S&J Bench Planes Review

When I blogged and even filmed about the Spear & Jackson hands saws it wasn't because they sponsored me, gave me a kickback or gave me free tools or equipment. They gave me zilch because I don't and won't take anything. Not taking any sponsorship from any manufacturer means I have the total freedom to speak it the way I see it. I take that responsibility seriously.

Last week I bought two brand new planes made by or for Spear and Jackson. I based my reasoning for the purchase on the successful purchase and use of their handsaws that I have trialed now and experienced over a number of years.

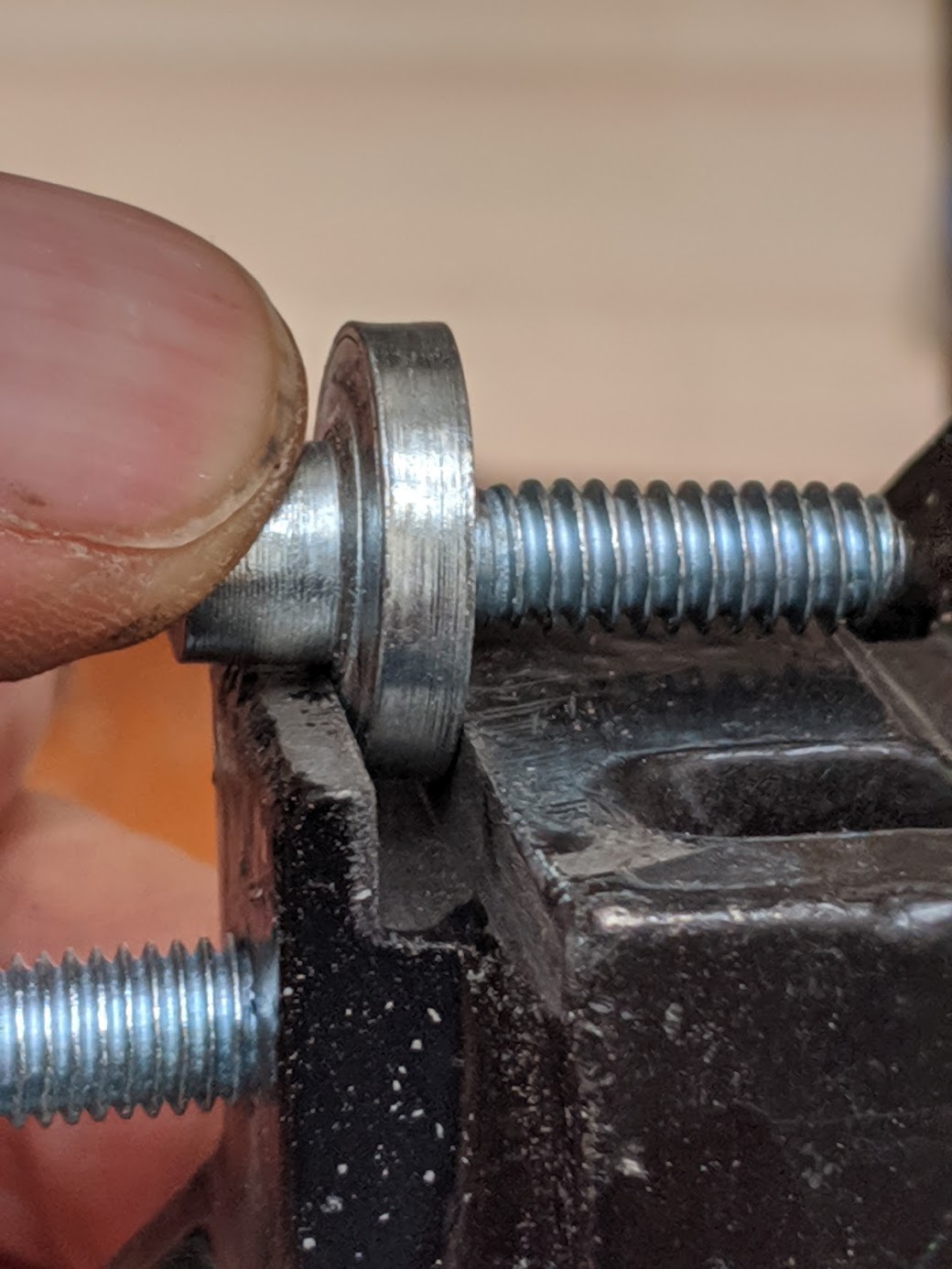

Taking the two planes from their boxes I felt pretty good about them. Pleased that I might be able to give a good report and offer another source for a less expensive plane. They felt robust and looked quite nice too. Without more ado I took shavings on pine with the #4 and achieved shavings straight off. I then sharpened the plane and it worked much better. The mouth was wide open so I went to adjust the frog forward and it was here, at the very heart of any good plane that I encountered the problems. The frog had been cinched to the sole as per usual but the new method they had developed by using a groove in the casting to engage the adjusting wheel seemed to be a slightly different angle to the wheel in the housing.

Though the wheel fit in the groove when not installed to the body of the plane, once screwed in the wheel was stuck tight meaning you could only make an adjustment with the frog out. This means that anyone following general guidelines for setting up a Bailey-pattern bench plane would fail. There were no instructions that came with the planes at all so I tried online and again there was nothing. These problems are insurmountable unless you have the skills and engineering background with equipment to rework the tool. Not something anyone should plan on anyway.

What I see as the problems

It is always depressing to see big companies rely on the original name of the founding fathers bring a product to market thinking the name is enough. I doubt that any new or even seasoned woodworker could actually get these planes to work effectively. Did nobody anywhere in the factory making them consider whether the tool worked or even try it out? I cannot for the life of me believe that they did. Yet I took the planes to the test granite for proving and guess what? The planes were indeed flat to within a thou. the plane is made from ductile iron and the threaded components had no slack.

With real wooden handles I at first had felt that I could fettle the handles and have a good plane. After an hour with the two planes I gave up. With all of my 55 years in the saddle of handling woodworking planes of any and all types these two got the better of me. I did finally get the #3 to work but had no confidence that anyone new to woodworking would be able to and no confidence that this plane would keep doing so. How disappointing.

In reality, if you are looking for a less expensive plane, I never had a secondhand Stanley or Record plane that I could not have up and running within ten minutes from eBay so in my view you can kill to birds with one stone; learn to restore and set up a plane and then save good money into the bargain. There will always be planes cycling through from here on on eBay as we can exhaust what was made for over a century.

Comments ()