Hall Hat, Coat & Shoe Stand

I have lived in rented houses long enough at different points in my life to know what it's like when you have to move and do so unexpectedly. Whereas mostly there are rental agreements in place, here in the UK at least it doesn't take too much to move someone renting on and contracts rarely go for longer than for a 12 month period after which rents get reviewed alongside your impact on the property you've rented. Based on this, it may or may not be renewable to you. Hopefully changes are on the way towards greater levels of protective fairness for both parties.

With people moving more and more and putting down less permanent roots we may well need to look at both what we make and how we make. I am sure it might well irk the puritan traditionalists to consider third party components to hold things we make together flat pack IKEA-style, but in today's work it is a great and progressive step to create as a feature for any piece when possible. We have done that with a few pieces now, the leaning wall shelf and the baby cot are two good examples. When large items don't dismantle they can be difficult to transport without the right transport and you will often end up renting a van. Of course dismantlable furniture goes back to many traveling armies through history. Pompous leaders and not so pompous leaders took with them everything that might diminish their personal comfort and wellbeing. Owning the minions that transported everything for them, a distinction of class, meant wood and metal furniture could readily be dismantled in minutes and dispatched to a new territory. Today, the army is of a different ilk, today's army are the younger people and then too the not so very young fighting against the odds and using many means when they have need to move on.

Leaving that seamier reality aside, let's move on ourselves. Flat-packs are here to stay and mostly it is because they are created as self assembly units which brings down the costs to the manufacturers, distributors and sales outlets and increases their profit margins exponentially. Make no mistake, they rarely if ever have the consumer in mind. Reducing assembly, warehouse storage and distribution costs raises their margins. Flat packs are a sort of DIY answer that makes the dismantlable a most popular option for the manufacturers and it was indeed a clever move. In my world of making and selling I had to go to great lengths to protect my pieces from damage on the way to delivery. I could easily spend a whole day boxing up, and blanket wrapping even small pieces like a chair or coffee table to ship from Texas to say Arizona.

Unfortunately it's usually not the fastenings that make the units sold environmentally unfriendly and cheap looking but the materials the units are often, not always, mostly, made from. MDF and particle board are both the very lowest quality material option yet for the poorer it is often their only option. Fastenings are ideal for dismantling larger framed projects and that is what I wanted for this one. Two triangular side frames are mortise and tenoned together in part and they provide the stanchions for the cross members to fit into that give permanent rigidity. All of the cross members combine joints with added bolt fastenings to allow for the next needed break-down.

The three shelves have a frieze around the ends and back with dovetailed corners but then I use a system that allows for expansion and contraction to the shelf they are attached to which would be too wide not to allow for.

I have considered draw-bore pins for some frame joints because it might be difficult to use clamps and this is an excellent way of drawing up long shoulders tight and permanently together. I will look at it more closely when I get there. The grain direction might disallow this. Using quarter-sawn wood for the shelves will minimise the possibility of cupping and twisting but well-seasoned and dry wood should be just fine if you laminate the boards instead of going for single piece wide stock.Of course this depends on the wood typer and other things too.

The prototype can still be used when finished should I decide to use it in say the office, which I may well do. It can be simply finished with a clear finish of some kind or then too painted which I also like.

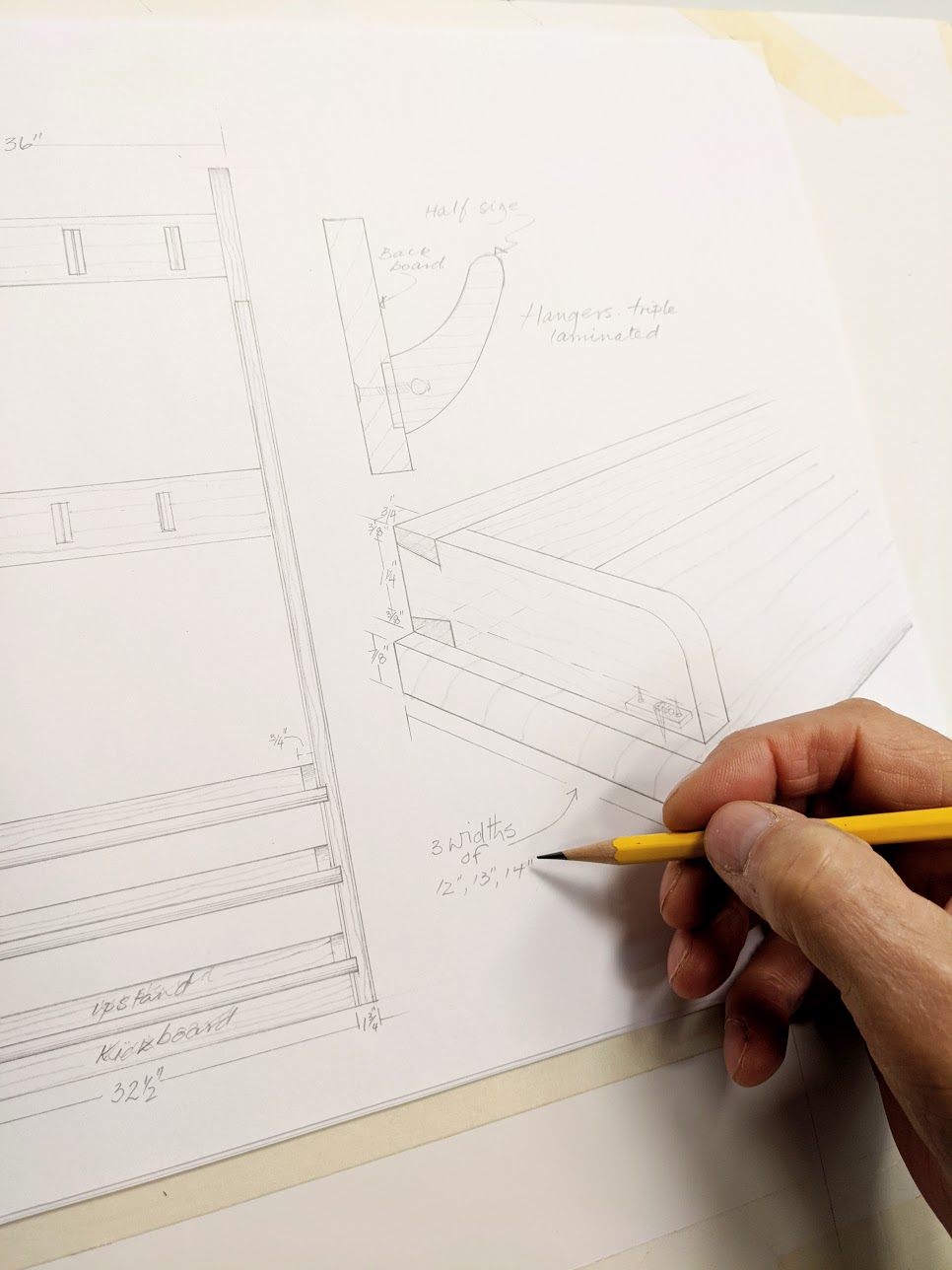

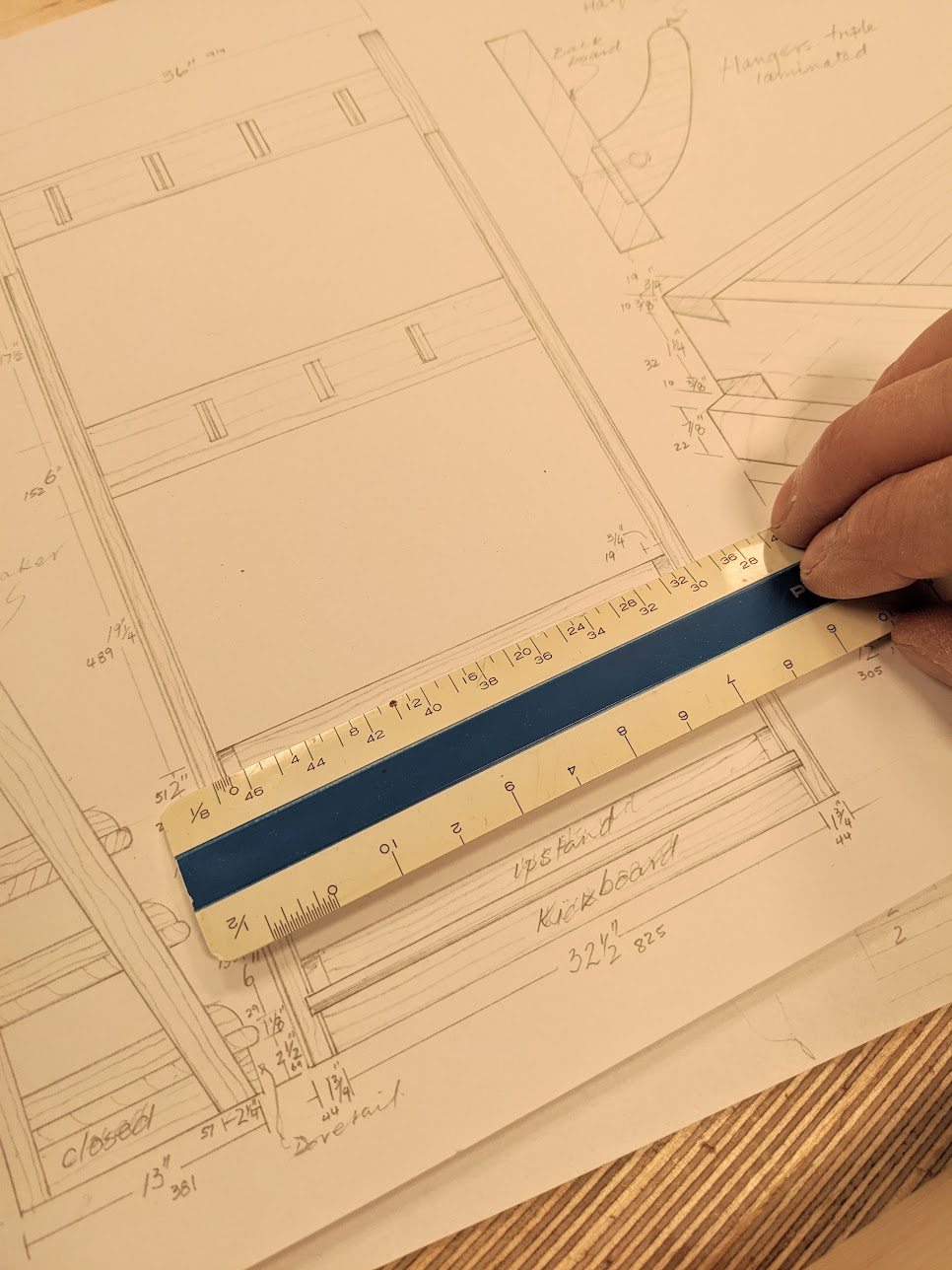

I started with my drawings first and then created my cutting list from this. I'll try to use scraps for any prototype elements where possible and will then laminate parts too to make up sizes I don't have. Sometimes this means using thinner stock for components because of standard sizing from my supplier. Whereas I might like 7/8" material in the final piece, I may well only have 3/4" pine or even plywood to work with in the prototype's first iteration. When I am part way through I may well change this or that to change something I don't care for or take care of a weakness I didn't foresee.

Comments ()