Tweaking life at the workbench

I plane wood flat most days. It's inevitable and I enjoy it. And I use just a hand plane or two. I often work with two or three plane types I freshly sharpen before I begin. With my planes sharp first, I know I will be sharpening at least one of them within a very short time, that's inevitable. What's remarkable to me is the reality that nothing created in the last hundred years has really improved on this reality and that's more likely in many centuries -- cutting edges dull by use just as easily as they ever did. We may have more advanced steel types that give greater wear resistance and better edge retention, but that too comes at a cost. Harder steels make sharpening harder and longer to do. One way or the other, there is a compromise. Here at the workbench, where the real testing takes place on a day-to-day basis, nothing changes except that we become more discerning as to when we need to sharpen and hopefully we change our reluctant attitude to do it in just the right time too. Just as thick plane irons can take two to three times longer to sharpen, extra hard cutting irons do the same, and especially is this so if you choose no mechanical methods to do it. I do use a grinding wheel for grinding bevels once in a rare while, but 98% of my bevel work is just hand pressure on diamond plates.

I always aim to resharpen again before the cutting edge dulls too much so time-wise it's not so very long between sharpenings. I cannot possibly say how long it will be before I 'feel' the need to sharpen up but I have learned through experience what is just the right time to do it. I am often asked how long it is before I sharpen my plane again as though it's a distance and time-led thing -- a bit like it's an mpg (miles per gallon) thing, but in feet or metres squared and calculable. In other words, a 1" x 6" board two feet long would be roughly one square foot per wide face and with edges and end grain that might be somewhere around 2.5 sq ft of surface planing. I think that some might think it would be great to get out the app and punch in 2.5/ft/oak/english and see how many boards could be planed or how long it would take to do such a task and then how many miles before I need to resharpen. I digress.

The bookcase I made below in cherry with seven shelves plus a spare, two sides and many other bits, might total 100 square feet. It would be handy if I could divide that hundred square feet by a set amount to calculate my miles per inch surface area and say I will need to sharpen up nine times to true-up and smooth and size all of the components to complete the job. Where I hit the bumps and forks in the road is that no two pieces of wood, even within the species and even in the same board, will wear down the cutting edge of my plane irons at the same rate. This, I am confident, is invariably incalculable, thank goodness!

So I say to myself, wood is just like life, it comes with knots in it. Knots, silica in the grain, wiry, awkward grain patterns to contend with minute on minute, all take their toll. Even with the best cryogenics in the world, and thick, cryogenic irons offer no real benefit over a standard blade*, a single knot in many if not most wood types, including most softwoods, can take out any fresh sharpening in a heartbeat . . . and I mean even a single pass! Compare hand planing teak to cherry and teak will dull your plane irons 4 times faster, even if it has no knots to contend with.

So asking me how often you should sharpen your plane is the same as asking how long is a piece of string? It takes what it takes. When I used machines to level and true my wood I was less concerned about such things. I used high-speed steel cutters in my planers and they held up for weeks at a time with no problem. Pass a board over a jointer bed and then into the open jaws of such machines and the twist was gone in two passes because, well, that's what planers do well and do deeply. A single-pass can take out an eighth of an inch of twist and two passes a quarter-inch no problem. The same operation with hand planes, depending on the board width and length, could be half an hour's work easy. Since I stopped using what industry uses a few years ago, I have been far more considerate and judicious in my working. My reasons for not resorting back to power planers? Shop space, health and safety, dust and mess and the fact that most amateur woodworkers around the world cannot (for a dozen reasons) own or use such power equipment. I use what they can use and get hold of and I don't want anyone to think a shopful of machines with the necessary dedicated floor space is at all necessary to be a good and functioning woodworker. I have personally proven more than any other that they are not -- we've produced many dozens of beautiful pieces, large and small, ranging from dining tables to baby cots and large cupboards. Oh, and then of course, there is the physical exercise I favour in my woodworking too. I see no reason to push boards into a machine and then go to a very boring gym to get the exercise I need throughout the day. Think two birds one stone!

I hand planed many square feet of oak for my prototype TV unit over the last few days. This includes an experiment using 10" wide, 36" long veneers of 1/8" thick oak stock for laminating. I ended up abandoning this thought because of the time consumed in doing it and it is quite a trick to do with hand planes anyway. What I have come to notice over this decade of hand planing almost every stick and stem I have used, is just how much wood moves to points of distortion. Even when you go to great lengths to get the moisture levels in the wood down to a perfectly matched level to the surrounding atmosphere, wood will usually move to some degree. What was true and trued one day can be different the next. Leave it a week and it could be back to true again or it could be worse still. This is wood at the workbench and not the discussion in the textbook although they give insights too, of course.

In circumstances like this, a sharp hand plane is critically essential with a double emphasis on its essentiality. In my understanding of people as a whole, procrastination is almost always the issue in just about everything we do. Bins overflow, apologies come too late and dishes fill the draining board to toppling levels. It's funny how we will push that plane to its absolute limit of our laziness rather than pop that lever cap, take out the plane iron and reestablish a sharp cutting edge. We humans will beat that wood and our bodies into submission with a dull cutting iron for an hour before we will take it out and sharpen it, yet when we do what we were supposed to do an hour ago we feel blissfully happy until we do the same again. My oak sections, boards and panels did move even after my curing of wood was down to around 7% and acclimatised to and by the surrounding atmosphere of my garage workshop by airconditioning to equal perfection. How can this be? The books all say blah, blah, blah! Well, it's wood. It moves, it changes its mood and its mind and its memory! Wood is not always compliant and neither is it always predictable.

I remember when MDF came into being and how magazines of the age extolled its virtues as the new wood that could be nailed, screwed, stained and made to look like any wood you wanted it to look like. 50 years on we have firmly established its limitations. We no longer make chair rails from it and thankfully we never made ladder rungs from it, but some entities did come close. What MDF offers the industry of woodworking is stability. In general, whatever you cut MDF to stays. Unlike wood, expansion and contraction doesn't happen to any discernible level. Inert to the level that it is, it usually works perfectly as a substrate for facing with veneers of all kinds including wood, plastic and fabrics. IKEA loves the stuff as do most furniture industry giants making tabletops and desks and case goods. For me, the stuff is as soulless as it gets. As hand toolists, we seek that which has proven longevity and we choose what can be best worked with our hand tools because we value the efforts of our physical and creative input. MDF, chipboards, pressed fibreboard and such, were designed for mass-making of all kinds using mass-making methods and equipment and then with little concern for longevity beyond the one-year warranties given. In that world we want product to become obsolete by design and by build quality. Built-in obsolescence is not just by wear alone but by fashion outmode too. In my world, MDF has no place at all. So I must resign myself to the reality that my wood will almost always move, even when I have done all to reduce that likelihood and, indeed, to allow for it. I resign myself to the reality that I will need to occasionally tweak it as I work it and that people will occasionally do stupid things with water after they have bought it from me. I know too that I might just get blamed for some distortion and even cracking when they place a table end grain up against a primary source of home heating such as radiators in winter.

Conclusion: Be prepared. Sharpen up more regularly than you want to, perhaps twice as much. Allow time for acclimation. Recheck yourself by casting your eye along a corner to see if what you had yesterday, last week or last month is still as good. Be ready to tweak things, especially your attitude and unbelief that this or that happened when you only turned your back for a minute.

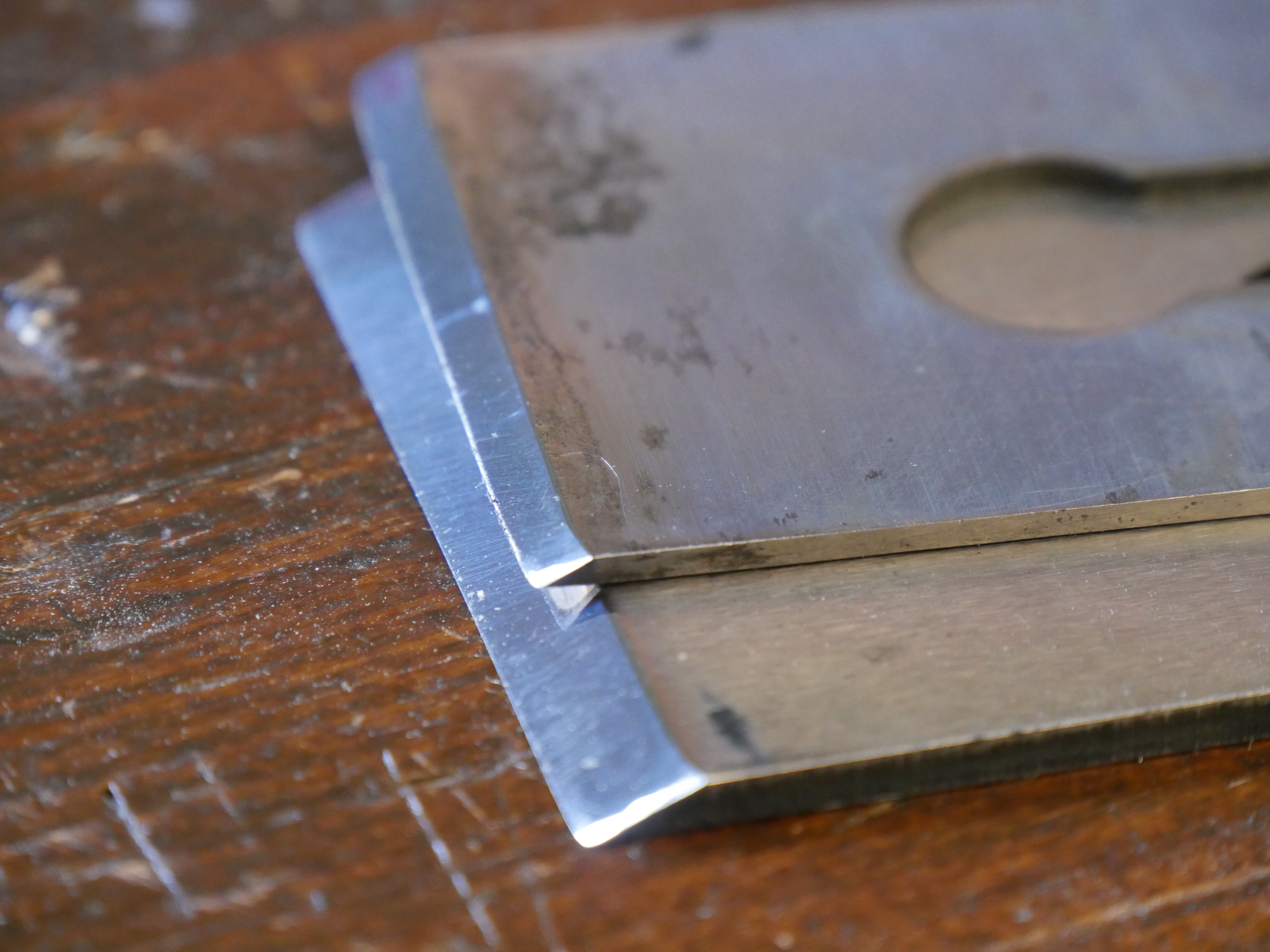

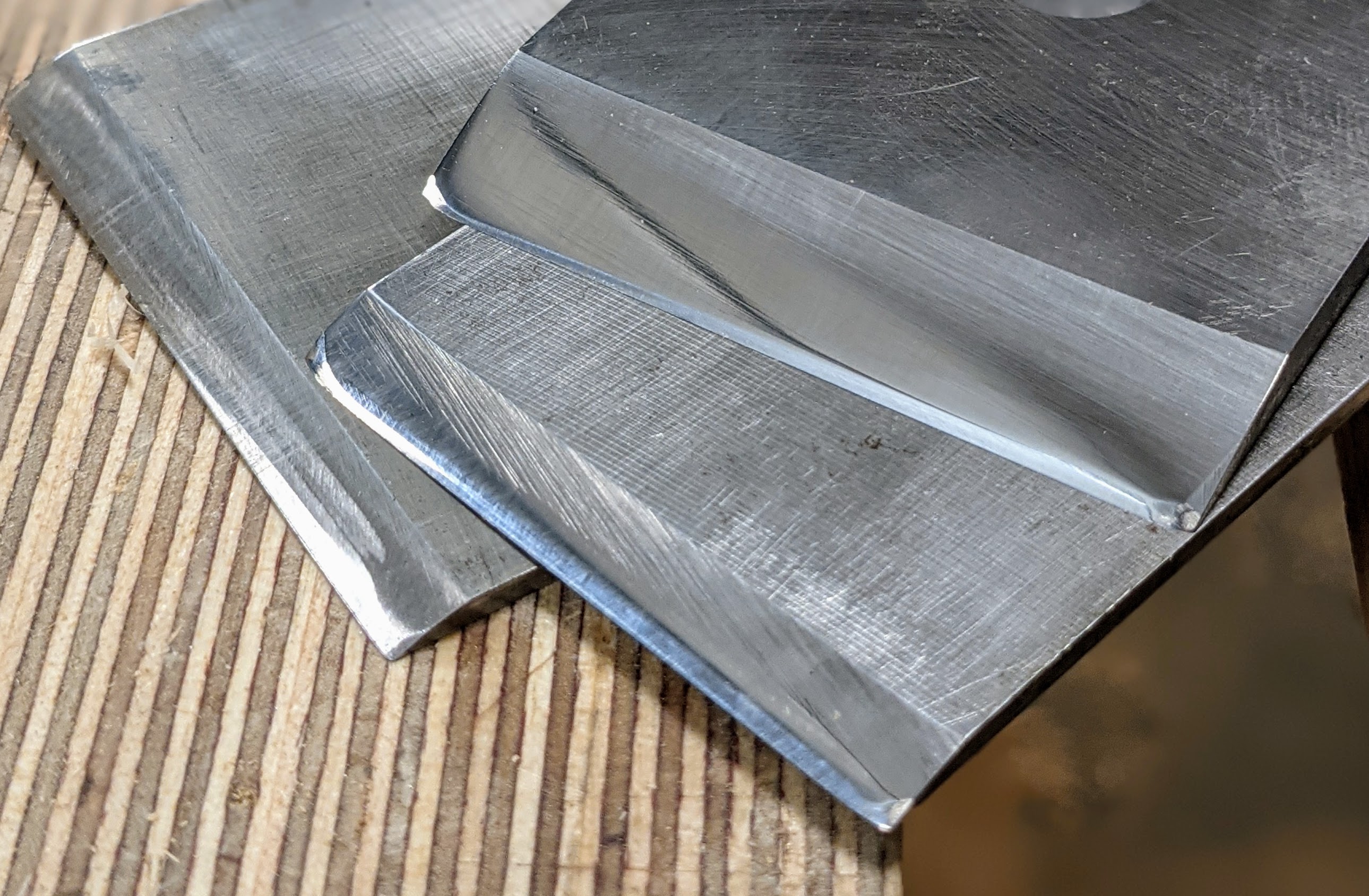

*Retrofitting your plane with a Cryogenic cutting iron is simply a matter of choice and not an essential or even a necessity. These cutting irons cost twice the price of buying a complete secondhand Stanley plane on eBay, so up to four times that of a replacement iron provided new by Stanley. At £40 a pop for the new retrofit cryogenic version, plus shipping and handling, it's not a low-cost upgrade and the advantage if any is at best negligable. The standard Stanley is just under 2mm thick and the ones being offered at 3.5mm simply mean you must spend about two to three times the time sharpening them. What difference does this make with regards to functionality? Well, none, really! A sharp iron is a sharp iron. The boast of longevity of a cutting edge is there but it is more fractional and not anywhere near say twice as long; I'd guess maybe 20%, extra, but of course, it is unmeasurable in the actual zone of woodworking, really. But whatever gain you have there is quickly lost in the extra time the hardness and extra thickness the iron takes to sharpen it. Effectively, you're better off staying with the regular iron your plane came with. You must also watch out for the hidden salesmen who tout plane chatter as the result of using standard thinner irons. That is simply untrue.

Comments ()