All in a day's wood work

I've been a maker all of my life. From age fifteen, I've made and sold everything I've ever made except the things intended for my home and my family and friends. That's over five decades and some thousands of pieces large and small. I don't sell now although I could but I don't know if I would these days because the work I do now is not to live, as in times past, but to pass on what I now know better and do and did. I remember the first pieces I made of my own volition. My sister's boss wanted some bench/bar stools for his staff to work from. He drove two cars, a Jensen and a Lamborghini. He ran me like he ran his business. Everything was about making money. Unwittingly, he cut my price for making them in half and when I was done he got hand-made stools for the bargain price of something mass-made. My stools were fully jointed with hand-cut mortise and tenons and all of the tenons were shouldered on four sides to tapering legs meaning that no shoulder was actually square but all were angled and married to the legs. I would that I would have known then what I now know. Read on!

A man made the chair above. He would be one of millions of the anonymous makers through the millennia who knew no fame and usually had no recognition for anything made. He would have never wanted any nor expect any - no disappointments there. It was an era of no competitions for first place, second or any place in those days of the real makers, there were no fakers, no stages for and no showing off even though there would have been so many trade secrets and hidden gems of wise working. This era of making will never return to our world of woodworking and no one should try to compare what we have today as hobbies and pastimes with what was had back then. It ended when the Industrial Revolution and global economies displaced them with mass-making and global trading on the widest scale in human history became what it is today.

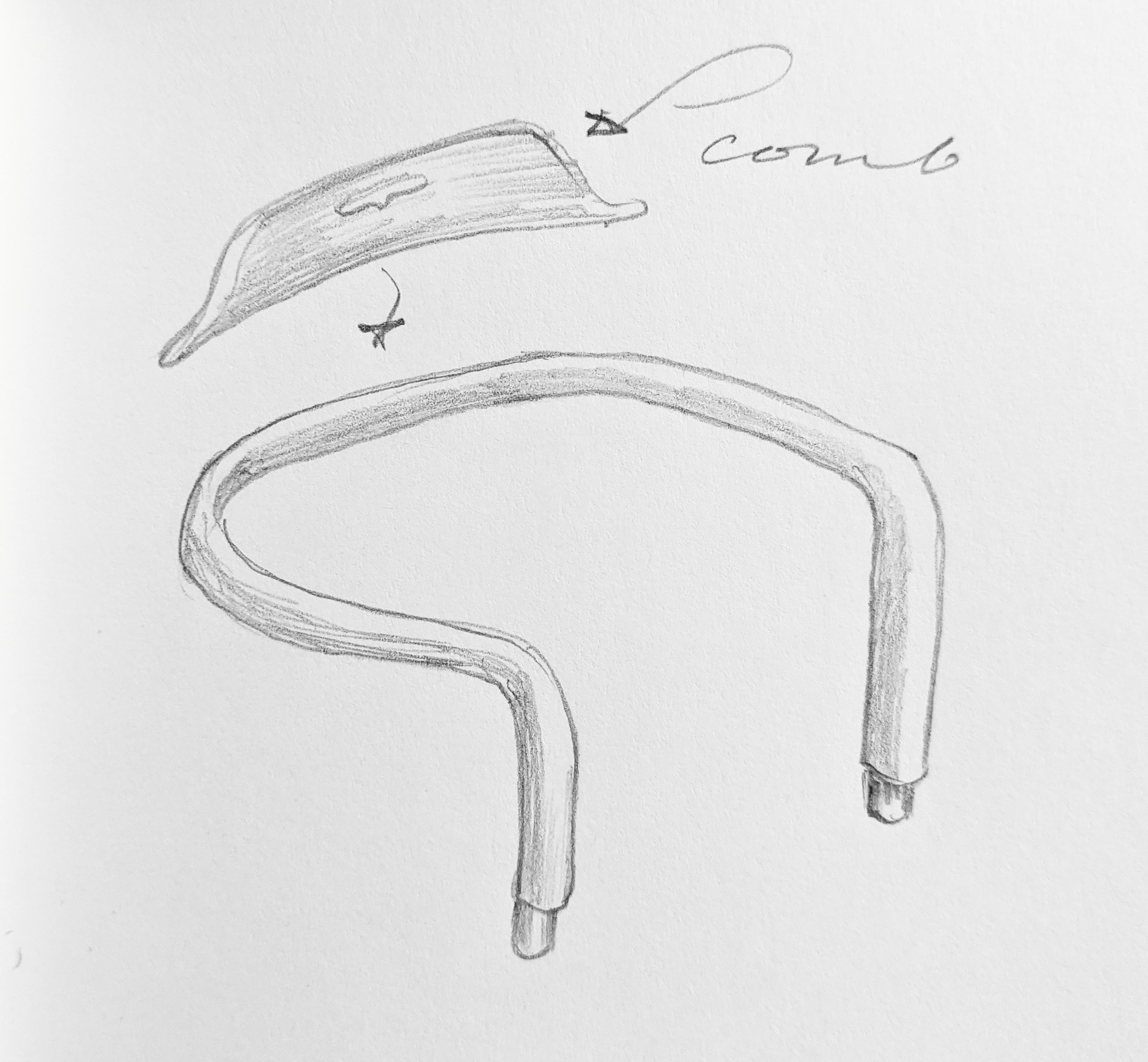

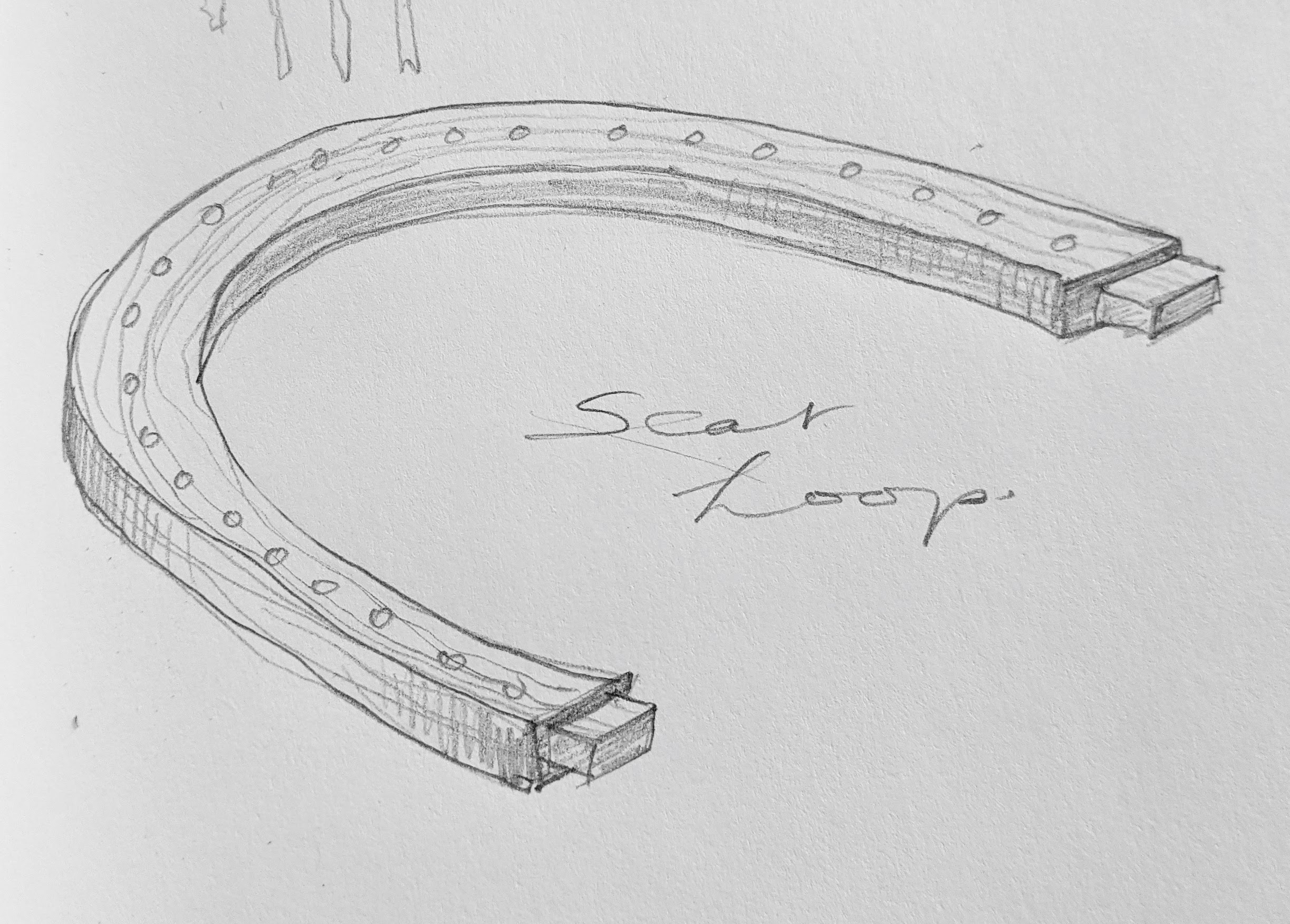

The chair arm he bent from staves split with froe and club, wedges and a drawknife too. Those days would soon disappear and chairmaking would grow on the continent of Europe in countries like Romania that would for a long season supply the world with cheaper but well-made chairs. His arms for his chair would be bent weeks before fitting and so too the seat's for a frame held by two mortises as shown. I saw the chair in the back of the auction room with a black number 202 on a white card backer and fastened to the damaged seat.

The man made the chair to last a hundred years and it did that and more. The bidding started and ended with my offer of two pounds. This three-dimensional work of art, as have dozens of other such pieces purchased and seen, became my walk with the craftsman. How could I deny the humility of a man expressed through the thing that he made? When a man in times past made a piece to sell became the, "little man I found in the village". The phenomenon of nameless "man" referred to as "a man" only may be a British thing. But again, the anonymity continued as if some secret but well-kept knowledge preserved the ability of the monied to get work of any kind done by someone unknown beyond a first-name acknowledgement of him being somehow an owned being.

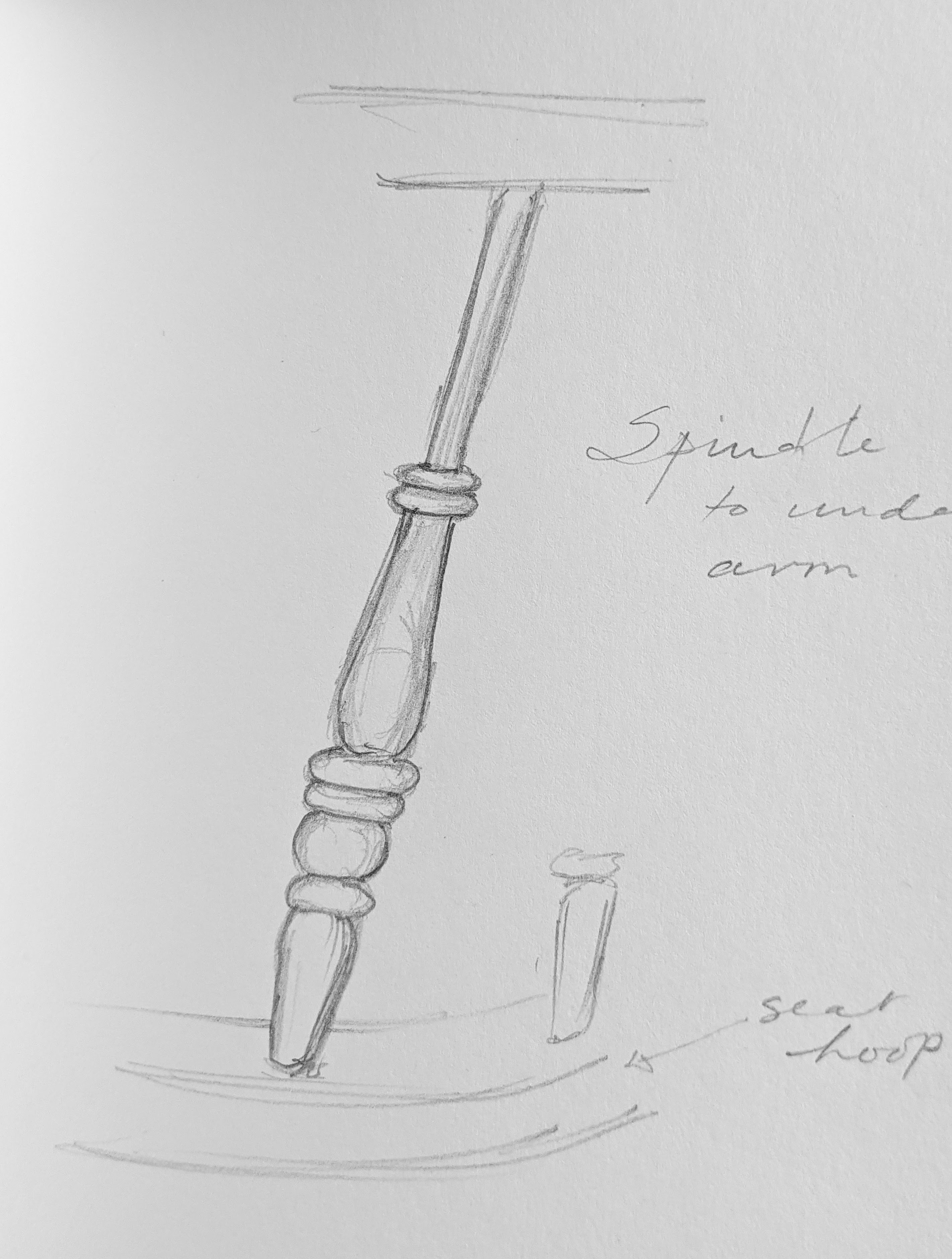

The spindles, each mildly different one to the other, showed just enough difference to know that each was eyed for shape and minimally different after turning many a few thousand over a life's working span.

The chair, painted white when I bought it, had a solid framework of oak, and luckily the paint and the chair were both old enough for the paint to flake readily away as I removed it. As a woodturner as well, I could fully relate to the making of spindles, legs and rails as much as I could the framework. Woodturning for chairmaking makes chairs simple and fast to make.

The turning has nothing unique to it but likely more so compared to today's woodturning made all the easier by much modern chuck gadgetry including the multispeed lathe itself. Rolling the gouge on coves and beads turns out a spindle in a minute or two and with just thirteen and four legs we're talking an hour's work there. The bending too is just a question of creating a steam chamber and heating the wood for an hour before the bends begin. Once bent, the wood is either heat-dried in warmed sand or left to dry for a few days and the remainder is simply bored holes and tapered spindles driven and wedged as necessary. Spindled chairs are the easiest to make because they are the simplest form of joint with no shoulders to fit and no tenons as such. When you look at the continuous arm you see the dynamic of transferring upper body back and shoulder weight to engage every spindle to the upper body support of weighty people.

Looking back on events like my experience with my sisters rich boss, at first can leave a bad taste in your mouth, but I learned to admire the success less and look more to the man and the character. I never entered into the bargaining syndrome as I grew in my confidence and became secure in the knowledge that they couldn't go anywhere else to get the same that I could give. The man saved a few pounds but when he asked for more work some years later I declined by saying I didn't want to work for him. When he asked why, I told him that he had taken advantage of a teenager and he should be satisfied with that.

Comments ()