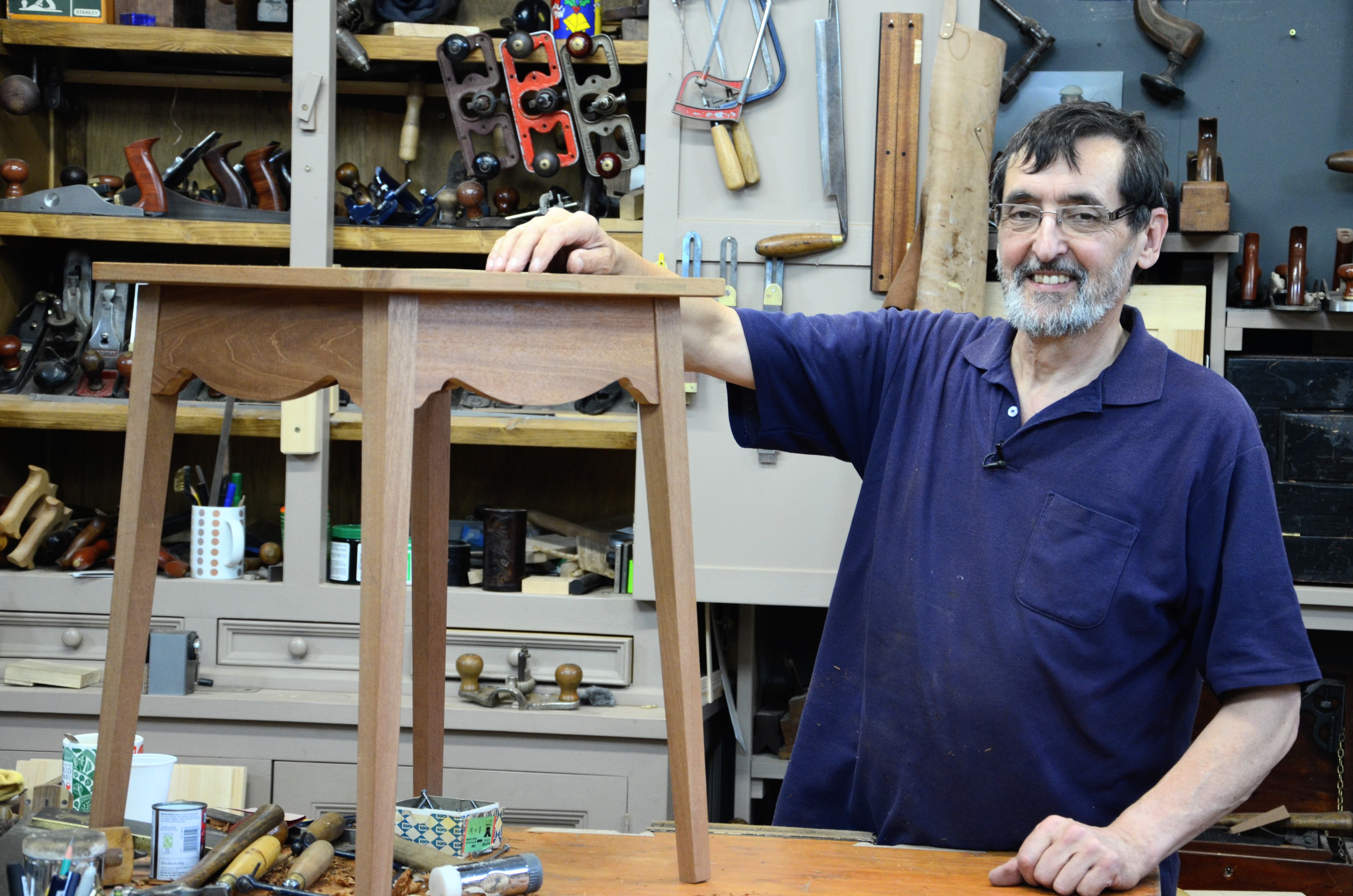

So, the table design has flex. It can be round or square, octagonal or indeed elliptical too -- maker's choice. Simple designs like this fill the gaps in the floor space of any room you care to name. A bedside table, a lampstand, plantstand, cup space near to hand and readily moveable, to anywhere your guests are sitting, and with just a single hand. I have enjoyed finding the gaps and discussing them with my inner man to see what the consequences are between the round, square, rectangular, oval, octagonal considerations. Then there are the rounded corners, rounded edges, rounded legs to think through too. Oh, and I am thinking of painting the wood to colour too. I like brights like reds and blues, yellows and purples. The colours float from one to the other in my head and, faster than any computer can ever produce, my mind makes the shift and I see them in multidimensional realness right there in my brain changes.

The nuts and bolts of making are just the smallest part of designing. We should truly consider how our brain is working and steering us automatically towards a particular way of doing what we do, and, can we make a conscious delivery of an alternative possibility outside of our comfort zone. I am truly surprised how much some people cannot leave an edge square or sloped or simply and gently rounded to round or oval and must install a Roman ogee, an astragal or an ovolo without even knowing where the idea came from that tells the world it was done by a powered router and today is 'unhand' made. The undersides of my tables have plane marks left by the slight scallop one or two of my hand planes make. They are part of the story and the history my life and work will yet become. I might leave in my work marks as part of my story. The chopped mortises don't come from the set depths of a mortise-machine stop dialed into the machine's mechanism, but a mark on the side of my chisel; too simple! There is no quick succession of circles from the mortise machine bits burning their little circles at the mortise bottom. I like the subtle steps I leave from my chisel tip that will be there in 150 years when someone restores what I have made and says to his colleague or coworker (these terms that now replace buddy and mate, pal), 'Hey, look at this, these were hand-cut mortises! His work is really nice and look how he used a super-sharp chisel to make it.' I have learned far more from old craftsmen by searching their work for telltale signs than any human I worked alongside. The walls of the mortise, the chiseled corner left dead square or angled, these tell me so much about their work and how I should work. I can even tell how much pressure they were under to produce in the day.

It takes eight minutes to chop a 3 1/2" mortise 3/8" wide and 1 1/4" deep in cherry, including the haunch. I have 32 minutes for the mortises in my table and six minutes in the half housings. Then the tenons take twice as long because they do and they must then be fitted to slide smoothly into the relative mortise holes. No matter that they are usually not interchangeable because I mark them to be married to each mortise hole. Repetition is all part of the work I do. I make one, finish it and start another. Modernists laugh at me and even mock me. It's bound to be so because they don't know what I feel when I use skill to make, draw, think and design. I am influenced by all things and I make my decisions according to what has and is informing me. Inform means to form in. We see something that attracts us and inspires us and we file it in our minds for later use and later allow it in our designs and our methods of working. I think machines cut nearer to perfection than handwork with hand tools does. Even though this then has become skilless work, it is admired by those who never knew true art. Painting by number and colouring in the lines laid is never to be admired unless it is done by a three-year-old. I know! It's explosive to say such things, but it is a reality that machine work has replaced skilled workmanship in most realms and a CNC router can never replace the qualities I can get in both mind and hand by using my body to work the tools that go with the sure and positive art and craft of the hand maker.

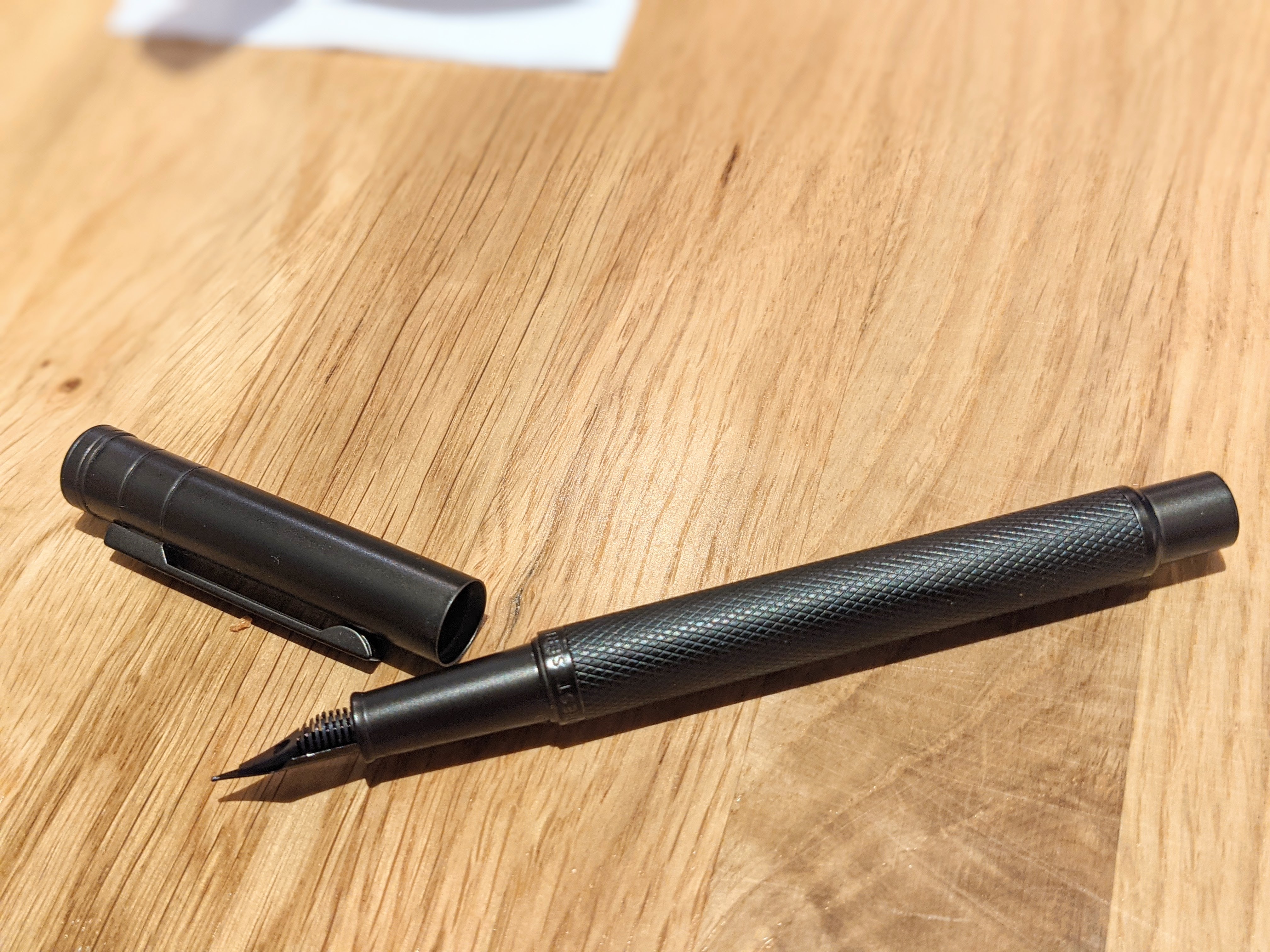

This, for me at least, is and always has been the true power of hand-making anything. It does not mean that I don't or cannot admire a pen that is made by machine in China that sells for £15 that writes more smoothly than a vintage Shaefer or Waterman costing hundreds of pounds. Do I forsake the benefits of a good pen or wait until I `can afford a £200 pen?

And then there is the art of writing too. Did you know that I write 2,000 words every single day and that many of my passages begin in a plain-page journal written with a fountain pen and drawn with a #2 graphite pencil? Is it because I am 71 and haven't entered the technical/digital era? You judge! I type all of my blogs, usually a couple of thousand words, daily, from my written notes but often directly.

I like the way they float on the page as though my hands typing are detached from my body. But who can deny the deep, deep value of the flow of fresh blue ink on a white page? I could never achieve such a thing with a ball-point pen nor even a pencil because the fountain pen floats on the ink as the pen point touches the pages. This beauty cannot be described and it comes from a pen made in China that never clogs nor drips nor leaks and is made throughout from metal, not plastic yet feels light in my fingers as I write. Why do I not use a British Parker? I haven't found one that works that well yet and I do not know where they are made anyway. Those that might suit me are expensive.

A saw I just bought to see a few close details on is the Crown 10" gent's saw I have used for two decades, the smaller one you see me using in most of my videos. In the advert description it says made in China yet it looks exactly like the one I bought all those years ago. On the saw plate, it says 'Sheffield' and 'England'! What on earth does this mean. Was it par-made in China and assembled back in Sheffield by the distributor? Who can tell? If they can send live hogs from the USA to China for killing and processing and send it back to the US as rashers to escape FDA ruling they can surely send other things to and from other continents to cheapen all the more by cheapened labour, that is nothing new. Look what giants like Stanley do in the USA by having tools made to the south of their borders down in Mexico, or Nicholson files, for that matter. The advantaged can do these things. Maybe after Covid, this will change. Who knows? Governments like the UK are now investing heavily in what they once sold to other continents: apprenticeships and manufacturing. The problem? Those highly trained and skilled makers who were made redundant over a half-century period that left the gap of working knowledge by skilled artisans. Oh well!

So anyway, back to my mortise holes, trimming tenons and fitting them rightly but not too tightly. When I've done, the world will be right again and let it vote as it will.

Good Sunday morning everyone! Hope that your day is as good as it can get.

Comments ()