Eastern and Western Saws Part I

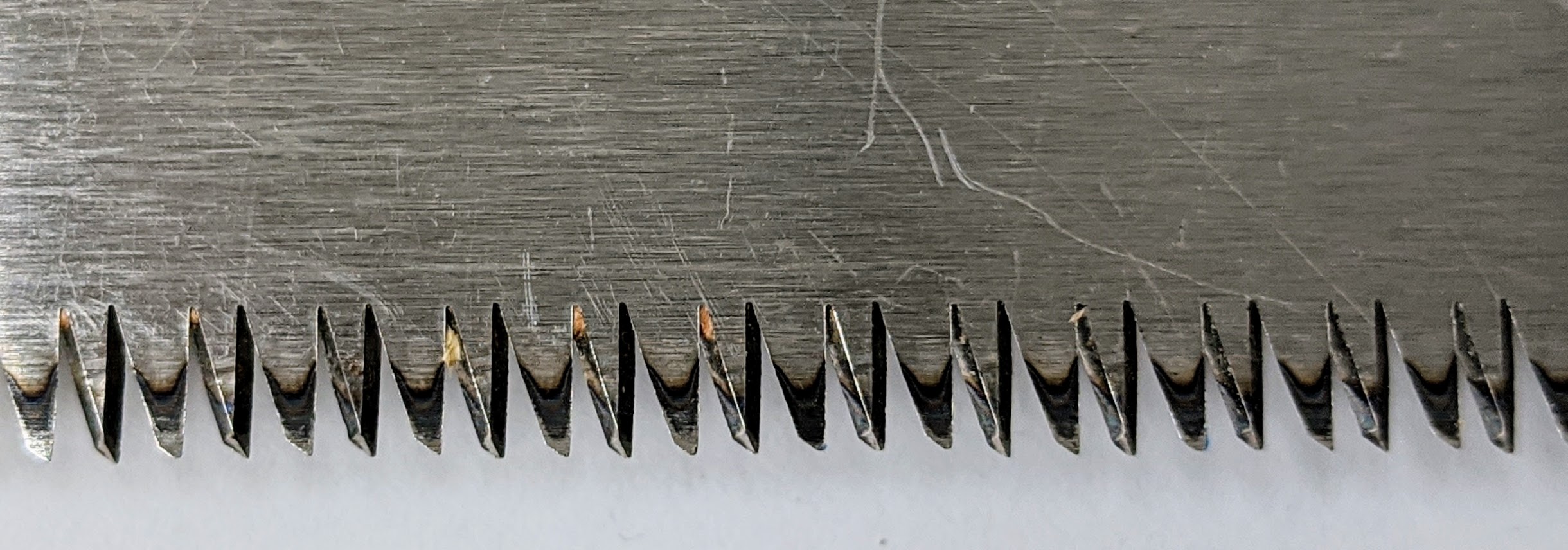

I have considered this issue for a long time--a very long time. I always come back to the same place. In fairness to all, it is most unlikely that I would actually recommend new woodworkers to buy into and use Japanese pull-stroke saws. I think with good reason. Looking at the high standards of Japanese woodworking it is not because the saws are inferior tools, more that I do prefer western push-strokes, but then it does go further. I will get to that as we progress through this. Also, it does have some to do with how I was raised, yes, but more than that, I don't believe that pull-stroke saws are superior in any way. That said, as it is with many things, often an alternative option might well perform better when used in certain tasks or in tight corners or on a specific application and then too by an experienced user of the particular style or type of saw. No matter the direction of the cutting stroke, one saw will often outperform another. That goes without saying. I suspect that this may well be a controversial issue. There is a lot of claptrap coming mostly from writers and presenters who are often the least experienced of all.

I think that it is true that modern-day engineering creating continuous repeatability without the use of people is today's normal. That said, it is truly amazing stuff too. A man sits in an office that is completely isolated and detached from the production facility. He determines stock levels at the click of a mouse, determines demand and then arranges shipping details before hitting the send button as if a page to the remotely disconnected connected printer. The CNC kicks in and everything begins spinning and whirring like in the Charlie and the Chocolate Factory film. The out tray is virtual on the screen and someone somewhere in East Asia, three thousand, five thousand miles away lifts the boxes filled with saw blanks to the finality of the assembly line and soon they are out for delivery with DHL, UPS or some other equally detached outfit stuffing it through our letterbox.

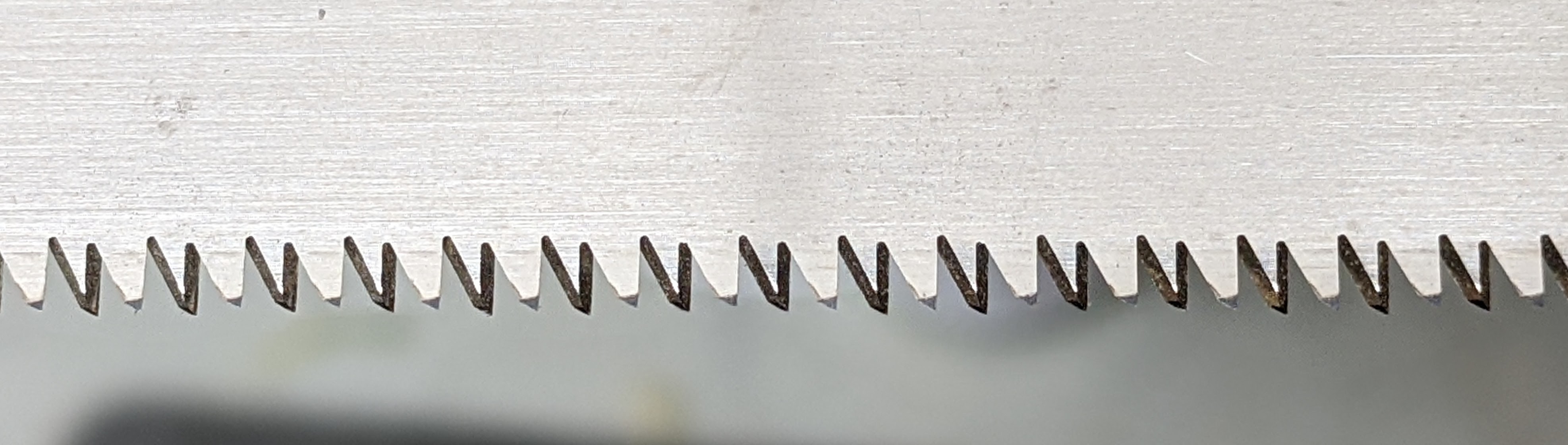

To consider today's mass-manufacture of Japanese-style, pull-stroke saws in the continuum of Japanese culture where saws were once made from hand-hammered and hammer-drawn-out steel as part of the same mystical creation coming from the art and effort of skilled artisans is delusional at best. The same is true of Spear & Jackson thrust-cut handsaws which come similarly from Taiwan in East Asia in the same way. They are made with both impulse-hardened teeth that cannot be sharpened and then as sharpenable versions too. Spear & Jackson allude to their vintage past of 250 years in saw making to disingenuously present their credibility when no one in the Taiwan production facility has any knowledge at all about the tempering and tensioning of steel plate to effectively create the hand made versions made in the late 1700s and on throughout the 1800s. Imagery in the digital world of creation creates strong impressions that can be far distanced from reality. Sparks flying from the blacksmith's anvil as the hammer strikes the red hot steel, pouring molten metal in flasks of sand and such. From the black and darkened atmosphere of an old-world forge and foundry sparkles on hour screens, a pirouetting hard-point saw spinning on its own long axis until it makes that final stand and we in awe by that much-needed hard-point saw into our stable of fine tools.

Tomorrow or sometime very soon I will put more flesh on these bones. Stay with me. Both Western thrust strokes and Eastern pull versions obviously have their place. Not knocking either.

Comments ()