Lightweight or Heavyweight Bandsaw Part I

Owning more than one bandsaw is usually not an option for most woodworkers: they must decide one over all of the other options to make an economical choice in both costs and floorspace. In my bandsaw blog last week I tried to offer practical help for those in the market for buying one and to that end two or three months ago I ordered one of the least expensive 10" lightweight models I could find but one with what seemed like a good reputation. On the larger models I showed some proof positive that many models throughout the world are as near identical to one another that we can naturally assume that they come out of the same Asian factory and no doubt this has happened to almost all models available including the small models also. In most cases, of over 190 countries in the world, the chances are if you buy a new or newish bandsaw it will have been made in China or Taiwan even if it carries a well-famed domestic named brand according to the country you or I live in or are familiar with. There is no loyalty with brand owners and distributor sales outlets. Companies buy and sell one another like changing their socks or shirt. In light of this reality, we the consumer must either buy secondhand machines (and most other woodworking tools and equipment) or buy new knowing that we now have no true competitive market even if we think we do.

My smallest bandsaw is lightweight. With a bearhug I can lift and swing it to where I want without a problem. For safety's sake you must decide this for yourself based on your strength, height and weight as well as your manipulative body dexterity. It is however best to think about a mobile base because in tight spaces you want to move it in and out of action without exerting undue pressures on the points that matter. If a machine is to retain its accuracy and precision it must be handled with care.

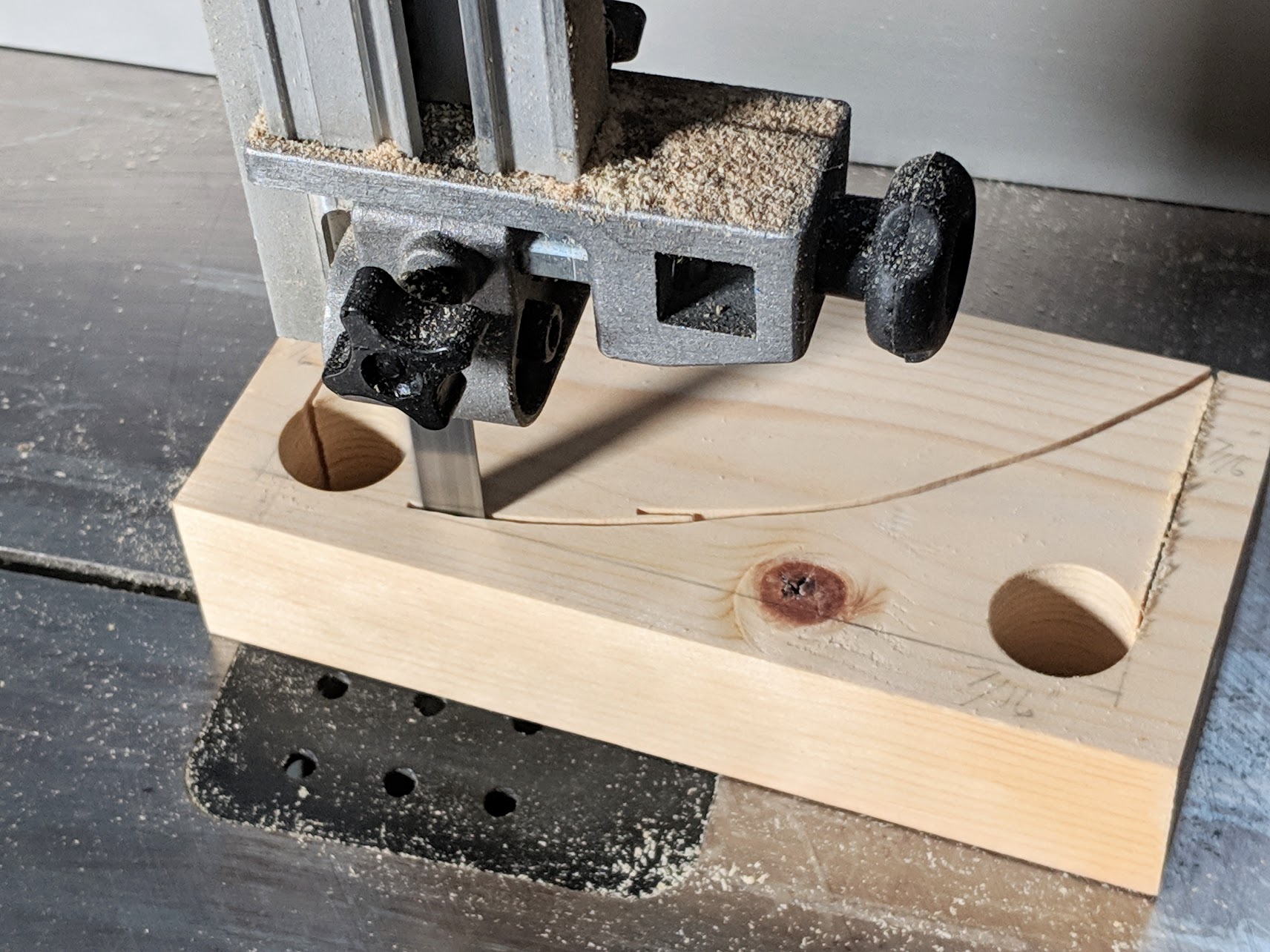

I was very surprised with my small machine. It arrived sensibly packaged in a rectangular cardboard box and stood with the courier on end outside my front door. An hour or so later I had it assembled and was cutting my wood. Whereas the machine is made mostly of lightweight parts, it comes with a cast iron table and once everything is cinched down and tightened up I felt enamoured by its compactness. The first pine piece slipped into the cut just fine. Some flex in the lateral aligning made me add more tension with a quick half turn of the tensioner. Problem solved. Now I know this is what would be referred to as a hobby level machine. I understand that, but most woodworkers today are hobbyists and they outnumber the so-called professionals thousands to one. This is not a machine made for heavy commercial use but I found that with precise set up I could cut through anything a hobbyist might need to cut through including a 6" section of oak I wanted splitting in two for a book-matched panel. With a new blade from Tuffsaws, my favourite blade suppliers to deal with, and careful consideration as to feed rate, the oak section became two and both with smooth-cut faces with no undulation at all. I did have to back off being over bearing with my push, and it is slower than my larger bandsaws, but how often do I cut 5 3/4" thick oak?

Most amateur woodworkers need to resize sections by ripcutting or crosscutting and most woodworkers buy a bandsaw with curved cuts in mind. In reality they think less about straight cutting yet for the main part straight cutting far surpasses the need for curves-possibly a thousand to one. With any bandsaw top performance revolves mainly around the blades. In my mind `i wish I had the equipment to sharpen the hardened teeth and keep a blade going longer than its single life use. Truth is, as with many machines, the speed of the blade means it actually makes a million more actual cuts per teeth than is really needed. Were it not for the hardening of the teeth the teeth would be dull in a matter of minutes rather than a few hours. So we live with hardened teeth for longevity and the premium cuts we need. Another issue is that steel bands rotating at consistently high speeds and under high tension begins to fatigue. In many cases, especially on small or short bands, the steel may not hold up or hold an edge near as long as with the first sharpening. In this case the blade will usually snap, mostly at the weld where the weld itself, because of the welded steel and the difference in the juncture of the steel band, will give In materials science, fatigue is the weakening of steel caused by the pressure of continuously applied loads.This progressive and localised area results in structural damage that occurs when a material is subjected to cyclic loading as with and especially with the bandsaw.

I was surprised by the way my bandsaw performed. Yes, I would like a bigger motor. Not much bigger. I found the machine easy to set and tension and TuffSaws supplies the right thickness of blade so that they tension just right. I ripped through laminated stock 3 3/4" thick in birch and oak without any issues. Take it slow and steady. I realised that the lightweight wheels are lightweight alloy and not heavy cast metal because the added weight would require a larger motor. In this case it is well balanced between wheel weight and motor. I recall in the past when earlier models came out they used light alloy wheels that worked just fine. These do too. Often issues arise around fastenings and part holders, especially when made for lightweight pot alloys. Pot metal is an alloy mix made from low-melting point metals that manufacturers use to make inexpensive castings. Sometimes, more often than should be, the alloys set with undetected air bubbles and pockets within the casting and this results in a weak component. Done properly, perhaps using centrifugal casting techniques where the diverse forces of centripetal acceleration distributes the molten material throughout the whole mould and all air is expelled by the force, you end up with a solid casting. So in purchasing a lesser machine all of this should be taken into consideration.

For the main part I might say best to use the small bandsaw for small work. A new blade will resaw the 3/8" box sides you want and split 1" stock for book-matched tops and bottoms without an issue. You could take 1by 8" stock and cut two 3 1/2" table aprons to width or cut 2" tapered or curved legs with no problem at all. I recently ripped a few hundred linear feet of 3/4" plywood without drift and very quickly. As fast as I would on my larger bandsaws. I didn't find any problematic vibration in the body of the bandsaw nor in the blade as it worked the wood. For radius work, with a small 1/4" blade, I could cut turning blanks quite readily. I am sure it would balk in large and heavy or hard stock but I generally don't do that. Let me think! Of all our recent masterclass projects, going back to the workbench at the beginning of 2018, there was not one of these projects that I could not use this 10" bandsaw for more than adequately. That should tell you lots.

My oak baby cot

My pine workbench

My oak Eco waste bin

My medicine/bathroom cabinet

My Walking canes

My pine and my hardwood blanket chests

My Oak hanging wall shelf

My stock of hardwoods, all of this can all be reduced in size on a small bandsaw

My key safe bird house

My what a gathering and that is far from all. So the choice is yours. if a bandsaw has a year or two's worth of warranty chances are it will pay for itself in time saving without invading your hand tool work too much at all and if something does go wrong you can return the whole machine at the suppliers cost.

In conclusion I would say that the lightweightness of the machine tells you not to think you can push beams and larger logs into the machine. You cannot do this safely. There is a good chance you will overturn the machine or damage it or the material or indeed yourself. Stay with the small stuff and you will save a lot of hand sawing to dimension your wood.

Comments ()