Whats My Worth—Part III

In modern times we might refer to our self-employment as freelancing. It sounds better and seems to settle the matter for those we're telling the outcome of our recently completed degree years to. Of course in certain spheres large companies force you to become 'independent contractors' so as not to have to employ you directly. Sub-contracting is common enough. Lump all the terms together and you still end up with a band aid on the problem. Giant conglomerates and not so giant ones, I think of Carrillion on the one one hand, and then Joe Bloggs round the corner who scuttles of like a roach before the full bill gets paid. Milking the world's workers and leaving them hanging dry when they pull the plug on themselves to declare bankruptcy is not at all uncommon. In the USA this happened to me twice with companies like Gander Mountain ordering my work for sale in their outdoor super outlets. Two or three more here in the UK did the same. Beware the bigger orders. Especially when they pay you for a couple of years and then suddenly the payments are late.

In reality there are many freelancers without work in the same way there have always been the unemployed self employed. From free freelancer to subcontractor, and self employed to independent, It takes guts to be any one of them when you're out there walking the streets in search of work. I think its sad that a culture can show disdain for those who go out to find work in what they're passionate about rather than just taking any old job. Somehow it distances us from helping with the reality of our unemployed reality. Its interesting that Sir Walter Scott's 'Ivanhoe' was the first time the word free and lancer was written evidence of the term freelance. It was directly attributed to fighting men who were indeed free lancers, those who would hire themselves out as a medieval mercenary to fight for whichever nation, group or person paid them the most. Today it still seems more associated with writers and journalists writing and photographing for magazines and media sources; freelancers actually do the same in that they will hire out to the more prestigious or high paying. But of course it does sound better to be a freelance this or that. You're in work and working for the best, yourself. You determine who you sell to and for how much. Freelance as a term has crept into all areas of work life. Especially is this so with applicants for jobs if they recently graduated from University. The question to a 'freelancer',? "What freelance work have you undertaken since you left university?" Results often in your being told of work they actually did in the last year or two at university. Personally I would be asking, "how have you progressed in your quest to gain experience since leaving university?" "What have you made, written, practiced and so on?" Putting positive spin to impress is disingenuous. I'd rather help someone get a job they need and presents truth.

There never was anything wrong with being just plain self-employed. I first went self employed soon after my apprenticeship in 1973. In 1975 I took a full time job again that gave me steady pay and continued my self employment in woodworking. It worked.

Now to the question in hand and that is does hand made using hand tools command a higher price than say using machine methods to speed up the process?

I think that it is important to understand that machine methods indeed speed up the process of making. They lead to consistent levels of accurate replication and minimise the need for skilled input by hand work. Everything and I mean everything gets dialled in. The assumption that hand sewn is better than machine sewn is always in the eye of the beholder. Only the very wealthy are the buyers of hand stitched suits. It's not too much different for truly hand made furniture.

The issue for me is when the machine dictates what you make according to their single axis, rotary cut. Inlay with a router is not really skilled work so much as easier work. Pouring resin laden with black toner and belt sanding it level is unskilled and not inlay. It stands in truths stead to say it's inlay work. That doesn't mean it shouldn't be done, just that we shouldn't believe all the signs that say, "Hand inlayed turquoise". Now watch a skilled person make and inset string inlay sand shaded maple to form oysters or purfling, rosettes and binding unbought for musical instrument making, such like that, and you have art formed by human hand. That's skilled work for which a well practiced maker can expect good pay.. Carving the scroll of a violin, now there you have more highly skilled and risky work.

There are things, some things, that machines cannot do or cannot do as efficiently as skilled hand work. Someone asked me how much they should sell my chairside table for should they make it by hand. I'm not sure that simple pieces like this are worth more if hand made so it would be right to sell it at the price of a machine-made piece. The difference of course is that the machine-made table takes three hours and the hand made one a day and a half. You cannot really charge more for two identical articles that look the same. Your hourly rate must include all overhead for the piece and then hidden costs such as property ownership, maintenance costs and much more. In my work hand making has made sense. I'm not batch producing so each step is individual. A customised piece designed for a specific opening demands the production of drawings, all the parts are sized as a one-off series, the work requires more direct input from start to finish. This is what my customer wants and this they must pay for. On the other hand I make a speculative design on a regular basis and my plans and design are all ready to go. It's a familiar piece and I can work efficiently. A customer comes by, sees the piece, the price and buys it. Two completely different scenarios treated differently. So, back to my chairside table. I need to earn £1,000 a week to cover all things. I am generalising. Our circumstances are all different. Regardless. Divide my forty hours into 1000 and I come up with £25 per hour. By hand I can make only 3.33 tables a week. By machine I make 13.33 tables a week. To make the same money my hand mades must sell for around £300. For machine mades go for £75, a quarter the price for what looks like the same product. This may seem simplistic but complication with more formula will not make the example much different.

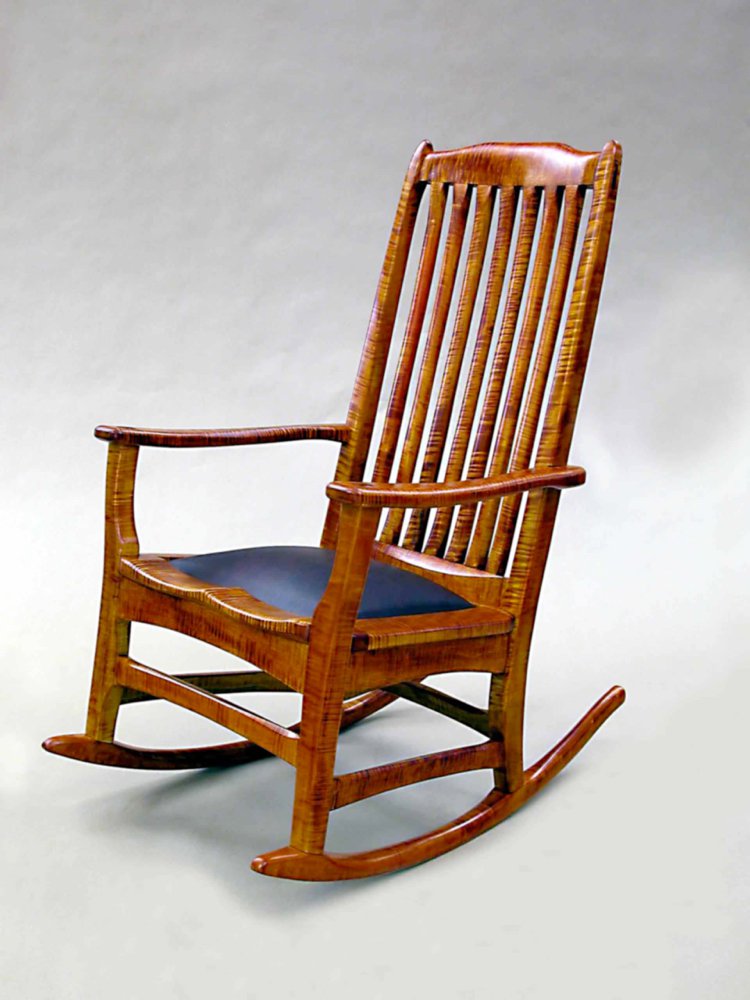

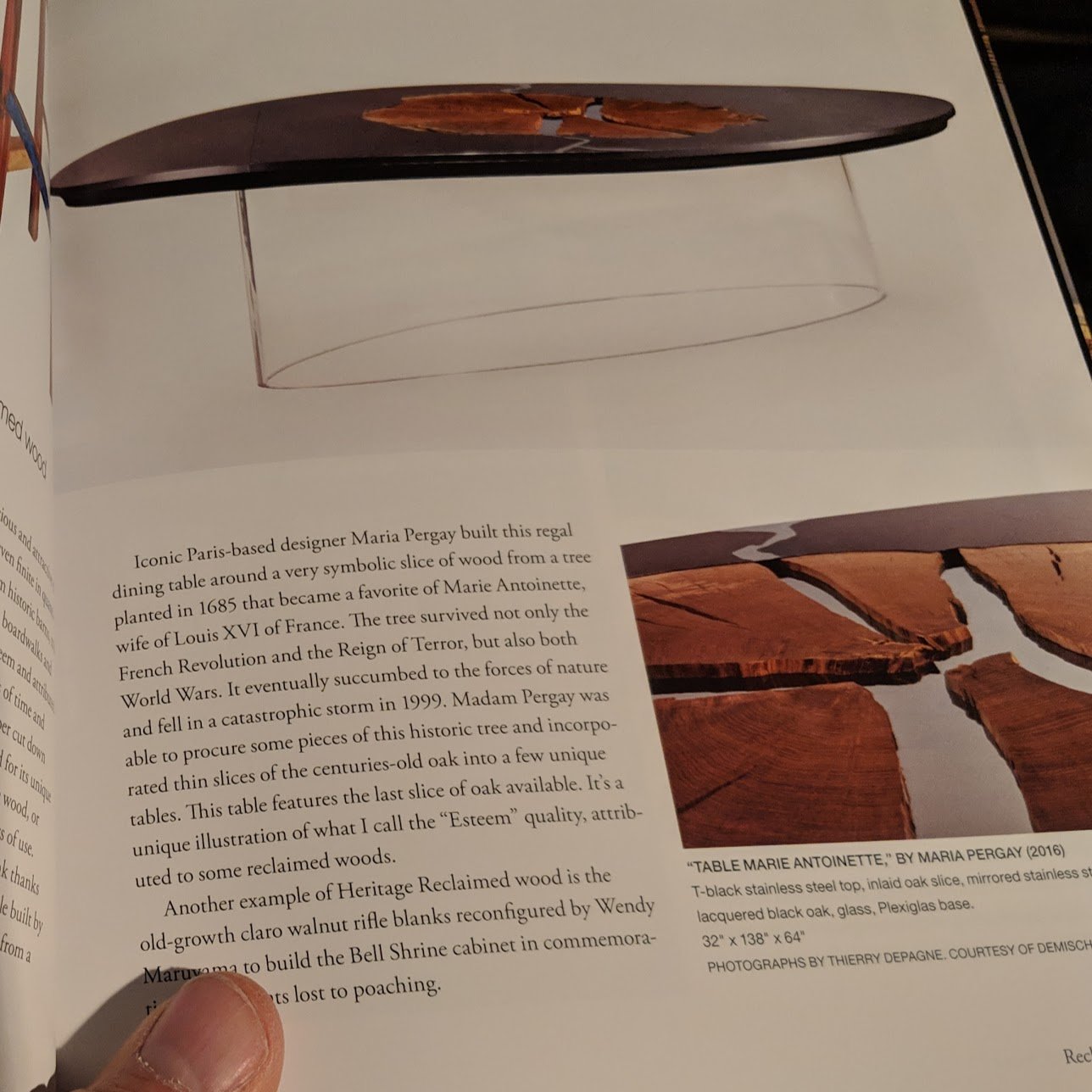

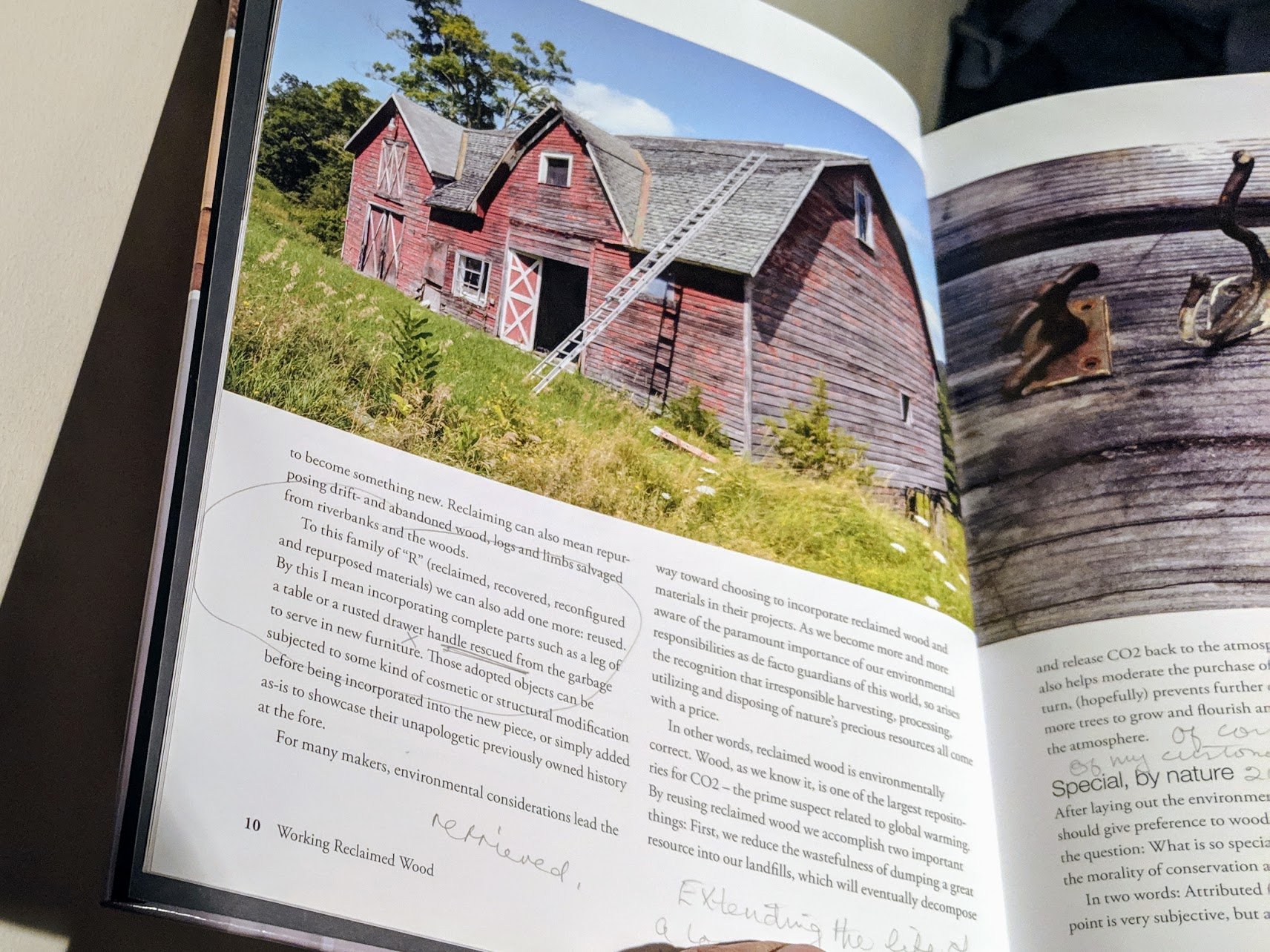

It's from here that we must venture into the realms where woodworkers with independence and hand skills must rethink our ambitions. Hand skills are not always necessarily slower than machines. You must look at the work type. You might think that I have lost the plot here but bear with me. In the midst of the questions I get I receive Yoav Leberman's book Working Reclaimed Wood; A guide for Woodworkers, Makers and Designers. Having found time to both read it and examine what's said in it, it's important to note that many furniture maker/designers may often well play a different tune by using their freelancing opportunities as more militant radicals to set the scene quite differently. Especially is this expanded when hand skills are considered important to the creative and freeing process of making. We can well carve out a future for our work with or without relying on working with reclaimed materials or any such thing. And I am in no way saying that we shouldn't. Just that for some there will be a settledness about making conventional pieces, but that adding in some of what Yoav speaks of in his opening chapter real intrinsic aesthetics adds to the value in a variety of ways.

More to follow!

Comments ()