Resistance to Change

Some things can seem contentious but mostly they are not meant to be so. At least that is here on my blog. Highlighting an issue that's causing a problem is not necessarily anything more than pointing out a need to change. It's not an opportunity to jump on someone or something. At least that's what I hope when I offer a blogpost countering something said or done. It's unfortunate when things spiral out of control because often there is little you can do to stop it if it happens.

A saw that buckles under thrust-cuts and pull-cuts might result from the wood itself, the saw, and then the user too whether the user is experienced or not. Who knows what causes it sometimes? The same is true when a plane arrives unsharpened or miss-set or the bed of a spokeshave has a bump in the casting. Such is the result of mass making wherever that may be. These things happen and we must understand that the issue is not always us.

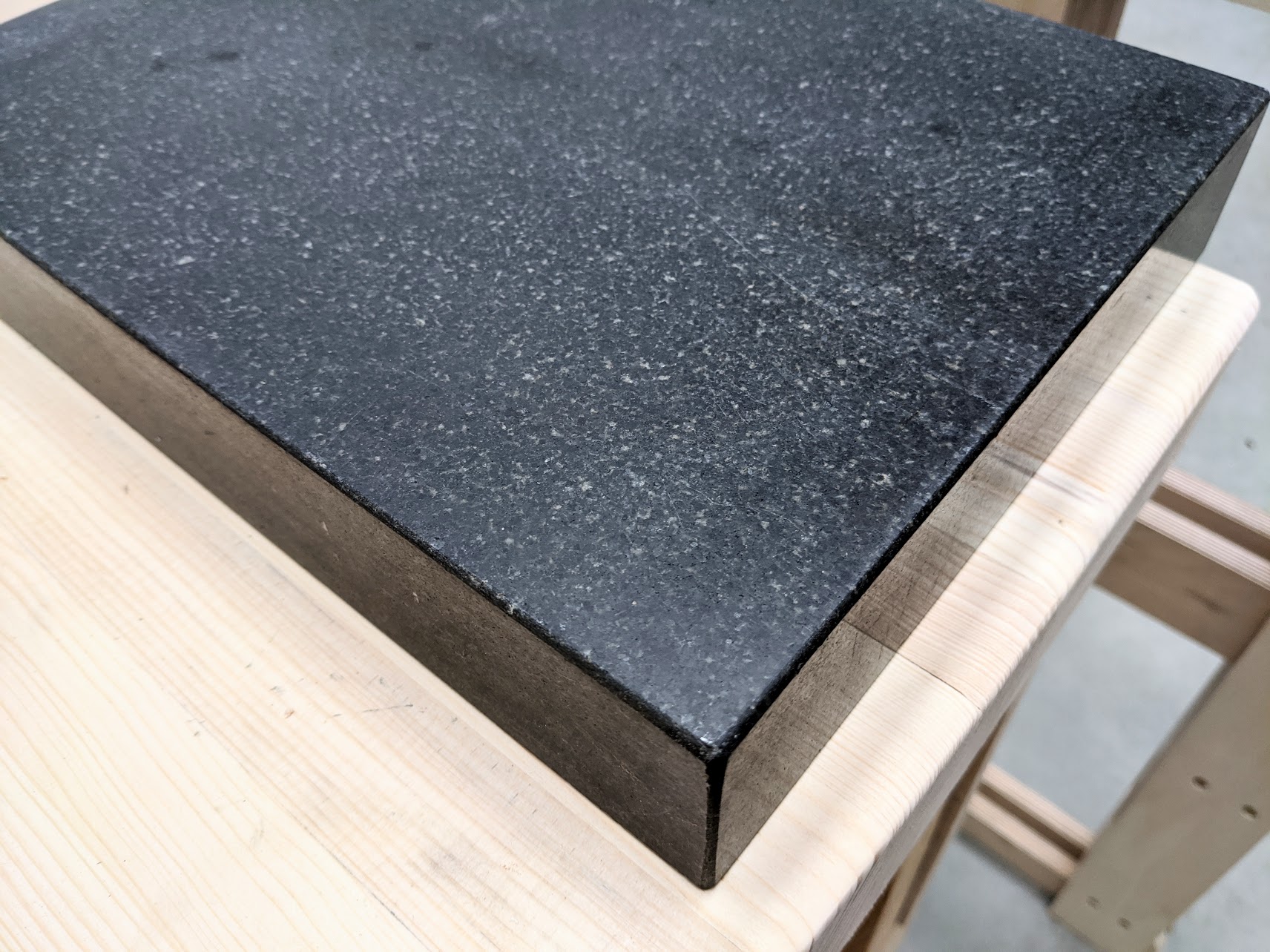

The issues I've raised at different times and then of late too are to point out problems with the manufacturing or the design that result in additional work. The sets in the saw post showed that it was too simplistic to say that the stud would indeed fit this or that saw by drilling a 1/4" hole. In reality the extra work needed might well baffle someone new to woodworking and drilling metal to make the bolts go through the hole. Drilling a 1/4" hole as directed wouldn't work because for the wood to receive the stud itself it needed two holes larger than said and then a possible third hole of 1/4" through the steel plate. Also, often the saw plate is too hard to be drilled with a regular twist drill because it has never been softened as with the teeth. I have had that result many times. Small things can make all the big differences. The dead flatness issue is something we all got caught up in and of course, wooden planes didn't have the same issues as metal cast planes because the wood couldn't be noticeably bent or flexed by hand in planing as can the cast metal planes and especially those longer than the smoothing planes. If you have never drilled metal there a few issues you need to know to do it like what type of drill bit do you use? Auger, Forstner, spur bit? Well, no, none of these will drill through metal and especially hardened steel.

So many of you today acknowledge the reality that tools need sharpening and that you have conquered not just your own inability to sharpen but more importantly the intimidation you once felt. Venturing into woodworking has so many pitfalls but working your wood with hand tools introduces the importance of a tactile approach you cannot get without hands and hand tools working together. As sentient beings, we respond to woodworking differently when the tool becomes the extension of who we are, what we want and how we achieve the results we so enjoy. It is often the most difficult to explain this to those who shun the use of hand tools and never did use them. Even the ones that did often never mastered them and so a percentage of them are indeed likely to scorn those who use them. Paring that wood back to the face of a tenon or the recess of a housing dado with a paring action is still quite magical even for me after 55 years.

Tackling the flatness issue to make it less obsessive seemed important to me because I learned something from teaching the thousands of students and apprentices I worked with over the decades. I think the ratio was about 1 in 50 that came to class with mixed levels of obsessive compulsivity issues. Those new to sharpening watched and listened and then, when sharpening became necessary in the class, went to the sharpening stations and sharpened according to the patterns demonstrated. They were back to the woodworking with sharp and not so sharp tools in a matter of minutes. Those that approached it with an alternative method often spent ten times longer sharpening, snd then fell behind the rest of the class and even ended up holding the class up because the method or methods they had adopted seemed to replace the actual woodworking.

Something I do understand though is that many actually enjoy extending themselves into the sharpening. They enjoy the feeling and effort it takes and then too they simply like to peel off those onion-skin shavings one after another. In some cases, it wasn't the joinery or the making of things they wanted but the sharp edge alone followed by shavings; pure shavings. Of course, micro bevels and so-called scary sharp systems are no different to and no sharper than freehand sharpening used through the millennia by artisans on every continent, even when using a honing guide with the three stones and the strop already set up and ready to go.

There is, I must say, the ever-increasing level of hype and spin these days that go with guruing. Just my very brief glimpses as to what's available on YT makes me realise how hard it must be for new woodworkers especially to find the haystack never mind the needle. Many people just feel better with the practice they know and choose and then too they like the more legalistic approach because to them it seemed more risk-free. The freedom of freehand sharpening for me was as freeing as never starting with training wheels but with the two-wheeler pointing slightly down the incline and learning to first balance with my legs spread sideways until I got it. My dad nudged me off and kept me upright for the first yard or two and then I was off. In many cases, we put off what we really need to do to master the skills.

Well, remember that for the salespeople the end product is not the thickness of a shaving or even a project because their end product is the sale. Ultimately they enjoy seeing statistics resulting in the bottom line. One owner of a catalogue company here in the UK said to me, "All that matters to me and my company is the bottom line." That's understandable. He was in the business of making money, had no interest in woodworking per se and liked traveling to buy in stuff, do deals and so on. But I also know one or two where the service is the most important and the resultant sale is the outcome of genuinely putting their customer first. I think I could name several makers and sellers, distributors and so on, who have that approach. Maybe one day I should publish the list of my own suppliers who have truly served me well.

So many things I write are not intended to be critical but more a critique intended to shift from compulsive to intuitive. That said, I admit it is compulsive of me to always count 30 times when I strop my tools on the strop and many of the other things I do in the mix of things. If I appear hard, harsh or rigid sometimes, I apologise. When someone suggests I try this or that or shift from this to that it's usually not because I am so rigid or resistant to change but that I have either tried it and found it lacking or at least less acceptable or I simply know what I want altogether.

You all have that nice day now!

Comments ()