Edge Sharpening Under £10

Today I thought I might share with you how in my day to day I often take 10 edge tools from dull to maximised sharpness levels in somewhere around five minutes max. I do also sharpen tools individually too because, after all, they rarely all dull at once. I know hand on heart that I have striven to be as truthful as I know with you all about what it takes to sharpen edge tools with minimal effort and time. I have also striven not to diss other so-called experts in woodworking, sales outlets, and manufacturers. The truth is that I decided never to take sponsorship or other forms of remuneration when I started to have a more public face and I have the freedom to endorse whoever or whatever I feel might help you. Truth matters and without sharp hand tools, you cannot complete good work. This post is about what you really need to sharpen your edge tools with minimal fuss and the lowest cost yet without compromising quality.

My most commonly used chisels are my 1", 3/4", and 1/2". Anything smaller stays sharp much longer because I generally use them so much less. I also have two 1" chisels going at the same time. The two planes I use are the #4 and the #5 and then my two flat-bottomed spokeshaves. But often, maybe twice a week, I will take all of my chisels and planes from my two work areas, the garage, and the big teaching and research workshop. That way I will do them all at the same time. This doubles the number to somewhere around 12-14 edge tools. The place I do 95% of my work is in the garage workshop. It's a convenience issue to have the same tools in my teaching area as I do in the garage space.

By saying I take my edge tools from 'dull to maximised sharpness levels' I mean from them still cutting reasonably well but not with the super-crisp sharpness I get from beingly freshly sharpened at 10,000 grit with a beautifully polished edge. I say this because sharpening is not something you should be lazy or neglectful about. I wish that there was some regimen that popped up to remind us to sharpen after so many minutes of use--a Fitbit???!!! But of course, there really isn't. There is however a sensitive area we can cultivate that triggers our willingness to resharpen and that is the unwillingness to labour unnecessarily as we respond to the awkwardness brute force always demands. I also know through experience that a plane needs sharpening after not that many minutes, whereas a chisel generally goes for considerably longer. Sharpening a plane you are using should be repeated every ten or fifteen minutes, of course, that's in my view and it will depend on several other factors too--wood density and hardness, silica in the wood, things like that. Usually, my edge tools are still cutting well enough to keep going but I have adopted a policy of, 'don't wait until it's too late,' sharpen up earlier rather than later because it takes so much more effort to sharpen badly worn cutting edges than to engage a strategy of regular maintenance as an investment in the ease and pleasantry of using tools with sharp edges.

My system of sharpening has remained relatively unchanged for decades. I have found nothing more effective or better in any other offering. I generally rely on three abrasive levels to take me through to a final stropping level at 10,000 grit using a buffing compound on a leather strop. I still use three diamond plates held on plywood as my preferred abrasion type because the plates stay flat, cut steel fast and are readily retrievable as a ready-to-go for use with near-zero set up from a shelf at the left-hand end of my workbench. They also give me the cleanest sharpening system, which I find important for my working environment.

A comment recently confirmed my own growing concerns that anyone just starting out in woodworking might well be reluctant to spend £150 and more on any kind of sharpening system and that includes plate glass, film abrasive, diamond sharpening plates and any and all-natural or manmade whetstones or whatever. Often they look to tool and equipment sellers for information and that can be the most confusing place to turn to for several reasons not the least of which is that they are selling stuff and not makers. So, the cost can be just too much to expect if you go to the wrong source for information. That means it can be prohibitive for a large percentage of people. I reconsidered how to better help any amateur with their plight to take the most important step in woodworking--sharpening their edge tools. Owning, sharpening and using only sharp tools is always and forever a non-negotiable. You must have sharp edge tools, saws, etc. I knew if it was me that I would not spend £150 on the setup until I absolutely knew without a doubt, that I would become a serious and competent woodworker. Truth is, you can't postpone beginning to sharpen. Even if you buy sharp tools to start out, within a very short time, even minutes or so sometimes, there is a good chance they will have lost their edge on a knotty area or wiry grain somewhere. You can't know that until you understand what sharpness really is and that only comes by experiencing a sharp edge.

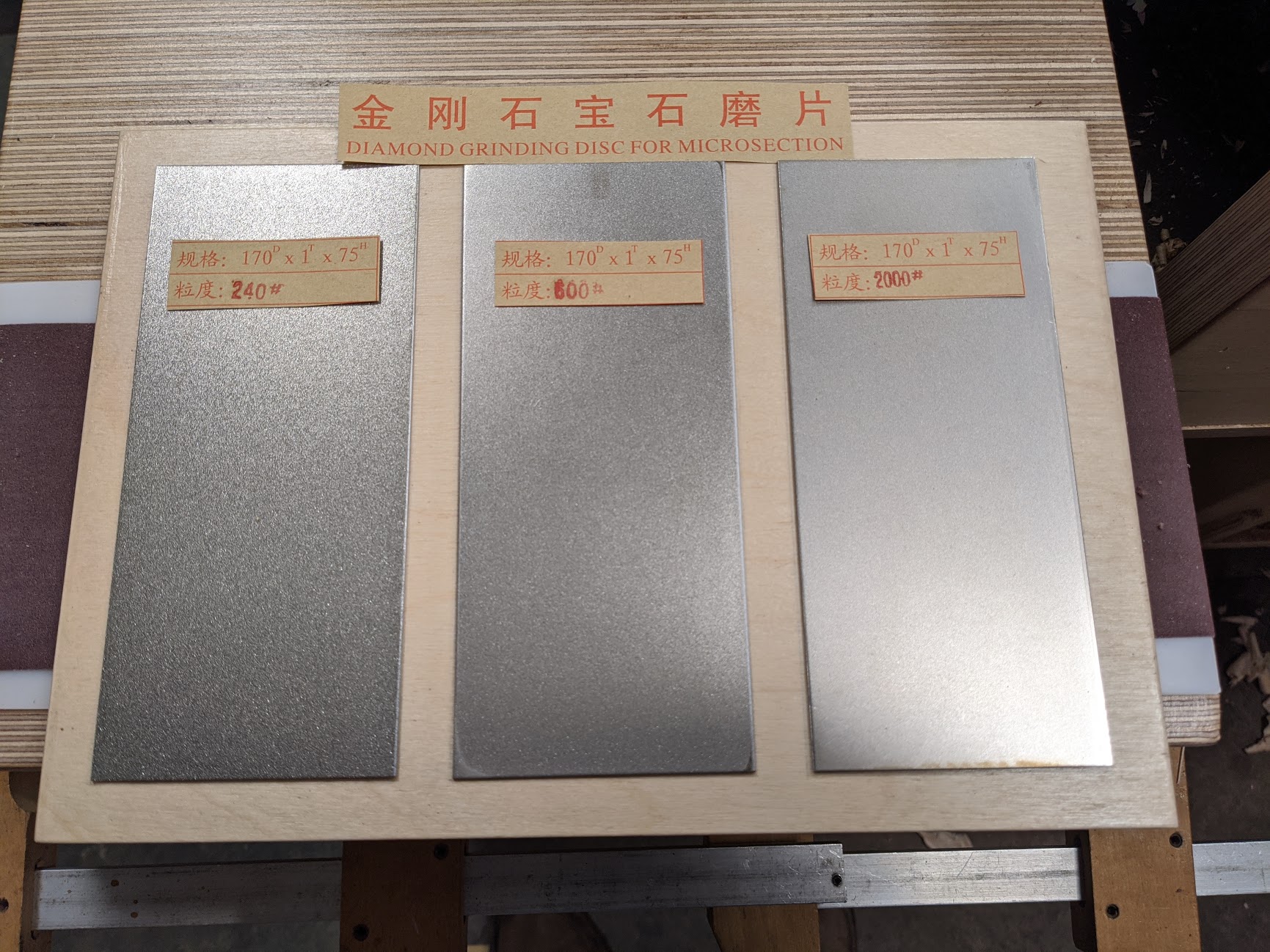

I decided to buy in some thinner diamond plates I had found that were made in China. I knew that if the plate was fairly thin that they could be pulled and held to flatness by adhesive or double-sided tape. I'd decided that thick steel plates were no more guaranteed to be flat than simply gluing thin plates to a good grade of 3/4" plywood. It proved true. See the video below.

The plates came in and I have been using them now for a month's worth of daily grinding and I am certain of this one thing, I probably do sharpen up more than 99% of woodworkers and that is not obsessing about it at all. These plates have worked just as well as any other types of plates including the most expensive offered, so I am continuing with them until I wear them out altogether. Hazarding a guess, they should last as long as the more expensive plates based on this one reality. The grit particulate governs the thickness of the abrasive by the particulate size itself. If that is the case, we have solved the issue of the fastest, most efficient and economic system of sharpening our edge tools for all right from the get-go. Also, even though my plates are as flat as the thinnest feeler gauge in my metric gauge set, to sharpen an edge does not require a dead flat surface, it's just a good place to shoot for and that's all. Having given this the amount of thought I have it's a win-win situation because no one can really lose. Why? Well, if the plates have already sharpened dozens of hand tools several times over for about 30 days, and most woodworkers might only be able to work four hours a week, my days divided by four hours means the plates should give you 24 four hour slots in the workshop. Six months' worth of sharpening. The plates cost less than £10 remember.

When the plates came in I knew it wouldn't matter if they weren't dead flat because gluing them down to a substrate would make them as flat as the substrate. These plates would indeed give me the abrasive I needed to reestablish the 25-30-degree bevel. 3/4" birch, 13 ply plywood pretty well guarantees a perfectly acceptable level of flatness. By the time mine were adhered down and tested with a straightedge they were so flat my thinnest feeler gauge would not enter between the straightedge and the surface at any point.

See if this might work for you.

I set them out with a 1/2" distance from one long edge, 1/2" from each side (short edges) and a 1/2" gap in between. I allowed 3/4" from the edge that would be nearest to me. I added a 34" by 3/4" strip to the fore-edge and simply glued and screwed this un place. Before installing the plates I coated all surfaces with three coats of waterbased varnish. This will keep the surface cleanable with a wipe from a dampened wipe.

My new strop takes care of the final buffing and polishing out. Whereas just gluing down leather works adequately, I thought for just a little more effort I would enjoy its looks all the more and thereby just feel better about. You can see how to make one here. It'll take you 20 minutes, that's all, and it will last you for a lifetime, I'm sure.

This brings me to a final piece I have added into the system but it needs just a little explanation. My advocacy for three diamond plates remains unchanged. One thing has influenced my introducing a level of abrasive that needs regular changing and that is a cloth-backed abrasive belt. Whereas I bought a roll of 5" wide cloth-backed abrasive produced by Klingspor and bought from Germany, you can buy a 4" abrasive belt sander belt that works just as well. The grit I suggest is 150-grit. I found that the 250-grit diamond plates soon lose their aggressive abrading quality but that it is still highly effective as a finer grade (somewhere around 300-400 would be a good estimation). Abrasive belts also lose their aggressiveness but I calculate that using a 2" wide by 6" long section of the belt will sharpen about 10 plane sharpenings before I need to move over or down the belt. My 150-grit abrading, roughly 24" long belt or length and 4-5" wide, will, therefore, sharpen 80 X 2" to 2 3/8" wide plane irons before I need to change and this is a very aggressive and productive abrasive very capably reestablishing that initial 25-degree bevel. The cost of this section of abrasive costs around £1 per belt. After that, there is no gain at all to using abrasive paper or film and of course, the diamond plates may well serve most woodworkers for months possibly years, if not decades. It becomes tedious and intrusive as well as time-consuming to change out abrasive paper and film. In my initial look at reintroducing an aggressive abrading level, I used abrasive paper. I found that the corner of the chisel could and would easily rip the paper so I tried a belt sander belt instead and that resolved the issue. Between the cloth-backed abrasive and the plywood support, I added a sheet of 3mm hard sign plastic. This evened out the surface and made the action even smoother. The plywood support can be lifted to the benchtop in a single move with the abrasive kept in place with three spring clips. The video in this blog shows how everything works in action.

The plates I bought were all made in China and looked identical even though they came from three different suppliers. The surfaces looked the same as any diamond plates I have seen and used. I used eBay, Amazon, and Aliexpress and found this heading took me to the plates: 80-300 grit thin diamond polishing plate sharpening stones.

I found no difference between the plates though the prices varied from £3.40 to £9, but I believe, under close scrutiny, they were all from one manufactory. They measured all the same at 17cm x 7.5cm / 6.69" x 2.95", enough for any and all sharpening of edge tools. If you do try a set of these with me, please let me know how they are after you've used them for a while.

Comments ()