thinking we see the whole

I have a few thoughts about tools like planes. We often think that we see the whole and when we do we can fail to continue searching for answers and often miss the point. Planes are the troublesome entity in the tools of woodworkers that often seem too unpredictable and awkward to use in the early days. In fact, I will go further, they seem always to many to create more problems than they resolve and new woodworkers using a plane for the very first time can be forgiven for their enthusiasm and their over expectations. To them it is no more than a gamble -- too many variables to take in and work to accordingly.

New or vintage, secondhand or whatever, unless a plane is correctly set, adjusted and sharpened, those opening strokes with a plane can be highly discouraging or encouraging, refining or damaging. In the hands of an experienced hand tool woodworker, any plane ever made will give those premium, calculable shavings according to the twist of an adjustment wheel or the shift of a lever. Getting the plane to be predictably productive every time is the challenge of every new woodworker. New planes may well seem the better choice and especially is this so if the makers take the time to align and set everything ready to go, out of the box. This ingredient alone may seem well worth having. At least it proves what the plane is capable of right from the first stroke. I must say this though, it doesn't usually last. Planes dull in the first few minutes of use and there comes a point when you must do something about it. Herein lies the reality.

Any modern maker producing planes will tell you that the plane's sole has a guaranteed flatness to within plus or minus of one-thousandth of an inch. That this trued flatness goes from side to side and full length. Do we woodworkers need such a thing? I suggest not. If anything will get me shot it is this statement alone. Plane soles do not need to be dead flat but they do need to be near to it. More later.

The second espousal is that the planes when built heavier are better for planing. Well, you know how I feel about that. It's just not true. But many might suggest that because I use a plane for many hours in a week that that is a good reason for me to prefer a lighter weight plane. Whereas this is true, I actually prefer a lighter-weight plane regardless of how much I use a plane for. Lightweights do everything a woodworker needs. I am not opposed to new, heavier planes, but it's the equations I look at. For two decades I used a # 4 and a #4 1/2 bench plane without ever checking the soles for flatness. These two planes flattened my wood and leveled adjacent surfaces around joints every day, and whereas I agree that the soles of planes can be too distorted to achieve good results without some serious flattening, the reality is that we can become too obsessive about flatness and we might be better if we can adjust our attitude just a little. I like the thought that one such a maker might one day give us a 10mm bevel going from .5mm on the outer edge to the sole surface. Do this all the way around and I would be very happy. I actually don't really need it because my planes are indeed worn on these outer reaches. It means that the plane surfs up onto the highs and reduces those levels down to the lows with successive, unimpaired strokes.

And of tight thread tolerances for adjusters I might say great, except that it is something I just like in engineering rather than see the benefit of in the field. My plane adjusters spin for take-up with a single-finger propulsion. I am perfectly content with this. The lever for lateral adjustment can be as loose as can be too. Whereas it is better tight but not too tight, I have had them as loose as can be and they have worked perfectly well for years. I say all of this to say the sales spin is often not altogether relevant to the functionality of a basic plane.

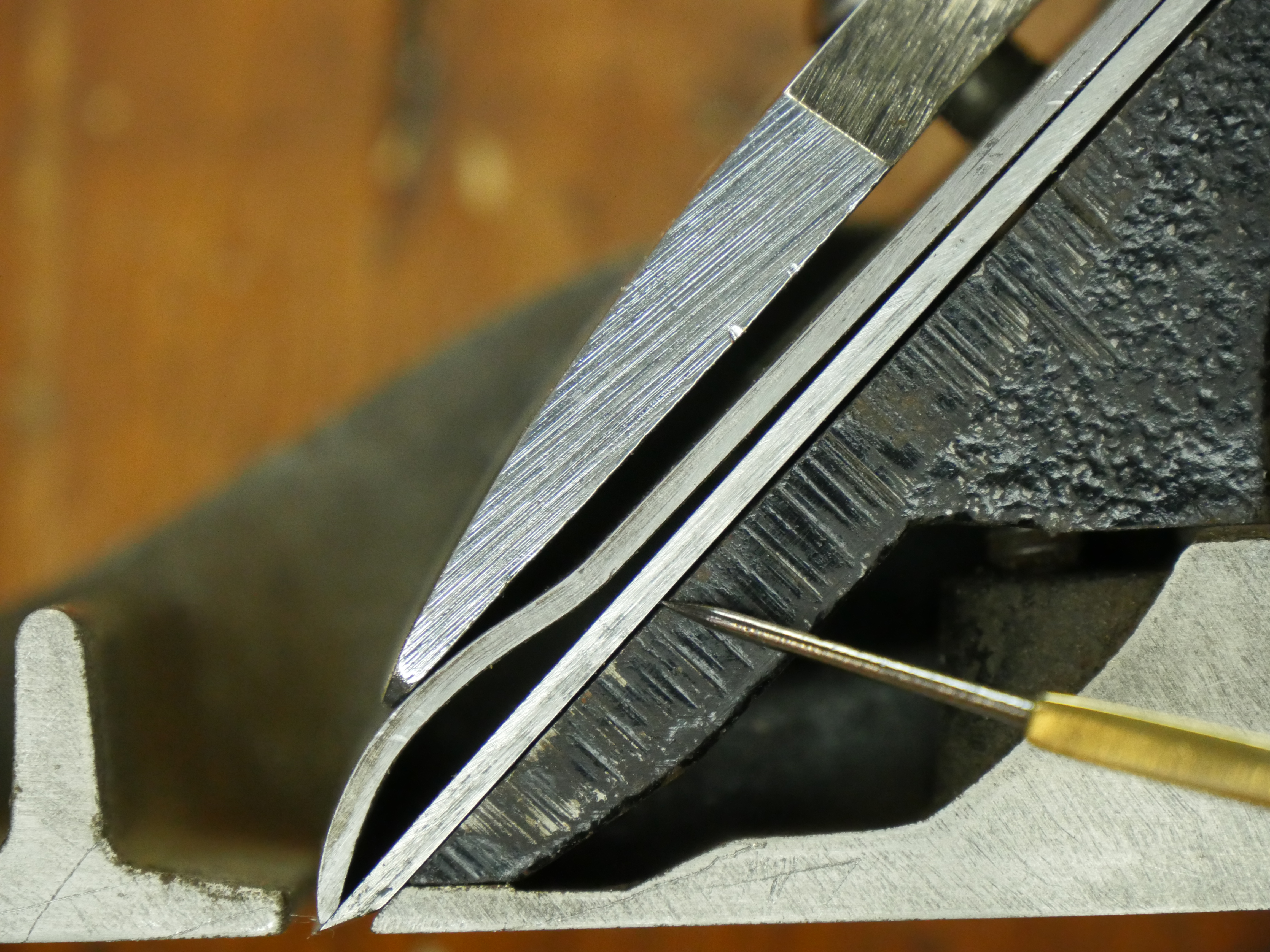

I have always encouraged woodworkers to spend a little time flattening their plane soles through the years. It's as good a place to start fettling your eBay finds as it is establishing a 25-degree bevel to your cutting iron, setting the frog and making sure that the cap iron (chip breaker USA) fits tightly to the back (upper) face of the cutting iron when cinching the setscrew tight. In reality, if the primary bevel of your plane is ground anywhere between say 20-degrees and 30-degrees, you will not be able to tell any difference because, usually, we try to hone somewhere around 30-degrees anyway. That being the case, the primary bevel is just to get the bulk of the steel out of the way so that we can establish a nearish-thirty-degree cutting edge because that seems to be the strongest practical cutting edge. Because I very rarely if ever grind my bevels (nor establish two bevels anyway) it's ultra-quick to go through my three-stone system to a polished bevel in a matter of a minute or less. Legalists insisting on twin bevels at precise angles, on the other hand, make this insistence as a sort of legal requirement yet throughout an expanse of 300 years, woodworkers working daily in the craft did exactly as I do. You see, the 25-degree-30-degree scenario was only ever a guideline. I never check with an angle protractor to see what bevel angle I have, I just hone. Using a honing guide is a great idea if you simply haven't yet practiced and established the skill, there is nothing wrong if that's the case or indeed you use one forever. But here is what I want to say, what if, as I did and have for 56 years to date, you can free yourself from certain misconceptions that speed up your woodworking and become highly efficient with your time?

And here's another. If the frog of your plane is set at 44-45-degrees, then theoretically you could grind your plane iron bevel at 45-degrees and it would not alter the cutting dynamic because the bevel is on the underside of the presentation. In other words, because the bevel is down under and out of the way, it does not offer any difference when it comes to cutting the surface. In reality, however, we discover that a bevel on the underside of the cutting iron that is level and coplanar with the sole will not cut well or even cut at all. Why? For two reasons. One, for the cutter to cut, there must be a relief to the underside and two, edge fracture occurs in minute degrees right along the cutting edge as soon as the iron cuts the wood. The more you plane, and the more knots you hit, the more the plane iron dulls. The angled relief allows the cutting edge to engage in the wood.

Take any plane type, the router plane, the side rebate plane, bevel-up planes of every type and even spokeshaves, there will always be a relief angle. It is also important to note that many such tools, where the bevel is uppermost, are usually found with a bed angle of around 12-degrees and if, as with the router plane, it doesn't, then there will be an angle of presentation that holds and suspends the blade so that the underside of the cutting iron is indeed angled up.

Flattening plane soles needs to take place now and again. We all have biases and biases always affect our attitude. When we humans present our planes to the wood we usually do it according to how we align our whole body. This is a body bias. Our plane soles do wear unevenly albeit by minute and indiscernible amounts. The accumulative effect can create twists and hollows in our plane soles. I may be one of the very few people who have had to flatten their plane soles more than once in using the same plane for 56 years simply because fo wear. For a long time working in shop fitting from 21-25 years old I planed a lot of plastic laminate attached to plywood and skinned both sides. After a few years of edge planing and planing narrow edges anyway, I had worn a very definitive hollow along the length of my #5 jack plane. In the general scheme of things, it made very little difference to the functionality of the plane but sometimes it did make a difference. Some woods can do the same, teak, for instance, and mesquite. Using these woods for any length of time will reflect your bodily biases in the soles of the planes you use. It is easy therefore to ultimately create a twist in the sole of your plane. This twist will then create twist in the wood you plane. How about that!

So we see that an occasional, periodic flattening can become necessary, though I believe it may be more the rarity if you only use your planes for an hour or so a week, even over the long term. This is, of course, following any initialisation that you did in preparing the plane for use after purchase or acquisition. Plane soles can change according to temperature. I have never really found this to be a problem. It is a mistake to flatten a sole when the temperature is unseasonably high because when the temperature drops it will most likely alter again and having flattened the sole after a new change you might find yourself with a hollow instead of a round. Minor discrepancies will only marginally affect performance and you will learn the idiosyncrasies surrounding your own plane as you use it over time. Shorter soled planes like a #4 smoother distort very little. Experience tells me that allowing the plane to adjust to its new environment for a week or two is best before flattening and keeping the plane cool without raising the heat in the casting is best. This is why a belt sander is not too good an idea as it will take the temperature up.

What is truly flat or good enough is where I want to drive us to. Because of the amount I use my plane, I actually accept tolerances within certain, immeasurable parameters and other realities that others might not. In my view, it's not a good thing to obsess over flatness. By this, I mean taking the flatness across full-width corner edge to corner edge and then too full length from half moon to curved fore-end. I think it is actually better if the outer reaches, say up to half an inch in from all the outer edges, allows us to feather-ease the plane over the rises of undulation and joint lines and thus prevent the inevitable jarring associated with premium planes that often occur when the plane is dead flat corner to corner and edge to edge.

Comments ()