Finishing With Danish Oil

I've used a wide range of so called Danish oil products made by different manufacturers. The one thing they all have in common is the Danes had nothing to do with it. There is no such thing as Danish oil as an oil, and there is no recipe that constitutes Danish oil. If I took two or three liquids, oil or not, and called it Danish oil, I could sell it without misleading you. But I hope I do have a moral compass to steer by. There are many wood treatments out there sold as "oil" finishes that have no oil them at all. The reason anything termed oil sells is because we like to think that oil has the kind of water repelling and nurturing qualities that 'nurture' the wood and nurture too is a common term used by manufacturers to describe their 'oil' finishes. Such is the disingenuity of most if not all manufacturers of wood finishes. They play on our ignorance of course. Rarely would we ever take time out to research exactly what for instance hydrocarbon is or what hydrocarbons are. And that's the case when safety data sheets or a mere click away from where we are sitting.

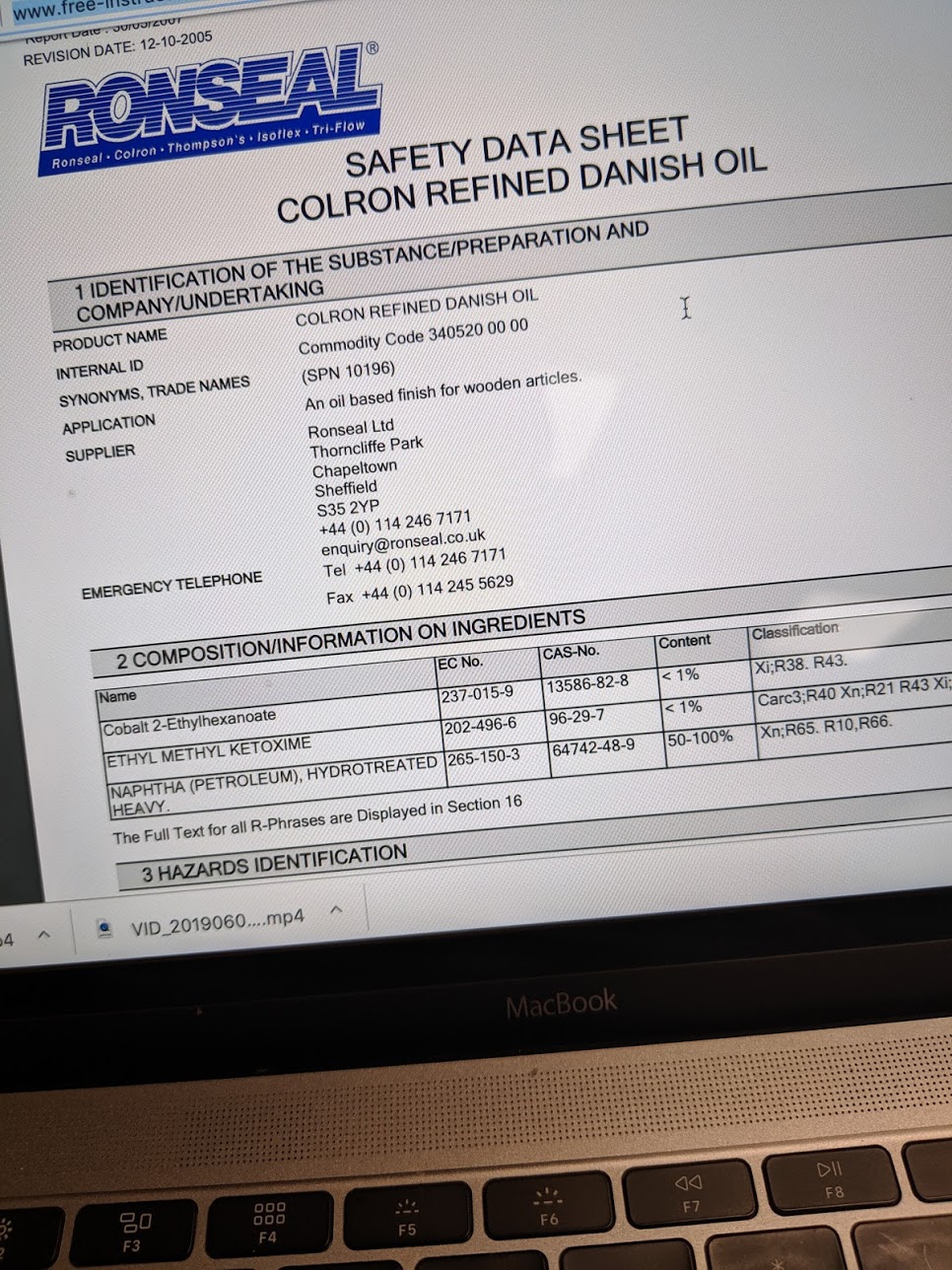

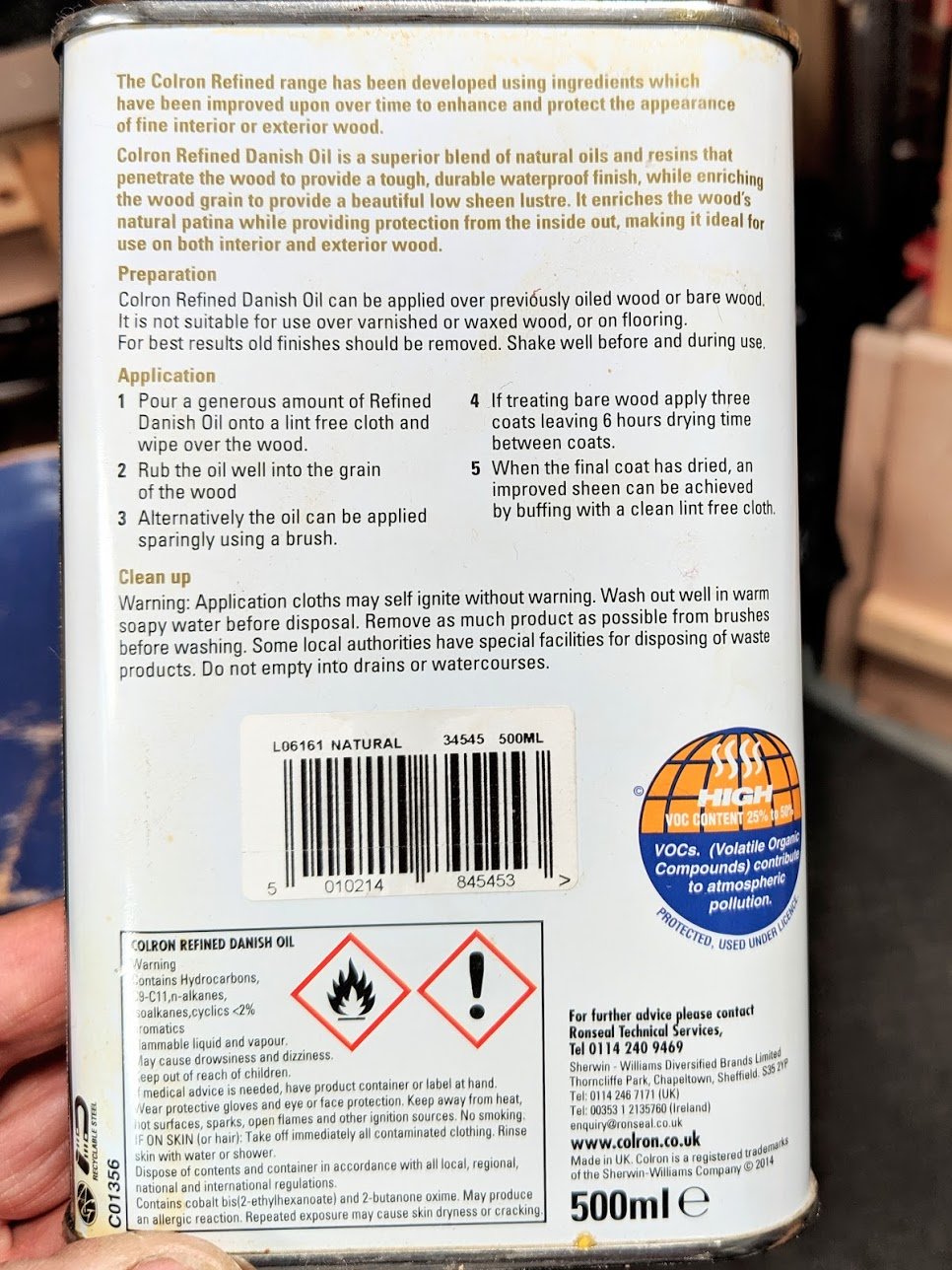

On the Ronseal Danish Oil can it states boldly that their Danish Oil is "a unique blend of natural oils". Now for me that sounds like they have taken a range of oils from nature, you know, eucalyptus, walnut, tung, and some others, and combined them in some special way to give me a protective skin to coat my beautiful pieces with. Of course hydrocarbons come from plants, trees and then fossil fuels too. We have no idea really what we are using when we buy. I say all of this because almost if not everything made is made from something that fully exists; something that occurs naturally in nature. So claiming natural is not entirely dishonest. But what we might hide is that the product we are using could more easily hide the reality that we are using a petrol-based product rather than a blend of whats is around us in nature.

In my making my oak project recently I used some Ronseal Danish Oil, a highly volatile, flammable liquid mixture of hydrocarbons distilled from petroleum, coal tar, and natural gas. It was the smell that troubled me most. It smelt chemically. I have used this and many others before but I am less and less inclined to. I did however get the exact look in the finish I wanted. Had I followed the makers instructions it would not have given me what I wanted.

The thing is Danish oil is really a wipe on finish even though you can spray, it brush it or pad it on. The reason people like this and all wipe on finishes is it is a skill-less task to apply it even though many makers use the term 'hand rubbed finish' to describe the exacting standards of their craftsmen and women. Ragging it on is what it is. Nothing more.

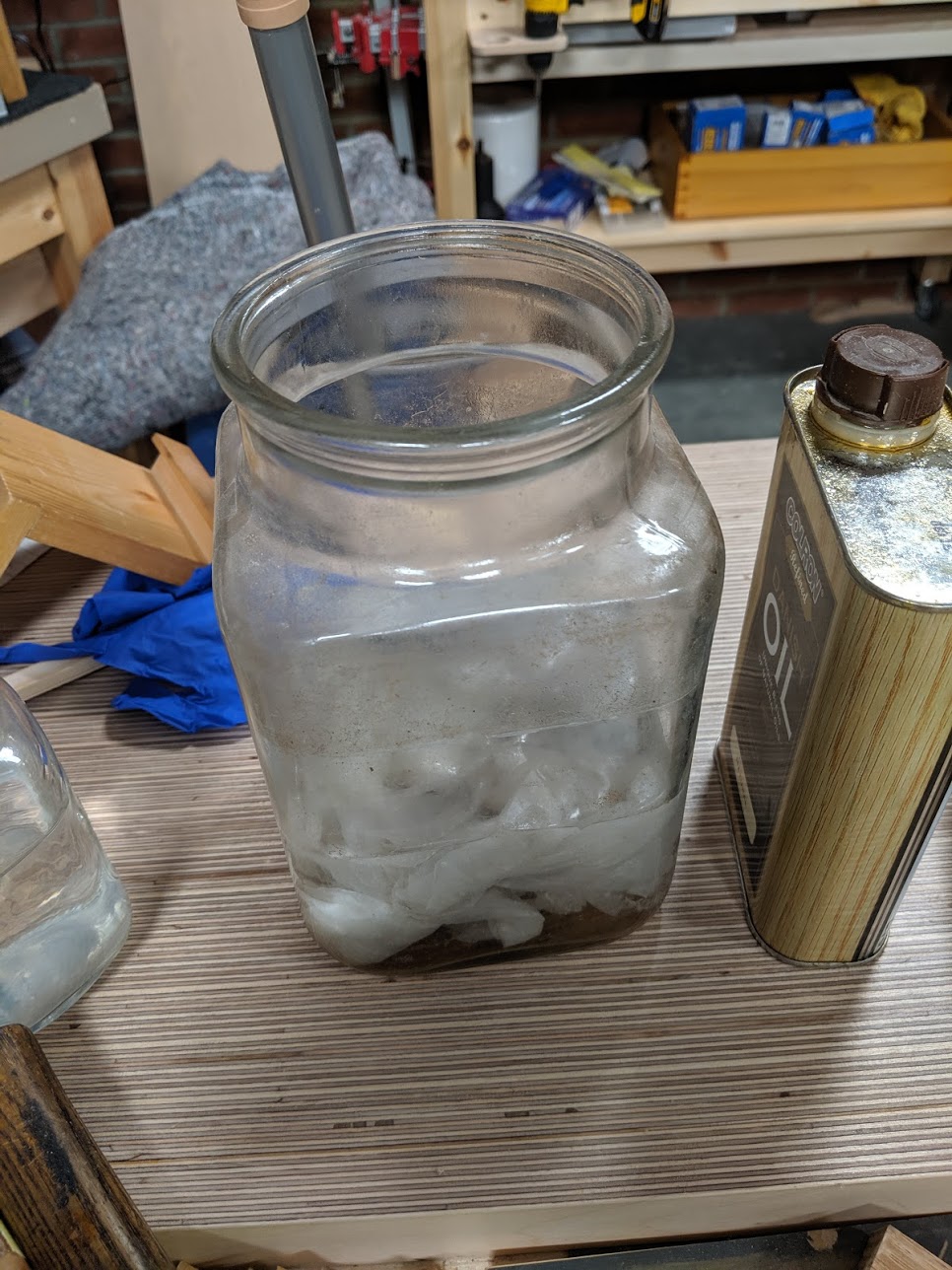

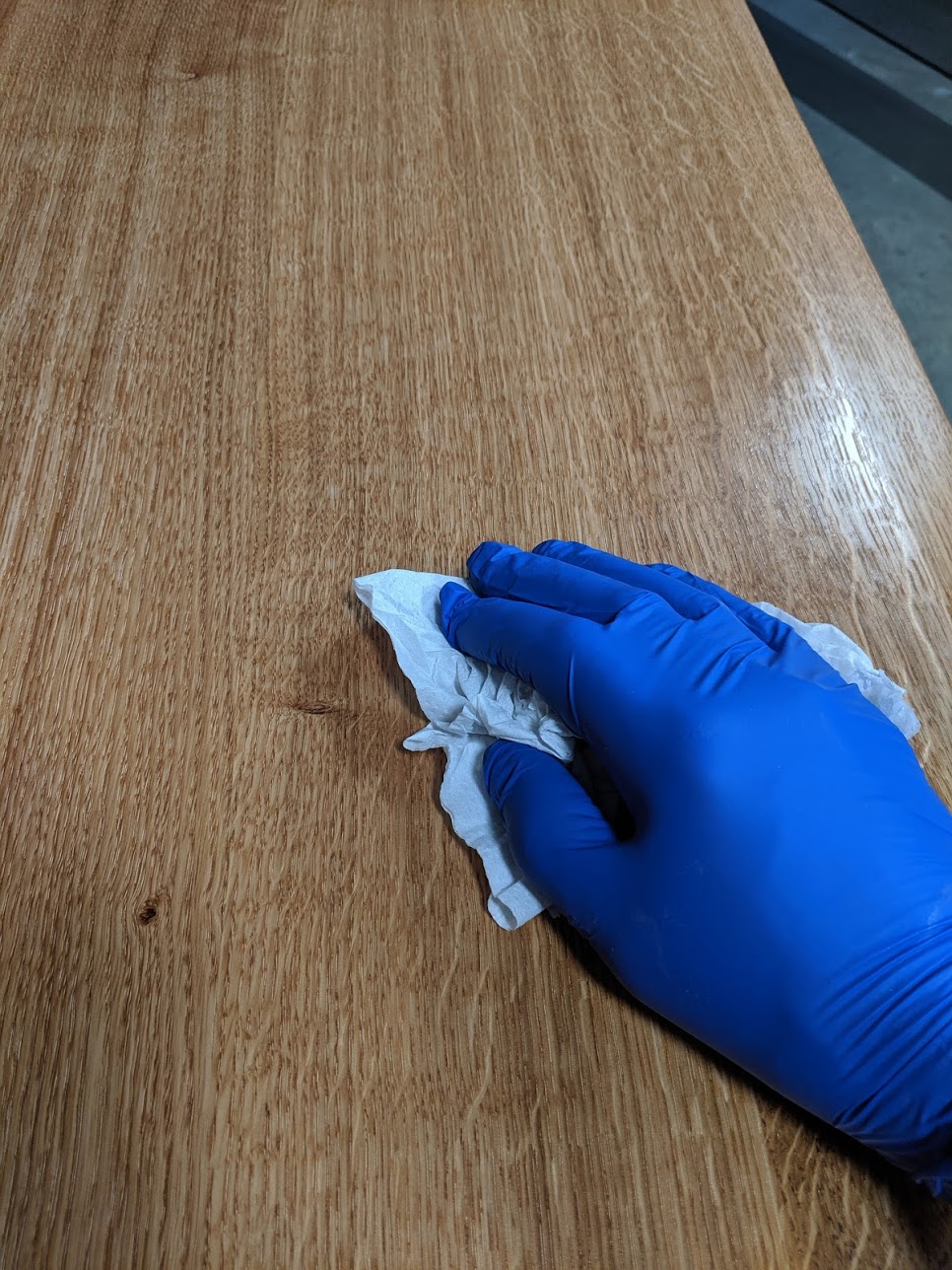

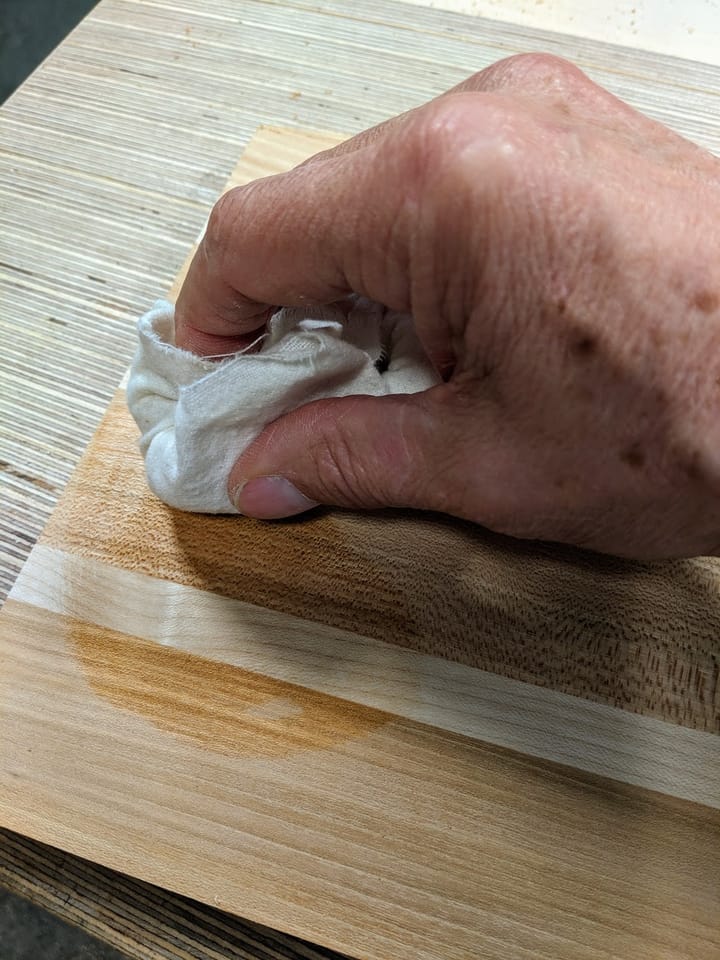

In my case I used paper towel. A couple of sheets of kitchen towel will do a whole table with a first coat. Drop the used towel into a jug of water and you're safe from spontaneous combustion issues. Squeeze out and leave outside to dry out when all applications are completed and you can dispose of in accordance with your local County Council advice. Nothing need go into the drains, rivers or other water courses. The water and oil will not mix. We use it only to prevent the risk of fire that can occur spontaneously with wadded up oil-soaked rags and paper.

I find it best to rub the oil on with the paper pad and then wipe off with a dry paper towel finishing my strokes with the grain. I waited 20 minutes and then went back with a dry paper towel and wiped a second time. with oak, the open pores release air or gasses from the wood as temperatures change. If left the surface feels prickly. The second wipe removes this surface nibbing and opens back up the pores. I then waited until dry, six hours, and repeated same. I did not sand between coats because this method means the surface is smooth. The last, third coat is identical. The finish should feel fine but you might want to use a soft furniture polish applied with a 0000 steel wool.

Comments ()