Measuring Moisture

Many years ago I wrote about the wood I worked with in Texas called mesquite. Mesquite can be mistaken for a mahogany-type wood because of its red-to-brown colour, but touch it, lift it and work it with hand tools and you can feel the massive difference. Back then, in the article I wrote, I resaturated different species of North American hardwoods to prove a point. Mesquite is most likely one of if not the most stable wood in the world. It makes the best cutting boards ever and believe it or not (I don't care) a single-piece mesquite cutting board will not crack or warp no matter how many times you leave it in dishwater and otherwise mistreat it. Try that with any other hardwood from North America!

Anyway, back on track! Back then 20 years ago, I took 152mm (6") wide sections of wood and soaked them for 24 hours in a bucket of water. Previously all dried down to 5% MC levels, maple, oak, cherry, walnut, together with others, all expanded to between 10mm (3/8") to 12.7mm (1/2"). Mesquite only expanded 2mm max (1/16"). I have done things with mesquite that you cannot do with any other wood. A piecrust table for instance. In solid wood, the outer circumference edge will expand a hundred times more than the inner areas. You'll end up with cracks and separation of the components, hence they are made with a substrate and veneered with piecrust veneers only.

Currently, I have been experimenting with how and what changes take place in black cherry for my rocking chair. I am using four different moisture meters supposedly by four different manufacturers to trial them for efficacy, so if you see me using different meters, that is why.

That said, I suspect that inside the plastic outers the innards are all Chinese made by the same maker no matter which name is stretched over the outside or which country they are supposedly made or assembled in. Who knows anymore?

I had bought in some 4/4, 5/4, 8/4 and 9/4 boards of cherry which all checked in at around 10-11% MC three months ago. I have made two cherry rockers from that wood and on one of the chairs, the seat is allowed to 'float' atop the frame so no problems except a slightly bigger gap here and there. No more than expected.

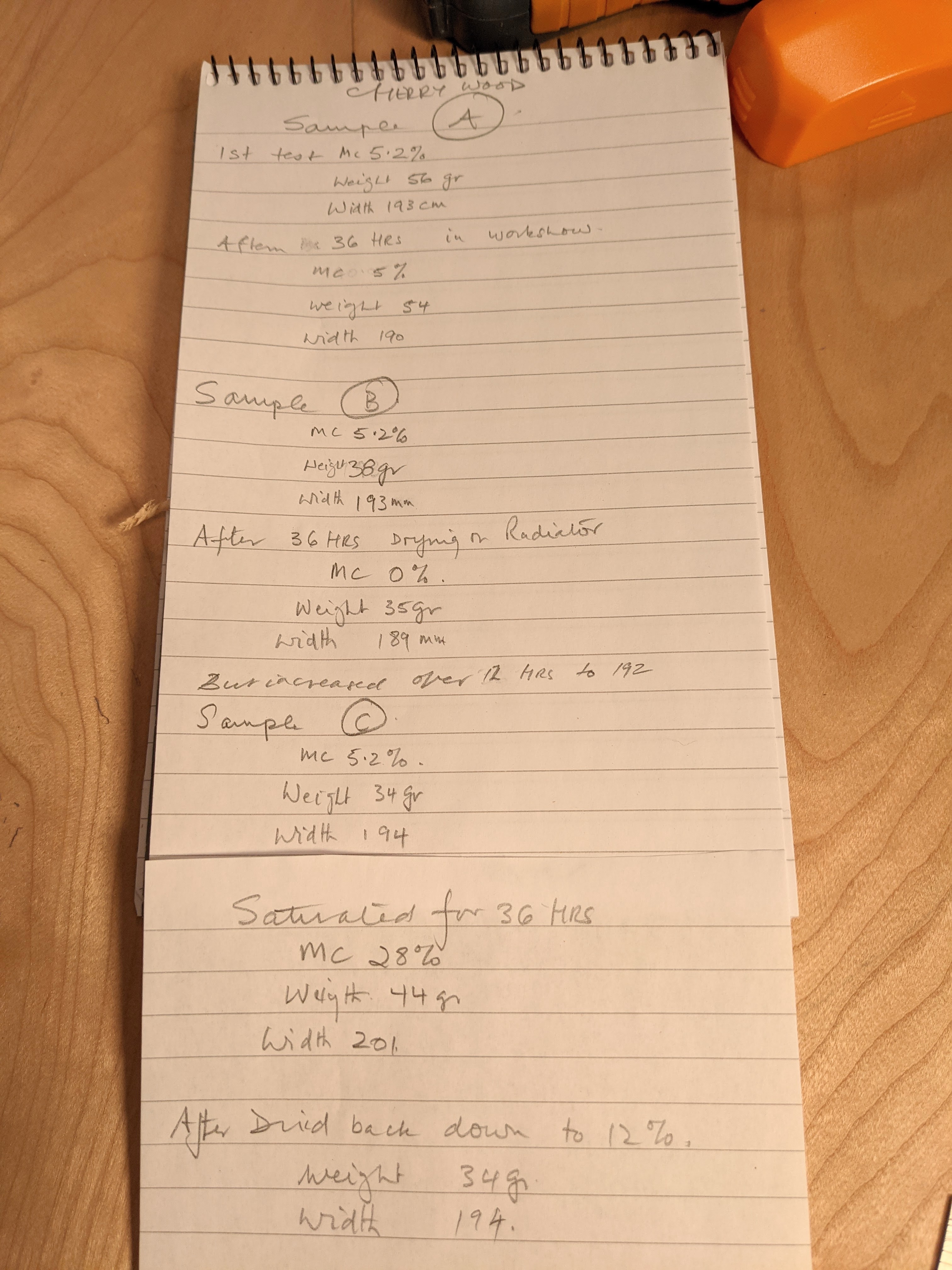

Wanting greater control or to compensate for such movement I decided to know more. I have done this on other pieces I have made. I like it. In 36 hours my tests on my cherry wood showed as follows: I increased the moisture in sample 'C' from 5.2 on up to total resaturation of 28% by immersion. I dried sample 'A' down to 0% using radiated heat. The text shows details. Sample 'B' remained static in the garage workshop with no interference. Interestingly, sample 'C' went back down to 12% in 36 hours. Sample 'A' increased in width by 1mm with no weight change. By testing samples this way I can better gauge what my wood will actually do in the zone. It's not the type of thing you can read in a book. I want facts at the bench. And if I want to I can thus minimise risk to achieve what might not normally be achievable if I just winged it (and I do wing it too). I can now calculate how much cherry will shrink or expand in a permanent domestic situation. Something that varies markedly according to different households.

In the case of my rocking chair, I am trying to get guaranteed results for my audience should they decide to build one for their family use. I have made the same rocking chair in oak recently. Oak is usually quite forgiving with regards to expansion and contraction because it is so very ring-porous. It has stretch and elasticity due to the large open pores at each level between growth rings. In other words, it's 'spongier' than cherry is. Some woods do not. Cherry and oak are different. And you can see the lighter band of ring-porous wood on the outer of each band here (the bands go top to bottom). This is the band that gives stretchability and compression in oak.

In cherry, you will see porosity is much more evenly and densely distributed throughout the wood in much smaller pores. This is termed diffuse-porous wood. My non-scientific testing gives me to understand that cherry is less stretchable and compressible than the oak I have is.

I think that this is interesting enough to write about here but it is much more mind blowing in the zone at the bench and it doesn't take long to do either.

Comments ()