I Like These Things

Going South

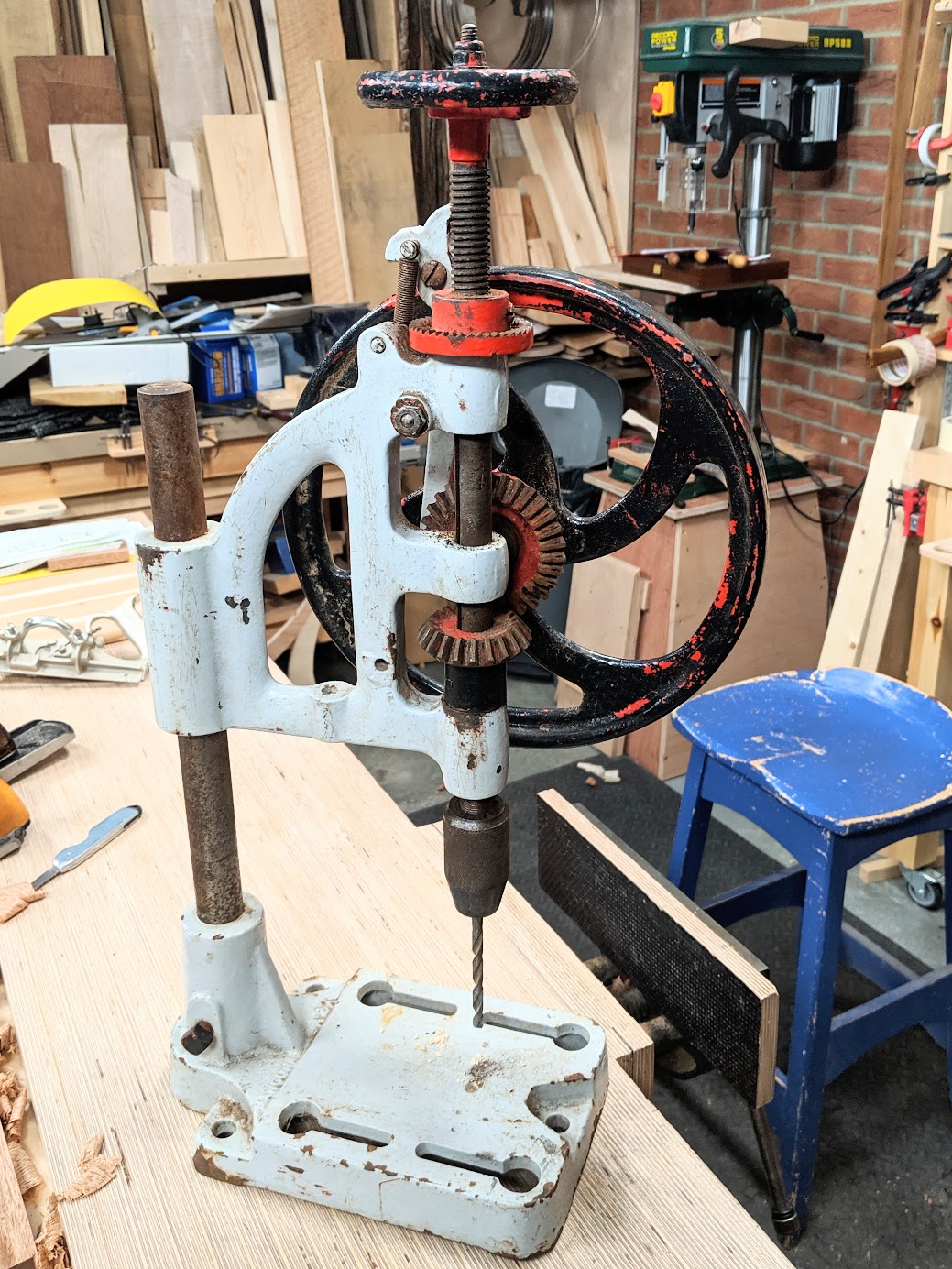

Over the past few months I have been looking at vintage pillar drills (or they could be called drill presses too if you live in the States.) I didn't know too much about them in the beginning but my knowledge grew as I investigated. The difference between the models is fairly significant as some can self feed with every rotation of the hand wheel or they can be moved downwards by a top wheel manually and then too by gravity. All the ones I've bought so far were self-feed models but that does not mean there is something automatic about the outcomes; I found the rate of feed a little less predictable than I wanted between models, then also between say metal and wood and then within the different woods as well. It seems self evident that the user can switch between autofeed to simply turn the horizontal feed wheel manually and this for wood takes out any ambiguity and the feed is very progressive.

My reasoning for manual drive was to do with the work I am doing to develop curriculum and methods of work for autists. Many autists dislike always having to work with machines and of course for some autists that cannot happen. For those who just love working with their hands, this mechanised piece delivers the goods in a totally controllable and very safe way and that is all important. Many autists prefer to use non-machine methods because they offer uncomplicated ways to drill holes with in a non-intimidating way. Human speed is much more important for us all if we did but know it but we have been made to be more industrial beings which is very different to industrious being.

Drills like this mean you are working within and accepting of your human rhythms and not subject to super-fast spin, vibration and such that can be difficult for autists. It's important to bring everything within our ultimate control and something autists can have complete control of with regards to feed rate, drill speed etc. It's all too easy to say if that's all you need why not just use a hand brace, wheel brace or something like that? Well, often it is about having perfectly vertical holes passing through the wood too, and that is where we all might go a little awry.

Also, you can set up for replication of identical pieces too - for building birdhouses and and bee/insect hotels for instance. This piece of equipment means you only have to hold the piece of wood and turn the handle. Totally and beautifully controllable.

Diving south to Southampton down the motorway for an hour and a half I couldn't help but wonder if this model would be missing an irreplaceable part, as had a couple in the past, or whether it had had some additional element cobbled in to make it look more authentic. I am also a little leery of terms on eBay saying "fully restored" too. A fresh lick of paint, no matter how pretty, can mean something is covered up. I am very distrusting of "See pictures for description as no returns." That's a lazy-man way of saying 'bought as is' and 'no refunds or returns'. This pillar drill is nice. The seller was straight up and because I changed my time of arrival to earlier and he couldn't be there he left it on the front porch for me to pick up. I now have four of these, two smaller versions and then one geared, that can double the RPM and then the torque too. Whereas it is nowhere near as fast as a more up-to-date electric version, it's what I want for testing out and will likely deliver the answer I'm looking for.

Going North

Driving to familiar territory I stopped to hook on my trailer. Northwards is a small town called Market Harborough, an hour and a half away from home but very dependent on traffic. My friend, George, had bought some mixed woods some years back but felt he would not use the wood into the future. The price was right so I went to take the wood off his hands. What we had was elm, beech and sweet chestnut slabbed into various thickness from 1 1/4" to 4". It was a heavier load by my trailer pulls well and it was fine towing it back. Loading with two of us was easier than unloading with one and because of the quantity I had to split the load so I will return soon for nine more 14 footers of flamed beech.

I am looking for to seeing exactly what wood I have in stock for building the furniture pieces for the house. I am sure i already have enough for about one third of the what I am planning. I have some very choice boards of mesquite, from the same trees I used when I designed the two White House pieces 10 years ago, so what I build will need to be pretty special. I still have goodly amount of quarter-sawn oak boards which I am thinking of making a matching suite from and then everything from sycamore to big-leaf curly maple, cherry, walnut, ash, chestnut and some vintage mahoganies I have salvaged from old Victorian furniture pieces over the years. Who can know what the future holds.

Comments ()