What Cost the White House Pieces?

Mesquite is a lowly wood. It covers 56 million acres in Texas alone, more than any of the other few states that host this very unique tree. I have much more to tell you about this tree's lovely uniqueness but perhaps in later White House posts. For the main part, people, ranchers, mostly, seem destined to bulldoze it, burn it and diesel-poison it. Diesel poisoning is where a rancher takes a quart of diesel and pours it into the ground around the mesquite. That's a sad affair! For the main part, mesquite is used in Texas homes for heat, ambiance and for Texan barbecues. Some ranchers keep them around with the live oaks to shade their cattle in unending hot Texas summers. The blend of mesquites in the Texas Hill Country and a fine heard of finely-bred longhorns is unequalled by any other breed of cattle, geographic location or tree species. Now there are mesquite pieces in the White House. How 'bout that!

A Texan barbecue is different to the rest of the USA. Bigger and, of course, better! I have seen piled-high mountains of it burn for weeks slap bang in the middle of cattle land. The problem is that mesquite is the slow-growth, stealth invader that silently spreads its roots to plumb depths no other tree does. Vast tracts of land are owned by landowning lawyers and oilmen in Houston who visit their few thousand acres in the Hill Country once in a blue moon. They run a few head of Longhorns for image and meet fancy clients for a weekend's shooting of anything that moves on four legs and two. Their kids run riot in a vintage, open-topped jeep and stir up the dust doing something called fun and the neighbours are driven crazy once a year by it.

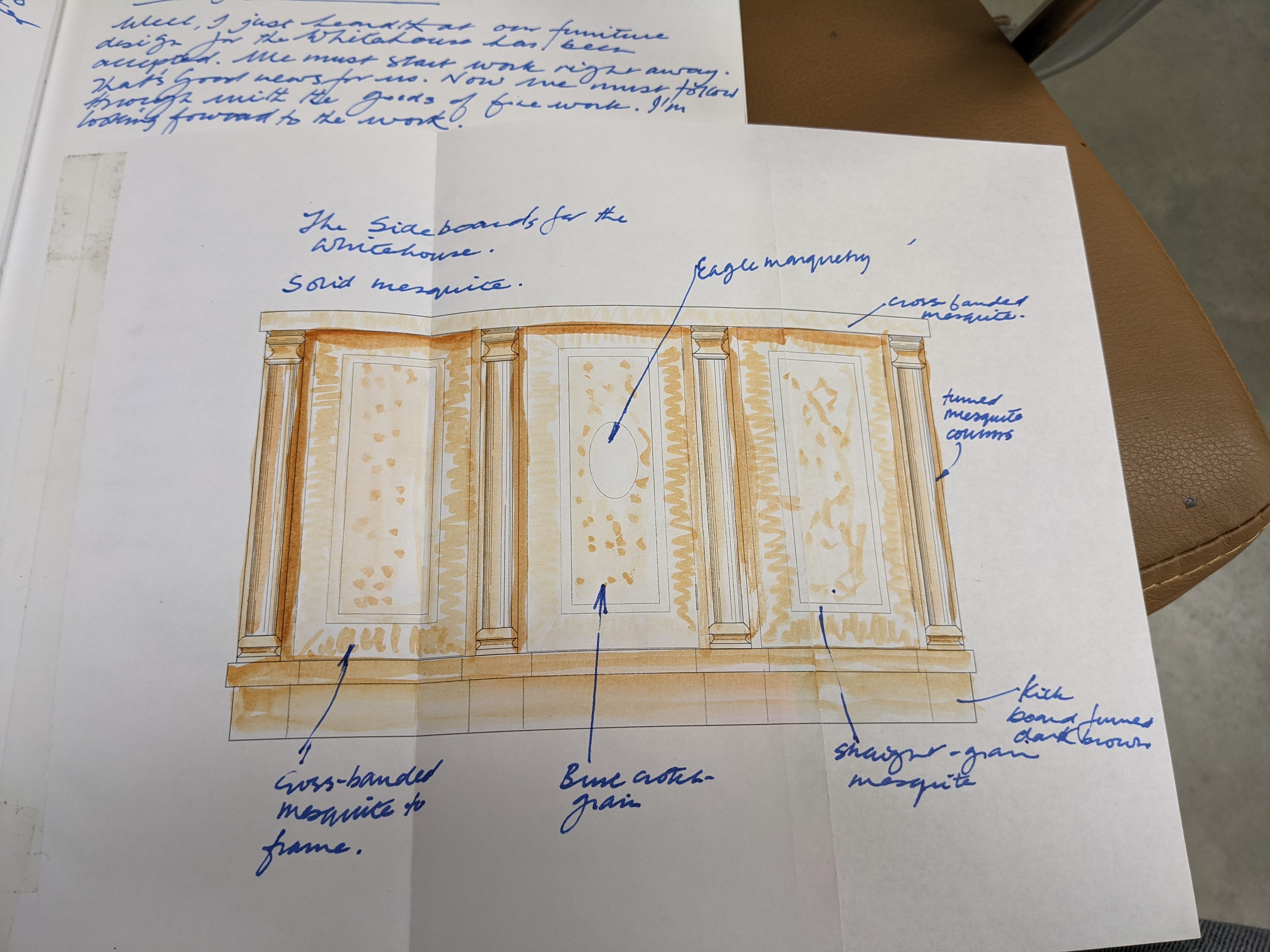

To make the White House pieces I was asked the length of time it would take. I said to the questioner, "It's three month's work." This was in the middle of December 2008. He replied, "We need them by the 25th January 2009!" I said, "OK! No pressure then?"

Ultimately I assembled those who I knew knew my ways of working: men who I had worked with for almost 20 years but men who were once but young boys when I started training and teaching them about hand tool woodworking. School-aged, they had been looking for their calling and found it. They'd become fine men, working men with willing hearts but for the asking. To bring them in meant abandoning their own existing workload to bring two pristine credenzas from a pile of rough and almost hopeless boards, twisted and cracked; the work became exemplary works of art highly fitting for the Cabinet Room of the White House. This was indeed a major ask.

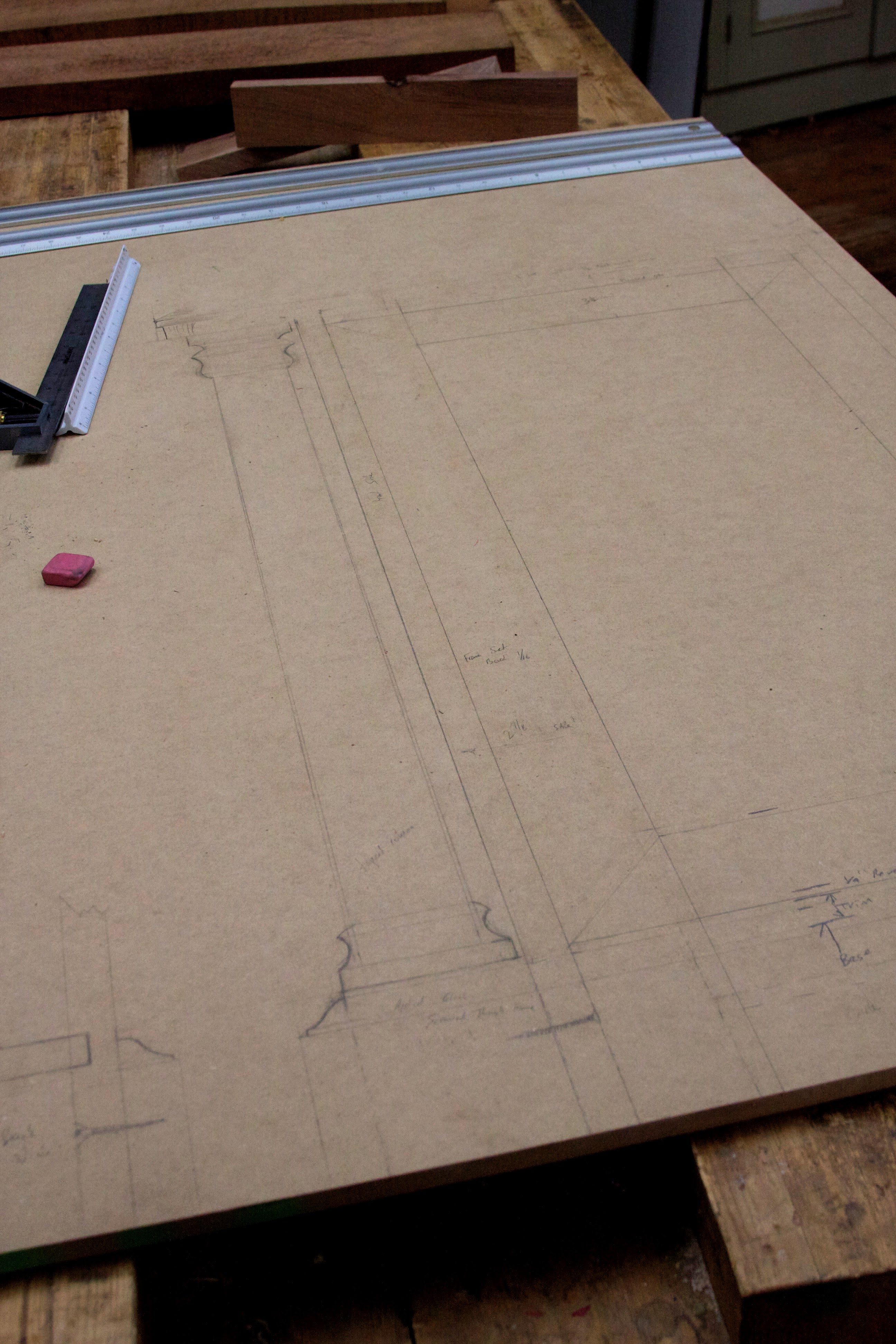

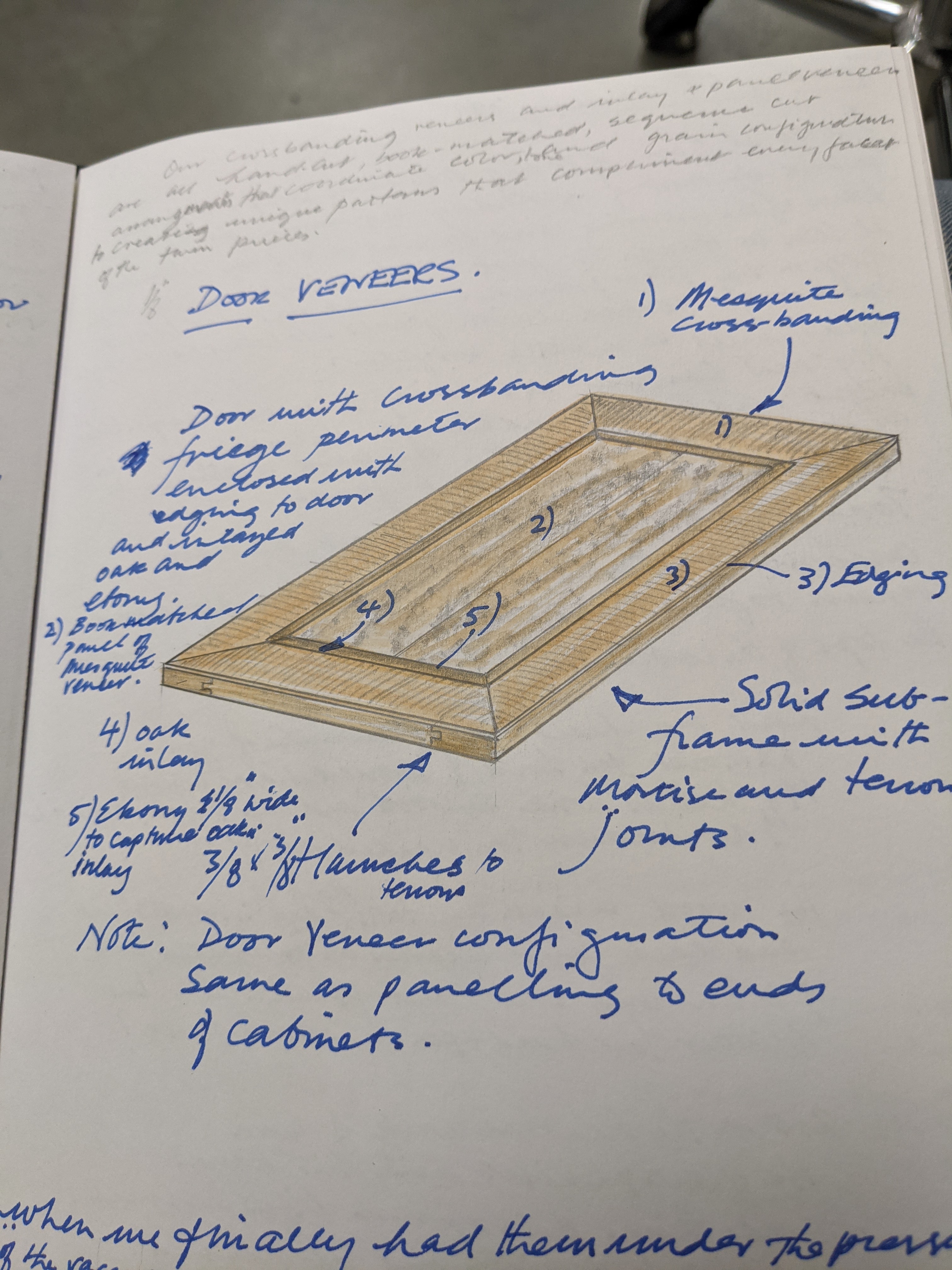

We sat together in the workshop one evening to work out what could be done by when and how we could actually pull off the impossible. Remember we wouldn't be programming a CNC machine of any kind. I'm not even sure if they existed then, but we never would have used that system anyway. We knew craftsmanship and skill were of the essence and we knew we had this to the man. Mostly we would rely on the standard machines for the donkey work dimensioning and then handwork would take over to just make things fit. How many joints were in each piece I have lost track, but we had plenty. . . and the days were ticking away, with Christmas slap bang in the middle of it, and we hadn't even sourced the mesquite at that point, we had our work cut out for us.

Without this cluster of friends, I could not have completed the work on time. Things happened, we were slowed, but we never stopped working way into the dark, cold winter nights for a full-on month. Oh, and we delivered a day early--the 15th January 2009. George Bush was giving his departing speech before the Obama Inauguration on the 20th, clipping a week off our delivery date. Could we do it? We didn't find this shortened time slot helpful, we didn't know until two weeks before the due date that this would happen. We then worked twice as long, twice as hard and three times as smart. No mistakes! The one thing we never compromised was the quality of workmanship. We delivered top quality. That was all that mattered.

To say that both designing and then making the White House pieces was an honour for me would be to miss the point. I was honoured privileged to give the designs my best effort and so too the making of them. Looking back through my journals of the day, seeing the drawings and the notes, I found myself thinking about the men involved with the making. Believe it or not, at an advanced stage in the making I had a week-long class. Visitors kept coming in too and the two pieces stood side by side on leveled stands in full view. People would ask about the customer but we kept our secret. Well, until one of my students came over to me and leaned on the bench and said, "These are for the White House aren't they?" Whereas it was the White House that made these pieces important to me, more than that it was the men I was working with and grown to love. Just as the mesquite wood itself had its idiosyncrasies, so too the men. Their individual personalities came through. The ones that joked irritated the sober-minded and the sober-minded irritated to jokers. Suddenly everyone burst into laughter when they saw the funny sides of things twixt the two and the work kept going. These men gave their everything to creativity and every plane and saw stroke meant something to them. One mistake by one would telegraph through the piece to affect another area of the work. They were each of them uncompromising in their work. Framed doors with mortise and tenons interchanged between openings as though each one was fitted to the other. Watching over them as a sort of pastoral shepherd I was amazed at how well they were willing to defer to one another in every way. The wood went from rough-sawn to silky smooth beneath a mere smoothing plane. Hinge recesses were perfected by deft chisel strokes. But more important than all of this was this one reality. As each piece of wood was made to fit the composition of the whole, so too the men working together were being tested and tried by their work and their working. The minor irritations of abrasiveness seemed aptly able to wear down the rough surfaces in personalities. At the end of the work we all hugged and breathed a sigh of relief. We knew at a certain point that we would, at last, be able to deliver on time.

Time passed all the quicker as Christmas came and went and I found myself planning the route that would that would make the pieces a reality.t Throughout what would have been the holidays and indeed Christmas day meant me working through the realities. Planning is one thing, engaging in the actual physical work another. No one of us ever missed a beat. Twelve-hour days were needed and they quickly went to fourteen-hour days, fourteen went to sixteen- and some later days even went over twenty-hour days too. I was so proud of these young men, which included two of my own sons!

Comments ()