Retro-thinking Bandsaws

It's the strangest thing. As far as I know I've never advocated that people not use machines, except perhaps in the odd situation where it was unnecessary and it might have stunted their growth in mastering a skill. Something like that. Neither have I ever said I don't use them either. What I have always catered to is those like me who just love skilled hand work, the hand tools we use and the methods and techniques that are one by one being lost to emerging generations. What I have had the greatest battle with is those who make a living as wood machinists, those who teach in colleges and then those who sell machines and those who sell hand tools. Over the decades that translates into the ones who really don't know too much about hand tool and hand tool work and creativity. The ones that say you can't make your living with using hand tools do a disservice to the ones I teach and train and then reach out to extract them one by one from the plant manufacturing technologies. You see not everyone want to earn their living from woodworking. Those that do, that have trained and have skill, can actually make their living just fine from hand work.

I am not at all an anti-machine guy and never have been. I think machines have their place and so too machinist woodworkers making their living using them. Where the issue is is influencing others on what they may well know very little about. I made my living from using primarily hand tools with machines more in the background for taking the donkey work out of resawing. Dare I say that cutting tenons on a tablesaw is just resawing. Dare I say that it takes me 8 minutes to chop a mortise 4" long, 2" deep and any width you like. For a dining table that translates into an hour or so. In the grand scheme of things, say two days to make a handmade dining table or coffee table, that is not at all prohibitive. That said, using the combination of hand tools, with the bandsaw for resawing and dimensioning, is good complementary cooperation. I will never call machines anything other than what they are. I draw the line there. So I say this to counter the misconception that I do not use machines. I just don't look at them the same way most machinists, machine sales staff and hand tool sellers and teachers and proponents of machine woodworking do, that's all.

So, if I am anti anything I am anti about people who are machine-only woodworkers thinking that machining wood is the more progressive way and an advancement on hand tool methods of working wood: that these two spheres are equally skilful when in my view the one is truly skilful and the other can often be more perhaps an impost. I would just hate for anyone to think that working wood by hand and machining wood or using CNC systems to that end are in any way relatable. Certainly machining is not the more advanced way, just the efficient industrialised model for prepping wood, that's all.

It should be plain to anyone that machines replace the need for skill but that they do not replace skilled work with an alternative skill. Machines, in my world at least, mostly displace satisfying and fulfilling elements of diversity and versatility only hand work dexterity brings to design. I've used machines all of my life and am as much an expert on machines and their use as I am with hand tools. Generally, you can learn as much as you ever need to control and use any machine safely in a couple of hours per machine to become safely competent. Mostly it's a question of changing blades, aligning fences and stops and pushing on and off buttons before you push the wood along or across its long axis. Beyond that you end up making lots and lots of jigs to give a guaranteed outcome and then to repeatable cuts to identical parameters. On the other hand, hand tools are a continuous learning curve for the rest of your life because you and your body and mind are not restricted by the limits of a rotary cut fixed to a single arbor. Power planers and tablesaws plane and saw wood. They do this efficiently. They can rebate and rip grooves, cut tenons and so on, but it's not what they do do perhaps so much as what they cannot do that matters. The freedoms they supposedly bring are soon countered by the adverse elements surrounding safety, noise, consumption of floor space and general mess.

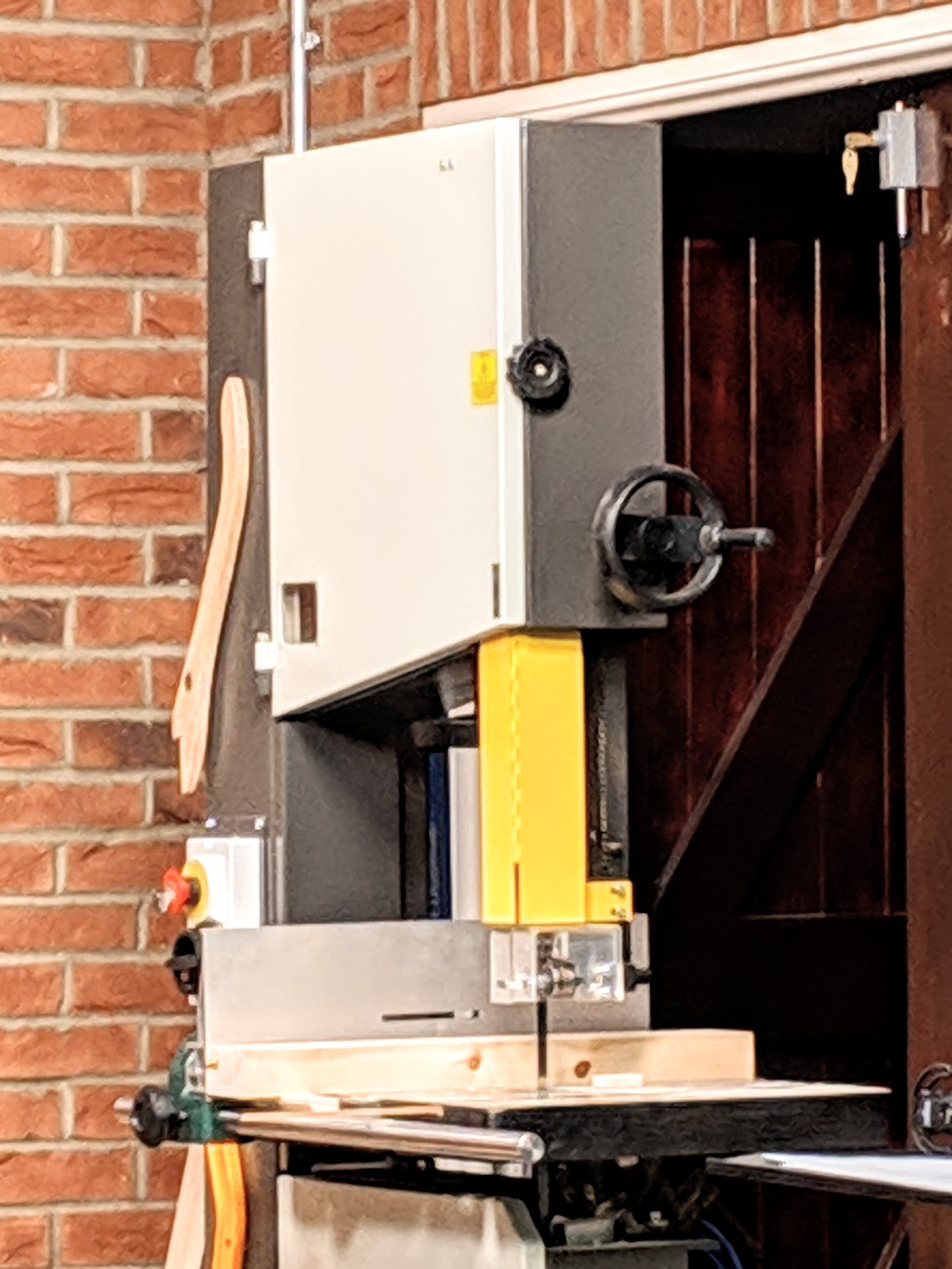

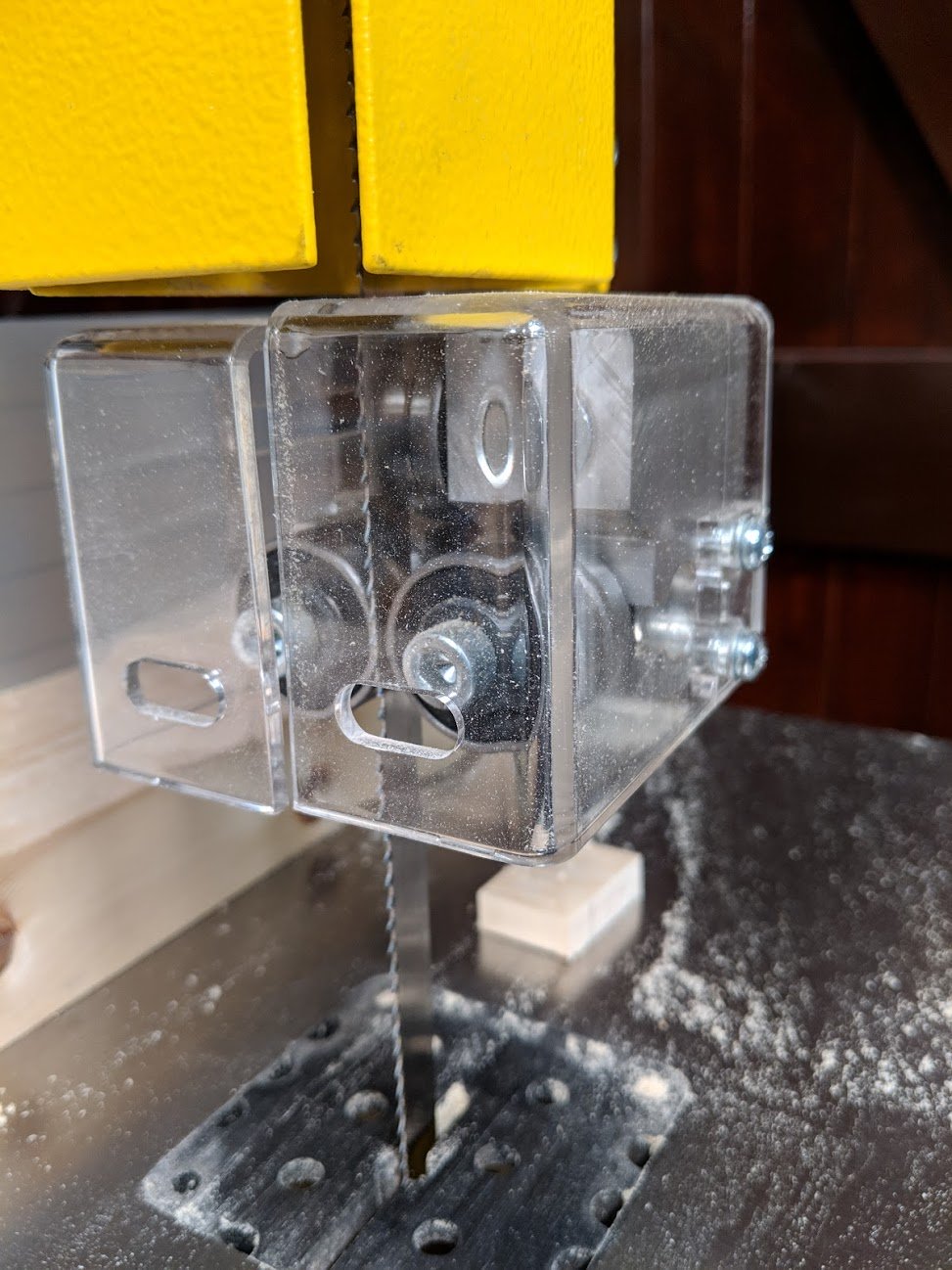

I am introducing the bandsaw at this time in my training others because it's time. We now have a few hundred thousands of woodworkers who have adopted hand tools to work with because they see their validity for them and they want the skills to use them through what we teach and have taught. A bandsaw is a machine I rely on considerably for reducing stock size to smaller sections and proportions. It's a remarkable machine and one I have always enjoyed. The others? I can take them or leave them. The only reason I have owned them through the last decade is because my classes have required the sizing of 100 pieces of wood per student. That's 2,000 per week-long class, far too much for hand work and absolutely unnecessary.

Whereas the bandsaw will be coming more to the front edge for some of my work teaching and working, it will not replace skilled work and the teaching of such things. I think you will enjoy the extra I will bring for you to consider. If you ever see me lift up a power router with a dovetail jig to cut dovetails, you will know then that I have lost the plot!

Stay with me now!

Comments ()