Making A Door

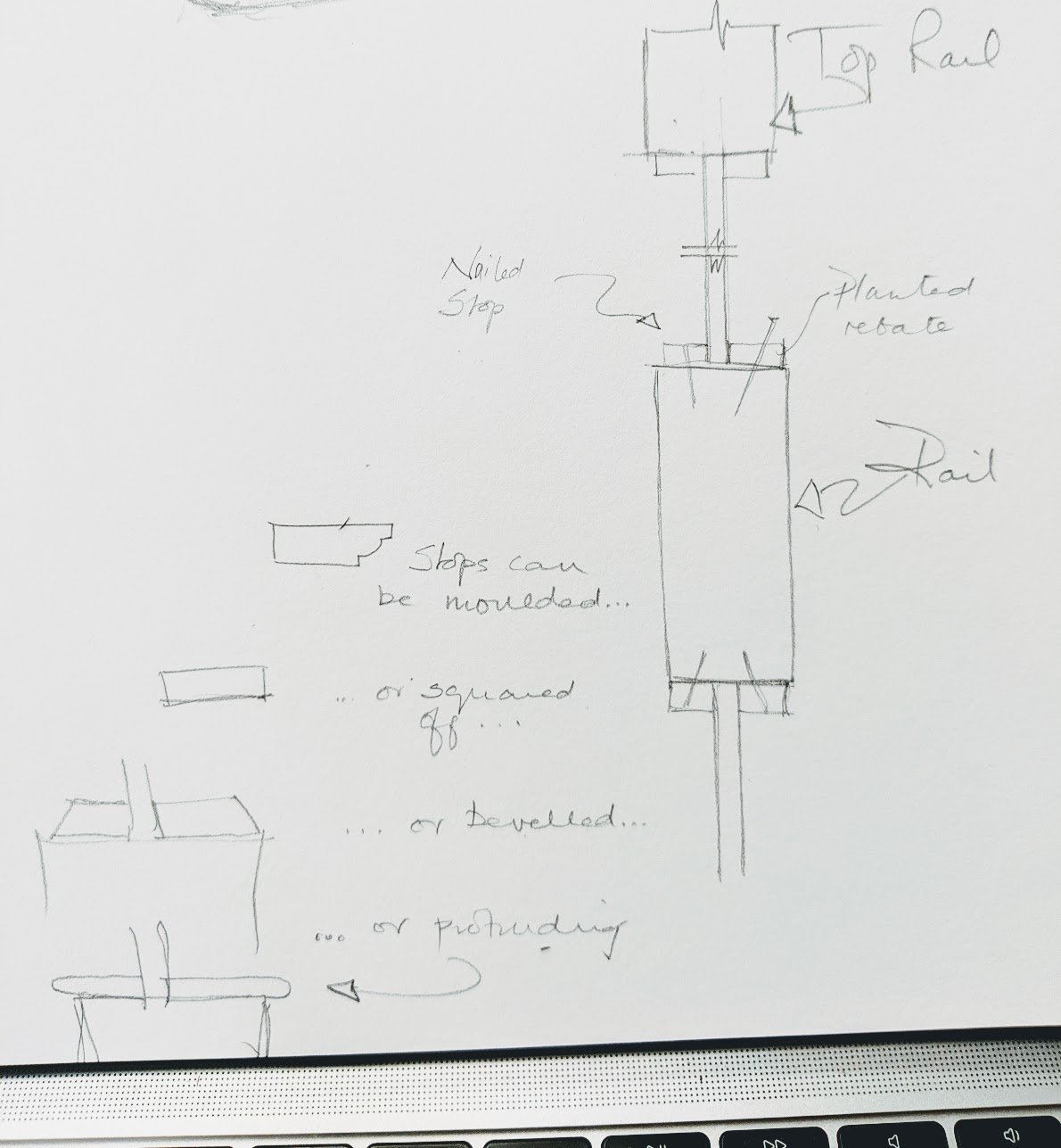

I should explain about my cheap door a little more, perhaps. Some of you picked up on the lack of grooves or rebates (rabbets), perhaps wondering why they were missing or suggesting that the simplified version is lacking in some way. Eliminating the built-in moulds and rebates is ideal for a quick door-making project and though this is a shed door, it is still a good method for any door. You should remember that with industrial production came the ability to set up huge tenoners with the capacity to create matching copes that replicated the mouldings. One pass through into the tenoner meant staggered shoulderlines and reverse moulds that matched the stiles in a single pass. With some tenoners you can pass many rails through at one pass. Not so easy with hand tools. The square edges to rails and stiles makes it so simple. If you want moulded rebates then you can simply add what we call planted stops. This simply means that they are nailed on or nailed and glued on. They perform exactly the same as the single piece moulded stock to retain panels of glass, plywood or other panelling types.

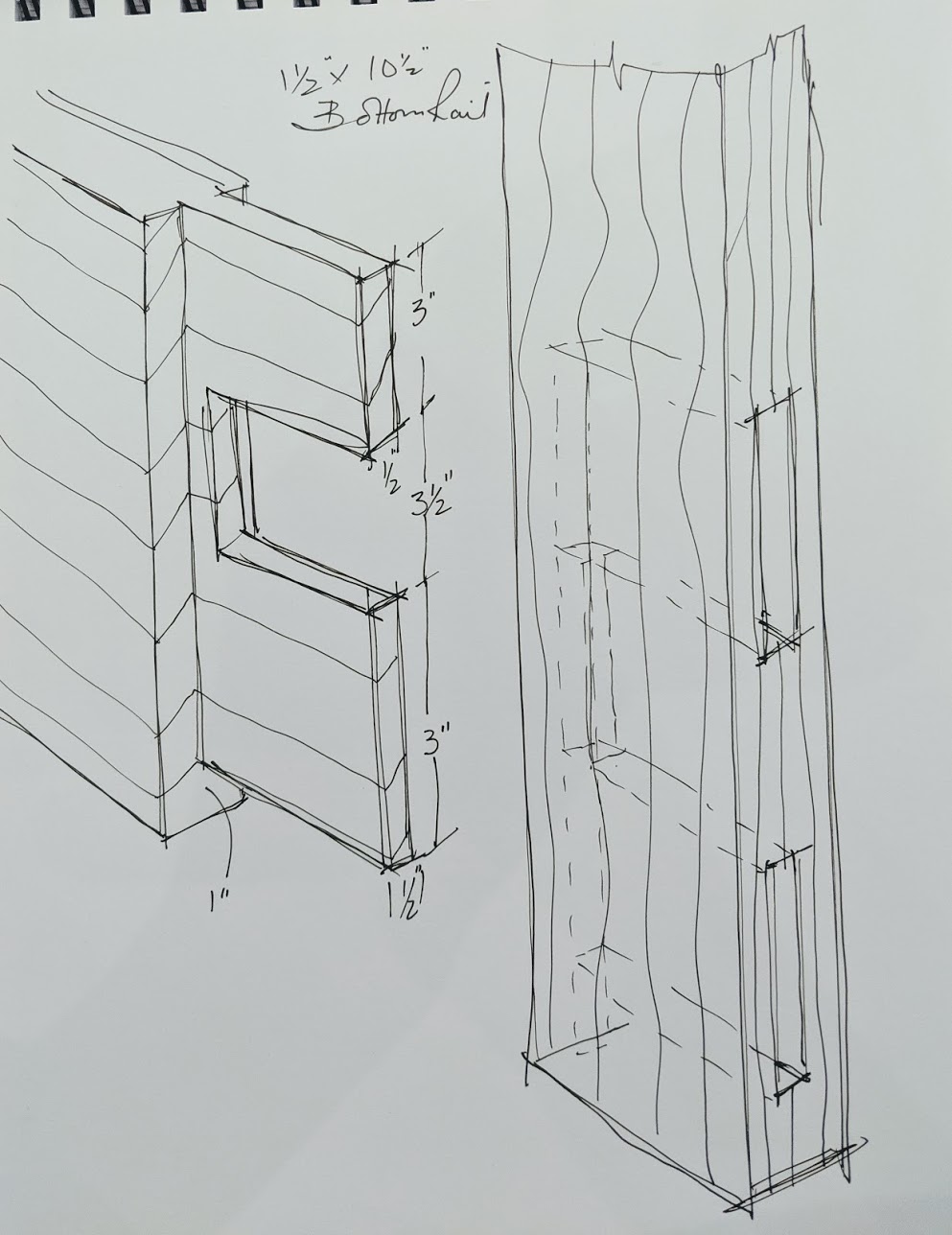

My studs came with the standard 'eased' corners as in the USA style studs - also called comfort corners too. I planed these off by planing the narrow edges of the meeting faces where the jointed edges or shoulder lines come together. That doesn't take much effort with a jack plane. Then it is a question of choosing the mortise and tenon type for each rail. The top rail is a standard mortise and tenon for a corner. My stock is the standard 1 1/2" by 3 1/2" of a stud. Studs are the most inexpensive form of softwood available because they must be produced and sold at a competitive price. I needed custom sizing because of the reduced height at the eaves.

The stiles are 3 1/2", top rail too, the middle rail is two stud widths at 7" and the bottom rail is 3 studs at a total of 10 1/2".

With jointing, the rails were about 1/16" undersized per stud width. The drawings show sizing etc per joint.

The panels will be held in with what we call a planted stop or rebate (described above). That means that we use a piece of 1/2" thick wood by 5/8" nailed in to form a rebate that will take either glass or wooden tongue and groove boards or plywood.

The door frame came from studs and that was simply creating a simple straddle joint as shown and then screwing same together with two long screws. This prevents any toque movement and of course it is screwed to the main frame structure too.

These simple joints take only a few minutes to make with a chisel, a hand saw and pencil lines.

Comments ()