Who Would Have Thought?

I have written often enough about preparing for a project from time to time, but thought then to put together something more cohesive, to help others to see what I actually go through in prefacing a project. I am still not done after eight episodes. Who would have thought it could take eight substantive blog posts to get to this point in prepping wood across? But I thought it was both interesting and important to count the costs that come up, that exceed the material costs but yet include our costs in time, physical and mental output, wear and tear on vehicles, trailers, peace of mind and so on.

If you have been following me, you will see that the planes come to play a key part when we don't have machines like a planer to do the hard graft and replace the more skilled work needed for us. Using hand planes requires a change in attitude, if you are a pure machinist, in the same way walking does when every journey you ever took since school was in a car, on a bus, train or even on a bike. I spent 12 months riding to and from work last year and pretty much abandoned my car to do it. It took quite an attitude change because for over 50 years I had relied on something I had not really altogether needed but merely preferred. Cell or mobile phones have done the same to just about every individual I know. They are mostly the new security blanket for adults and very artificial ones at that.

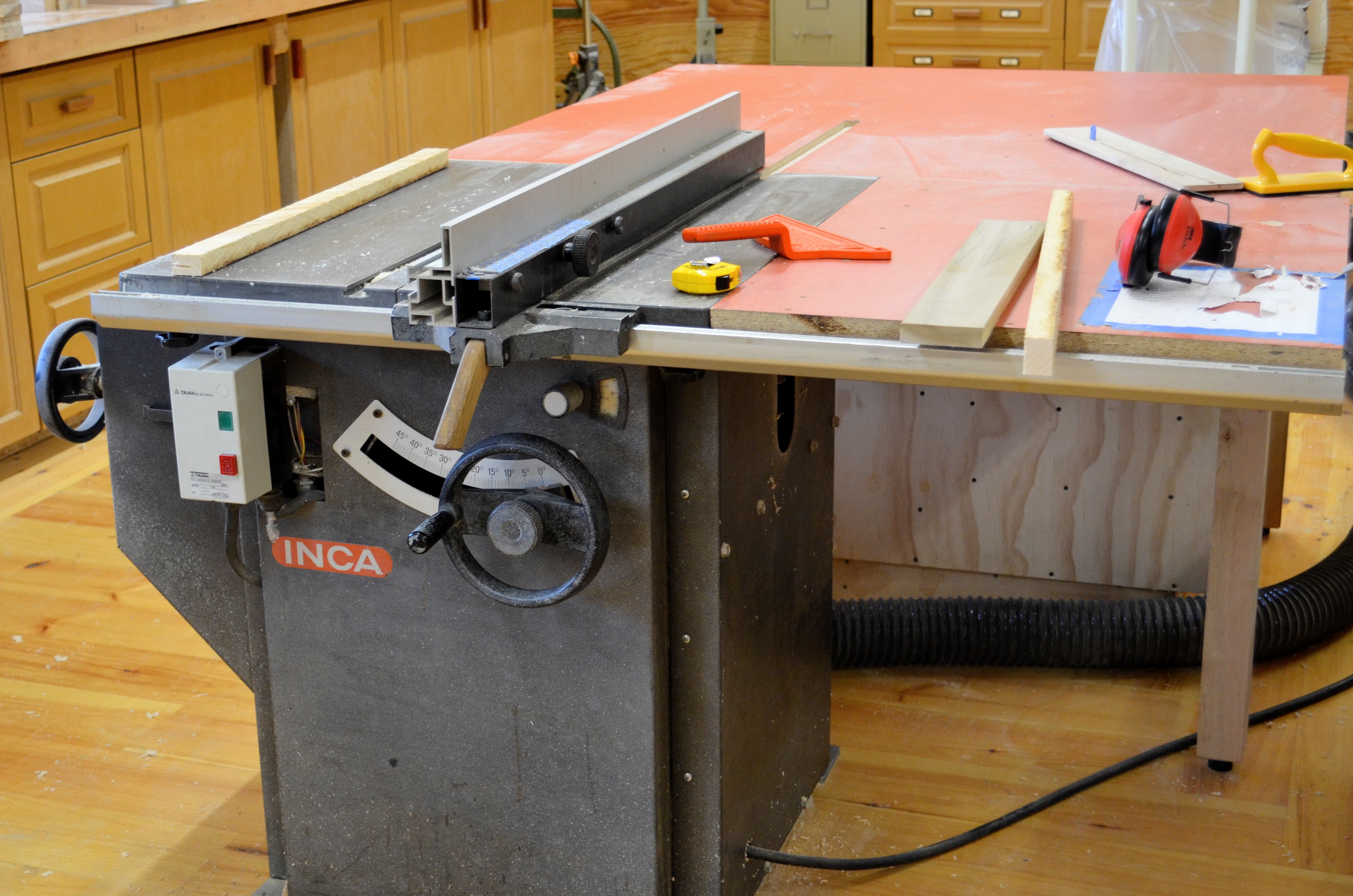

In the first month in January 2020, it seemed always to rain most days and then snow over ice. I know, not quite arctic conditions, but the point is that we compare situations and think we are all offered the same opportunities when rarely is it apples for apples. From my 23 years living and working in the USA I noticed that it was not that unusual for an average home garage to contain half a dozen woodworking machines in a two- or three-car garage alongside all kinds of routers, jigsaws, air-nailers and compressors. That's on one side of the garage. On the opposite wall, you might find a MIG welder and a wide range of support equipment including a chest of mechanic's tools and such. For those in an apartment in Ealing or East Manhattan or Brussels, it doesn't compute. Hand tools on the other hand do. I think that it is true to say that, for the majority of woodworkers worldwide, a machine workshop is out of the question - even a small bandsaw is out of the question. But it's here that hand tool woodworking comes into its own. I am not here to beat machinists over the head. I have said it before and I will say it now. Woodworking by machine is not the same as woodworking by hand and neither is it meant to be. It is, however, an advanced way of industrialising woodworking for industry, and therein lies the difference for me and many others too. In my world, our world, it is the less advanced and not the more advanced way. Someone said that Britain and the US are two nations divided by a common language. So it is twixt woodworking and machining wood. I like machines as long as they don't invade the wonderful workspace by more than 5 square feet. That's me.

Machines have their place, but machining wood is not the more advanced method of working wood, it's the less advanced in many ways. Fact is, most machinists are not actually woodworking but simply machining it. Now I hope that those reading this will not get offended and click me off here: hear me out before you do. First of all, there can be a dozen reasons, good ones, for owning and using machines. You are time-strapped, it's what you have, you don't have the skill for hand-working wood, you have a disability, you have less strength than you did, a medical condition. My bandsaw saves me hours of work in any given week. I could not do all that I do without it. Why? Time, mostly! Well, that's the same for most everyone. I drew the line at the bandsaw because I wanted to keep the physical strengths and mental acumen working my whole body the way handwork demands gave me. Rather than resign my body and mind to waste, as I did when in the business of making products as more of a machinist again, I wanted the high-demand handwork gives me. Making that decision made me determine that I had to have an answer not for the machinists, who might never give up on the ease machining gave them, but for that vast majority that would never work wood because they would never nor could ever own a place that could accommodate machines. Of course, it goes much deeper than that. People are looking for something more demanding than passing and pushing their wood into the teeth and cutterheads of one machine after another. They want the enrichment that skilled handwork brings to their lives. Calligraphers don't switch on their computers to develop their skills at handwriting and creativity, do they?

You have to believe me when I say that machining wood is a pretty skilless pastime. Especially does this become apparent when you take a plane in your hands that you just picked up from a cobwebbed shelf in the basement of your father's home; a plane that lay unused and untouched for fifty years. Indiscriminately, you place the rusted sole onto a piece of knotty two-by-four and lunge at it with a two-handed fist grip. For your effort, all you see is chunks and tears beneath brown skidmarks and you immediately put it back. The expedition is over - the jungle is too thick. Forget the swollen rivers and the hard climbs. It's just too much!

Now that said - that machining is usually skilless - the outcome of machining is quick and easy and this is where the appeal is. In the UK, you probably work a 35 hour week, so it's not like the US where a workweek might be many hours more and then you might have a second job too. My personal workday has consistently been 12 to 14 hours in a day, mostly at least 10. Now my workday is different than most. I finished shoveling gravel on a pathway in my garden at 9.15 pm the night before last. My choice. I was filmed for the last episode of building the bookcase throughout the day and of course, every ounce of that was skilled handwork. I don't have a commute which believe me is work too. An hour and a half both ways does extend your day and you have school pickup, kid's bath time, meals to cook and then there is the trip to the game for the kids' sports to pack into the yet incomplete day. I get it! But here is the rub! Most woodworkers can never have machines. "Most" being the worldwide world! Making time for woodworking is a struggle. In times past it was easier, I think, because I went to work for another and then came home to the garage to make my own stuff and find my sanity. Throughout my life, I supported a largish family on a single wage - some might say it was more survival. Well, one day I might just tell you about the rich rewards of having three or four boys in the workshop with you most evenings as they made everything from garden boxes to violins, three legged stools and spoons and spatulas. This was a decision. Some may not have that choice. I don't know.

My struggle to wake up the once sleepier world of woodworking has now paid off. Aside from hosting three young woodworkers in their 20s and 30s in my workshop every day, I have a following of woodworkers from around the world copying what I have taught them online. They've bought those rusted planes that once were made redundant on cellar shelves and fixed them up. They've found old saws and sharpened them after derusting them and they have become competent woodworkers. You see, they believed what they saw, read and heard and that is all it really takes to become a hand toolist to a skilled level. The ingredient you need to do anything is a made-up mind.

If you have got machines then no one is saying get rid of them. All I am saying is that they can stop you from becoming skilled and that many if not most operations are indeed faster if not better by hand - cutting dovetails for instance, or making a housing or dado joint. This being a reality, that once you start with machines, you might well postpone developing the skills you might well have been searching for at the beginning and/or put it off forever. Also, the cost of hand tool woodworking is a small percentage of buying machines and then there is the space you will need to house the machines, the dust extraction, support equipment, etc. Mostly, it is about finding a balance and what suits you the most and it can be hard to find that needle in the haystack of YouTube if you are new to a craft like mine. I am here to short circuit the learning curve without compromising the quality. Our commonwoodworking.com site has helped hundreds of thousands to better understand the basics of woodworking and so too our subscription to woodworkingmasterclasses.com. Both are free. Give it a shot and join us. It's not all about making money, nor is it about exclusivity. Mostly it's about making wood work for you!

Comments ()