Thick V Thin

I have visited this many times in classes, on my blog and in a variety of venues ranging from Monterey, Mexico to Canada, England to Israel, and then Wales to the USA. This one came by way of a question from a genuine enquirer not seeking to be argumentative but to understand the reason why. There we are in a class full of people learning the basics of woodworking and he pulls out a thick plane iron from a vintage English wooden plane, passes it over the bench, and humbly questions my saying that, "You don't need to retrofit your Stanley or Record plane with a thicker iron. The one that came with the plane will work just fine." You see, experience tells me to look into the history of planes. Seeing how ten decades of full-time woodworking craftsmen throughout Britain alone, as many again in the USA, and then others in other countries on other continents in different woodworking trades, would all attest that these Bailey-pattern bench planes worked well, and guess what? They never chattered when engaged in planing wood.

Well, I humbly responded, "What's the difference between a standard Stanley and Record plane iron and the vintage wooden version?"

"Thickness!" he replies.

I ask, "Is that all?"

"I think so." he responds.

"Doesn't this plane iron taper from thick to thin?" I ask.

"It does." he answered.

"Why?" I asked.

"To save metal?" he queried.

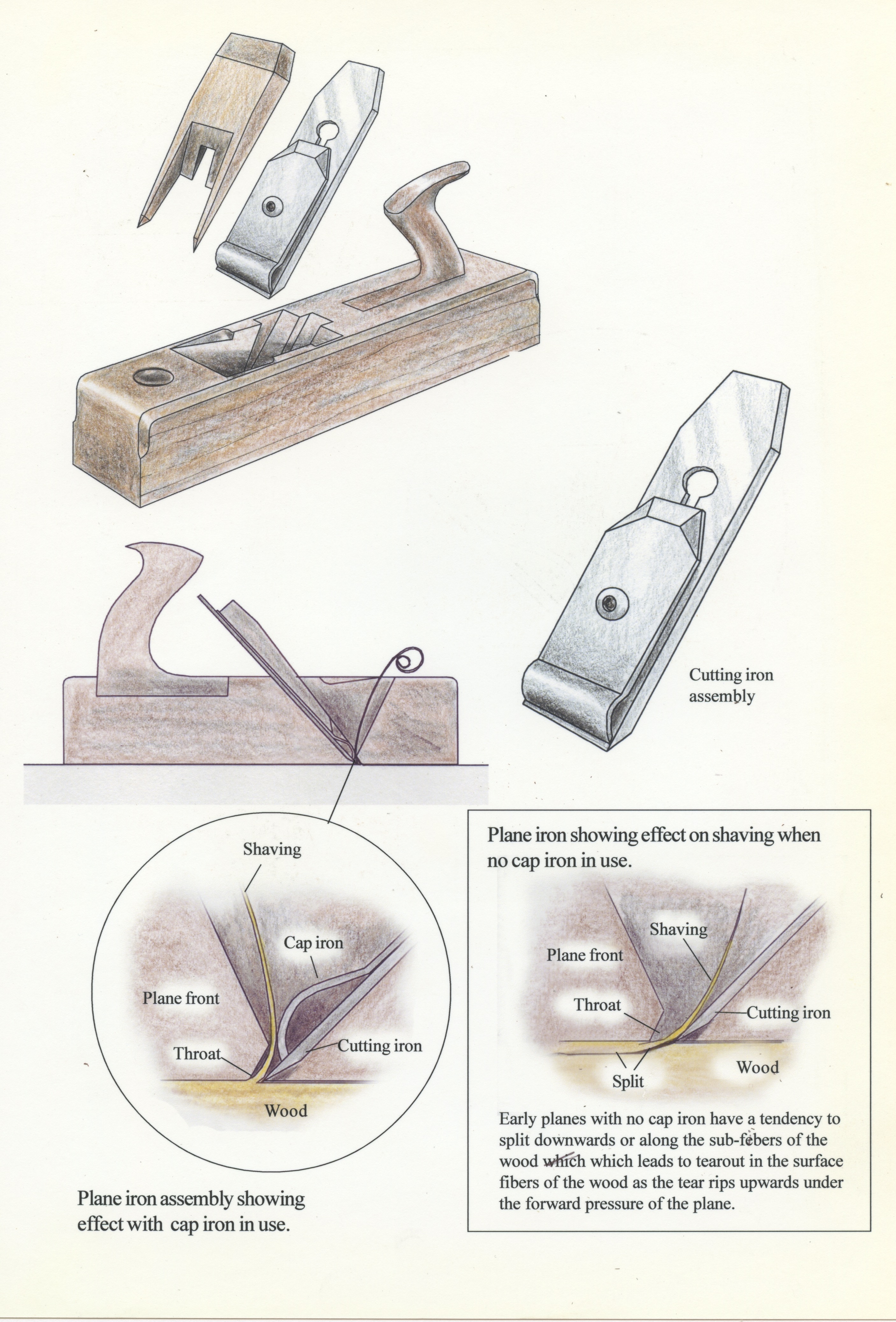

Well, it does do that, and it is easier to draw out the steel from thick to thin under a trip hammer or a sledge, but the real reason was to create a wedging dynamic when the plane is in action. The Bailey-pattern planes rely on the yoke adjustment mechanism to resist forces working against the blade when being thrust forward into the wood. Knots and hard grain will tend to and will occasionally push the blade back up and into the plane's throat. No such mechanism was available to the wooden planes at that time, only a wooden wedge. Using a wedge on parallel steel blades would work most of the time but is unreliable as the wooden retaining wedge alone is already angled to back out under pressure. Adding the wedge shape to the cutting iron and then using a wedge to oppose and lock it in place was a perfect solution. Should that blade jar in a forward thrust for whatever reason, the wedge shape of the cutting iron retained by the wooden wedge would actually tighten with the thrust and lock it all the more in the recesses either side.

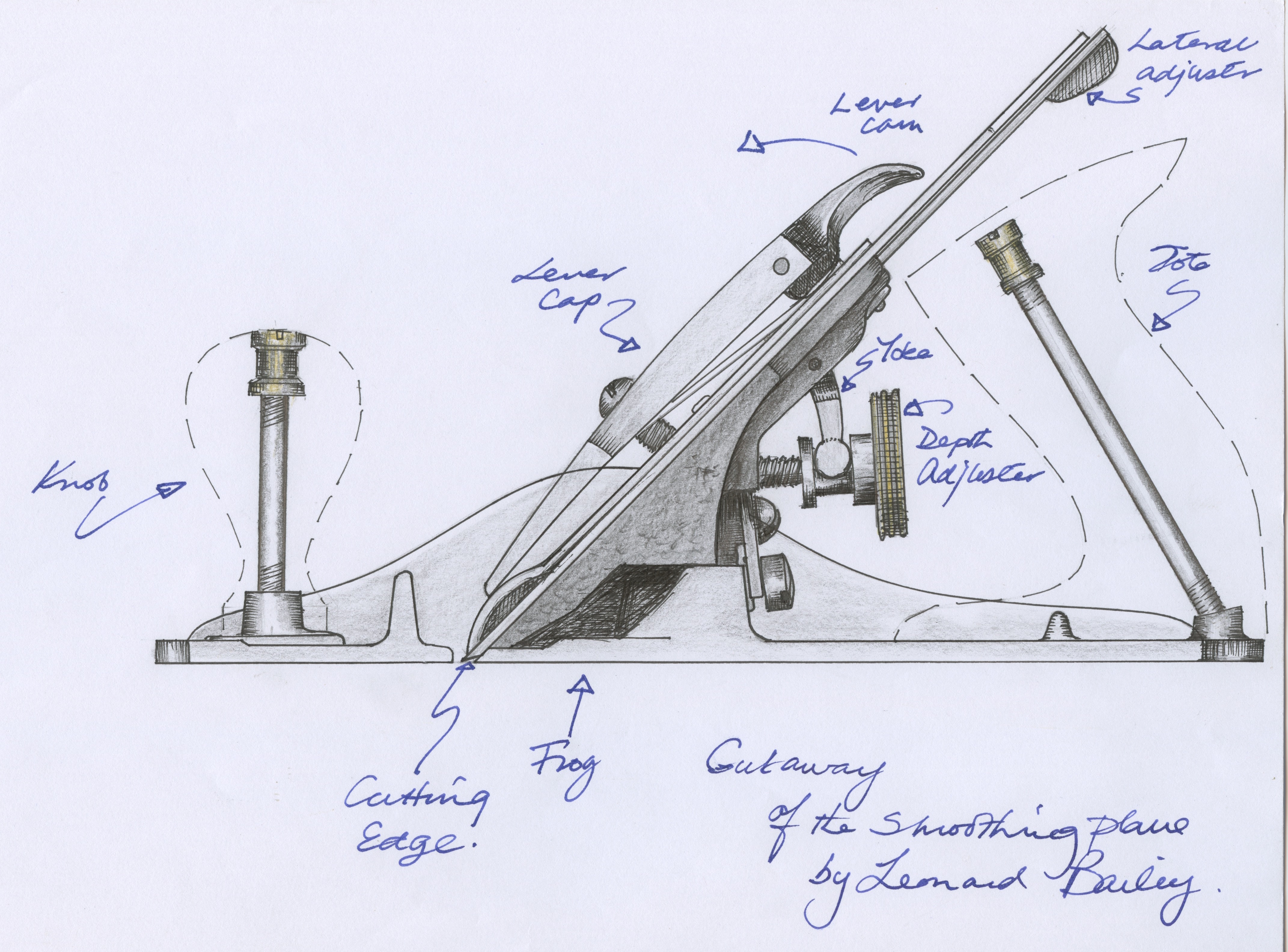

Leonard Bailey of Stanley fame developed the most perfect of modern planes in the Bailey-pattern series of bench planes for his day and time and really, nothing changed for over a century because no one really developed a mass-manufacturable plane offering the functionality his plane offered. Hundreds of thousands of planes went out through the century to practicing tradesmen who worked successfully with them, all of that without any retrofitting of anything on the planes at all. Don't you think that it's actually remarkable that all of a sudden, after a century of planes being used full time by craftsmen, we amateurs suddenly encounter planes that chatter so badly in the cut that we suddenly need thick irons to correct this newly developed malevolence in bench planes of the Leonard Bailey pattern? How could this be? Where on earth did this come from? Well, think engineer! Think a man in need of inventing something perceived as a need rather than an actual need at all. Think someone who made an additional improvement who takes a piece of steel, hardens it and then starts to sell it in competition. He cannot sell the same cutting iron for a higher price because, well, no one would buy it. But make the iron thicker, tell your future customer it stops the phenomenon of chatter, knowing that it's not actual chatter at all, and suddenly you've got customers. The problem with this is that the plane iron was not guilty.

In a recent video posted on my FB/Instagram platform, someone made a commonly stated comment about their plane chattering. Of course, 98% of these planes sold never chattered at all. Most surfaces resulting in an uneven, washboard surface is almost always user-error or some other phenomenon that causes the plane to hop, skip, skud and jump over the surface. Too much force, too little force, a limp fist-to-wrist linkage, diffidence, lack of confidence, lack of experience, and so on, all lead to skudding as the plane negotiates a surface.

My thinner, standard-fit cutting irons do not chatter and they never have chattered for any of the above reasons. Chatter is a very unique and isolated occurrence in planing with a plane on so rare an occasion, it might happen only once in five years. So, where is the confusion? Chatter is very difficult to produce, sometimes difficult to evaluate and is so fine it barely takes more than two rubs with fine abrasive paper to remove it. In my own life of woodworking daily for 56 years I have witnessed chatter only a half dozen times under my own plane and from beneath the planes of the 6,500 students I have trained over the past three decades. Doesn't that tell you something? Look, you are having struggles planing. The questions you might not be asking of your bench plane are:

- Is the blade sharp?

- Is it set precisely for the appropriate depth?

- Is the blade the right way up with the bevel down?

- Is the lever cap set firmly but not too tight and not too loose?

- Are you using a firm and positive grip without bulldogging the plane to the wood?

- Do you in particular have enough strength, upper body mass, developed ability for control?

- Have you developed the confidence to land the plane to the wood at a level parallel to the surface?

- Is the wood itself even-grained or is there fibre that counters your effort?

- Is the plane presented in such a way that it engages the grain with the ability for you to apply even pushing power?

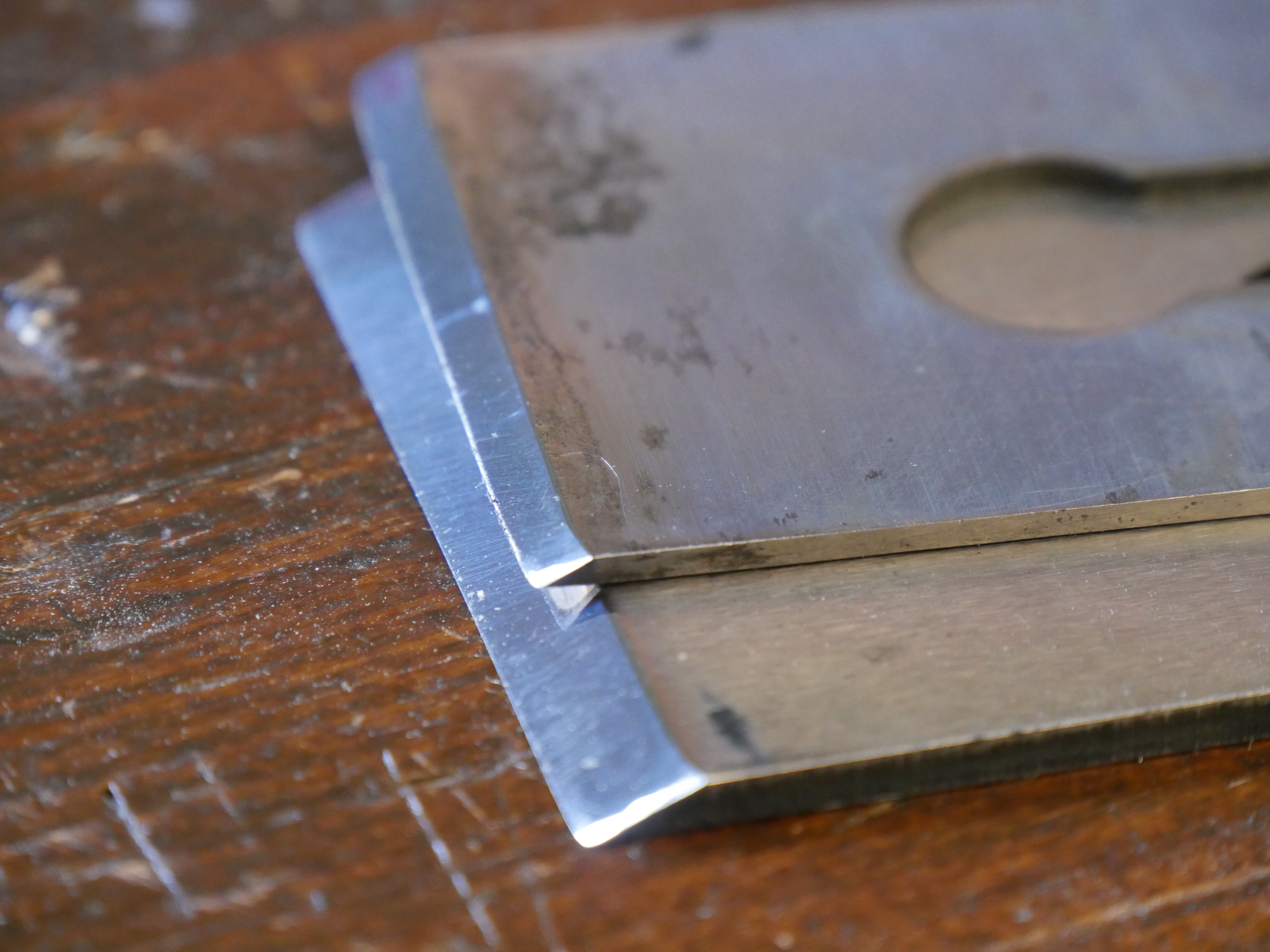

It is a sad thing that makers and sellers of planes can sometimes be a little low on integrity and fail to admit that any and all Stanely and Record plane irons worked well, work well and never needed any replacement. Now, low-angle planes might need thicker irons by their very nature. Were they made from thinner steel they might indeed flex as they pass over the surface of the wood. Take a close look at my cutaway plane picture above. Leonard Bailey's strategy was incredible in that it answered the need with superb measure. The strategy? The tension between the cap iron (erroneouly called the chip breaker) and the cutting iron. This inbuilt tension twixt the two tackled all and any grain with no issue. In 98% of cases, the corrugated surfaces produced by users are due to inexperience, lack of confidence, and several more already given above. Manufacturers are good at not stating what chatter actually is but use chatter as a catchall term for several surface defects left after planing. It is easy to blame thin irons for causing this phenomenon not so much by proving that that is what caused your dilemma but by simply saying thick irons eliminate chatter. Let me say this: if you can visibly see staggered steps on the surface of your planed area that are anything from say 1/8" to 1/2" apart (as in pic below), this is NOT CHATTER! Chatter is apparent as iterent steps on a super-fine level not dissimilar to the surface of say a very fine file.

I recommend not fitting thicker irons in your Bailey-pattern planes. All you will end up with is twice as much steel to remove each time you sharpen up. The amazing entrepreneur/inventor, Leonard Bailey, pegged everything to do with the plane with exactly what was needed at the point of his developed prototype through to our present-day and this was all that we needed in an all-metal plane - In the words of Bert Lance, "If it ain't broke, don't fix it."

For more in-depth understanding of a wide range of planes and all of the tools I consider essential to my woodworking, get my book Essential Woodworking Hand Tools here. It might just change a chunk of your woodworking life!

Comments ()