I Wonder!

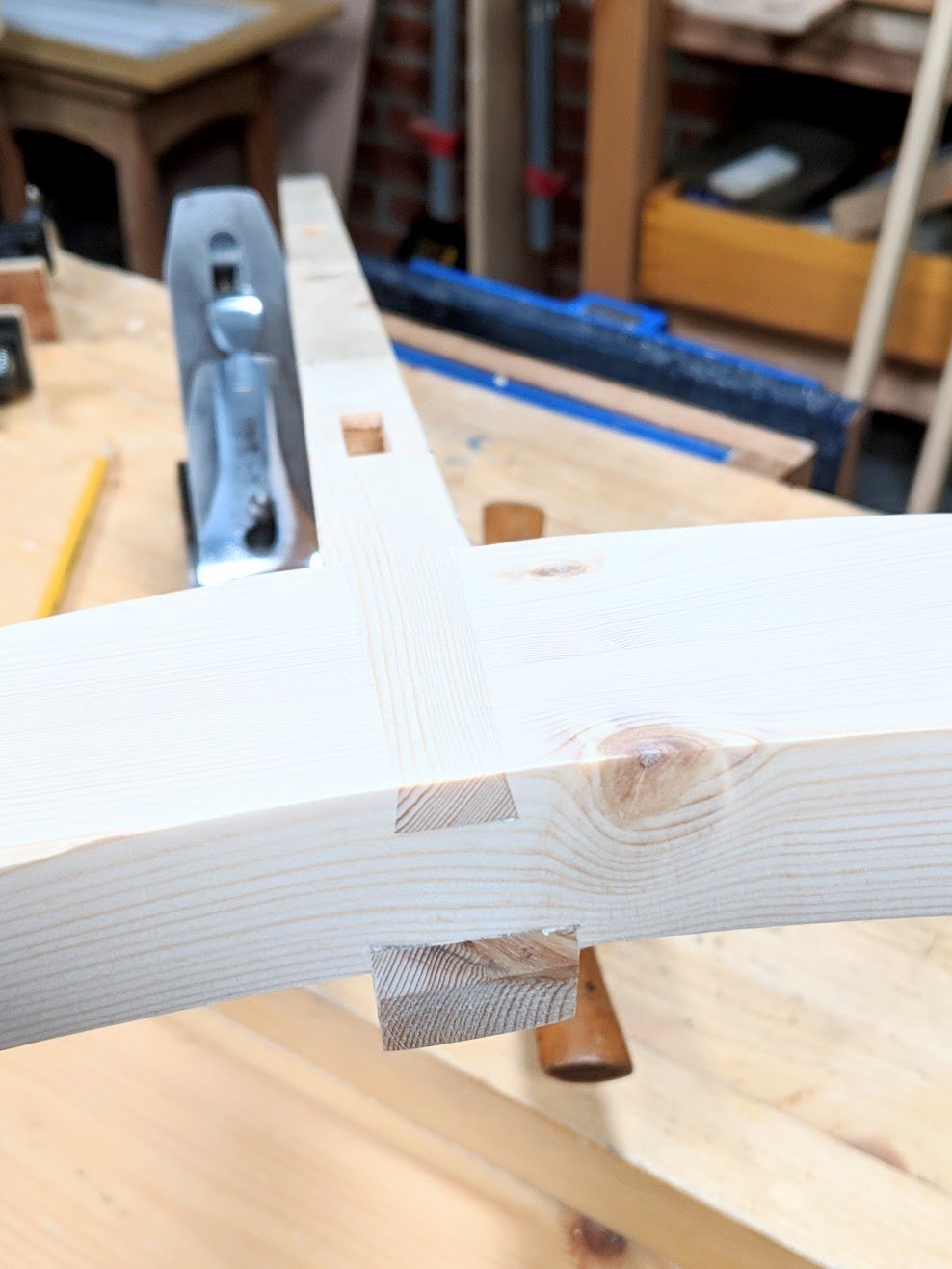

I woke with a feeling about something this morning. Is perfectionism truly a part of who we are or is this pride that just gets in the way of our enjoyment in making? Are we obsessed about getting every facet of our work just right and is it possible that we do it not so much for ourselves but to gain the approval of others? I am not exaggerating if I say I have most likely made tens of thousands of woodworking joints on a daily basis throughout my woodworking life of 55 years. And in those hundreds of thousands, many have been dovetails, housing dadoes and mortise and tenons, but then there are many others too, ranging from splined mitres to combination joints comprising two and even three joints in one that has no name. Think the sliding housing joint I developed on my latest and newest triple-leg floor lamp stand with table. Or the breadboard cutting boards with tongue and groove joints along with pegged and stopped through tenons into mortises.

This past few days I have been developing a a linen press, a sort of airing cupboard for linens such as bedding and bathroom towels and such. There are nine dovetails to each of the four corners and as I concluded each one I said to myself, "Perfect!" I actually do this to camera all the time too. So, am I being genuine if I say that and there is a gap or even a little looseness to some part of it? Perfection is in itself almost indescribable. Do we look at a part or the whole when we make such a declaration. In the Science Museum in Oxford there is a section dedicated to instruments that were part of capturing information for early science research. Perhaps a wooden telescope or a dovetailed wooden camera. Tripods were all wood with brass parts and zero plastic anywhere to be found. The joints holding them together were perfect in that they were developed carefully by an artisan of no name. His working knowledge was evident in the care and construction but knowledge of him was utterly hidden. I said to myself, "Perfect!" What was perfect was its functionality and its aesthetic. Yes, I could see small gaps here and there, a file mark left in the brass of a hand-made hinge and such. These character marks weren't the excuse people use today for rough work, they represented careful thought for where the work needed to stop and the use of the equipment to begin.

As my dovetails seated into their individual recesses I could see one joint that had a perfect parallel gap to the line resulting in a gap. With around 54 joint lines surrounding the pins and tails it was the only gap and it was about 1/10 of a millimetre wide. The gap was perfectly parallel. I should reiterate this because, well, it looked nice. Showing my work to a hundred people, I am sure everyone's eye would be drawn to this 'imperfection' and, as my work often does in videos or photographs on my blog, would induce someone to make comment assiduously on my erring saw cut. Smiling as they say, "I am sure no one else will notice but I did perceive a small gap there in the dovetails." and tapping the side of their nose to say, "Your secret is safe with me!" Fact is, for me, what was perfect was that the joint's efficacy did not depend on that joint aspect being tight. With nine recessed dovetails in place the joint will remain together for 300 years. Why would I worry? It was, indeed, perfect!

From time to time I have filled a joint where it truly mattered. Not for my own peace of mind or my reputation but to save others from not understanding what was important. I have had to deal with many a student who says of him and herself that they are 'too much of a perfectionist' when in reality it is nothing to do with perfectionism and all to do with their pride. Look over any of my pieces and you will find fault even if it si not a fault that you find. It's not much different than people who say, and this often enough for me to say all the time, "I was doing okay with Paul until he put his plane sole down on the bench. Surely he knows this is a no-no!"

Whereas we all should strive for the highest standards in our work, we should also look at the reasons we do so. I just enjoy woodworking. I don't do anything for the approval of my peers. if I did I would be long dead and buried by now. It is not good to choose the wrong piece of wood that sticks out like a sore thumb in the whole and say, "It's character!" when it was a bad choice and often even laziness. It's the same with careless cutting throughout our work that results in torn grain, stopped strokes and steps in the wood. This is not character. What is character are the plane strokes left from a plane with a cambered iron from 1650, the saw kerf marks left on the back of a cabinet that would spend 200 years against a wall and the cuts to the sides of dovetails that did not stop at the depth line on occasion. Think life! A skilled craftsman was given five hours to dovetail five drawers in oak or mahogany on all four corners and fit the drawers into their individual recesses. The methods were transferred to me 200 years on and I knew exactly how the pieces were made. Phenomenal!

Enjoy your woodworking today!

Don't obsess for the approval of others! It's not an exam!

Comments ()