Sharpen Your Teeth

I sometimes think saw sales and the makers shoot themselves in the foot. Whether it is because they fail to change with the times or just plain shortsightedness, I can't tell. Perhaps that's a little strong but don't think it is even strong enough. There is though something about old businesses that are prepared to just survive rather than prosper and serve. I think it must be two decades ago when I wrote for a US woodworking magazine suggesting some UK makers put out a tool kit disguised as a fully functioning tool rather than a quality product designed and made to work. It is no wonder that people buy competitor tools and tell me how an Eastern this or that is better than a Western other. Truth is, some tools look good and fit for purpose yet when engaged in the wood they become dull and sloppy.

This Crown gent's saw is one such tool. The wooden handle is nicely formed to fit the hand perfectly and it is indeed nicely finished, the brass back is plenty stout and rigid enough, it has a nice brass ferrule and, overall, it is built to last. The saw plate is exactly the right thickness and of the right steel to last for a lifetime of several woodworkers working full time and most importantly the teeth will take and hold a good edge. What stymies this saw is that it, along with thousands upon thousands of others they have supplied through at least three decades to my knowledge, is they are sent out unsharpened. I know, it makes no sense and yet it does make sense if as in times past they knew the new owners would automatically sharpen the saw first. This was of course when they supplied the trade and the knowing woodworker. Those days have long since gone. Crown cannot see that their prospective buyers are those who mostly have never even considered that the saws might not be sharp but that the reason they not effective is them, the users. Nothing could be further from the truth. What Crown and other UK makers didn't and [possibly still don't know is that people, potential customers, have shifted from buying European and US makers to buy Japanese throwaway saws because at least their saws arrive sharp and ready to go.

Were you to buy a Japanese saw, and most now are made by Eastern communities like Taiwan and China as well as Japan, you will most likely buy into a throwaway economy to buy a saw destined for either the landfill or recycling. Why? These makers want returning customers. They harden the teeth of all their saws so that we woodworkers cannot do what we really might prefer to do and that is to sharpen our own saws time and time again for decades. That way they have a guaranteed moneymaker because we will keep going back for a new saw replacement. And instead of us learning how to do a three- or four-minute task in resharpening our saws and using saws that would then last for a century, we buy into the economy of companies who see only planned obsolescence and a guaranteed way to make more money.

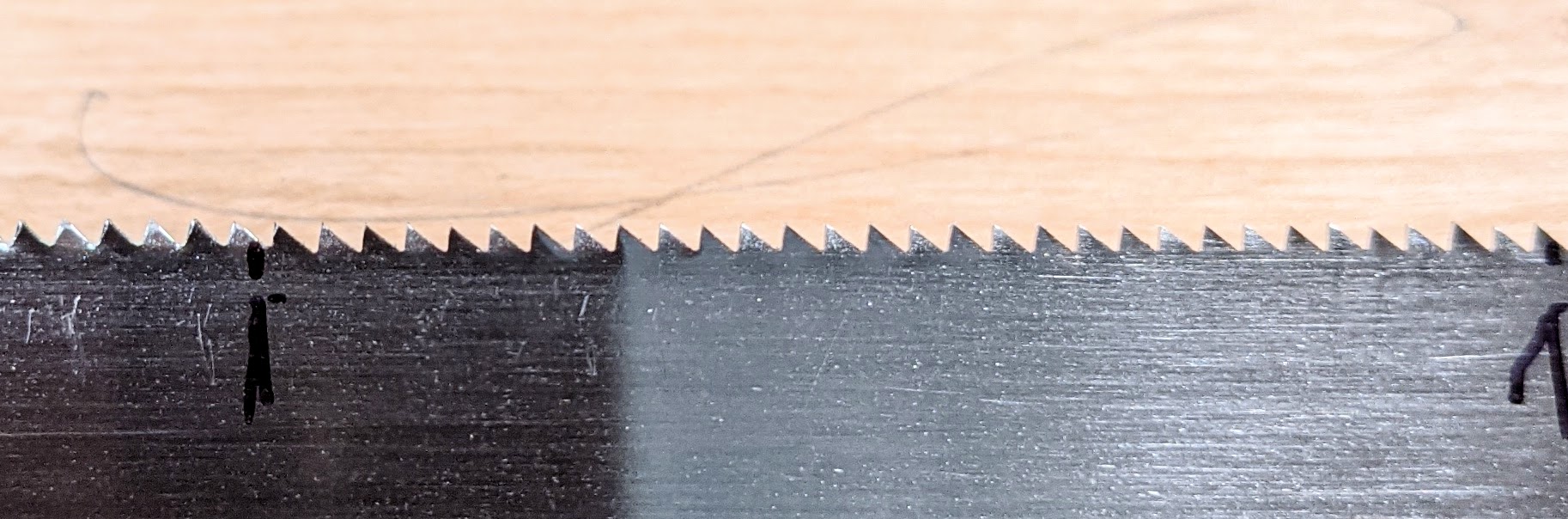

In these two images, you can see before-and-after pictures of teeth in a new saw I purchased from Crown Sheffield, UK. It's worth double the selling price of £17 because it is built to last. This saw takes me two minutes and 40 seconds to sharpen. It will hold an edge for 2-3 months of daily use but I sharpen mine more than that. In the decades that I have owned my first one of these, I have only reduced the plate depth by 4mm. It would therefore last about 100 years of daily use.

You can see how the teeth are punched out by a saw tooth toother, a machine set to depth that then determines the depth of the gullets by the spacing of the teeth. This is really the first of a two-step process and should be followed by a tooth filer. An automatic tooth filer is not the best method, hand filing is better, but it is better than no filing at all. If one was used in my new saw it is not apparent in the gullets so I think this step is negated to bring the price down to its lower point. This machine shear-cuts each gullet and you can see the bend from the impact reflecting in the slight buckling of the metal. It still needs that second process called sharpening, but even these rougher teeth will cut but poorly. Hand filing is a simple and quick-enough remedy to this slovenly practice so don't be put off as sharpening needs to be done within a few weeks of purchase anyway.

All in all this short-sightedness is an industry problem with many old and ageing companies where owners either care too minimally about their name and reputation or indeed they feel it is not worth pursuing the quality so that they are of true service to their customers. If a hand filer could be had for £20 an hour he could likely sharpen a saw every five minutes. Doubling that cost for 12 saws would not cost but £2 more per saw more. Selling such a saw for £21 would add £2.44 profit which is not very much to pay for a lifetime saw.

Comments ()