It's Gone Bad...

Three decades ago we used to pick up a four-in-hand rasp at any hardware store in the US knowing it would be good to go and at an economical price. They weren't fancy, just functional. The farriers used them to trim and shape the hooves on horses during and after shoeing them. Not a fine tool in any way, they had a round side and a flat side and to each end on both sides was a coarse rasp and then a reasonable finer end opposite. Basically this tool is used for heavy removal of keratin, the stuff a horses hoof is made of and so too our fingernails and hair.

Around that period I held evening classes for the local kids to come into the workshop and make spoons, spatulas and cutting boards and such. It was basic woodworking and the children didn't really have any spare cash. It was here that I introduced the four-in-hand. It worked effectively at an affordable cost. Of late though I've noticed how poorly they work after just a short period of use. The investigation begins!

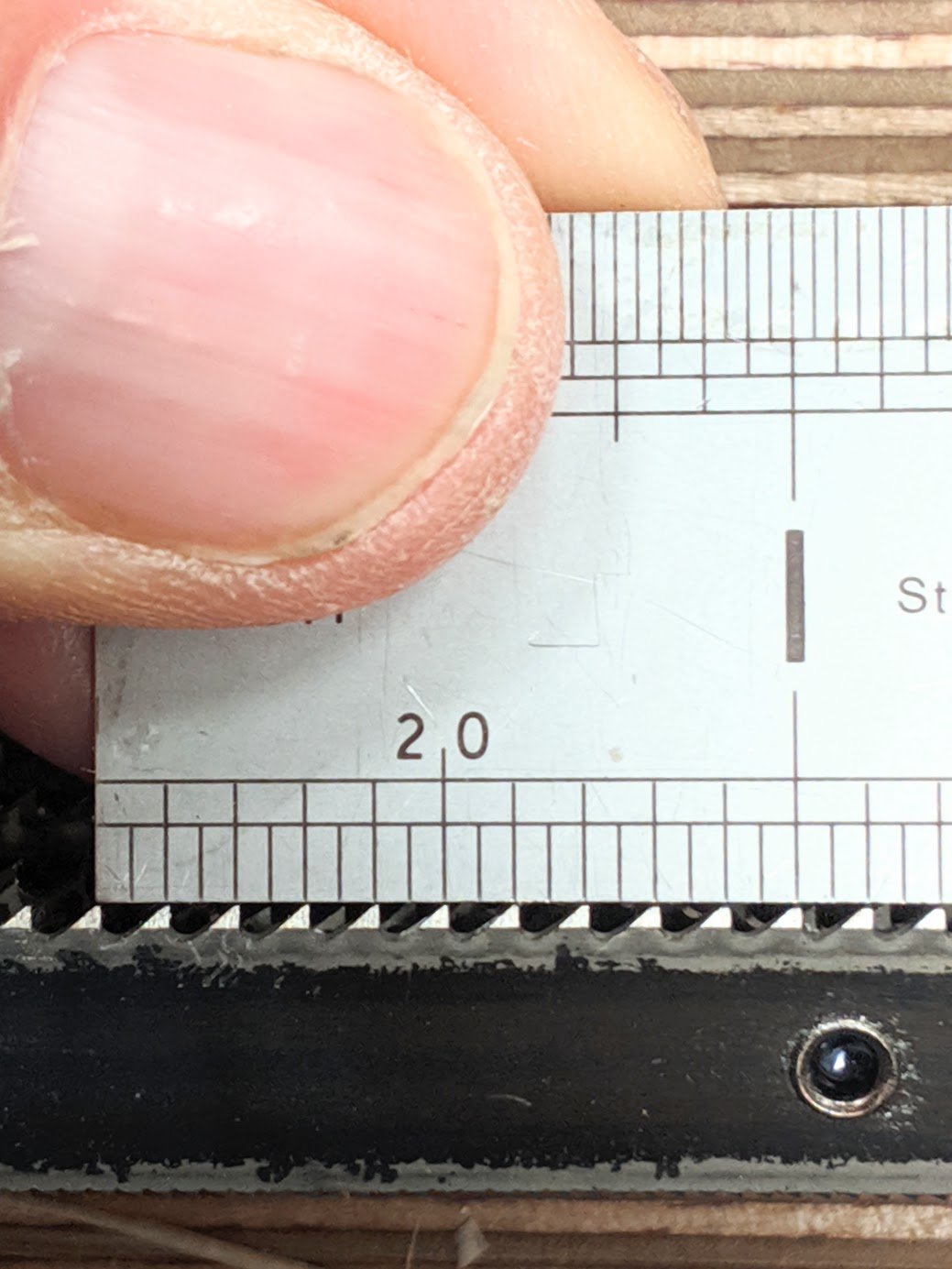

Taking a regular 10" flat file to one I tested the tool for hardness and found the metal to be as soft as any untreated mild steel. Zero hardening and zero resistance at all. The before and after pictures below show what I mean. Three strokes only!

So, just why do they think that they can get away with it? It's because they did. But, this ever more is as it has been with many tools through the years and no matter how much anyone shouts that things are always improving, getting better engineered and better made it is actually getting worse. The problem arises if we didn't know that they were indeed better at one time than now. Some coming after us might think that this is the industry standard but they are not. These are a mere apology for what once was and it's time we found tools we can truly rely on again. And it's not just the makers that need to answer to us, so too the suppliers on eBay and Amazon, the big box stores and of course the online catalogues. Give credit where credit is due and give bad press to those that think we are duped. If you have one of these then give an honest revue.

Now I personally use three premium rasps made by European makers, one in the Czech Republic who I can no longer find trace of and two in France. Rasps of this ilk range in price from £80-140 so not a price a parent might make for a child to use and not the price someone might pay when they are dipping their toes in the water to see if they like woodworking either. No, it's something you might aim for if you've put in a little time and you are sure you will reach for one as I do on a day to day basis. So you might ask what the alternatives are?

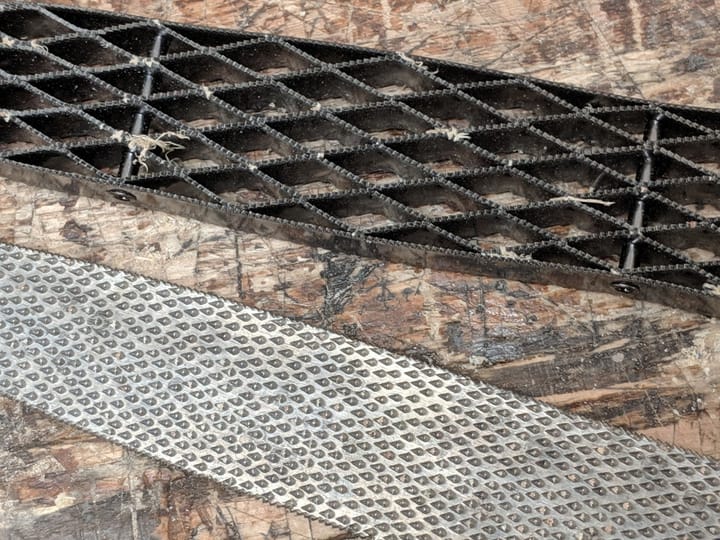

I have now tested out the Shinto rasp long enough to say that it's a reliable tool at an affordable price and it really does work well after a little practice. At around £20 you get two levels of cut in one rasp. The issue between the Shinto and the traditional rasp is the traditional rasps have a half round face one side and a flat the other. The Shinto is two faced, both flat, one coarse and the other fine.

They work on the thrust stroke as with any file or rasp and for rapid removal of wood I think this tool will take you by surprise with both its aggressiveness but then too its finessing qualities.

The teeth to one face are 10ppi and the opposite face is 20ppi. With the final strokes lightly taken you can develop close-to-finished surface that a file will readily perfect with two or three strokes.

As a final thought. Don't forget about making simple paddles 10" long, 1 1/2" wide and 3/8" or so thick with abrasive paper glued to the face. You can make three levels of abrasive on three paddles and you can also round the back of them to make a half round surface. Use contact cement to stick the abrasive down and these will work well for you too.

Comments ()