Eastern and Western Saws Part II

It's hard to say who came up with the first saws for woodworkers with hardened teeth. I first saw it in the USA in a catalogue maybe two decades ago where the description said, "Lasts five times longer than conventional saws!" This was a Spear and Jackson catalogue. Since then came the stupid names we all put up with and started using, names like Predator, Venom, Pirhana, Barracuda Fatmax and then all the worse 'Professional'!" Did the Japanese pull stroke saws start the trend of hard-point teeth or no? Hard to say. Back in the early days of strategising Japanese marketing of hand tools, their saws were traditional and non-hardened teeth. Problem was they were expensive and needed saw sharpening skills. The steepness of the angles forming the teeth meant the need for an additional bevel at the point of the teeth to add strength to the weak and fractious point. Some makers and marketers refer to this as the 'new triple-bevel technology'.

So we now start seeing sales marketers refer to the ordinary sharpening of saw teeth, be that Asian saws working on the pull stroke or westerners at a push, describing teeth as "dual ground teeth, "double ground", high-frequency hardened teeth, and many more together with, how about this for selling plastic, "ProTouch grip with three times more elastomer for maximum soft feel." Or what about this, a "High swarf removal woodsaw." And then, "Blade is water-based lacquered to provide four times better rust protection than standard lacquer. I mean what idiots do Irwin think they are dealing with here? Or, "Lacquered coating to reduce friction and prevent corrosion." Just how much corrosion takes place on a hard-point disposable saw that is intended to last for no more than 30 hours work max? So you buy into these £15-30 saws in packs of two or three (and that should tell you something) every few months. At least that is what I would have to do because that is how long a so-called "Professional" hardpoint saw would last me in my daily use of saws and the savings soon become non-saving and ever-more costly. And please don't write in as one writer did to tell me he'd (I'm guessing the gender here) rather be doing woodworking than sharpening a saw every few minutes. That's a gross exaggeration by the uninitiated and that's not what happens! Sharpening saws is woodworking! Sharpening is as much a part of woodworking as cutting the wood with the tools you sharpen. And why would someone find sharpening a plane and a chisel acceptable and not the saw? Hmm. . .

The Asian pull-strokes are now made and sold so cheaply that they put their own masters out of business for the main part. Western makers put themselves out of business because for many decades they seemed only capable of producing inferior grade saws. This was pure arrogance on the part of those claiming Superior in their branding and such. This prefaced the import of western-style saws from Asian producers and at one time people were informed of the country of origin because it was on the product packaging and product. Something shifted and often we have no idea where a tool is made. Some independent makers in the west realised that all they needed to do to find a small corner of the market was to what western mass-makers were too arrogant to do and that was to improve their products. I think that it is fair to say that Stanley and Record have continued to decline in much of what they produce. Or perhaps it's fairer to say, well, they haven't improved much at all. I don't think that Stanley ever produced the kind of quality saws say Spear and Jackson once produced in their 1800 early 1900 days. The more recent introduction of hard-points is little more than three decades old. These saws, western or eastern, are all made in this anonymous place called overseas or abroad or import. I am ashamed to say that few saws made in Britain since the 1950sever came from the manufacturers in good condition and ready to cut from the packaging they came in. That has changed but only marginally. I have proven that I can take almost any western saw, old or new, and in less than a few minutes make it cut like a premium version. I can also alter the pitch to change aggression levels and take the same saw to make it a ripcut or crosscut in under four minutes. I don't do that because dedicated saws are the efficient way to go.

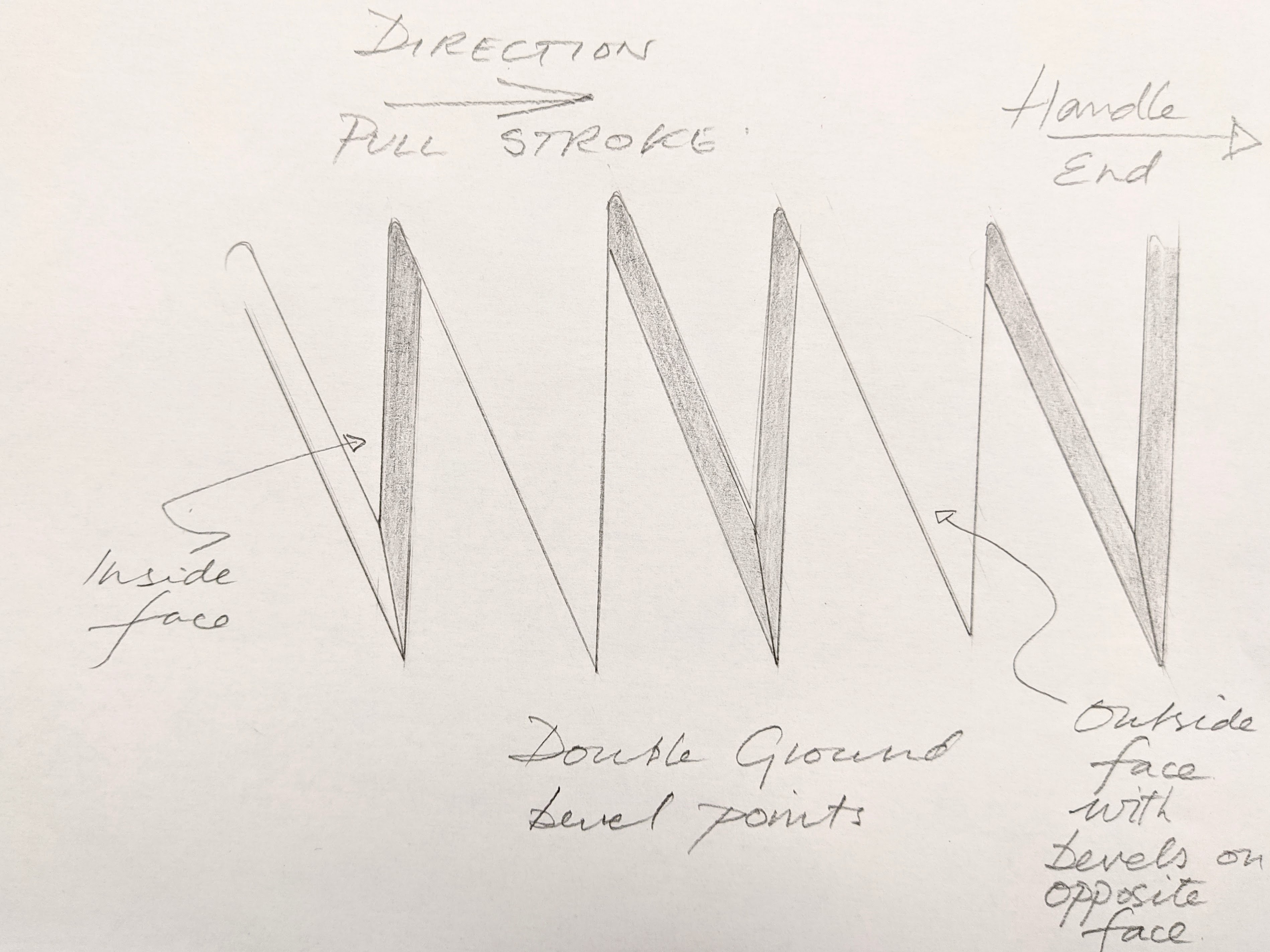

Asian saws have a steep pitch to the front and back of the teeth. The files used to sharpen them are very steep-sided and short in length. The crosscut saws actually cut on the return push stroke too but much less aggressively. This is exactly the same as western crosscuts, by the way. The reason Asian saws have a triple ground bevel to each tooth is because the angle of pitch necessitated the extra bottom bevel to strengthen what would technically be a non-viable point. That's not to say that it would not cut, just that the pinnacle point at that meeting point of the two facets would break off in a matter of strokes and so render it less viable for longer-term cutting. The bottom bevel, now the third grind, strengthens the cutting point on crosscuts. The newer technique of producing impulse-hardened teeth exponentially opened the market to the world because it costs almost nothing to do. Indeed, the saws now totally produced by machine came to closely match those made by the Eastern masters in traditional Japanese saw making but in a matter of minutes not hours. We are just a few years away from seeing all pull-stoke saws being made by machine as will ultimately happen with western saws as there is only a handful of western saw makers making saws in the West. As a boy living in Stockport, I could have walked into a dozen workshops offering saw sharpening services. Not so today!

Comments ()